Introduction

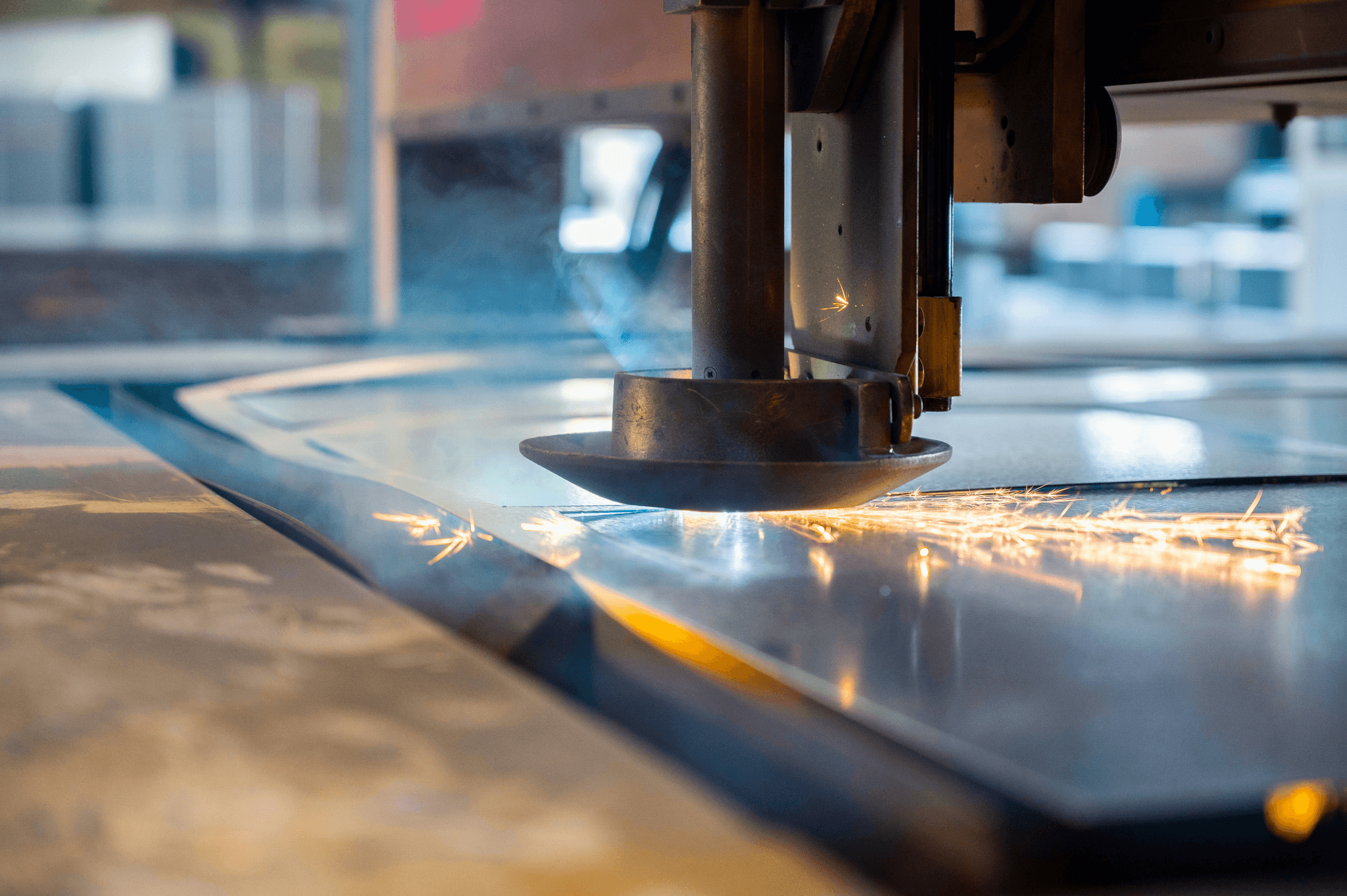

In the world of manufacturing, precision and efficiency are paramount, and metal laser cutting machines have emerged as game-changers in this arena. These advanced cutting machines utilize focused beams of light to slice through various materials with remarkable accuracy, making them indispensable in industries ranging from automotive to aerospace. With the advent of technology, particularly fiber laser cutting machines, businesses can now achieve intricate designs on iron sheets and other metals like never before.

Understanding Metal Laser Cutting Machines

Metal laser cutting machines represent a sophisticated blend of technology and engineering prowess that allows for high-speed processing of materials. The core principle behind these machines is the use of a concentrated laser beam that melts or vaporizes the material it contacts, resulting in clean cuts with minimal waste. Whether you’re looking at a desktop laser cutter for small projects or an industrial-grade metal cutting laser cutter for large-scale production, understanding their mechanics is essential for optimizing your operations.

The Evolution of Laser Cutting Technology

The journey of laser cutting technology has been nothing short of revolutionary since its inception in the 1960s. Initially used for basic tasks, advancements have led to the development of highly efficient fiber laser cutting machines that offer superior speed and quality compared to traditional methods. Today’s innovations continue to push boundaries, integrating automation and smart technologies that enhance productivity across various sectors.

Key Players in the Industry

As demand for precision metalwork grows, several key players dominate the landscape of laser cutting machinery manufacturing. Companies like Kiant Machinery have carved out a niche by offering robust solutions tailored to meet diverse industry needs—from compact desktop laser cutters suitable for hobbyists to heavy-duty cutting machine lasers designed for large manufacturers. Understanding these players helps businesses make informed decisions when investing in their own metal laser cutting capabilities.

What is a Metal Laser Cutting Machine?

Metal laser cutting machines are high-tech devices that utilize focused laser beams to cut through metal materials with precision and efficiency. By harnessing the power of laser cutting technology, these machines can achieve intricate designs and detailed cuts that traditional methods may struggle to replicate. Whether it's an iron sheet laser cutting machine or a more advanced fiber laser cutting machine, the result is a clean, smooth edge that minimizes the need for secondary processing.

Overview of Laser Cutting Technology

Laser cutting technology involves directing a powerful beam of light onto a material's surface, causing it to melt, burn, or vaporize in precise patterns. This method allows for exceptional accuracy and speed, making it ideal for various metal types including steel, aluminum, and brass. With advancements in technology, modern metal cutting laser cutters have become increasingly sophisticated—offering features like automated controls and real-time monitoring to enhance productivity.

Types of Laser Cutting Machines

There are several types of laser cutting machines available on the market today, each designed to meet specific needs within different industries. The most common include CO2 lasers, fiber lasers, and solid-state lasers; each has its unique advantages depending on the material being cut. For instance, fiber laser cutting machines excel at processing thin metals quickly while desktop laser cutters offer smaller-scale solutions perfect for hobbyists or small businesses looking to create intricate designs without breaking the bank.

Applications of Laser Cutting in Industries

The applications of metal laser cutting machines span across numerous industries—from automotive manufacturing to aerospace engineering and even artistic endeavors like sculpture creation. In automotive production lines, for example, an iron sheet laser cutting machine can efficiently produce parts with tight tolerances needed for vehicle assembly. Meanwhile, industries such as construction benefit from metal cutting laser cutters that provide structural components with precision cuts essential for safety and durability in their projects.

Benefits of Using Fiber Laser Cutting Machines

Fiber laser cutting machines have revolutionized the way industries approach metal fabrication, offering a myriad of benefits that traditional methods simply can't match. From precision cuts to enhanced production speed, these machines are game-changers in the world of manufacturing. Whether you're using an iron sheet laser cutting machine or a desktop laser cutter, the advantages are clear.

Precision and Quality of Cuts

One of the standout features of fiber laser cutting machines is their ability to deliver unparalleled precision and quality in cuts. Unlike conventional cutting methods, which may leave rough edges or require additional finishing work, a metal cutting laser cutter can produce clean and intricate designs with ease. This level of accuracy not only enhances the aesthetic appeal but also ensures that components fit together perfectly during assembly.

The technology behind fiber lasers allows for fine-tuning of settings to achieve desired cut depths and speeds, making it ideal for various applications—from delicate engravings on a desktop laser cutter to heavy-duty tasks on an industrial machine. Moreover, the consistency in quality means less waste material and fewer errors, leading to higher overall productivity for manufacturers. In essence, investing in a cutting machine laser translates into superior craftsmanship and reliability.

Speed and Efficiency in Production

These machines can operate at high speeds without compromising on quality, allowing businesses to meet tight deadlines without breaking a sweat. The rapidity with which an iron sheet laser cutting machine can execute complex cuts means more parts produced per hour—an attractive proposition for any manufacturer looking to optimize operations.

Moreover, automation features integrated into modern fiber lasers enhance efficiency further by minimizing manual intervention required during operation. This translates into lower labor costs and reduced risk of human error—two critical factors that contribute positively to overall productivity levels in factories and workshops alike. With advancements such as these, it's no wonder that industries are increasingly turning toward this technology for their metal fabrication needs.

Cost-Effectiveness Compared to Traditional Methods

Cost-effectiveness is another compelling reason why businesses are opting for fiber laser cutting machines over traditional techniques. While the initial investment may seem daunting when purchasing a metal cutting laser cutter or an industrial-grade model, the long-term savings quickly become evident through reduced operational costs and material waste management. Fiber lasers consume less energy than their CO2 counterparts while providing faster turnaround times—a win-win situation!

Furthermore, maintenance requirements for fiber lasers tend to be lower due to fewer moving parts compared with older technologies; this results in decreased downtime associated with repairs or part replacements over time. As companies seek ways to maximize profitability while maintaining high standards of production quality, choosing advanced technologies like a fiber laser becomes not just beneficial but essential for staying competitive in today’s market landscape.

Choosing the Right Laser Cutting Machine

Factors to Consider for Your Needs

Before diving into the world of laser cutting machines, consider factors such as material type and thickness, production volume, and desired precision. For instance, if you're primarily working with thin iron sheets or intricate designs, a fiber laser cutting machine might be your best bet due to its superior accuracy and speed. Additionally, think about the available space in your workshop; a desktop laser cutter may be more suitable for smaller operations compared to larger industrial machines that require significant floor space.

Another critical aspect is budget; while investing in high-quality equipment can yield long-term benefits, it’s vital to find a balance between cost and functionality. Don't forget about future scalability—selecting a flexible cutting machine laser that can adapt as your business grows will save you from costly upgrades down the line. Assessing these factors will help ensure you choose the right metal cutting laser cutter for your specific needs.

Comparing Desktop Laser Cutters and Industrial Machines

Desktop laser cutters are fantastic for small projects or hobbyists who need precision without breaking the bank. They are generally compact and user-friendly but may lack the power needed for heavy-duty tasks like cutting thick metals or high-volume production runs that an industrial machine would handle effortlessly. If you're focused on crafting prototypes or small batches of items from iron sheets, these machines can deliver quality results without overwhelming complexity.

On the other hand, industrial machines are designed for heavy workloads and large-scale production environments where efficiency is paramount. These metal cutting laser cutters boast higher wattage lasers capable of slicing through thicker materials at remarkable speeds—perfect for businesses needing quick turnaround times on large orders. Ultimately, choosing between these two types depends on your operational demands; weigh their pros and cons carefully before making a decision.

Recommended Manufacturers like Kiant Machinery

When it comes time to purchase your ideal metal cutting solution, look no further than reputable manufacturers like Kiant Machinery known for their innovation in this field. Their range of products includes everything from entry-level desktop laser cutters perfect for beginners to robust fiber laser cutting machines designed for serious industrial applications. Each machine is built with durability in mind while maintaining excellent performance standards across various materials including steel and aluminum.

Other notable manufacturers also offer competitive options worth exploring; however, Kiant Machinery stands out due to their commitment to customer service and support post-purchase—an essential factor when investing in equipment like an iron sheet laser cutting machine or any advanced technology tool! Always conduct thorough research on reviews and testimonials before settling on any brand; after all, you want equipment that meets not just today’s needs but also those of tomorrow!

Maintenance Tips for Your Laser Cutting Machine

Keeping your laser cutting machine in tip-top shape is essential for optimal performance and longevity. Whether you’re using an iron sheet laser cutting machine or a fiber laser cutting machine, regular maintenance can help prevent costly downtime and ensure precision cuts every time. Here are some key maintenance tips to keep your metal cutting laser cutter running smoothly.

Routine Maintenance Best Practices

Routine maintenance of your laser cutting machine should be part of your operational checklist. Start by regularly cleaning the lenses and mirrors, as dust and debris can significantly affect the quality of cuts made by your desktop laser cutter or industrial machines. Additionally, check the alignment of the beam; a misaligned beam can lead to uneven cuts, which is a nightmare when working with intricate designs on iron sheets.

Don’t forget about lubrication! Regularly lubricating moving parts will reduce friction and wear, ensuring that your cutting machine laser operates efficiently. It's also smart to inspect electrical connections and cables for any signs of wear or damage—better safe than sorry when it comes to safety! Lastly, maintain a log of all maintenance activities; this will help you track patterns that may indicate larger issues down the line.

Troubleshooting Common Issues

Even with regular upkeep, you might encounter some hiccups with your metal cutting laser cutter from time to time. One common issue is inconsistent cut quality; if you notice this happening, first check if the lens is clean and free from damage. If everything looks good there but the problem persists, it could be due to improper settings—double-check speed and power settings based on material thickness.

Another frequent issue is excessive smoke or residue during operation which can affect visibility and cut quality. Ensure that your ventilation system is functioning properly; consider upgrading filters if they are dirty or clogged. Lastly, if you're experiencing unexpected shutdowns or error messages on your fiber laser cutting machine's display panel, consult the user manual for guidance before attempting any fixes yourself.

When to Seek Professional Support

While many maintenance tasks can be handled in-house, there comes a time when professional support becomes necessary—especially with complex machines like an iron sheet laser cutting machine or advanced fiber lasers. If you've tried troubleshooting common issues without success or if you encounter mechanical failures that seem beyond repair capabilities, don’t hesitate to reach out for professional help.

Additionally, consider scheduling routine professional inspections at least once a year; these experts can catch potential problems before they escalate into costly repairs or replacements. Remember that investing in expert assistance not only prolongs the life of your metal cutting laser cutter but also ensures consistent performance across all applications—from intricate designs on thin sheets to heavy-duty industrial tasks.

Future Trends in Metal Laser Cutting Technology

The metal laser cutting industry is on the brink of a revolution, driven by technological advancements that promise to reshape how we think about manufacturing. As companies increasingly turn to automation and artificial intelligence (AI), the capabilities of machines like the iron sheet laser cutting machine are set to expand dramatically. These innovations not only enhance efficiency but also improve precision, leading to better quality outputs that meet the demands of modern industries.

Advancements in Automation and AI

Automation is no longer just a buzzword; it’s becoming a fundamental aspect of metal cutting laser cutter technology. With AI integration, laser cutting machines can now analyze materials in real-time, optimizing cutting paths and reducing waste. This means that operators can expect their fiber laser cutting machines to deliver faster production times while maintaining exceptional accuracy—ideal for high-stakes projects where every millimeter counts.

Moreover, desktop laser cutters are evolving with smart features that allow for remote monitoring and control, ensuring seamless operations from anywhere. This shift towards intelligent systems also means less downtime due to enhanced predictive maintenance capabilities, allowing businesses to stay ahead of potential issues before they arise. As automation continues to advance, expect more customizable solutions tailored specifically for unique manufacturing needs.

Eco-Friendly Innovations in Laser Cutting

As environmental concerns take center stage across industries, eco-friendly innovations in laser cutting technology are gaining traction. The latest models of metal cutting laser cutters are designed not only for efficiency but also with sustainability in mind—reducing energy consumption significantly compared to traditional methods. For instance, fiber laser cutting machines use less power while providing higher output quality than their CO2 counterparts.

Recycling waste materials generated during the cutting process is another trend gaining momentum among manufacturers aiming for greener practices. Many companies are now investing in advanced filtration systems and recycling technologies that allow them to reclaim scrap metal effectively. This commitment not only enhances their sustainability profile but also reduces operational costs associated with material procurement.

The Growing Demand for Custom Solutions

In today’s fast-paced market, there’s an increasing demand for custom solutions tailored specifically to client specifications—a trend that's reshaping how we view metal fabrication processes involving iron sheet laser cutting machines and other technologies. Businesses require flexibility from their equipment; hence manufacturers are focusing on developing versatile models capable of handling diverse materials and thicknesses efficiently.

This demand drives innovation within the industry as producers strive to offer machines that can adapt quickly without sacrificing performance or precision—making both industrial-grade and desktop laser cutters essential tools for modern fabricators. By embracing customization options like interchangeable heads or adjustable settings based on project requirements, companies can enhance productivity while meeting specific customer needs more effectively than ever before.

Conclusion

In the ever-evolving landscape of manufacturing, metal cutting laser cutters have emerged as a game-changer. The precision and efficiency provided by machines like the fiber laser cutting machine have transformed production lines, enabling businesses to meet the growing demands of various industries. By integrating a cutting machine laser into your operations, you can significantly enhance productivity and output quality.

Enhancing Your Production with Laser Cutting

Utilizing an iron sheet laser cutting machine can streamline your processes and reduce waste, ultimately leading to cost savings. The accuracy of these machines ensures that every cut is clean and precise, minimizing the need for post-processing work. Whether you're using a desktop laser cutter for smaller projects or an industrial-grade model for larger tasks, the benefits are clear: faster turnaround times and superior product quality.

The Role of Manufacturers in Innovation

Manufacturers play a crucial role in advancing laser cutting technology, continually pushing boundaries to improve performance and capabilities. Companies like Kiant Machinery are at the forefront, developing innovative solutions that cater to diverse market needs while enhancing user experience with their metal cutting laser cutter offerings. As competition intensifies, these manufacturers will likely focus on refining their products to include more automation features and eco-friendly options.

Making the Most of Your Metal Cutting Laser Cutter

To maximize your investment in a metal cutting laser cutter, regular maintenance is key—this ensures longevity and optimal performance over time. Familiarize yourself with routine checks for your fiber laser cutting machine to prevent common issues from escalating into costly repairs or downtime. Finally, leveraging support from reputable manufacturers can provide valuable insights on best practices and troubleshooting tips tailored specifically for your iron sheet laser cutting machine.