Introduction

In the world of manufacturing, precision and efficiency reign supreme, and the sheet metal laser cutter has emerged as a game changer. This sophisticated technology allows for intricate designs and high-speed cutting that traditional methods simply can't match. As industries evolve, understanding laser cutting becomes essential for staying competitive.

Understanding Sheet Metal Laser Cutters

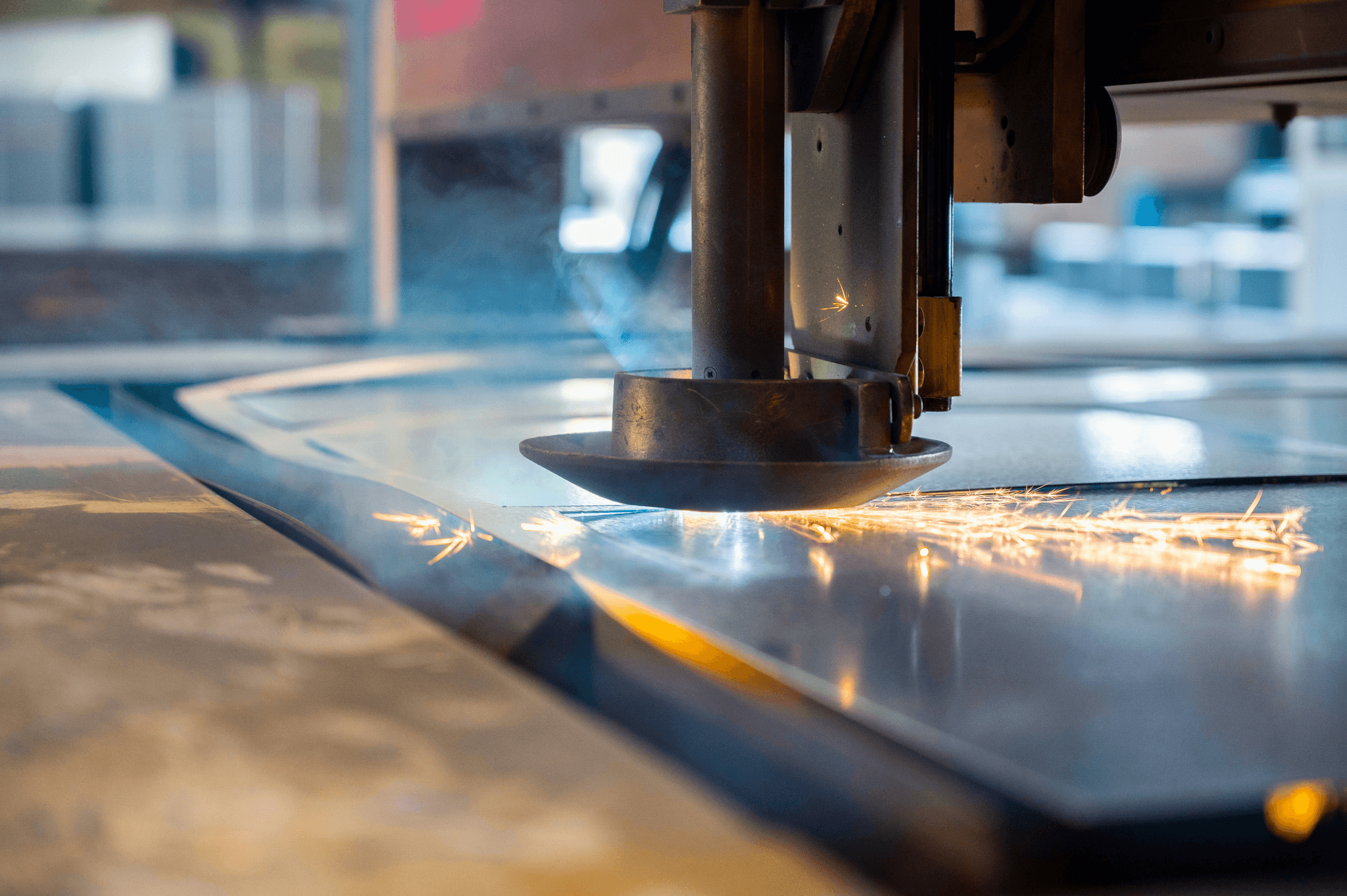

At its core, a sheet metal laser cutter harnesses the power of focused light to slice through metal with unparalleled accuracy. Unlike conventional cutting tools that rely on mechanical force, a laser machine uses thermal energy to melt or vaporize material, resulting in clean edges and minimal waste. This innovative approach to CNC sheet metal cutting not only improves productivity but also enhances design possibilities.

Importance of Laser Cutting Technology

Laser cutting technology has revolutionized how manufacturers approach production processes. The ability to create complex shapes quickly and accurately means businesses can reduce lead times and respond more effectively to market demands. Moreover, the versatility of a metal cutting laser cutter allows it to cater to various materials beyond just steel, making it an invaluable asset in diverse applications.

Applications of Sheet Metal Laser Cutting

The applications of sheet metal laser cutting are vast and varied, ranging from automotive parts fabrication to intricate artwork design. In industries like aerospace and electronics, precision is paramount; thus, laser machines play a crucial role in ensuring quality standards are met consistently. Additionally, custom projects benefit immensely from the flexibility offered by a laser cutter, enabling creative solutions that push boundaries in design and functionality.

What is a Sheet Metal Laser Cutter?

Sheet metal laser cutters are advanced machines designed to cut metal sheets with precision and efficiency. These cutting-edge devices utilize focused laser beams to slice through various types of metals, making them indispensable in modern manufacturing processes. Understanding how these machines operate and their benefits can significantly enhance your CNC sheet metal cutting capabilities.

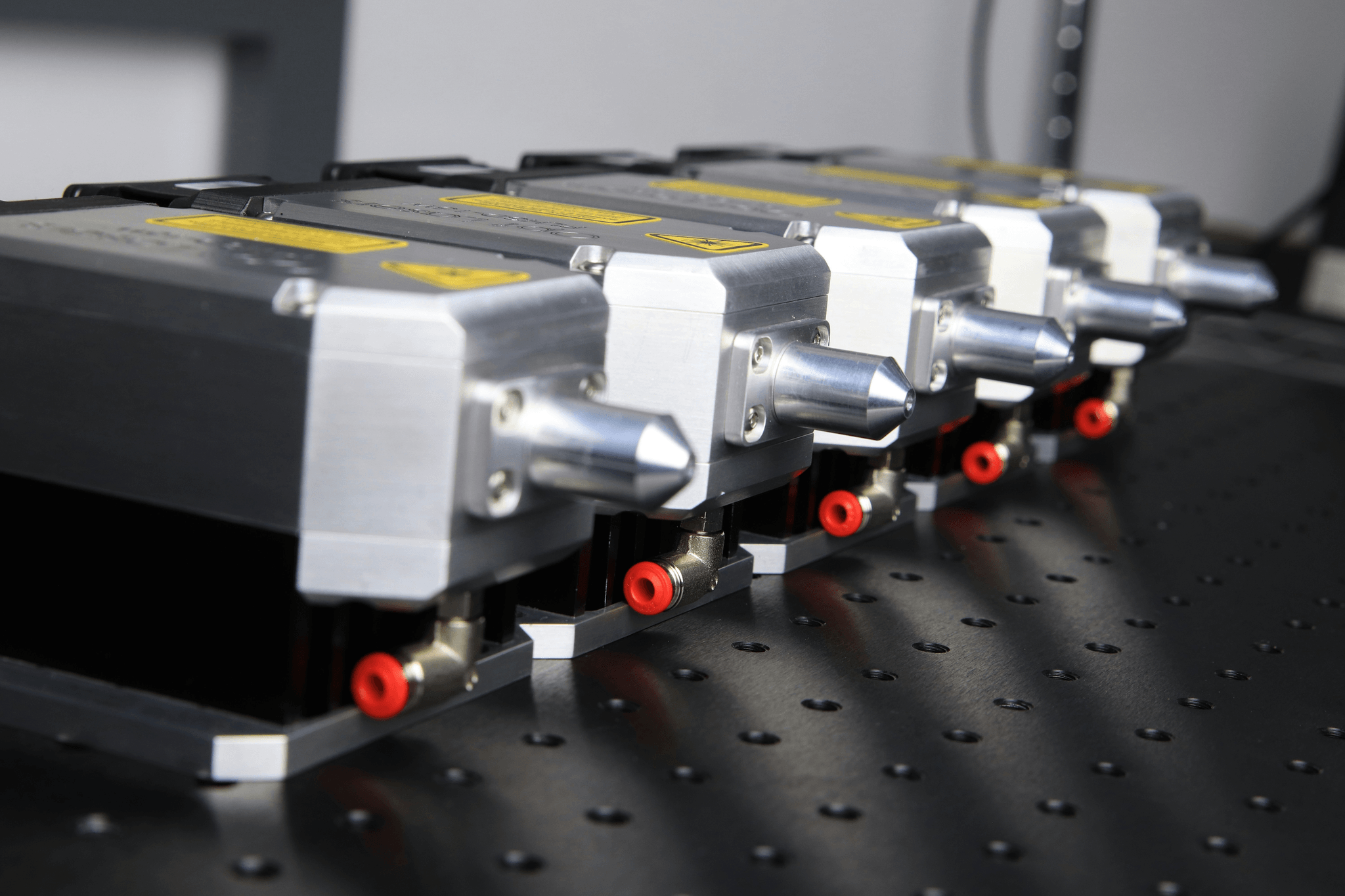

Overview of Laser Cutting Machines

Laser cutting machines are highly specialized tools that employ concentrated light energy to cut through materials. The process begins with a laser beam generated by a powerful source, which is then directed through optics to focus on the workpiece. In the realm of sheet metal, a laser cutter excels at producing intricate designs and shapes with minimal waste, making it an essential asset for manufacturers looking to optimize their operations.

The versatility of a laser machine allows it to handle various materials beyond just metals, including plastics and wood. However, its true prowess shines when dealing with cutting laser metal due to its ability to maintain tight tolerances and smooth edges. This makes the sheet metal laser cutter a favorite among industries ranging from automotive to aerospace.

How a Laser Cutter Works

At its core, the operation of a laser cutter involves three main components: the laser source, the focusing optics, and the motion system. The process begins when electricity energizes the gas or solid-state medium within the machine's core, generating a high-intensity beam of light. This beam is then directed through mirrors or fiber optics that focus it onto the material being cut.

Once focused on the sheet metal surface, this intense heat causes localized melting or vaporization of the material along predetermined paths programmed into the CNC system. As a result, operators can achieve complex geometries that would be nearly impossible with traditional cutting methods. Moreover, modern advancements in technology allow for real-time adjustments during operation for enhanced accuracy and efficiency.

Benefits of Using a Metal Cutting Laser Cutter

The advantages of using a metal cutting laser cutter extend far beyond just precision; they encompass speed, flexibility, and cost-effectiveness as well. One significant benefit is speed—laser cutters can operate at high speeds without compromising on quality or detail in cuts. This rapid processing time translates into improved productivity for businesses engaged in CNC sheet metal cutting tasks.

Another notable advantage is flexibility; these machines can easily switch between different materials and thicknesses without extensive setup changes or tooling adjustments required by traditional methods. Additionally, using a laser machine minimizes kerf (the width of material removed during cutting), resulting in less waste and more efficient use of raw materials—an essential factor in today’s eco-conscious manufacturing landscape.

In conclusion, investing in a sheet metal laser cutter not only streamlines production but also enhances design possibilities while reducing overall costs associated with material waste and labor-intensive processes.

Types of Laser Cutting Technologies

When it comes to sheet metal laser cutting, the choice of technology can significantly impact efficiency and quality. Two primary types dominate the landscape: CO2 laser cutting and fiber laser cutting. Understanding their differences can help you select the best option for your specific needs.

CO2 Laser Cutting

CO2 laser cutting has been a staple in the industry for years, known for its versatility and effectiveness in cutting various materials, including metals. This type of laser cutter utilizes a gas mixture that produces a high-powered beam capable of slicing through thick sheets with precision. However, while CO2 lasers excel at thicker materials, they may not perform as efficiently on thinner metals compared to other technologies.

One major advantage of CO2 laser machines is their ability to cut intricate designs with smooth edges, making them ideal for artistic projects or detailed components in manufacturing. The operational costs are often lower due to their longevity and lower maintenance requirements when compared to newer technologies. Still, it's essential to consider that CO2 systems may require more space and can be heavier than fiber options.

Fiber Laser Cutting

Fiber laser cutting is relatively new but has quickly gained popularity due to its speed and efficiency in CNC sheet metal cutting applications. Utilizing a solid-state laser source, fiber lasers produce a concentrated beam that delivers exceptional precision while consuming less energy than traditional CO2 systems. This technology shines particularly when working with thin sheets of metal, where it outperforms its counterparts by delivering faster cuts with minimal heat distortion.

The benefits extend beyond just performance; fiber laser machines are typically more compact and easier to integrate into existing setups than larger CO2 cutters. Additionally, they offer lower operating costs over time because they require less maintenance and have longer lifespans—an attractive feature for manufacturers looking to optimize productivity without sacrificing quality. As industries evolve towards automation and smart manufacturing solutions, fiber lasers are becoming increasingly relevant.

Comparison of Laser Technologies

When comparing CO2 versus fiber laser technologies for metal cutting applications, several factors come into play: material thickness, speed of operation, cost-effectiveness, and overall versatility in design capabilities. For thicker materials or intricate designs needing finesse, CO2 might still hold an edge; however, for rapid production runs involving thinner metals or high-speed operations—fiber lasers have proven themselves superior time after time.

Moreover, energy consumption is another critical consideration; fiber lasers tend to consume less power while providing faster processing times—a win-win scenario for any manufacturer focused on sustainability as well as efficiency! Each type has its merits depending on specific project requirements; hence understanding these distinctions will empower businesses when investing in a suitable sheet metal laser cutter.

In conclusion, whether you opt for the traditional charm of CO2 or the modern prowess of fiber lasers will depend on your unique needs within the realm of CNC sheet metal cutting processes. Evaluating both options thoroughly ensures you make an informed decision that aligns perfectly with your operational goals!

Choosing the Right Laser Cutter

When it comes to selecting a sheet metal laser cutter, the choices can be overwhelming. With various features and technologies available, it's essential to know what factors will influence your decision. This section will guide you through the critical elements of choosing a laser cutting machine that meets your needs.

Factors to Consider for CNC Sheet Metal Cutting

First and foremost, consider the material thickness you'll be working with; different laser machines handle varying thicknesses effectively. The power output of the laser cutter is crucial, as higher wattage allows for faster cutting speeds and thicker materials, making it ideal for CNC sheet metal cutting. Additionally, evaluate the size of your workspace and whether you need a compact model or a larger machine capable of handling bigger sheets.

Another important factor is the type of laser technology used in the machine. CO2 lasers are excellent for non-metal materials but may not perform as well with metals compared to fiber lasers which are more efficient in cutting laser metal. Lastly, think about your production volume—high-volume operations may benefit from automated systems that enhance efficiency.

Key Features of a Laser Cutting Machine

A robust laser cutting machine should come packed with features that enhance its usability and efficiency. Look for machines equipped with advanced software that simplifies design importation and optimizes cutting paths; this can save both time and material costs during production runs. Additionally, consider options like automatic height adjustment systems that ensure consistent performance across varying material thicknesses.

Safety features cannot be overlooked either; an effective sheet metal laser cutter should have built-in safety measures such as enclosures or emergency stop buttons to protect operators from hazards associated with high-powered lasers. Lastly, pay attention to maintenance features; machines designed for easy access during routine checks can save valuable downtime when issues arise.

How Kiant Machinery Stands Out

Kiant Machinery distinguishes itself in the competitive market of metal cutting laser cutters by offering innovative solutions tailored to diverse manufacturing needs. Their commitment to incorporating state-of-the-art technology ensures that each laser machine delivers precision cuts while maximizing speed and efficiency—perfectly suited for CNC sheet metal cutting applications.

Moreover, Kiant Machinery provides exceptional customer service and support throughout your purchasing journey—from expert consultations on selecting the right model to ongoing maintenance assistance post-purchase. Their comprehensive warranty packages also give peace of mind knowing you’re investing in quality equipment designed to last.

Safety Protocols in Laser Cutting

In the world of sheet metal laser cutting, safety should always be the top priority. The powerful capabilities of a laser cutting machine come with inherent risks that operators must navigate carefully. By implementing solid safety protocols, manufacturers can ensure a safe working environment while maximizing productivity.

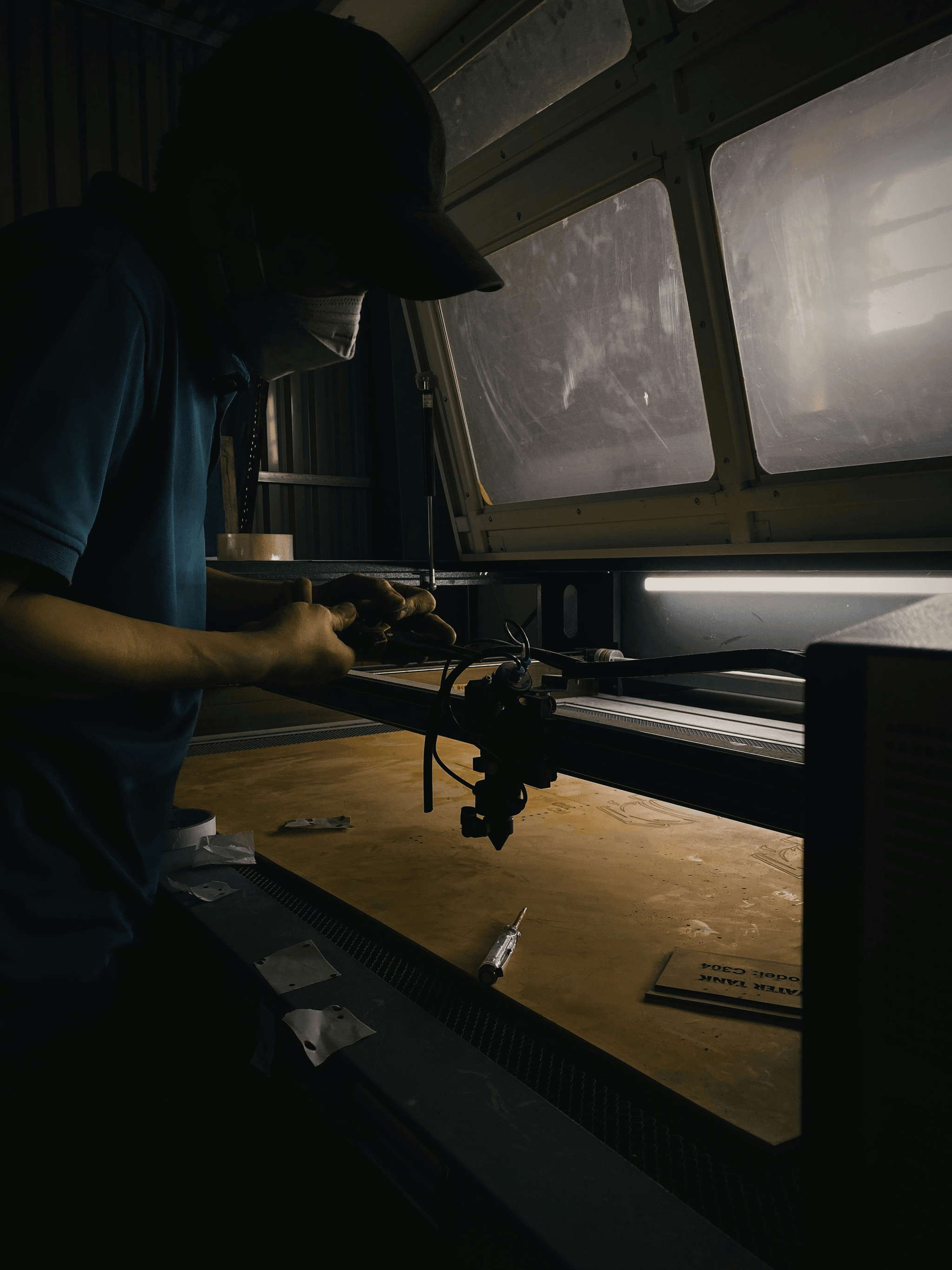

Essential Safety Gear for Operators

When operating a laser cutter, wearing appropriate safety gear is non-negotiable. Operators should don protective eyewear specifically designed to shield against the intense light emitted by the laser machine; this prevents potential eye damage during CNC sheet metal cutting tasks. Additionally, flame-resistant clothing and gloves are essential to protect against hot materials and sparks generated during the cutting process.

Other important gear includes hearing protection, as some metal cutting laser cutters can produce significant noise levels, and steel-toed boots to safeguard feet from heavy equipment or falling materials. It’s vital to maintain a clean workspace free from clutter to prevent accidents caused by tripping or falling objects while using a laser cutter. Remember, investing in proper safety gear not only protects operators but also promotes a culture of safety within the workplace.

Risk Management in Laser Cutting Processes

Effective risk management is crucial when dealing with any form of laser cutting technology. This involves identifying potential hazards associated with using a laser machine and developing strategies to mitigate them before they lead to incidents or injuries. Regular risk assessments should be conducted to evaluate operational processes and identify areas where improvements can be made.

Moreover, ensuring that all operators understand emergency procedures is essential for minimizing risks during CNC sheet metal cutting operations. This includes knowing how to shut down the machine quickly in case of an emergency and understanding fire evacuation routes if something goes awry with equipment or materials used in the process. By fostering an environment where risk management is prioritized, companies can significantly reduce accidents related to metal cutting laser cutters.

Training for Safe Operation of Laser Machines

Training plays an indispensable role in ensuring safe operation when utilizing a sheet metal laser cutter or any other type of laser machinery. Comprehensive training programs should cover everything from basic operation principles to advanced troubleshooting techniques specific to each model of the laser cutting machine being used. Operators who are well-trained are more likely to recognize unsafe practices and take corrective actions before accidents occur.

Additionally, ongoing training sessions can help reinforce best practices and introduce new technologies or methods that enhance both efficiency and safety in CNC sheet metal cutting processes. Encouraging operators to share their experiences can foster teamwork while also addressing common challenges faced during operation—leading ultimately toward improved overall performance on the shop floor!

Maintenance and Troubleshooting

Maintaining a sheet metal laser cutter is crucial for ensuring optimal performance and longevity of the machine. Regular maintenance not only enhances the cutting precision but also minimizes downtime, making it an essential part of operating any laser cutting machine. In this section, we will explore effective maintenance tips, common issues that may arise during metal cutting, and guidance on when to seek professional support.

Regular Maintenance Tips for Optimal Performance

To keep your laser cutting machine in top shape, establish a regular maintenance schedule that includes cleaning, inspection, and calibration. Start by routinely checking the lenses and mirrors for dirt or damage; even tiny specks can affect the quality of your cuts in CNC sheet metal cutting. Additionally, lubricate moving parts as recommended by the manufacturer to prevent wear and tear—after all, a well-oiled machine is a happy machine!

Another key aspect of maintenance is monitoring the cooling system; overheating can lead to significant issues with your metal cutting laser cutter. Make sure coolant levels are adequate and that there are no leaks in the system. Lastly, don’t forget to keep software updated; many modern laser machines rely on software for optimal performance.

Common Issues with Cutting Laser Metal

Even with proper maintenance, you may occasionally encounter problems while using your laser cutter. One common issue is inconsistent cut quality—this can manifest as rough edges or uneven thickness in the material being cut. Often, this problem arises from worn-out consumables like nozzles or lenses that need replacing.

Another frequent headache is misalignment during operation; if your sheet metal isn’t aligned correctly on the bed of the laser machine, it can lead to wasted materials and time. Always double-check alignment before starting a job to avoid these mishaps! Additionally, if you notice excessive smoke or burning around cuts, it could indicate incorrect settings or issues with gas flow—tackle these problems promptly for smoother operations.

When to Seek Professional Support

Sometimes despite your best efforts at troubleshooting with regular checks and adjustments on your metal cutting laser cutter, things might still go awry. If you find yourself facing persistent issues that disrupt production timelines or compromise safety standards, it’s time to call in professionals who specialize in laser machines.

Professional support becomes essential when dealing with complex electronic failures or mechanical breakdowns that require specialized knowledge beyond basic maintenance skills—don’t risk further damage! Investing in expert help not only resolves immediate concerns but also ensures long-term reliability of your CNC sheet metal cutting processes.

Conclusion

In the realm of manufacturing, the evolution of technology continues to shape the future of production processes. The sheet metal laser cutter stands at the forefront, offering unparalleled precision and efficiency in metal fabrication. As industries increasingly rely on advanced laser cutting techniques, we can expect to see innovations that further enhance productivity and reduce waste.

The Future of Laser Cutting Technology

The future of laser cutting technology looks bright, with advancements promising to revolutionize how we approach CNC sheet metal cutting. Emerging technologies such as artificial intelligence and machine learning are set to optimize laser machines, making them smarter and more adaptable to varying materials and designs. Additionally, sustainability will play a crucial role; manufacturers are likely to prioritize eco-friendly practices in their laser cutting operations, ensuring that metal cutting laser cutters contribute positively to both business and environmental goals.

Key Takeaways for Manufacturers

For manufacturers looking to invest in a laser cutting machine, understanding the key benefits is essential. The precision offered by a metal cutting laser cutter not only improves product quality but also minimizes material waste—an important consideration in today's competitive market. Furthermore, investing in reliable equipment like a high-quality laser cutter can lead to long-term savings through reduced operational costs and increased throughput.

Why Kiant Machinery is Your Best Choice

When it comes to selecting a partner for your sheet metal laser cutter needs, Kiant Machinery emerges as an industry leader you can trust. Their commitment to innovation ensures that their machines utilize the latest technologies for optimal performance in CNC sheet metal cutting applications. With exceptional customer support and comprehensive training programs for operators, Kiant Machinery not only provides top-notch equipment but also empowers businesses with the knowledge needed for safe and effective operation.