Introduction

In the ever-evolving landscape of manufacturing, laser metal cutting has emerged as a game-changer, revolutionizing how industries approach metal fabrication. This advanced technique utilizes high-powered lasers to achieve unparalleled precision and efficiency in cutting various metals, making it an essential tool for modern manufacturers. As we delve deeper into the world of laser cutting, we will explore its benefits, applications, and the exciting future that awaits this technology.

Discover the Revolution of Laser Cutting

Laser cutting is not just a trend; it's a revolutionary shift in how we perceive metal processing. With its ability to deliver intricate designs and clean cuts at remarkable speeds, the laser cutter for metal has become indispensable in numerous sectors. This innovative approach harnesses focused light beams to slice through materials with ease, setting a new standard for quality and performance in metal cutting machines.

Benefits of Laser Metal Cutting Techniques

One of the standout advantages of laser metal cutting techniques is their exceptional precision and accuracy compared to traditional methods. This level of detail minimizes errors and reduces material waste—an important factor for businesses looking to enhance efficiency and sustainability. Moreover, the versatility offered by these machines allows them to work with a wide range of materials, from stainless steel to aluminum, making them suitable for various applications across multiple industries.

The Future of Metal Fabrication

The future of metal fabrication looks bright as advancements in laser technology continue to unfold. Innovations such as smart technologies and integration with CAD/CAM systems are paving the way for even more sophisticated laser cutting machines that can adapt to complex requirements seamlessly. As industries increasingly embrace these developments, we can expect laser machine capabilities to expand further, solidifying their role as vital components in modern manufacturing processes.

Overview of Laser Metal Cutting

Laser metal cutting is revolutionizing the way industries approach precision and efficiency in metal fabrication. This advanced technology utilizes focused laser beams to cut through various types of metals with remarkable accuracy. As we delve into the specifics, you'll discover how laser cutting machines have become indispensable tools in modern manufacturing.

What is Laser Cutting?

At its core, laser cutting is a process that employs a high-powered laser beam to slice through materials, particularly metals. The precision of this method allows for intricate designs and shapes that would be difficult or impossible to achieve with traditional cutting methods. With the ability to control the intensity and focus of the beam, a metal cutting machine can produce clean edges and minimize post-processing work.

Laser cutting has gained popularity across various industries due to its efficiency and versatility. It can handle a wide range of materials, including steel, aluminum, brass, and even some plastics. This adaptability makes it an ideal choice for manufacturers looking for a reliable solution for their diverse production needs.

Types of Laser Cutting Machines

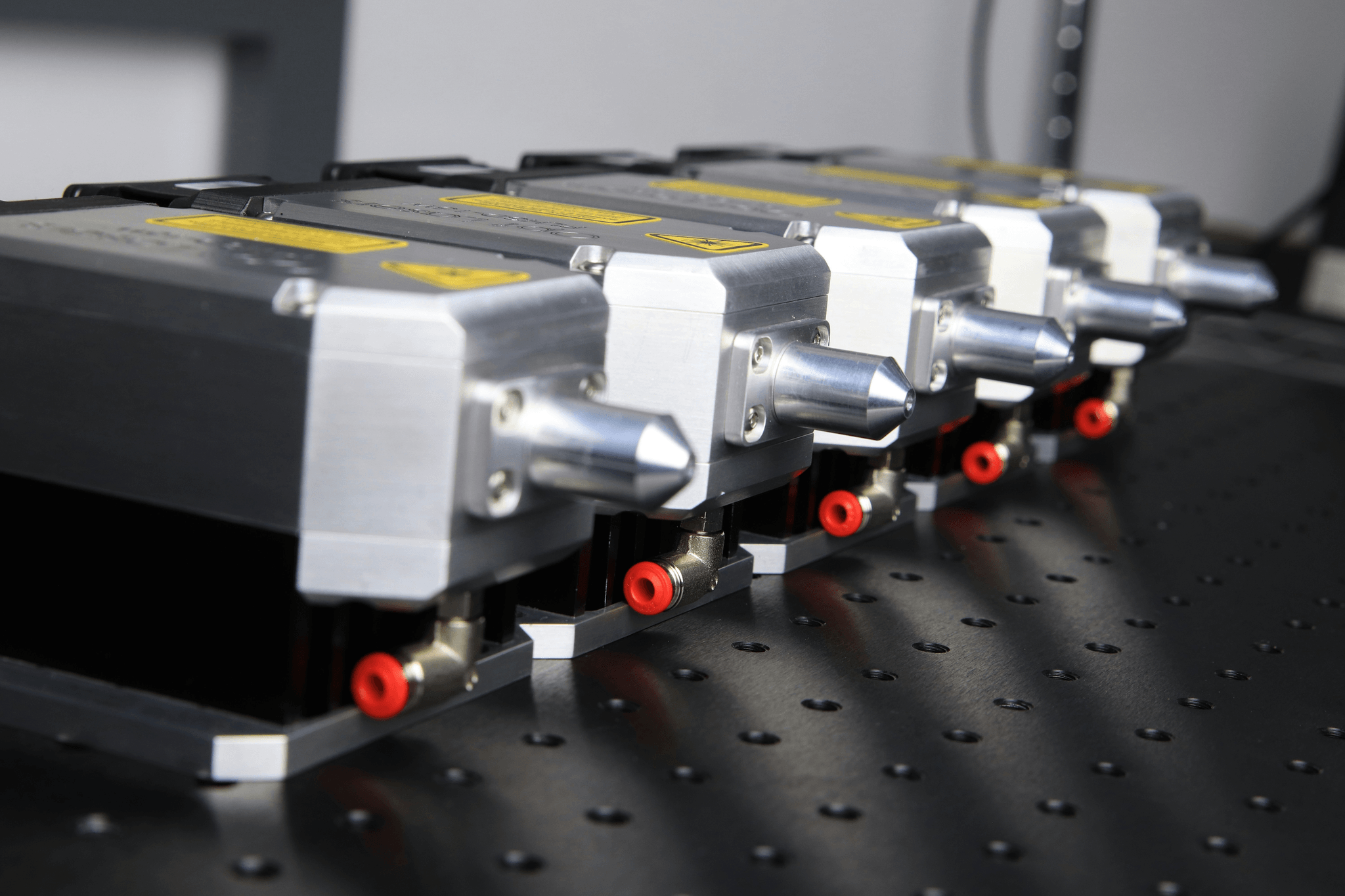

There are several types of laser cutting machines available on the market today, each tailored for specific applications and material thicknesses. The most common types include CO2 lasers, fiber lasers, and solid-state lasers. CO2 lasers are known for their ability to cut non-metal materials as well as metals but are often less efficient than fiber lasers when dealing with thicker metals.

Fiber lasers have surged in popularity due to their superior speed and efficiency in metal cutting applications. They deliver higher power density and can easily cut through reflective materials like copper or brass without complications typical in older technologies. Solid-state lasers combine aspects from both CO2 and fiber technologies but tend to be more specialized.

Choosing the right type of laser cutter for metal depends on factors such as material type, thickness requirements, and desired precision levels. Each machine comes equipped with unique features that cater to different industrial needs—making it crucial for manufacturers to assess their specific requirements before investing in a new machine.

How Laser Cutting Works

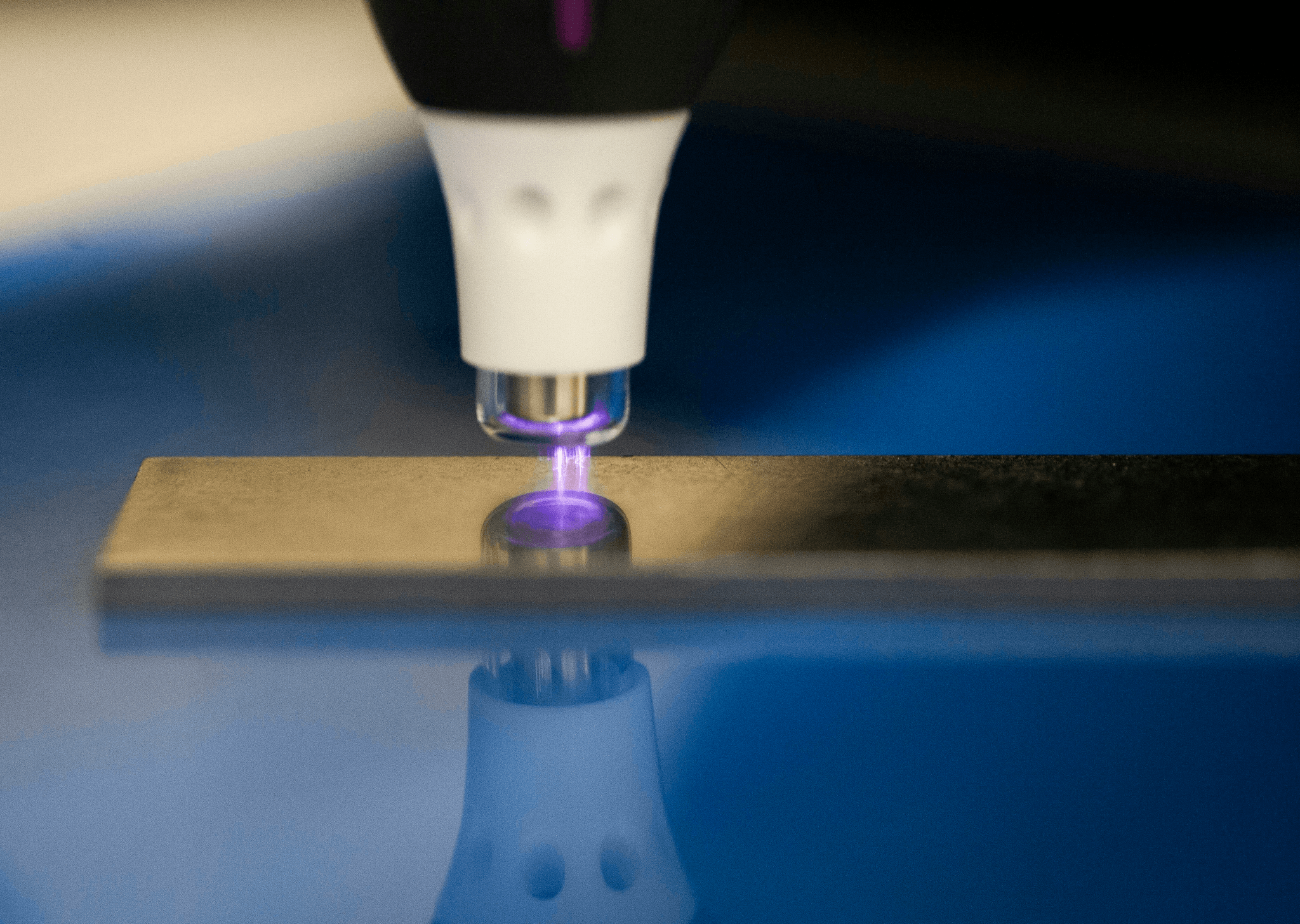

The operation of a laser cutting machine involves several key steps that ensure precise cuts every time. First, a focused beam generated by the laser source is directed onto the surface of the material being cut—this creates intense heat at the point of contact which melts or vaporizes the metal instantly. The motion system then guides this concentrated beam along predetermined paths according to digital designs created using CAD software.

As the laser moves across the material's surface, an assist gas such as oxygen or nitrogen may be used to blow away molten material from the cut area—this not only enhances speed but also improves edge quality by preventing dross formation (the unwanted residue left behind). Advanced systems incorporate feedback mechanisms that adjust parameters on-the-fly based on real-time data gathered during operation.

This synergy between technology and technique allows manufacturers using these metal cutting machines to achieve unmatched precision while optimizing production times significantly compared to traditional methods. As industries continue embracing advancements like smart technologies integrated within these machines, we can expect even greater efficiencies in future applications.

Advantages of Laser Cutting Metal

Laser cutting has revolutionized the world of metal fabrication, offering numerous advantages that traditional methods simply can't match. From unparalleled precision to material efficiency and versatility, laser metal cutting is a game changer for industries across the board. Let’s dive into these key benefits that make laser cutting machines the go-to choice for modern manufacturers.

Precision and Accuracy in Metal Cutting

One of the most significant advantages of using a laser cutter for metal is its exceptional precision and accuracy. Laser cutting machines utilize focused beams of light to achieve intricate designs with tolerances as tight as 0.1 mm, making them ideal for applications requiring detailed work. Whether it’s creating complex geometries or fine details, the accuracy provided by a metal cutting machine laser ensures that every cut is clean and exact, reducing the need for rework.

Furthermore, this level of precision minimizes human error during production processes, allowing manufacturers to maintain high-quality standards consistently. The ability to replicate designs flawlessly also enhances productivity since fewer mistakes mean less downtime and wasted materials. In an era where efficiency is paramount, investing in a laser machine can significantly elevate operational performance.

Reduced Waste and Material Efficiency

Another compelling benefit of laser cutting is its ability to reduce waste significantly while maximizing material efficiency. Unlike traditional methods that may require extensive machining or manual labor, laser cutting machines optimize the use of raw materials through precise cuts that minimize leftover scraps. This not only conserves resources but also translates into cost savings for businesses looking to improve their bottom line.

Moreover, advanced software integrated into modern laser cutters allows operators to plan layouts meticulously before any actual cutting begins. This preemptive approach ensures that materials are utilized effectively while also streamlining production processes further. By choosing a cutting machine laser over conventional techniques, companies can drastically lower their environmental impact while boosting profitability.

Versatility of Materials Using Laser Technology

The versatility offered by laser technology in metal cutting cannot be overstated; these machines can handle a wide range of materials with ease! From stainless steel and aluminum to brass and copper, a single laser cutter for metal can adapt to various applications without compromising quality or performance. This flexibility allows manufacturers to diversify their product offerings without needing multiple specialized machines.

In addition to different metals, advanced lasers can also cut through various thicknesses efficiently, accommodating everything from thin sheets to thicker plates with minimal adjustments needed between jobs. Such adaptability makes it easier for businesses to respond rapidly to market demands or custom orders without incurring excessive costs associated with equipment changes or downtime. Embracing this versatility not only enhances competitiveness but positions companies favorably within their respective industries.

The Role of Technology in Laser Cutting

The landscape of laser metal cutting is rapidly evolving, largely due to the advancements in technology that enhance efficiency and precision. Innovations in laser cutting machines have transformed traditional methods, making them faster and more reliable than ever before. As manufacturers seek competitive edges, the integration of cutting-edge technology into metal cutting machines has become essential.

Innovations in Laser Cutting Machines

Recent innovations in laser cutting machines have led to significant improvements in speed, power, and functionality. Modern laser cutters for metal are equipped with advanced features like fiber lasers and high-speed galvanometers that allow for intricate designs with unmatched precision. These enhancements not only streamline production processes but also reduce operational costs, making laser cutting an attractive option for businesses looking to optimize their metal fabrication techniques.

Integration of CAD/CAM with Laser Cutters

The synergy between CAD/CAM software and laser cutting machines has revolutionized how designs are translated into physical products. By integrating CAD/CAM with a metal cutting machine laser, operators can create complex geometries that were previously difficult or impossible to achieve. This seamless connection allows for real-time adjustments during the production process, ensuring that the final product meets precise specifications while minimizing material waste.

Smart Technologies for Enhanced Performance

Smart technologies are taking laser metal cutting to new heights by introducing automation and artificial intelligence into the mix. These advancements enable predictive maintenance, reducing downtime by alerting operators before issues arise with their laser cutters for metal. Additionally, smart technologies can analyze performance data to optimize settings automatically, ensuring consistent quality while maximizing efficiency across various applications of the cutting machine laser.

Choosing the Right Laser Cutter for Metal

Selecting the perfect laser cutter for metal can feel like trying to find a needle in a haystack, especially with so many options available. Whether you're a small business owner or part of a large manufacturing operation, understanding your specific needs is crucial for making an informed decision. The right metal cutting machine can significantly enhance productivity and efficiency, ultimately leading to better output quality.

Factors to Consider in Selection

First and foremost is the thickness of the material you'll be working with; different laser machines have varying capabilities when it comes to cutting through various metal gauges. Additionally, consider the speed and precision required for your projects—some applications demand high-speed cutting while maintaining exact tolerances.

Another essential factor is the type of laser used in the machine; CO2 lasers are great for thicker materials, while fiber lasers excel at cutting thin metals with speed and efficiency. Don't forget about software compatibility either! Ensuring that your chosen laser cutter integrates well with existing CAD/CAM systems can streamline operations and save you time in the long run.

Comparing Different Laser Metal Cutting Machines

With numerous options on the market, comparing different laser metal cutting machines becomes paramount for making an educated choice. Start by looking at their power ratings—higher wattage typically translates into faster cutting speeds and greater versatility across various materials. It’s also wise to evaluate features like automatic loading systems or advanced cooling mechanisms that can enhance operational efficiency.

Moreover, consider user-friendliness; some machines come equipped with intuitive interfaces that simplify operation even for beginners, while others may require specialized training. Maintenance requirements should not be overlooked either; some models are designed for easy upkeep while others might involve more complex servicing routines. In this competitive landscape of metal cutting machines, weighing these aspects will help you find a suitable fit.

Leading Brands: A Look at Kiant Machinery

When discussing reliable manufacturers in the realm of laser cutters for metal, Kiant Machinery stands out as a frontrunner known for its innovative solutions and robust performance. Their range of laser machines caters to diverse industrial needs—from compact models ideal for small workshops to large-scale systems designed for heavy-duty applications. Kiant Machinery's emphasis on quality ensures that their products are built to last while delivering exceptional results in precision and speed.

Kiant also offers excellent customer support and training resources, which can significantly ease the transition into using advanced technology like their metal cutting machine lasers. As industries continue evolving towards automation and smart technologies, investing in Kiant’s offerings could position your operations ahead of competitors who may still rely on traditional methods. For anyone serious about elevating their fabrication processes through effective laser metal cutting techniques, exploring what Kiant has to offer is definitely worth it.

Practical Applications of Laser Metal Cutting

Laser metal cutting has revolutionized various industries by providing efficient and precise solutions for fabricating metal parts. From automotive to aerospace, the versatility of laser cutting machines has made them indispensable tools in manufacturing processes. Companies are increasingly adopting cutting machine laser technology to enhance productivity and reduce operational costs.

Industries Benefiting from Laser Cutting

Several industries have embraced laser cutting due to its unmatched precision and efficiency. The automotive sector uses laser cutters for intricate designs and components, ensuring high-quality production standards while minimizing waste. Similarly, the aerospace industry relies on metal cutting machines for lightweight yet durable parts that meet stringent safety regulations.

Manufacturing sectors such as electronics and construction also reap the benefits of laser metal cutting technology. In electronics, precision is critical; thus, a laser cutter for metal can create tiny components with exact specifications. Meanwhile, construction firms utilize these advanced machines to fabricate structural elements quickly and accurately, streamlining project timelines.

Case Studies on Laser Cutting Success

One notable case study involves a leading automotive manufacturer that implemented a state-of-the-art laser machine to streamline its production line. By integrating a metal cutting machine laser into their workflow, they reduced material waste by 30% while increasing output efficiency by 25%. The result was not just improved profitability but also enhanced sustainability practices within the company.

Another success story comes from an aerospace firm that faced challenges in producing complex geometries for aircraft components. By adopting advanced laser cutting technology, they achieved unprecedented levels of accuracy and speed in their fabrication processes. This shift not only improved product quality but also allowed them to meet tight deadlines without compromising safety standards.

Future Trends and Developments in Metal Cutting

The future of metal cutting is bright as innovations continue to emerge in the field of laser technology. Expect advancements such as higher-powered lasers that can cut through thicker materials with even greater speed and accuracy than current models allow. Additionally, developments in automation will likely see more integrated systems where robots work alongside laser cutters for seamless operation.

Another trend is the increasing integration of artificial intelligence (AI) into laser cutting machines, enhancing decision-making processes during fabrication tasks. This could lead to real-time adjustments based on material properties or design changes, further optimizing efficiency in manufacturing workflows. As industries evolve, staying ahead with innovative technologies like these will be crucial for businesses looking to maintain competitive advantages in the market.

Conclusion

In wrapping up our exploration of laser metal cutting, it's clear that this technology has revolutionized the way we approach metal fabrication. The precision, efficiency, and versatility offered by laser cutting machines are unparalleled, making them a go-to choice for industries across the board. As we look to the future, the integration of smart technologies will only enhance the capabilities of these cutting machines, paving the way for even more innovative applications.

Key Takeaways on Laser Metal Cutting

To summarize the key takeaways on laser metal cutting: first and foremost, its precision and accuracy set it apart from traditional methods. This technology not only minimizes waste but also maximizes material efficiency—an essential factor in today’s eco-conscious manufacturing landscape. Finally, with a wide range of materials suitable for laser cutting, businesses can explore new design possibilities that were previously unattainable with conventional metal cutting machines.

The Impact of Laser Cutting on Manufacturing

The impact of laser cutting on manufacturing cannot be overstated; it has transformed production processes across various sectors. By enabling rapid prototyping and intricate designs without compromising quality, manufacturers can respond more swiftly to market demands. Moreover, as companies increasingly adopt advanced laser machine technologies, they are witnessing significant cost reductions while enhancing product quality—a win-win situation for businesses aiming to stay competitive.

Steps to Get Started with Laser Technology

For those eager to dive into the world of laser technology, there are several steps to consider when selecting a suitable laser cutter for metal. Begin by assessing your specific needs—what types of materials you’ll be working with and what thicknesses you require will guide your choice in a metal cutting machine laser. Next, compare different models and brands available in the market; leading names like Kiant Machinery often offer robust options tailored for various applications.