Introduction

In the world of manufacturing and design, laser cutting technology stands out as a versatile powerhouse, revolutionizing how materials are processed. Whether you're crafting intricate designs or executing large-scale production runs, the precision offered by laser cutting machines is unmatched. With advancements in CO2 and fiber laser innovations, industries are witnessing a transformative shift that enhances efficiency and creativity.

The Versatility of Laser Cutting Technology

Laser cutting technology has gained immense popularity due to its ability to handle a wide array of materials including metals, plastics, wood, and glass. The adaptability of machine laser engraving allows businesses to create everything from detailed engravings on jewelry to robust components for machinery. This versatility makes the cutting machine laser an essential tool across various sectors such as automotive, aerospace, and art.

What Sets CO2 Lasers Apart

CO2 lasers are known for their exceptional ability to cut through non-metallic materials with remarkable accuracy. The CO2 laser cutting machine operates by using a gas mixture that produces a high-quality beam capable of delivering clean cuts and intricate designs. This unique feature sets the CO2 machine laser apart from other types of lasers, making it a go-to choice for industries focused on quality and detail.

Exploring Fiber Laser Innovations

While CO2 lasers have their strengths, fiber laser technology is making waves with its own set of advantages that cater specifically to metal cutting applications. Fiber lasers boast higher efficiency rates and faster processing speeds compared to traditional methods; this means less downtime and more productivity for businesses utilizing metal cutting laser cutters. As we explore these innovations further, it becomes clear that both CO2 and fiber lasers play pivotal roles in shaping the future of manufacturing.

Understanding Laser Cutting Machines

Laser cutting machines have revolutionized manufacturing and design, offering unparalleled precision and versatility. Among the various types of laser cutters, CO2 laser cutting machines stand out for their effectiveness in working with a range of materials, including wood, plastics, and textiles. In this section, we will delve into how these machines operate, their advantages, and the diverse applications they serve.

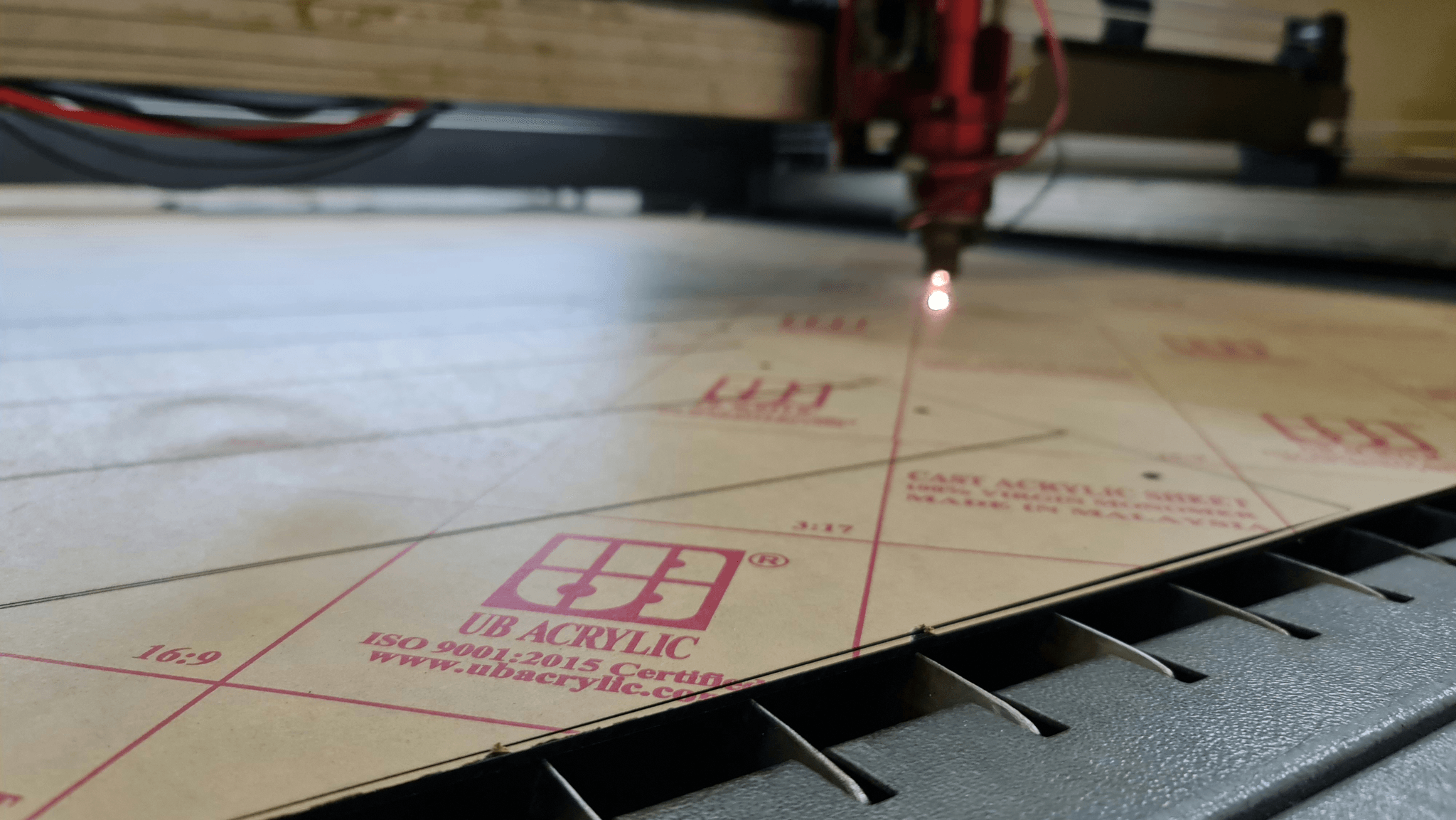

How CO2 Laser Cutting Machines Work

CO2 laser cutting machines utilize a high-powered beam of light generated by a CO2 gas mixture to cut through materials with remarkable accuracy. The process begins when the machine generates a focused beam that is directed onto the material's surface; this intense energy heats up the material until it vaporizes or melts away. The result is a clean cut with minimal kerf width and almost no mechanical stress on the surrounding area, making it ideal for delicate designs.

The operation of a CO2 machine laser involves several components: mirrors to direct the beam, lenses to focus it precisely on the workpiece, and a computer-controlled system that guides movement along programmed paths. This intricate mechanism allows for intricate patterns to be cut or engraved into various substrates efficiently. As such, many industries have adopted this technology for its ability to produce high-quality results consistently.

Advantages of CO2 Laser Machines

One of the primary advantages of using a CO2 laser cutter is its versatility; it can handle an array of materials ranging from soft woods to harder metals with ease. Unlike traditional cutting methods that may cause rough edges or require additional finishing processes, machine laser engraving provides smooth edges and intricate details right off the bat. Additionally, these machines are typically easier to maintain than other types due to fewer moving parts involved in their operation.

Another significant benefit is speed; CO2 laser machines can complete tasks much faster than manual or mechanical cutting methods without sacrificing precision or quality. This efficiency translates into higher productivity levels for businesses that rely on rapid prototyping or large-scale production runs. Moreover, as energy-efficient devices compared to their fiber counterparts in certain applications, they can offer cost savings over time while delivering exceptional performance.

Applications of CO2 Laser Technology

CO2 laser technology has found its way into numerous industries due to its impressive capabilities and adaptability. In manufacturing settings, metal cutting laser cutters are employed not only for creating parts but also for engraving logos or designs onto products—enhancing brand identity through precision craftsmanship. From signage creation in advertising agencies to intricate jewelry design in artisan workshops, there’s virtually no limit to what can be achieved with a reliable co2 machine laser.

Moreover, educational institutions utilize these advanced tools in art programs where students learn about design principles while experimenting with different materials using machine laser engraving techniques. The medical field also benefits from precise cutting capabilities when crafting surgical instruments or medical devices tailored specifically for patient needs—a testament to how versatile these technologies truly are!

In summary, understanding how CO2 lasers work reveals why they have become indispensable tools across various sectors; their advantages make them an attractive choice for anyone looking to enhance productivity while maintaining quality standards.

The Rise of Fiber Laser Cutting

The laser cutting landscape is evolving, and fiber laser technology is at the forefront of this transformation. While CO2 laser cutting machines have long been the go-to for various applications, fiber lasers are gaining traction due to their unique advantages and capabilities. This section delves into how fiber lasers compare to CO2 lasers, the benefits they bring, and their real-world applications that are reshaping industries.

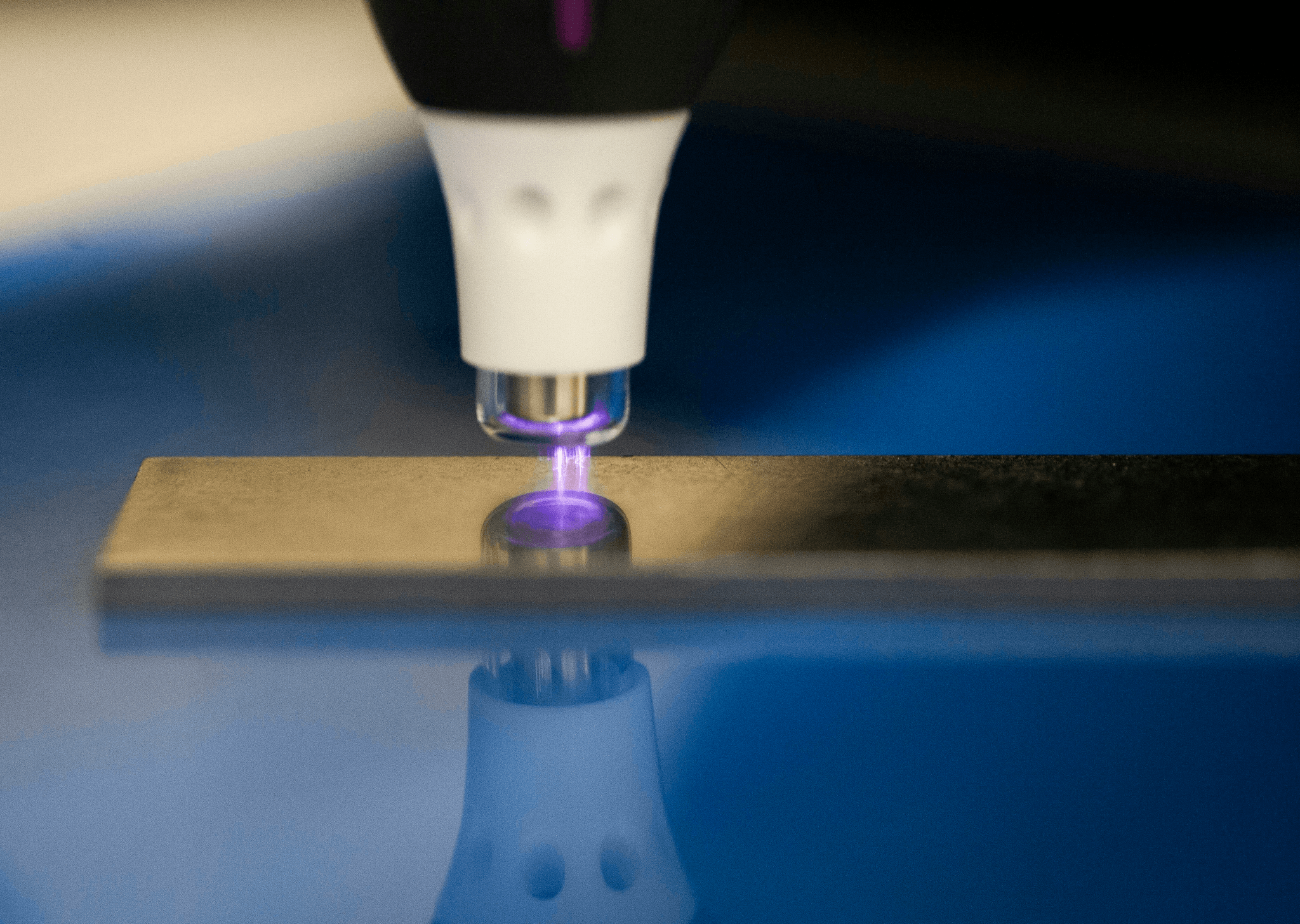

Comparing Fiber Lasers and CO2 LasersA CO2 laser cutter excels in engraving and cutting non-metal materials like wood or acrylic with precision, thanks to its longer wavelength. On the other hand, fiber lasers shine in metal cutting applications; they operate at a shorter wavelength which allows them to cut through metals more efficiently than a traditional CO2 machine laser.

Another key difference lies in maintenance and operating costs. While a co2 laser machine may require regular upkeep due to its gas-filled tubes, fiber lasers have fewer moving parts and typically need less maintenance over time. This makes them not only cost-effective but also reliable for continuous operation in demanding environments.

Furthermore, speed is another point of comparison; fiber laser cutters generally offer faster processing times on metal materials compared to their CO2 counterparts. This efficiency can significantly boost productivity in manufacturing settings where time is money. As we explore further into the benefits of fiber laser cutters, it's clear that these innovations are paving the way for advancements in various sectors.

Benefits of Fiber Laser Cutters

Fiber laser cutters come with a host of benefits that make them increasingly appealing for businesses looking to enhance their operations. One major advantage is their superior energy efficiency; these machines consume less power while delivering high-quality cuts—perfect for those looking to reduce operational costs without sacrificing performance. Additionally, the compact design of a fiber laser cutter allows for easier installation and integration into existing workflows.

Another significant benefit is versatility; while CO2 laser machines excel at non-metal materials, fiber lasers can handle a broader range of metals including stainless steel, aluminum, brass, and copper with ease. This versatility opens up new avenues for industries such as automotive manufacturing or custom metal fabrication where precision is paramount. Plus, thanks to improved beam quality from fiber technology, users can achieve finer details that were previously difficult with traditional methods.

Finally, let’s not overlook speed—fiber lasers can often outperform co2 machine lasers when it comes to cutting speed on metals due to faster processing capabilities. This means quicker turnaround times on projects which can be crucial in today’s fast-paced market landscape where customers expect rapid results without compromising quality.

Real-World Uses of Fiber Laser Technology

The real-world applications of fiber laser technology are vast and varied across multiple industries today! For instance, manufacturers utilize metal cutting laser cutters equipped with fiber technology for tasks ranging from intricate designs on automotive parts to large structural components in construction projects—demonstrating both precision and scalability in production processes using co2 laser cutter alternatives as needed.

In addition to manufacturing sectors like aerospace or automotive engineering that benefit from high-speed processing capabilities offered by these advanced systems; artistic industries are also embracing machine laser engraving techniques powered by fibers! Artists create stunning sculptures or intricate jewelry designs using these tools—showcasing how versatile this technology truly is beyond just industrial use cases.

Moreover, medical device manufacturers rely heavily on precise cuts achieved through advanced technologies like those found within modern-day cutting machine lasers too! From surgical instruments crafted from stainless steel down through implants—all produced faster than ever before thanks largely due innovations brought forth by advancements seen within our growing understanding surrounding both types (CO₂ vs.Fiber) alike!

CO2 Laser Engravers: Precision at Its Best

These machines utilize the power of a CO2 laser cutting machine to create intricate designs on various materials, including wood, acrylic, glass, and even some metals. The ability to achieve fine details and smooth finishes makes the CO2 machine laser a favorite among artists and manufacturers alike.

Features of a CO2 Machine Laser

A typical CO2 laser cutter is equipped with several features that enhance its functionality and ease of use. One prominent feature is its high-speed engraving capability, which allows for rapid processing without sacrificing quality. Additionally, many modern CO2 laser machines come with adjustable power settings, enabling users to customize their engraving depth according to material thickness—perfect for those delicate projects requiring precision.

Moreover, these machines often include advanced software that simplifies design integration and workflow management. With user-friendly interfaces and compatibility with various graphic design programs, operating a cutting machine laser has never been more accessible for both beginners and seasoned professionals. The combination of speed, adaptability, and ease of use makes the CO2 laser cutter an essential tool in any workshop.

Industries Utilizing Machine Laser Engraving

Machine laser engraving has found its way into numerous industries due to its precision and efficiency. The signage industry heavily relies on CO2 lasers for creating detailed signs that are both eye-catching and durable. From custom plaques to intricate logos, businesses can produce high-quality products that stand out in a crowded market.

In addition to signage, the fashion industry also benefits from this technology by using it for personalized items like jewelry or custom embellishments on clothing. Moreover, woodworking shops leverage the capabilities of a metal cutting laser cutter for creating intricate patterns or designs on furniture pieces—transforming ordinary items into works of art through precise engravings.

The versatility of the CO2 machine laser extends beyond traditional uses; it’s also making waves in sectors like aerospace where lightweight components require precise markings or cutouts without compromising integrity. This adaptability ensures that industries continue exploring new applications for machine laser engraving technology.

Choosing the Right CO2 Laser Engraver

Selecting the ideal CO2 laser engraver can be quite an adventure given the variety available in today’s market! First off, consider your specific needs—are you focusing on small-scale projects or large production runs? Understanding your requirements will help narrow down options when looking at different models of co2 lasers.

Next up is evaluating features such as bed size (which determines material capacity), wattage (affecting speed and depth), and software compatibility (ensuring seamless design processes). Don’t forget about customer support; opting for brands with solid reputations can save you headaches down the line if you encounter technical issues with your co2 machine laser.

Finally—and perhaps most importantly—take time to read reviews from other users who have experience with particular models before making your purchase decision! Their insights can provide invaluable information regarding performance longevity while helping avoid potential pitfalls associated with less reliable equipment in this competitive field.

Practicalities of Metal Cutting Laser Cutters

The choice between a CO2 laser cutter and other types can significantly impact the quality of your cuts and the materials you can work with. Understanding the nuances of these machines is vital for anyone looking to invest in a cutting machine laser that meets their specific needs.

Key Considerations for Metal Laser Cutting

Selecting the right metal cutting laser cutter requires careful consideration of various factors, including material thickness, type, and desired finish. For instance, a CO2 laser machine excels in cutting non-metal materials but may struggle with thicker metals compared to fiber lasers. Additionally, you’ll want to think about power settings; higher wattage typically translates to faster cutting speeds but may require more maintenance on your CO2 laser cutter.

Another critical aspect is the focus lens used in your machine laser engraving setup. The lens quality can drastically affect cut precision and edge quality; thus, investing in high-quality optics is essential for optimal performance with your CO2 machine laser. Lastly, consider software compatibility; ensuring that your cutting machine laser integrates smoothly with design programs will save time and increase productivity.

Top Metal Cutting Laser Cutters on the Market

The market is brimming with options when it comes to metal cutting laser cutters, each boasting unique features tailored to different applications. Among them are machines like the Trumpf TruLaser series and the FiberLaser from Mitsubishi – both known for their speed and efficiency in metal fabrication. However, if you're leaning towards a CO2 solution, brands like Epilog offer robust options that excel at intricate designs while providing versatility across various materials.

For those who prioritize budget without sacrificing quality, some entry-level CO2 lasers still deliver impressive results for lighter metal applications. Look into companies such as OMTech or Glowforge that cater to small businesses or hobbyists needing reliable yet affordable solutions for their machine laser engraving needs. Each option has its pros and cons; thus, thorough research before purchasing will ensure you find a suitable fit for your projects.

How to Optimize Your Cutting Machine Laser

To get the most out of your metal cutting laser cutter, regular maintenance is key—think cleaning lenses regularly and checking alignment settings often! For a CO2 machine laser specifically, maintaining optimal gas levels ensures consistent performance during operation; low gas levels can lead to subpar cuts or even equipment damage over time. Additionally, experimenting with different speed settings can help you achieve cleaner edges while reducing wear on components.

Training staff on how best to utilize these machines also plays a crucial role in optimizing performance; understanding how variables like focus distance affect outcomes will lead to better results overall with any co2 laser cutter or fiber option you choose. Finally, don't shy away from upgrading components as technology advances; investing in newer optics or software updates can make all the difference when aiming for top-notch results from your cutting machine laser.

Insights into Kiant Machinery

When it comes to laser cutting solutions, Kiant Machinery stands out in the industry with a robust lineup of innovative products. Their offerings include state-of-the-art CO2 laser cutting machines and advanced fiber laser systems tailored for various applications. Whether you're looking for precision in machine laser engraving or efficient metal cutting, Kiant has got you covered.

Kiant Machinery’s Laser Cutting Solutions

Kiant Machinery provides a comprehensive range of laser cutting solutions that cater to diverse industries and needs. Their CO2 laser machines are designed for high accuracy and speed, making them perfect for intricate designs and detailed engravings. Additionally, their metal cutting laser cutters deliver exceptional performance on various materials, ensuring that every project meets the highest standards.

The versatility of their product line allows businesses to choose between CO2 lasers and fiber lasers based on specific requirements. For instance, the CO2 laser cutter excels in non-metal materials like wood and acrylic, while their fiber lasers shine when working with metals such as steel or aluminum. This flexibility makes Kiant an ideal partner for any company looking to invest in a cutting machine laser that can adapt to evolving market demands.

Why Choose Kiant for Your Laser Needs

Choosing Kiant Machinery means opting for quality, reliability, and innovation in your laser technology investments. Their CO2 machine lasers are not only built with precision engineering but also come equipped with user-friendly interfaces that simplify operation and maintenance tasks. Furthermore, customers benefit from ongoing support and training resources to maximize the potential of their equipment.

Kiant's commitment to customer satisfaction is evident in their tailored solutions designed to meet specific business needs—be it through custom configurations or expert consultations on machine selection. With a focus on enhancing productivity while reducing operational costs, investing in a Kiant product ensures you’re at the forefront of technology advancements within your industry. Plus, they offer competitive pricing without compromising quality; what’s not to love?

Customer Success Stories with Kiant Machinery

Many satisfied customers have experienced remarkable transformations after integrating Kiant's machinery into their operations. One notable success story involves a small engraving business that upgraded from traditional methods to a CO2 laser cutter from Kiant; they reported doubling their production capacity within months! This leap not only improved efficiency but also allowed them to take on more complex projects they previously couldn't handle.

Another client specializing in metal fabrication switched from conventional cutting methods to a metal cutting laser cutter provided by Kiant Machinery and saw significant reductions in material waste as well as faster turnaround times on orders. These success stories illustrate how investing in high-quality equipment like the co2 machine laser can lead businesses toward growth and innovation while staying competitive in today's fast-paced market.

Conclusion

The world of laser cutting technology is rapidly evolving, and staying ahead in this dynamic landscape is crucial for businesses and manufacturers alike. With innovations in both CO2 and fiber laser technologies, the future promises enhanced precision, efficiency, and versatility across various applications. As we look forward to these advancements, it’s clear that the role of cutting machine lasers will only become more significant in manufacturing processes.

Future Trends in Laser Cutting Technology

Emerging trends indicate a shift toward more automated and smart laser cutting solutions that integrate artificial intelligence for improved accuracy and efficiency. The development of advanced CO2 laser machines is paving the way for enhanced capabilities, enabling users to tackle increasingly complex designs with ease. Furthermore, as industries demand faster turnaround times and higher quality outputs, the metal cutting laser cutter market will likely see substantial growth driven by these technological advancements.

Enhancing Efficiency with Laser Solutions

Efficiency remains a top priority for manufacturers utilizing machine laser engraving and cutting technologies. By investing in state-of-the-art CO2 laser cutters or fiber lasers, companies can significantly reduce waste while improving production speeds—ultimately leading to cost savings. Additionally, optimizing your cutting machine laser through regular maintenance and upgrades can ensure peak performance, allowing businesses to remain competitive in an ever-evolving marketplace.

The Path to Growth with Kiant Machinery

Kiant Machinery stands out as a leader in providing innovative solutions tailored to meet diverse industry needs within the realm of laser technology. Their commitment to quality ensures that customers receive reliable CO2 machine lasers that excel at both engraving and cutting tasks across various materials. By choosing Kiant Machinery for your laser needs, you not only gain access to top-tier equipment but also benefit from their extensive support network designed to foster growth and success.