Introduction

In the world of manufacturing and fabrication, precision is key, and nothing embodies this better than laser metal cutting. This advanced technique utilizes a laser steel cutting machine to achieve intricate designs and exact dimensions that traditional methods struggle to match. As industries evolve, understanding the nuances of laser technologies becomes essential for anyone looking to enhance their production capabilities.

Understanding Laser Metal Cutting

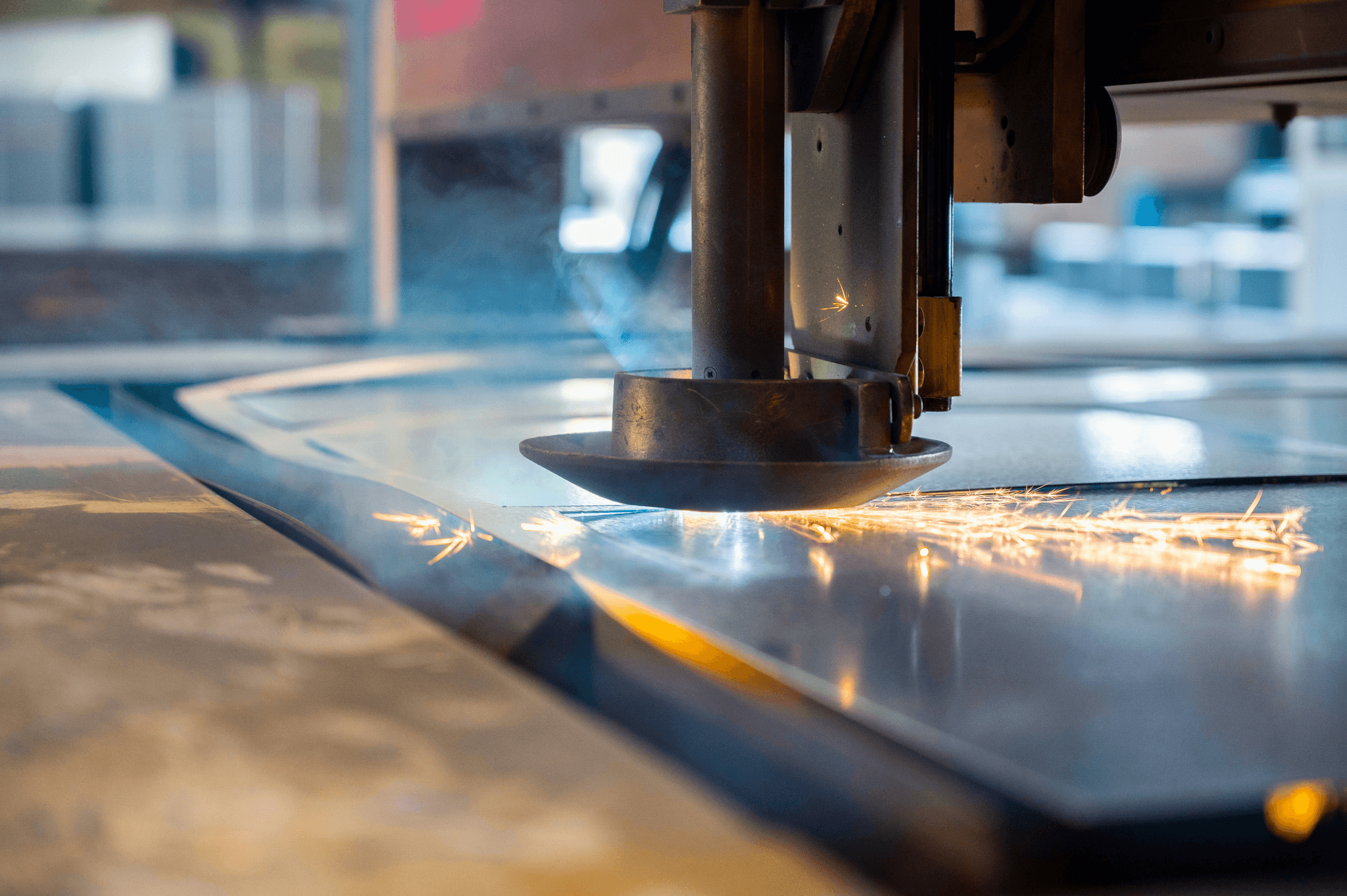

Laser metal cutting is a process that employs focused laser beams to slice through various types of metals with remarkable accuracy. The industrial laser cutter generates high-intensity light that melts or vaporizes the material, allowing for clean cuts without the need for extensive post-processing. By grasping the fundamentals of this technology, beginners can appreciate why it has become a staple in modern metal fabrication.

Benefits of Laser Steel Cutting

The advantages of using a metal cutting laser cutter are numerous, making it an attractive option for many manufacturers. For starters, laser steel cutting offers unparalleled precision and speed compared to traditional methods like plasma or mechanical cutting. Additionally, it produces minimal waste and reduces the need for secondary operations, leading to cost savings and improved efficiency in production processes.

Essential Equipment for Beginners

For those just diving into the realm of industrial laser machines, having the right equipment is crucial for success. A quality industrial laser cutting machine not only enhances productivity but also ensures safety during operation. Beginners should invest in essential tools such as protective eyewear, ventilation systems, and reliable software to manage their metal cutting machine laser effectively.

What is Laser Metal Cutting?

Laser metal cutting is an advanced technology that utilizes focused laser beams to cut through various types of metals with precision and efficiency. This method has revolutionized the way industries approach metal fabrication, providing a cleaner and more accurate alternative to traditional cutting methods. Whether you're working with steel, aluminum, or other alloys, understanding the intricacies of laser metal cut can help you make informed decisions for your projects.

Definition and Basics

At its core, laser metal cutting involves using a high-powered laser beam directed at a metallic surface to melt or vaporize the material away. The process is characterized by its ability to produce intricate designs and clean edges without significant mechanical force, which minimizes wear on tools and machinery. With the advent of industrial laser cutters, this technology has become increasingly accessible for both large-scale manufacturing and smaller workshops.

How Laser Technology Works

The operation of a laser steel cutting machine hinges on three primary components: the laser source, focusing optics, and motion control systems. The laser source generates intense light that is then concentrated into a fine beam capable of penetrating various thicknesses of metal. As the beam moves across the workpiece—often controlled by sophisticated software—it effectively cuts through materials by either melting or burning them away while simultaneously blowing away molten debris with assist gases like oxygen or nitrogen.

Comparison to Traditional Cutting Methods

When compared to traditional cutting methods such as plasma cutting or mechanical saws, industrial laser machines offer several distinct advantages. Firstly, they provide higher precision with minimal kerf width (the width of material removed during cutting), resulting in less waste and better use of raw materials. Additionally, while conventional methods often require more extensive post-processing due to rough edges or burrs left behind, a metal cutting machine laser delivers smooth finishes right off the cutter—reducing time spent on secondary operations.

Types of Industrial Laser Cutters

When it comes to industrial laser cutters, understanding the various types available can make all the difference in your metal cutting endeavors. Each type of laser metal cut technology has its unique features and capabilities, tailored for specific applications and materials. Let’s delve into the different types of industrial laser cutting machines to help you identify which one suits your needs best.

Overview of Laser Types

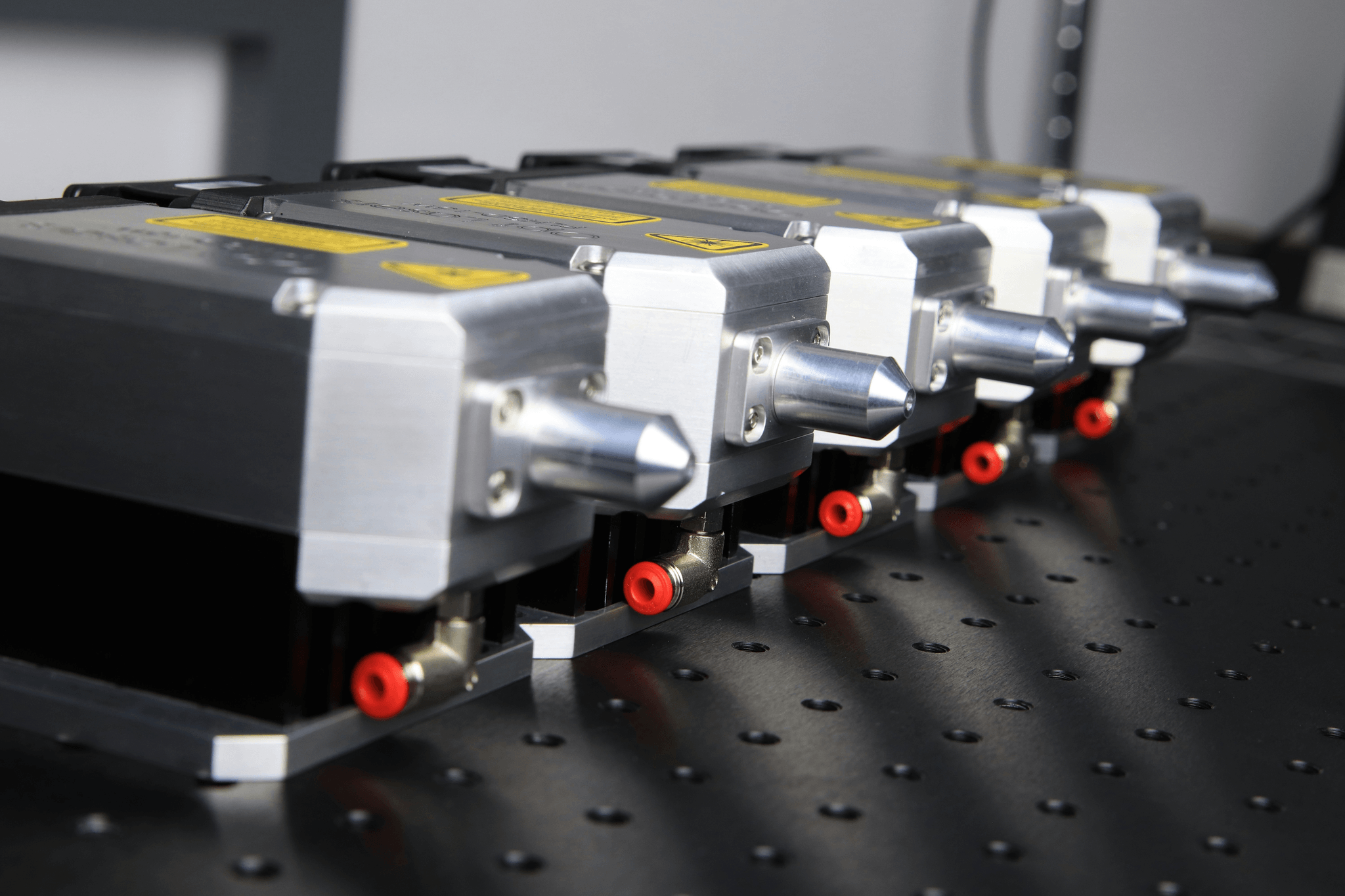

The primary types of lasers used in industrial applications include CO2 lasers, fiber lasers, and Nd:YAG lasers. CO2 lasers are renowned for their efficiency in cutting non-metal materials but can also handle metal with precision when paired with a suitable setup. Fiber lasers, on the other hand, have surged in popularity due to their speed and ability to cut reflective metals like copper and brass without excessive power loss, making them a top choice for many metal cutting machine laser setups.

Nd:YAG (Neodymium-doped Yttrium Aluminum Garnet) lasers are less common but still valuable in specific contexts where deep penetration is required. Each type has its strengths; therefore, understanding these distinctions is crucial when selecting an industrial laser cutter for your projects. The right choice will not only enhance productivity but also ensure that you achieve high-quality cuts consistently.

Choosing the Right Industrial Laser Cutting Machine

Selecting the right industrial laser cutting machine involves evaluating several factors such as material type, thickness, and desired precision level. First off, consider what materials you’ll be working with; if you're focusing on steel or other metals, a fiber or Nd:YAG machine might be more appropriate than a CO2 model due to their superior performance on reflective surfaces. Additionally, think about the thickness of materials you'll regularly cut—some machines excel at thin sheets while others are better suited for thicker plates.

Another vital aspect is your budget; while investing in advanced technology can yield excellent results over time, it’s essential to find a balance between cost and capability that aligns with your operational needs. Don't forget about after-sales support; choosing a manufacturer that offers robust customer service can save you headaches down the line if issues arise with your metal cutting laser cutter equipment. Ultimately, careful consideration will lead you to an industrial laser cutter that enhances both efficiency and quality in your work.

Applications of Each Type

Each type of industrial laser cutter has distinct applications based on its specifications and capabilities. For instance, CO2 lasers are widely used for engraving as well as cutting plastics and wood but can also handle mild steel effectively when configured correctly—ideal for businesses that work across multiple material types! Fiber lasers shine particularly bright in industries requiring high-speed processing of metals like stainless steel or aluminum due to their energy efficiency and minimal maintenance needs.

Nd:YAG lasers find their niche primarily in specialized applications such as precise drilling or thick material cutting where deeper penetration is necessary—think aerospace components or medical devices requiring intricate designs! Understanding these applications helps businesses leverage their investment by matching the right machine with specific production requirements while maximizing output quality from every cut made by their metal cutting machine laser setup.

Key Components of a Metal Cutting Machine Laser

When diving into the world of laser metal cut technology, understanding the key components of a metal cutting machine laser is essential. Each part plays a crucial role in ensuring precision and efficiency during the cutting process. From the laser source to the control system, knowing these components will help you make informed decisions about your industrial laser cutter.

Breakdown of Essential Parts

The primary components of a laser steel cutting machine include the laser source, optics, motion system, and control unit. The laser source generates high-intensity light that is focused through optics to create a concentrated beam capable of cutting through various metals. The motion system allows for precise movement and positioning, while the control unit manages all operational parameters to ensure optimal performance of your industrial laser cutting machine.

Importance of Each Component

Each component in an industrial laser cutter serves a specific purpose that contributes to overall functionality and effectiveness. The quality of the laser source directly affects cut quality and speed; therefore, investing in a reliable source is paramount for any metal cutting machine laser user. Optics must be clean and well-aligned to maintain beam focus, while an efficient motion system minimizes downtime by enabling swift adjustments during operation.

Maintenance Tips for Longevity

To ensure longevity and peak performance from your industrial laser machines, regular maintenance is key. Start with routine inspections; check for dust accumulation on optics and ensure all moving parts are lubricated properly to prevent wear and tear over time. Additionally, keeping software updated will enhance functionality while troubleshooting minor issues early can save you from costly repairs down the line—because no one wants their metal cutting laser cutter down for too long!

Getting Started with Laser Steel Cutting

Diving into the world of laser steel cutting can be both exciting and daunting. With the right setup, safety precautions, and skills, you can transform raw materials into intricate designs with an industrial laser cutter. Let’s explore how to create a productive workspace, prioritize safety, and develop essential techniques for mastering the art of metal cutting.

Setting Up Your Workspace

Creating an efficient workspace is crucial for effective laser metal cut operations. Start by choosing a well-ventilated area that allows for easy movement around your industrial laser cutting machine; this will not only enhance comfort but also improve workflow efficiency. Ensure your workspace is free from clutter and has dedicated storage for tools and materials related to your metal cutting machine laser.

Next, consider investing in a sturdy workbench that can withstand the weight of your equipment while providing ample space for projects in progress. Position your industrial laser cutter at a height that feels comfortable for you to operate while standing or sitting; ergonomics matter! Lastly, don't forget about proper lighting—good visibility is key when working with precision machinery like an industrial laser cutter.

Safety Precautions to Consider

Safety should always be your top priority when working with any type of industrial laser machines. First and foremost, wear appropriate personal protective equipment (PPE), including safety goggles designed to protect against intense light exposure from the metal cutting laser cutter. Additionally, ensure you have gloves on hand to protect yourself from sharp edges of cut materials.

It's also essential to familiarize yourself with emergency procedures specific to your equipment before starting operations on the laser steel cutting machine. Keep fire extinguishers nearby since lasers can ignite flammable materials if not monitored closely during operation. Lastly, always follow manufacturer guidelines regarding maintenance schedules—keeping your equipment in top shape reduces risks significantly!

Basic Skills and Techniques

Mastering basic skills is vital as you embark on your journey into laser metal cut artistry. Start by learning how to calibrate your industrial laser cutting machine correctly; this ensures precision in every cut you make! Familiarize yourself with various settings such as speed and power levels tailored specifically for different types of metals.

Practice makes perfect! Begin with simple shapes or patterns before moving on to more complex designs; this gradual approach helps build confidence while honing essential techniques needed for successful operation of a metal cutting machine laser. Finally, consider joining local workshops or online forums where experienced users share their tips—networking can often lead to invaluable insights!

How to Choose the Right Equipment

Choosing the right equipment for laser metal cutting can feel like navigating a maze, especially with so many options available. Your choice will depend on various factors including your specific needs, budget, and the types of projects you plan to undertake. By evaluating these elements carefully, you can ensure that your investment in a laser steel cutting machine pays off in the long run.

Evaluating Your Needs

Before diving into the world of industrial laser cutters, take a moment to assess what you actually need from a metal cutting machine laser. Consider factors like material thickness, cutting speed, and precision requirements that align with your projects. Additionally, think about whether you'll be using this equipment for small-scale tasks or larger industrial applications; this will help narrow down your options significantly.

Another crucial aspect is understanding the types of materials you'll be working with. Different industrial laser machines are designed for varying levels of complexity and material compatibility—some excel at cutting steel while others may perform better on softer metals or plastics. By clearly defining your needs upfront, you can avoid costly mistakes and ensure that you're investing in an industrial laser cutting machine that meets your expectations.

Top Models in the Market

Once you've evaluated your needs, it's time to explore some top models available in the market for metal cutting lasers. Brands like Trumpf and Mazak offer robust industrial laser cutters known for their reliability and performance across various applications. The Trumpf TruLaser series is particularly popular among professionals due to its advanced technology and versatility.

Another noteworthy contender is the Fiber Laser series from IPG Photonics which boasts high efficiency and low operating costs—perfect for those looking to maximize their return on investment. If budget constraints are a concern but quality cannot be compromised, consider entry-level models from reputable manufacturers like Trotec or Epilog Laser; they provide excellent performance without breaking the bank.

Regardless of which model catches your eye, always check reviews from fellow users to gauge real-world performance before making a purchase decision. Remember: investing in an industrial laser cutter is not just about choosing a brand but finding one that aligns perfectly with your operational goals.

Kiant Machinery's Offerings

If you're still feeling overwhelmed by choices after evaluating your needs and browsing top models in the market, look no further than Kiant Machinery's offerings! Their range of industrial laser machines includes everything from entry-level units perfect for beginners to high-end options tailored for seasoned pros tackling complex projects. With features designed specifically for efficient laser steel cutting processes, these machines are built to last while delivering exceptional results.

Kiant also emphasizes customer support; they provide comprehensive training resources alongside their machinery so you can hit the ground running once you've made your purchase. Plus, their commitment to innovation means you're getting access to some of the latest technology available in metal cutting lasers today—ensuring you're well-equipped for future trends as well.

In summary, when it comes time to choose your equipment for metal cutting processes such as laser metal cut applications or other intricate tasks requiring precision cuts—the right choice will make all the difference in achieving success!

Conclusion

In the world of manufacturing and fabrication, mastering laser cutting techniques is not just a valuable skill; it’s essential for staying competitive. With the ability to achieve precision and efficiency, the laser steel cutting machine has revolutionized how we approach metalwork. Whether you're a hobbyist or a seasoned professional, understanding how to effectively operate an industrial laser cutter will elevate your projects to new heights.

Mastering Laser Cutting Techniques

To truly excel in using a metal cutting laser cutter, one must practice and understand the intricacies of different materials and settings. Each type of industrial laser cutting machine comes with its own set of parameters that can significantly affect the outcome of your work. By experimenting with various techniques—such as adjusting speed, power settings, and focusing—you’ll gain invaluable insights that lead to flawless cuts every time.

Moreover, honing your skills in troubleshooting common issues can save you time and resources down the line. Familiarizing yourself with software that controls these machines is equally important; it allows you to optimize designs for more efficient cuts. Ultimately, mastery over these techniques not only enhances your craftsmanship but also prepares you for future advancements in technology.

Future Trends in Laser Technology

The landscape of laser technology is ever-evolving, with exciting innovations on the horizon that promise to enhance industrial laser machines further. One notable trend is the integration of artificial intelligence into laser cutting systems, which could streamline processes by predicting maintenance needs and optimizing performance automatically. Additionally, advancements in fiber lasers are making them more versatile and cost-effective than ever before.

Sustainability is also becoming a key focus within this field; manufacturers are increasingly looking at ways to reduce waste during production through more efficient cuts provided by modern metal cutting machines lasers. As industries seek greener alternatives, expect to see developments aimed at minimizing energy consumption while maximizing output quality. Staying informed about these trends will ensure you're prepared for what lies ahead in this dynamic industry.

Resources for Continued Learning

For those eager to deepen their knowledge about laser metal cut technologies and techniques, there are numerous resources available online and offline. Websites dedicated to fabrication technologies often feature forums where enthusiasts share tips on operating an industrial laser cutter effectively or troubleshooting common problems encountered with metal cutting machines lasers.

Additionally, consider enrolling in workshops or online courses focused on advanced practices related to your specific equipment model or application area—these can provide hands-on experience that's invaluable when working with complex machinery like an industrial laser cutting machine. Books authored by industry experts can also serve as excellent references for both beginners and seasoned professionals alike.