Introduction

In the rapidly evolving world of manufacturing, fiber laser cutting technology stands out as a game changer. This innovative approach not only enhances precision and efficiency but also offers a range of advantages over traditional cutting methods. As industries increasingly turn to laser machinery for their metal cutting needs, understanding the landscape of fiber laser cutting machine manufacturers becomes essential for making informed decisions.

Understanding Fiber Laser Cutting Technology

Fiber laser cutting is revolutionizing the way we think about metal fabrication. Unlike conventional methods, a laser cutter utilizes focused light beams to achieve intricate cuts with remarkable accuracy, making it ideal for various applications across sectors. The technology's ability to handle different materials and thicknesses efficiently has cemented its place in modern manufacturing processes.

Key Players in the Industry

The market for fiber laser cutting machines is populated by several key players who are pushing the boundaries of what’s possible with laser technology. Companies like Trumpf and Bystronic have established themselves as leaders by continuously innovating and providing high-quality solutions tailored to meet diverse customer needs. Understanding these key players can help businesses identify which manufacturer aligns best with their specific requirements.

Choosing the Right Manufacturer

Selecting the right manufacturer for your metal cutting machine laser is crucial to ensuring optimal performance and reliability. Factors such as product quality, technological advancements, and customer support should weigh heavily in your decision-making process. By doing thorough research on various fiber laser cutting machine manufacturers, you can make an informed choice that will benefit your operations in the long run.

Overview of Fiber Laser Cutting Machines

Fiber laser cutting machines have revolutionized the way industries approach metal cutting. These advanced tools utilize a fiber laser, which is a type of solid-state laser, to deliver high precision and efficiency in cutting various materials. Understanding what a fiber laser cutter is can help businesses make informed choices when selecting from the myriad of options available from leading fiber laser cutting machine manufacturers.

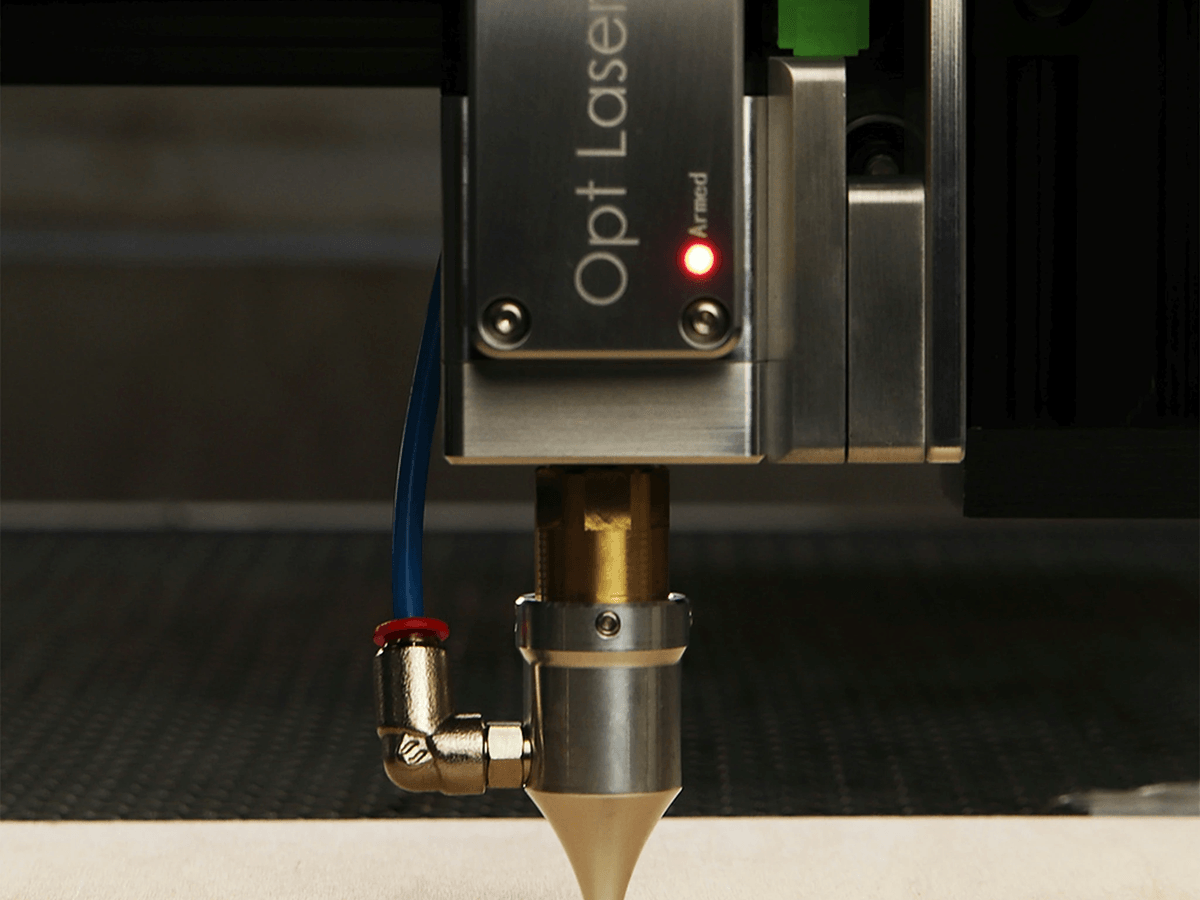

What is a Fiber Laser Cutter?

A fiber laser cutter is a sophisticated piece of equipment that employs a fiber optic cable to generate and amplify the laser beam used for cutting. This technology allows for exceptional beam quality and focus, making it ideal for intricate designs and high-speed operations. Unlike traditional CO2 lasers, which require mirrors to direct the beam, the compact design of a metal cutting machine laser enhances reliability and reduces maintenance needs.

The heart of this technology lies in its ability to cut through various materials with minimal heat-affected zones, ensuring clean edges without warping or distortion. By harnessing the power of light through optical fibers, these machines can achieve remarkable results in both thickness and speed. For anyone considering investing in a laser cutter, understanding its mechanics will clarify why it's becoming the go-to choice among industry professionals.

Advantages of Fiber Laser Cutting

The advantages of fiber laser cutting are numerous and compelling for businesses looking to optimize their production processes. First off, these machines offer unmatched speed; they can cut faster than traditional methods while maintaining high precision levels—perfect for those tight deadlines! Additionally, their energy efficiency means lower operational costs over time compared to other types of laser machinery.

Another benefit is versatility; fiber lasers can handle various materials like stainless steel, aluminum, brass, and even plastics with ease. This flexibility makes them indispensable across multiple sectors including automotive, aerospace, and manufacturing where diverse material requirements often arise. Furthermore, advancements in technology have made these systems more user-friendly than ever before—allowing even novice operators to achieve professional results quickly.

Applications Across Industries

Fiber laser cutters are utilized across an impressive range of industries due to their adaptability and precision capabilities. In automotive manufacturing, for instance, they play a crucial role in producing complex parts that demand accuracy while minimizing waste material—a win-win situation! Similarly, in electronics production where components require fine detailing without compromising structural integrity or performance levels.

Beyond automotive and electronics applications lie opportunities within construction and metal fabrication sectors as well; here they are employed for everything from creating custom signage to fabricating intricate architectural features. As businesses continue exploring innovative solutions for their production challenges, it's clear that engaging with reputable laser cutting service providers will be essential for accessing state-of-the-art equipment tailored to specific needs.

Leading Fiber Laser Cutting Machine Manufacturers

In the competitive world of fiber laser cutting, several manufacturers stand out for their innovative technologies and exceptional performance. These industry leaders not only provide cutting-edge laser machinery but also deliver tailored solutions that meet diverse customer needs. Let's dive into some of the most prominent players in the fiber laser cutting machine market.

Trumpf: Innovating Laser Solutions

Their advanced laser cutters are designed for precision and efficiency, making them a popular choice among manufacturers looking to elevate their production capabilities. With a focus on research and development, Trumpf continuously pushes the boundaries of what's possible with metal cutting lasers, ensuring they remain at the forefront of the industry.

The company’s commitment to quality means that their laser cutting service is second to none, providing customers with reliable tools that enhance productivity while reducing operational costs. Furthermore, Trumpf's extensive support network ensures that customers receive prompt assistance whenever needed, solidifying its reputation as one of the top fiber laser cutting machine manufacturers in the business. As industries evolve, Trumpf remains dedicated to delivering state-of-the-art solutions that meet future demands.

Bystronic: Excellence in Sheet Metal Processing

Bystronic has carved out a niche for itself by focusing on excellence in sheet metal processing through its advanced fiber laser cutting technology. Their range of laser cutting machines is engineered to handle various materials with unmatched precision and speed, making them ideal for high-volume operations. Bystronic's expertise lies not just in manufacturing high-quality metal cutting machines but also in providing comprehensive solutions tailored to specific applications.

With an emphasis on user-friendly interfaces and automation features, Bystronic's equipment allows operators to maximize efficiency while minimizing waste—a crucial factor in today’s competitive landscape. The company's dedication to customer satisfaction extends beyond sales; they offer robust after-sales support and maintenance services as part of their comprehensive approach to customer care. This commitment positions Bystronic as a leading choice among those seeking reliable and effective fiber laser cutting machinery.

Kiant Machinery: Tailored Solutions for Efficiency

Kiant Machinery stands out by offering customized solutions designed specifically for efficiency across various sectors utilizing fiber lasers. Their flexible approach allows them to cater to diverse industries requiring specialized applications from their metal cutting lasers—be it automotive or aerospace manufacturing or even artistic designs requiring intricate cuts from a metal-cutting machine laser. Kiant emphasizes not only performance but also adaptability within its product line.

Their focus on client collaboration ensures that each solution is tailored according to individual requirements, which helps clients achieve optimal results while maintaining cost-effectiveness in production processes. Moreover, Kiant Machinery prides itself on integrating smart technologies into its systems—enhancing overall operational workflows while keeping sustainability at heart as industries move towards greener practices in manufacturing environments. This forward-thinking mentality makes Kiant an attractive option among discerning buyers looking for innovative yet practical solutions from reputable fiber laser cutting machine manufacturers.

Evaluating Laser Cutting Service Providers

Key Factors to Consider

First and foremost, consider the specific capabilities of the service provider's equipment. A cutting machine laser that utilizes advanced technology will often yield superior results compared to older models. Additionally, assess their experience with different materials; a versatile metal cutting laser cutter should adeptly handle various metals like steel, aluminum, or brass.

Next up is turnaround time and flexibility in meeting your project deadlines. A reliable laser cutting service must be able to adapt quickly to changes in order volume or specifications without sacrificing quality. Lastly, check their reputation in the industry—customer testimonials and case studies can provide valuable insights into their reliability and expertise.

Comparing Services and Technologies

Not all laser cutting services are created equal; some may specialize in specific applications while others offer broader capabilities. Compare the types of laser machinery they utilize; modern fiber lasers typically offer higher precision and faster speeds than traditional CO2 lasers. This could translate into better performance for your projects, particularly if intricate designs are involved.

Moreover, consider whether they provide additional services such as design support or post-processing options like welding or finishing. The more comprehensive the service offering, the easier it will be for you to streamline your production process with one trusted partner rather than juggling multiple suppliers for different needs.

Finally, don’t forget about scalability—if you're planning on expanding operations or diversifying products in the future, ensure that your chosen provider has the capacity to grow alongside you.

Customer Support and After-sales

Customer support is another critical factor that should never be overlooked when selecting a laser cutting service provider. A responsive customer support team can make all the difference when you encounter issues with a metal cutting machine laser or need assistance with complex projects involving a laser cutter. Look for providers that offer dedicated account managers who understand your unique requirements.

After-sales support is equally important; inquire about maintenance services and warranties offered on their equipment and services. Reliable after-sales care ensures that any potential downtime due to equipment malfunction is minimized—keeping your projects on track without unnecessary delays.

Lastly, consider whether they provide training sessions on operating their machines effectively; this investment not only enhances safety but also maximizes productivity from day one.

The Importance of Quality in Metal Cutting Lasers

Choosing a reliable fiber laser cutting machine is crucial for achieving precision and efficiency. With so many laser cutting service providers out there, understanding the significance of quality can help you make informed decisions.

Material Compatibility and Performance

One of the first things to consider when evaluating a metal cutting laser cutter is its material compatibility. Different applications require different types of lasers, and not all machines are created equal; some excel at cutting stainless steel while others are better suited for aluminum or brass. High-quality fiber laser cutting machines from reputable manufacturers ensure optimal performance across various materials, enabling businesses to diversify their offerings without sacrificing precision.

Moreover, a superior laser cutter will provide consistent results over time, which is essential for maintaining product quality and meeting customer expectations. When selecting a machine, it's vital to assess how well it performs with the specific materials you plan to work with; this will save you from costly mistakes down the line. Ultimately, investing in a high-performance metal cutting machine laser ensures that your projects run smoothly and efficiently.

Durability and Maintenance Considerations

Durability is another critical factor when choosing among fiber laser cutting machine manufacturers. A robust metal cutting laser cutter should withstand rigorous use without frequent breakdowns or extensive maintenance needs. Quality machinery typically comes with warranties that reflect confidence in durability; thus, opting for machines backed by reputable brands can save you both time and money on repairs.

Regular maintenance also plays a significant role in ensuring long-term performance; however, high-quality machines often require less upkeep than their cheaper counterparts. Laser machinery that’s built to last will not only perform better but also contribute positively to your bottom line by minimizing downtime caused by repairs or replacements. Therefore, selecting a durable machine means fewer headaches down the road—something every business owner appreciates!

Efficiency and Cost-effectiveness

Efficiency is king in today’s fast-paced manufacturing world—and this holds true for laser cutting as well! A top-notch fiber laser cutter should provide quick processing times while maintaining exceptional accuracy; this balance leads directly to increased productivity levels within your operations. Furthermore, high-quality equipment often consumes less energy compared to lower-end models—making them more cost-effective in the long run.

Cost-effectiveness goes beyond just initial purchase prices; it encompasses operational costs like energy consumption and maintenance expenses as well as potential downtime losses due to equipment failure or inefficiency issues associated with inferior models. Investing in leading-edge technology from established fiber laser cutting machine manufacturers may seem daunting upfront but pays dividends through reduced operational costs over time! Ultimately, prioritizing efficiency alongside quality ensures that you’re not just keeping up with industry demands but thriving within them.

Future Trends in Laser Cutting Machinery

The landscape of laser cutting machinery is evolving rapidly, driven by advancements in technology and changing market demands. Fiber laser cutting machine manufacturers are at the forefront of this transformation, integrating innovative features into their offerings. As businesses seek to improve efficiency and reduce costs, the focus on automation, sustainability, and emerging markets is more critical than ever.

Automation and Smart Technologies

Automation is revolutionizing the way we approach laser cutting processes. With smart technologies being integrated into laser machinery, manufacturers can optimize production lines with minimal human intervention. A modern fiber laser cutter can now utilize AI-driven algorithms for enhanced precision and speed, allowing businesses to achieve higher output with consistent quality from their metal cutting machines.

These advancements not only streamline operations but also significantly reduce labor costs associated with traditional methods. By incorporating robotics and intelligent software solutions, laser cutting service providers can offer faster turnaround times while maintaining exceptional accuracy. The result? Increased competitiveness for companies that embrace these innovations in their metal cutting laser cutter operations.

Furthermore, automation opens doors for real-time monitoring of equipment performance, enabling predictive maintenance that minimizes downtime. This proactive approach allows fiber laser cutting machine manufacturers to ensure that their customers' machines operate at peak efficiency without unexpected interruptions. In a world where time is money, embracing automation in the realm of a laser cutter is simply smart business.

Sustainable Practices in Manufacturing

As environmental concerns take center stage across industries, sustainable practices are becoming a priority for fiber laser cutting machine manufacturers. The adoption of energy-efficient technologies within metal cutting machines not only reduces operational costs but also minimizes carbon footprints associated with manufacturing processes. Companies are increasingly turning to eco-friendly materials and practices to align with global sustainability goals.

In addition to energy savings, advancements in fiber lasers have led to reduced waste during the cutting process compared to traditional methods. This means less scrap material ends up in landfills while maximizing resource utilization—a win-win situation for both businesses and the environment! Laser cutting services that prioritize sustainability will likely attract more customers who value eco-conscious practices.

Moreover, sustainable manufacturing often translates into better long-term profitability as consumers become more discerning about product origins and production methods. As a result, companies investing in green technologies will not only comply with regulations but also enhance their brand reputation among environmentally aware clients seeking reliable metal cutting solutions.

Emerging Markets and Potential Growth

Emerging markets present significant opportunities for growth within the fiber laser industry as demand for advanced manufacturing techniques continues to rise globally. Countries experiencing rapid industrialization are increasingly adopting advanced technologies like a laser cutter to enhance productivity across various sectors such as automotive, aerospace, and electronics manufacturing.

Fiber laser cutting machine manufacturers stand poised to capitalize on this trend by providing tailored solutions that meet specific regional needs while offering competitive advantages over traditional machining methods. The ability of these machines to cut through various materials efficiently makes them an attractive option for new entrants into the market seeking high-quality results without extensive investment in infrastructure.

Additionally, as industries evolve towards more complex designs requiring precise cuts—think intricate patterns or lightweight structures—the versatility offered by modern metal cutting lasers becomes indispensable. Businesses looking beyond their borders will find ample opportunities as they explore new markets eager for innovative manufacturing solutions that can drive efficiency while maintaining quality standards.

Conclusion

In the ever-evolving landscape of manufacturing, technology plays a pivotal role in shaping processes and outcomes. Fiber laser cutting machines have emerged as game-changers, revolutionizing how industries approach metal fabrication. The integration of advanced laser machinery not only enhances efficiency but also ensures precision that was once unimaginable.

The Impact of Technology on Manufacturing

The impact of technology on manufacturing is profound, particularly with the advent of fiber laser cutting machines. These machines have transformed traditional methods, allowing for quicker production times and higher accuracy in metal cutting applications. As industries adopt these innovations, they experience a significant boost in productivity and competitiveness, proving that embracing new technologies is essential for growth.

Making Informed Decisions with Leading Manufacturers

Choosing the right manufacturer among fiber laser cutting machine manufacturers can be daunting but is crucial for long-term success. It’s essential to evaluate their reputation, technological advancements, and customer feedback to ensure you select a partner who aligns with your business needs. By making informed decisions based on thorough research and comparisons, businesses can secure reliable laser cutting services that enhance their operational capabilities.

Future-proofing Your Business with Fiber Lasers

To remain competitive in an increasingly saturated market, future-proofing your business with fiber lasers is key. Investing in quality metal cutting laser cutters not only provides immediate benefits but also positions companies to adapt to future technological advancements and market demands. With automation trends and sustainable practices on the rise, aligning your operations with innovative laser machinery ensures resilience and ongoing success.