Introduction

In the fast-paced world of manufacturing and design, efficiency and precision are paramount. Enter the flatbed CO2 laser cutting machine, a game-changer that combines advanced technology with unparalleled versatility. This introduction explores the myriad benefits of these machines, from their innovative capabilities to their potential for transforming your business operations.

Discover the Benefits of Flatbed CO2 Machines

Flatbed CO2 machines offer an array of advantages that can elevate your production game to new heights. With their ability to cut through various materials with pinpoint accuracy, they streamline workflows and improve overall output quality. Whether you’re in metal fabrication or creative arts, investing in a flatbed CO2 laser cutting machine opens doors to endless possibilities.

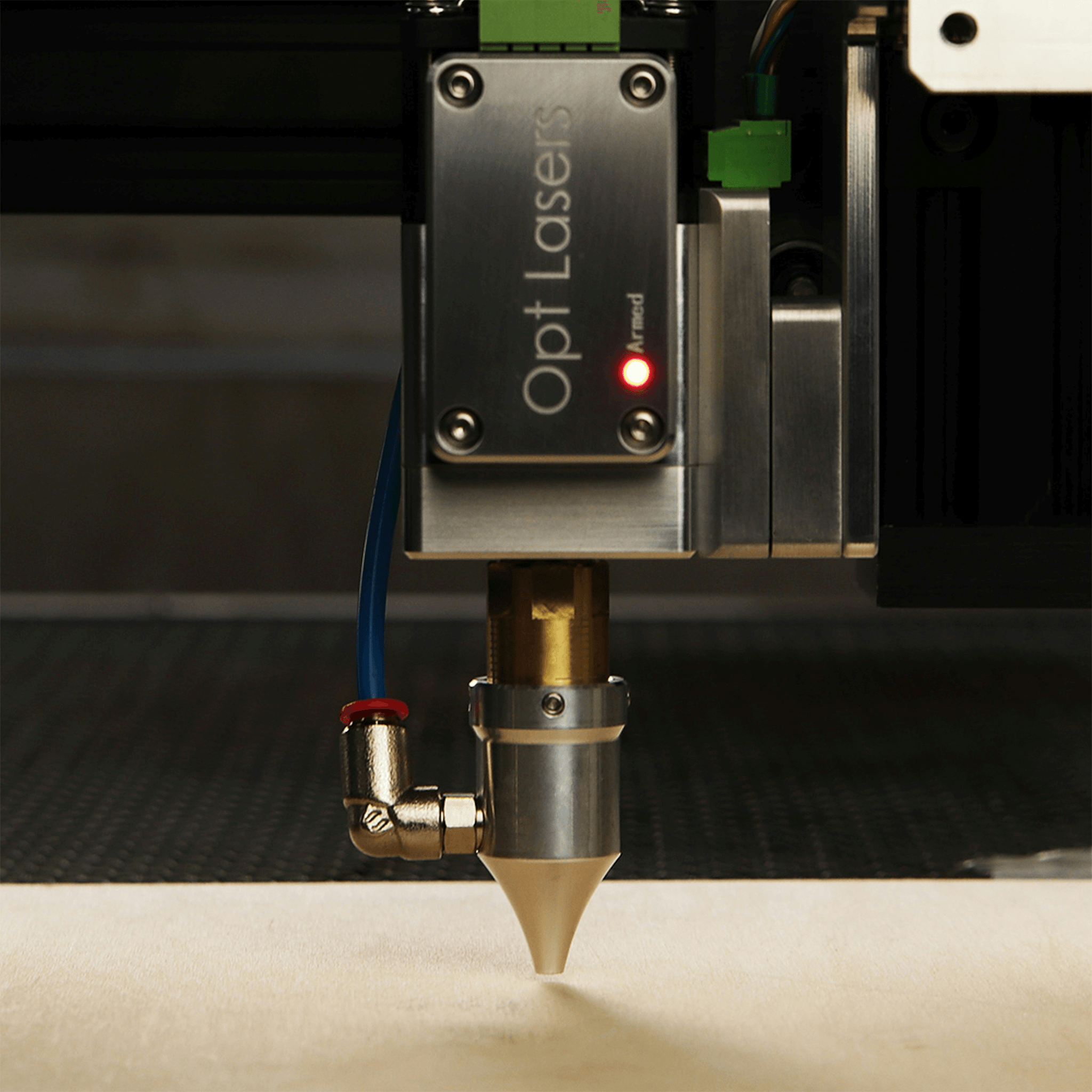

Understanding the Technology Behind Laser Cutting

At the heart of every successful flatbed CO2 laser cutting machine lies sophisticated technology that harnesses focused light beams for precision cutting. The process involves directing a high-powered laser beam onto materials, allowing for intricate designs and clean edges without the need for traditional tools. This innovative approach not only enhances efficiency but also ensures minimal material waste—an essential factor in today’s eco-conscious market.

Why Invest in a Flatbed CO2 Laser Cutting Machine

Investing in a flatbed CO2 laser cutting machine is not just about keeping up with industry trends; it’s about future-proofing your business. These machines deliver exceptional performance across various applications—from metal cutting with a metal cutting laser cutter to detailed engraving using a laser etching machine or even customization via machine laser engraving. By choosing this technology, you position yourself at the forefront of modern manufacturing while enjoying significant long-term savings.

Efficiency and Precision in Cutting

Enhancing Workflow with Laser Machinery

Laser machinery such as the flatbed CO2 laser cutting machine is designed to optimize production processes. With its ability to operate at high speeds while maintaining precision, this equipment significantly reduces lead times for projects. As a result, businesses can handle more orders efficiently, keeping customers satisfied and operations running smoothly.

Moreover, integrating a metal cutting laser cutter into your workflow means fewer manual interventions are needed. This automation allows staff to focus on other critical tasks rather than labor-intensive cutting processes. The outcome? A more productive environment where creativity can flourish alongside efficiency.

Accuracy Benefits of Metal Cutting Laser Cutter

Accuracy is paramount when it comes to cutting materials—especially metals—and that's where the metal cutting laser cutter shines. These machines utilize focused beams of light that produce clean cuts with minimal kerf loss, ensuring that every piece fits perfectly in its intended application. This level of precision not only enhances product quality but also minimizes costly errors during production.

In addition to producing flawless cuts, the machine laser engraving capabilities allow for intricate designs without compromising accuracy. Whether you're creating complex patterns or simple shapes, the consistent results provided by a flatbed CO2 laser cutting machine are hard to beat. It’s this blend of precision and versatility that keeps manufacturers coming back for more.

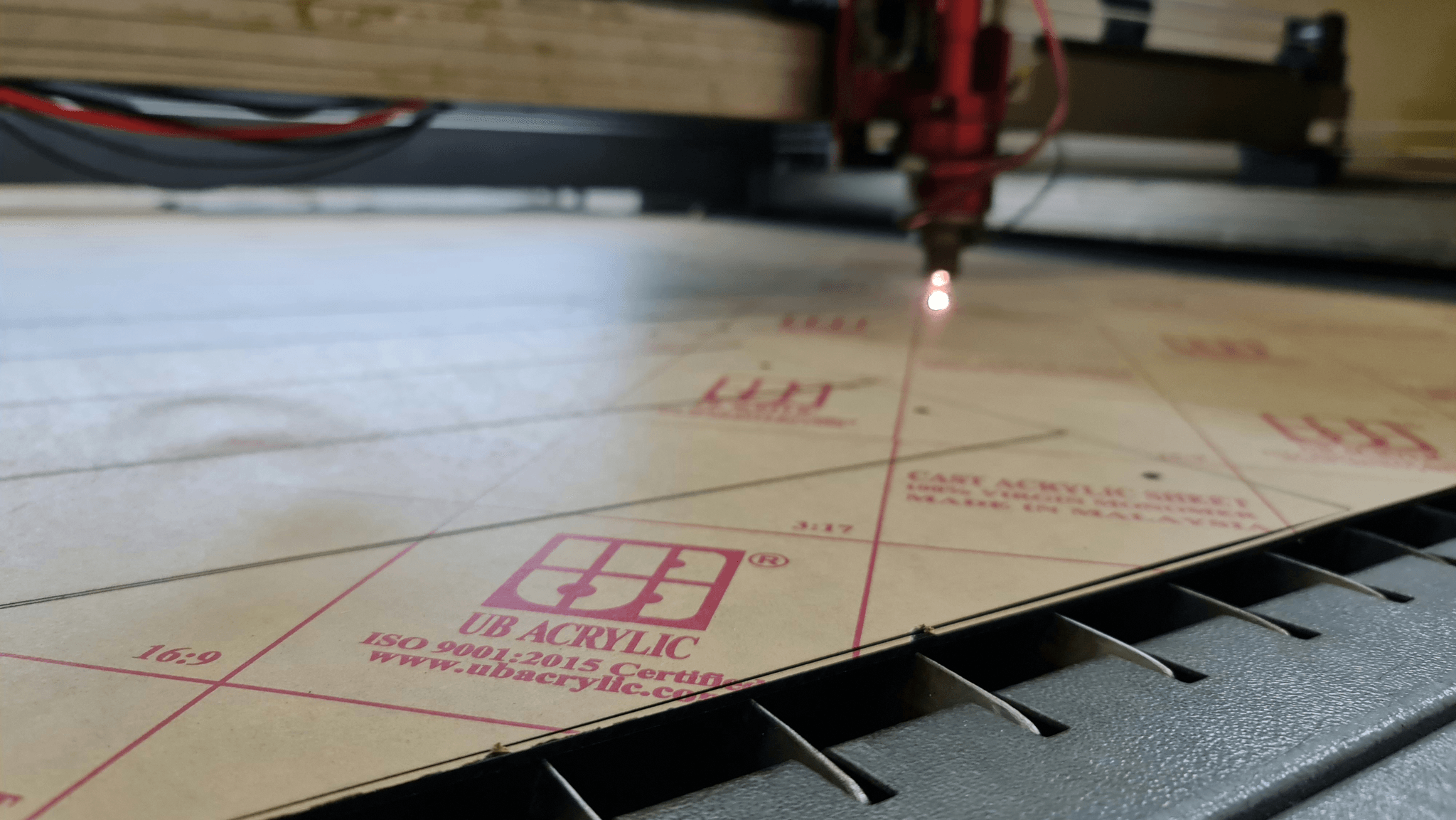

Versatility Across Materials with Cutting Machine Laser

One of the standout features of a cutting machine laser is its ability to work with an array of materials—from wood and acrylics to metals like aluminum and stainless steel. This versatility makes it an invaluable tool for any workshop looking to expand its offerings without investing in multiple types of equipment. The flatbed CO2 laser cutting machine can easily switch between tasks while delivering exceptional results across different substrates.

Furthermore, when paired with a laser etching machine or a laser and engraving machine, creative possibilities multiply exponentially! From custom signage to intricate prototypes, these machines empower artisans and manufacturers alike to bring their visions to life without being restricted by material limitations or design complexity. The adaptability offered by these machines truly sets them apart in today's competitive landscape.

Cost-Effectiveness for Businesses

When it comes to running a successful business, cost-effectiveness is often at the forefront of decision-making. Investing in a flatbed CO2 laser cutting machine can significantly reduce operational costs while enhancing productivity. This powerful tool not only streamlines processes but also provides unparalleled precision, making it an attractive option for businesses looking to maximize their bottom line.

Lower Operational Costs with Laser Cutting

One of the standout benefits of utilizing a flatbed CO2 laser cutting machine is its ability to lower operational costs dramatically. Compared to traditional cutting methods, laser machinery requires less energy and fewer resources, leading to significant savings on utility bills and material usage. Furthermore, the efficiency of these machines means that they can handle large volumes of work without needing extensive labor, allowing businesses to allocate their workforce more effectively.

Reducing Waste with Precision Engineering

Precision engineering is at the heart of what makes a metal cutting laser cutter so advantageous for businesses today. The accuracy offered by these machines minimizes material waste during production processes—every cut counts! With a cutting machine laser, you can achieve intricate designs and shapes without sacrificing valuable materials, ultimately leading to reduced costs and increased profitability.

Long-Term Savings with Durable Equipment

Investing in a metal cutting machine laser isn't just about immediate savings; it's also about long-term financial benefits. These machines are built for durability and longevity, meaning that they require fewer repairs or replacements over time compared to less robust alternatives like traditional saws or routers. By choosing high-quality equipment like a laser etching machine or laser and engraving machine, businesses can enjoy consistent performance while reaping the rewards of lower maintenance expenses.

Versatile Applications Beyond Cutting

When you think of a flatbed CO2 laser cutting machine, cutting might be the first thing that comes to mind. However, these machines are capable of much more than just slicing through materials. With advancements in technology, laser machinery has opened up a world of creative possibilities that go beyond traditional cutting applications.

Creative Possibilities with Laser Etching Machine

The laser etching machine is a game-changer for artists and designers looking to add intricate details to their work. Whether it's personalizing gifts or creating stunning wall art, the precision offered by these machines allows for designs that were previously unimaginable. With a flatbed CO2 laser cutting machine, you can etch graphics onto various surfaces like wood, glass, and acrylic, transforming everyday items into unique masterpieces.

Moreover, the versatility of the laser etching process means you can experiment with different materials and techniques without breaking the bank. Imagine being able to offer custom solutions to your clients or creating one-of-a-kind pieces for craft fairs; this level of creativity is now at your fingertips thanks to advanced laser technology. The ability to combine etching with cutting opens new doors for innovative projects that can truly set your work apart from the competition.

Expanding Capabilities with Laser and Engraving Machine

The introduction of the laser and engraving machine has revolutionized how businesses approach customization and branding. From logos on promotional products to personalized awards, this equipment allows companies to stand out in a crowded marketplace by offering tailored solutions that resonate with customers. The precision achieved by metal cutting laser cutters ensures that every detail is captured flawlessly, enhancing brand identity.

Furthermore, businesses can diversify their offerings by incorporating engraving services into their portfolio without investing heavily in additional equipment. A flatbed CO2 laser cutting machine provides the capability not only for cutting but also for high-quality engraving across various materials such as metals and plastics. This adaptability makes it an invaluable asset for any workshop or production facility aiming to expand its service range while keeping operational costs low.

Customization and Prototyping with Machine Laser Engraving

In today's fast-paced market, customization is key—and that's where machine laser engraving shines bright! Whether you're developing prototypes or producing limited runs of specialized items, having access to a metal cutting machine laser gives you the flexibility needed in product development cycles. The ability to quickly iterate designs through precise engraving means you can bring ideas from concept to reality faster than ever before.

Additionally, this technology enables businesses to cater specifically to customer demands by offering bespoke products tailored exactly as requested—no more generic solutions! With a flatbed CO2 laser cutting machine at your disposal, you have an edge over competitors who may not provide such personalized service options. The endless possibilities of customization ensure that every project becomes an opportunity for innovation rather than just another task on your list.

User-Friendly Features for All Skill Levels

When it comes to operating a flatbed CO2 laser cutting machine, user-friendliness is paramount. The latest advancements in laser machinery have made these machines accessible to everyone, from seasoned professionals to eager beginners. With intuitive designs and helpful features, the learning curve has never been easier.

Simplifying Operations with Kiant Machinery

Kiant Machinery has taken the lead in simplifying operations for users of all skill levels with their flatbed CO2 laser cutting machines. Their equipment is designed with streamlined processes that minimize setup time and maximize efficiency, allowing users to focus on creativity rather than complexity. Whether you’re using a metal cutting machine laser or a laser etching machine, the ease of operation ensures that you can achieve high-quality results without a steep learning curve.

Training and Support for Novices and Experts

For those who are new to the world of laser technology, comprehensive training and support are crucial for success. Kiant Machinery offers extensive resources tailored specifically for both novices and experts alike, ensuring everyone can confidently operate their laser and engraving machines. This commitment to education not only empowers users but also enhances productivity across various applications—be it machine laser engraving or precision metal cutting.

Intuitive Interfaces in Modern Laser Cutting Machines

Modern flatbed CO2 laser cutting machines boast intuitive interfaces that make navigation a breeze. Users can easily adjust settings for different materials or projects with just a few clicks—perfect for anyone looking to switch between tasks like engraving intricate designs or executing precise cuts with a metal cutting laser cutter. These user-friendly controls foster creativity while ensuring that even those unfamiliar with advanced technology can produce professional-grade results effortlessly.

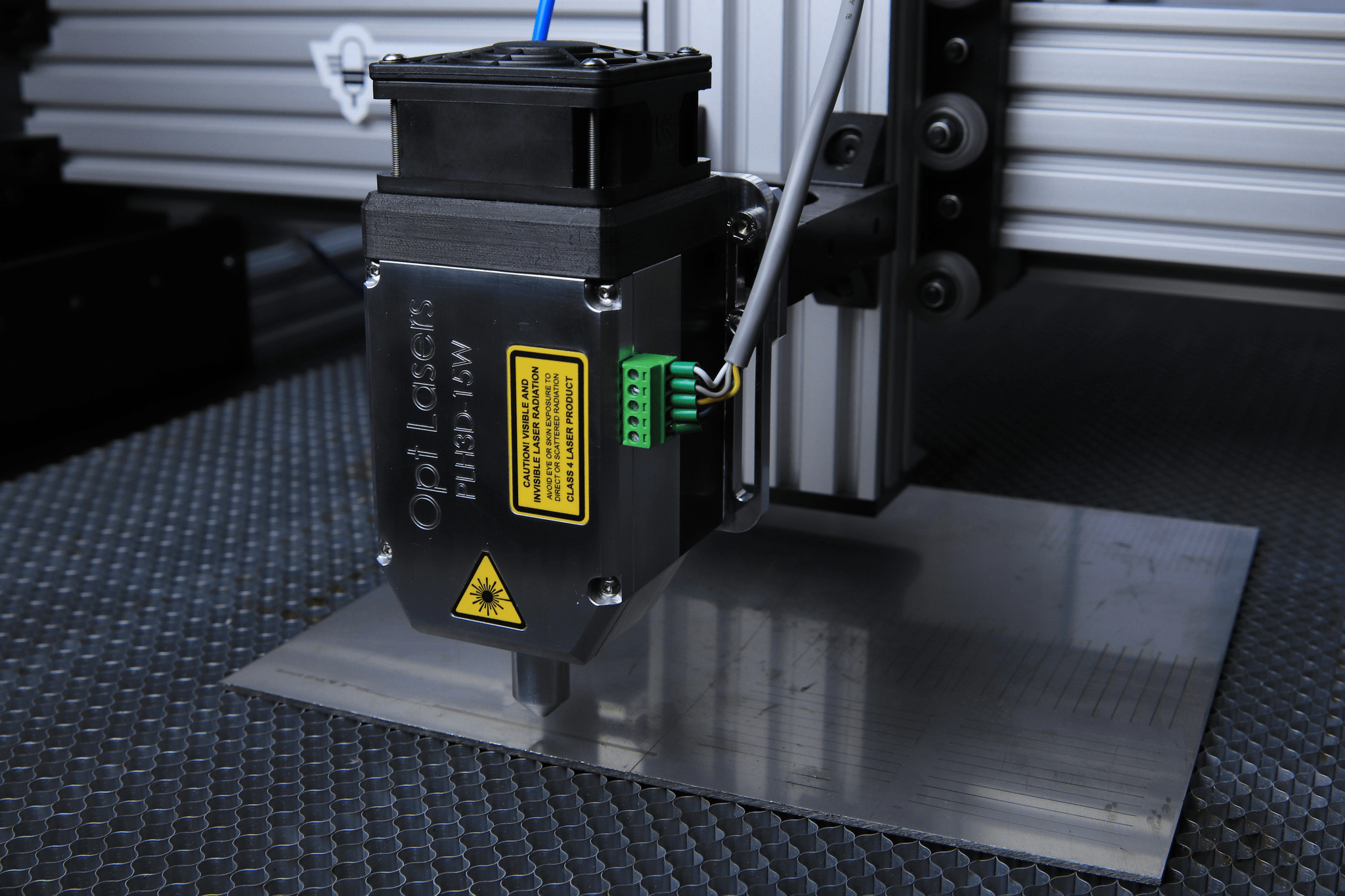

Reliability and Longevity of Equipment

When investing in a flatbed CO2 laser cutting machine, reliability and longevity are paramount. These machines are engineered with advanced technology that minimizes wear and tear, ensuring they remain operational for years. With proper maintenance, you can expect your laser machinery to consistently deliver high-quality results without frequent breakdowns.

Maintenance Made Easy with Advanced Technology

Modern flatbed CO2 laser cutting machines come equipped with features that simplify maintenance tasks. Automatic calibration systems and built-in diagnostics mean less time spent troubleshooting issues and more time focusing on your projects. Additionally, the robust design of metal cutting laser cutters reduces the frequency of necessary upkeep, allowing you to maximize productivity.

Routine care is straightforward; many manufacturers provide user-friendly manuals or online resources that guide you through the process. This means even those new to operating a laser etching machine can easily follow maintenance protocols without feeling overwhelmed. Ultimately, investing in a machine laser engraving tool with easy maintenance features saves both time and money.

Trusting Your Investment in Metal Cutting Machine Laser

Investing in a metal cutting machine laser is not just about acquiring equipment; it’s about securing peace of mind for your business operations. High-quality machines are built to last, often backed by warranties that reflect their durability and reliability. This assurance allows businesses to focus on growth rather than worrying about unexpected downtime due to equipment failure.

Moreover, reputable manufacturers stand behind their products by offering extensive customer support and service options, ensuring you have assistance whenever needed. With advancements in technology continually enhancing the performance of cutting machine lasers, businesses can trust that their investment will yield long-term benefits while maintaining efficiency and precision over time.

Real-World Testimonials on Longevity and Performance

Nothing speaks louder than the experiences of those who have already embraced the power of flatbed CO2 laser cutting machines in their operations. Many users rave about how their metal cutting laser cutter has outperformed expectations over years of use—some reporting consistent performance even after thousands of cuts! Such testimonials highlight not only the reliability but also the exceptional quality delivered by modern laser machinery.

Customers frequently share stories about how their investments have transformed workflows, enabling them to take on more complex projects without fear of equipment failure or inefficiency. The durability associated with these machines translates into real-world savings as businesses avoid costly repairs or replacements down the line—an aspect that resonates well within competitive markets where every dollar counts.

Conclusion

In today’s competitive landscape, the flatbed CO2 laser cutting machine stands out as a smart choice for modern manufacturing. Its ability to deliver precision and efficiency makes it an invaluable asset for businesses looking to enhance their production capabilities. By integrating this advanced technology, companies can streamline operations and remain ahead of the curve in an ever-evolving market.

A Smart Choice for Modern Manufacturing

The flatbed CO2 laser cutting machine is engineered to meet the demands of various industries, from automotive to textiles. This versatility allows manufacturers to tackle diverse projects without sacrificing quality or speed. With the integration of laser machinery into production lines, businesses can expect not only improved output but also a significant reduction in operational hiccups.

Boosting Productivity with Flatbed CO2 Laser Cutting

Utilizing a metal cutting laser cutter can dramatically boost productivity levels within any manufacturing setup. The efficiency of cutting machine lasers translates into faster turnaround times, which is crucial for meeting tight deadlines and increasing customer satisfaction. Moreover, with features like automation and user-friendly interfaces found in modern laser and engraving machines, even novice operators can achieve professional results quickly.

Investing in the Future of Laser Machinery

Investing in a flatbed CO2 laser cutting machine is not just about immediate gains; it’s also about future-proofing your business against industry shifts. As technology continues to advance, incorporating equipment like a laser etching machine or machine laser engraving will ensure you remain competitive in innovation and craftsmanship. Ultimately, this investment promises long-term savings through durability and reduced waste—making it an intelligent choice for any forward-thinking manufacturer.