Assess Your Cutting Needs

Understanding what materials you'll be working with, how much you need to produce, and the level of precision required will guide you in making an informed choice. This foundational knowledge ensures that you choose a laser cutting machine that aligns perfectly with your operational goals.

Material Types and Thickness

Whether you're dealing with metals like steel, aluminum, or brass, or other materials such as wood and acrylic, each has its unique thickness and properties that affect how they are cut by a laser machinery system. For instance, a metal cutting machine laser may excel at slicing through thicker metals but may not perform as well on delicate materials; hence knowing the types of materials you'll be working with is crucial for selecting the right industrial laser cutter.

Thickness also plays a significant role in determining the power and type of laser technology needed. Thicker materials will require more powerful machines capable of maintaining speed without sacrificing quality—a critical consideration for any production environment where efficiency matters. Therefore, understanding both material types and their respective thicknesses will help narrow down your choices effectively.

Production Volume Requirements

Your production volume requirements are another vital aspect to consider when selecting a cutting machine laser for your operations. Are you looking for high-volume capabilities for mass production or something more suited for smaller batches? An industrial laser cutting machine designed for high throughput can significantly enhance productivity but might come at a higher initial investment.

If your business model involves fluctuating demands or custom orders, versatility becomes key; some machines offer flexible features that allow quick adjustments between different jobs without extensive downtime. Balancing these factors ensures you select a machine that not only meets current needs but can also adapt as your business grows.

Precision and Tolerance Levels

Precision is paramount in industries where even minor discrepancies can lead to costly errors or product failures; thus, understanding the precision levels required for your projects is essential when choosing an industrial laser cutter. Different applications demand varying tolerance levels—some may need tight tolerances while others might allow greater leeway in measurements.

The capabilities of different laser technologies vary significantly in terms of achieving these precision standards; therefore, it's crucial to evaluate how finely detailed your cuts need to be before making a decision on which machine cut metal will serve best in your shop. Investing in a high-precision metal cutting machine laser can pay off by reducing waste and enhancing overall product quality over time.

Explore Technology Options

Understanding the differences between CO2 and fiber laser technology, along with exploring hybrid options and automation features, will help you make the best choice for your metal cutting needs. Let's delve into these aspects to find the perfect cutting machine laser for your operations.

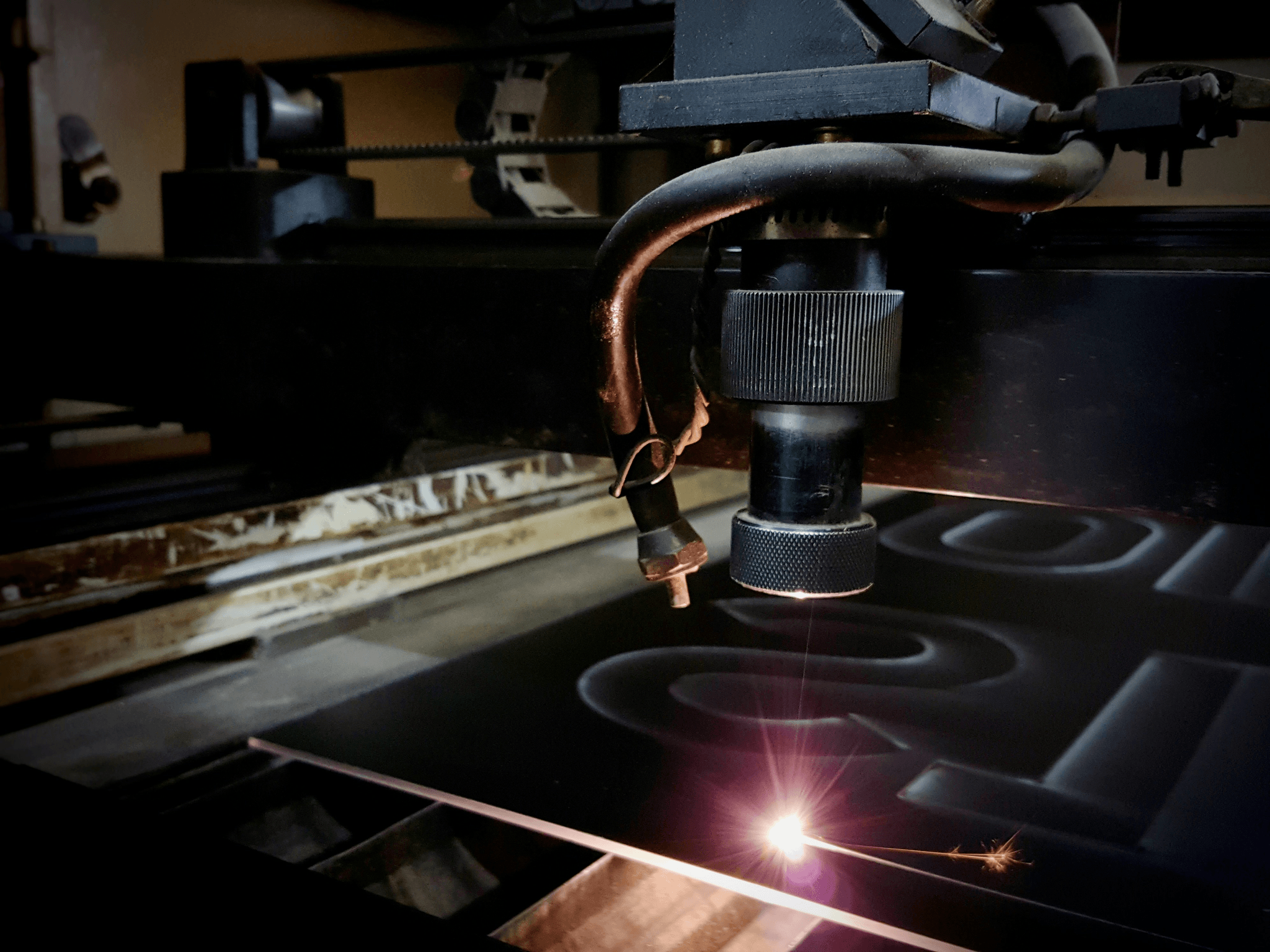

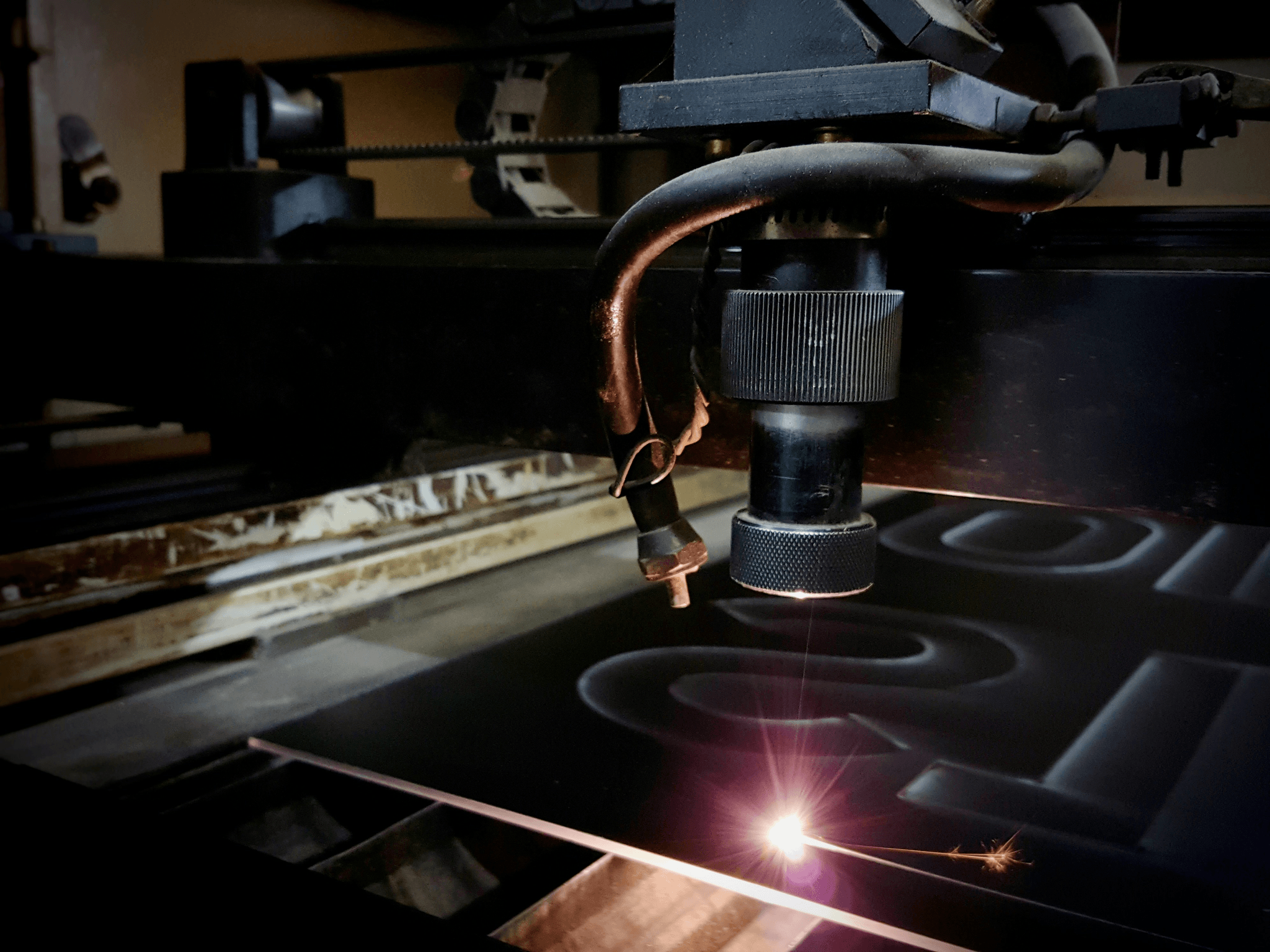

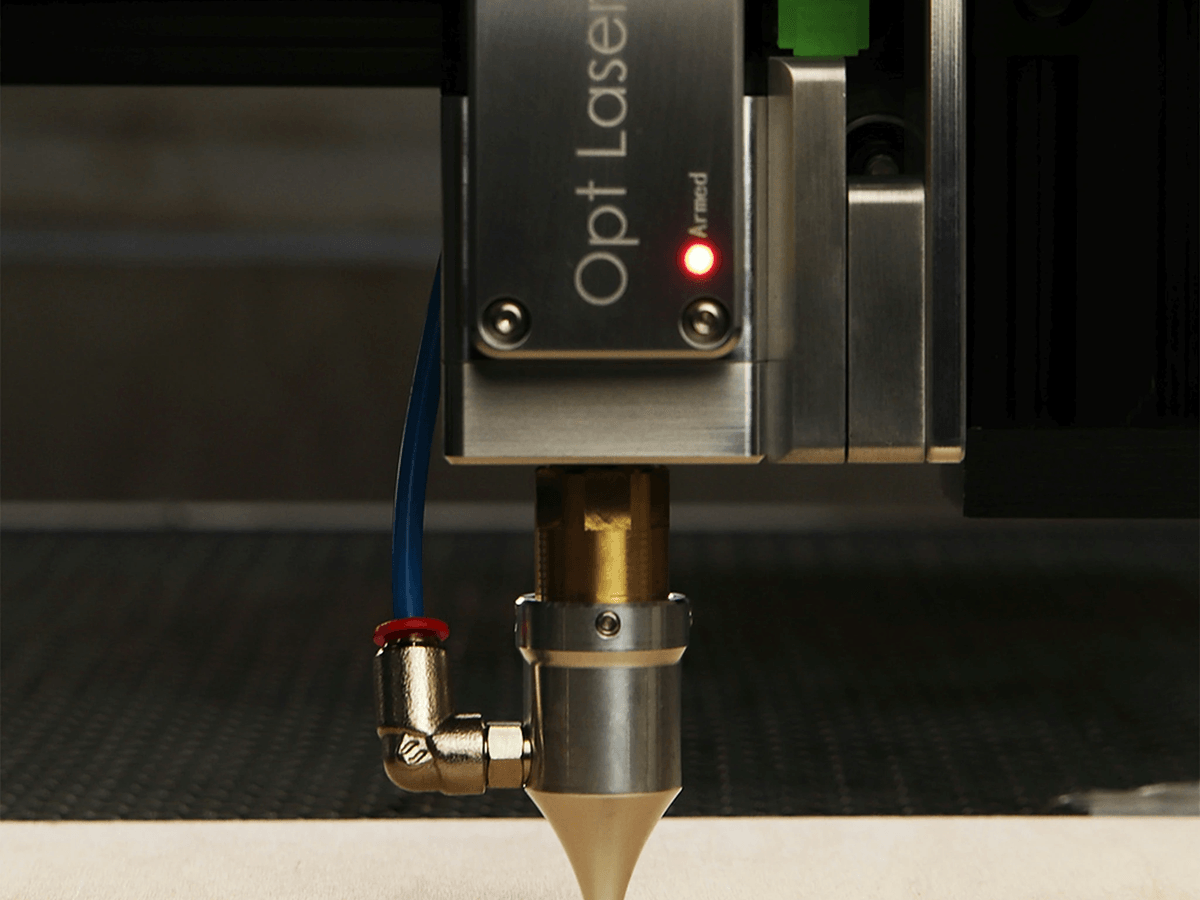

CO2 vs. Fiber Laser Technology

CO2 lasers have been around for decades, making them a reliable choice for many applications, particularly when cutting thicker materials like wood or acrylic. However, when it comes to metal cutting machines, fiber lasers are often favored due to their increased efficiency and speed. Fiber laser technology utilizes solid-state systems that allow for better energy absorption in metals, resulting in faster cuts with higher precision—ideal for industries where time is money.

On the other hand, CO2 lasers may still hold their ground when dealing with non-metal materials or thicker substrates due to their versatility. If you plan on working primarily with metal components and need a machine cut metal quickly and effectively, investing in a fiber laser cutting machine could provide significant advantages in terms of speed and operating costs over time. Ultimately, understanding your specific requirements will help you navigate this decision more effectively.

Advantages of Hybrid Cutting Machines

Hybrid cutting machines combine both CO2 and fiber technologies into one versatile system, allowing users to cut a broader range of materials without needing multiple machines. This adaptability can save space on your shop floor while also reducing overhead costs associated with maintaining different types of machinery—making it an attractive option for businesses looking to streamline operations. With hybrid systems rapidly gaining popularity among manufacturers seeking flexibility in their production processes, it's worth considering if this aligns with your goals.

Moreover, hybrid machines often feature advanced software capabilities that enhance performance by optimizing settings based on material type and thickness automatically. This means less manual adjustment is needed from operators—a huge plus if you're looking at scaling production volume without sacrificing precision or quality during laser cutting tasks. In essence, investing in hybrid technology can be a game-changer for businesses aiming to stay competitive in a dynamic market.

Automation Features to Consider

In today's fast-paced manufacturing environment, automation features within industrial laser cutters are no longer just optional; they’re essential for maximizing productivity and minimizing human error during operations. Look out for machines equipped with automatic loading/unloading systems that can significantly reduce downtime between jobs—allowing you to keep those profits rolling while enhancing overall efficiency in your workflow!

Additionally, consider advanced monitoring systems that provide real-time feedback on performance metrics such as energy consumption or cut quality; these insights can lead directly to improved operational decisions down the line as you adapt strategies based on data-driven results from your metal cutting machine laser setup. Embracing automation not only streamlines processes but also positions your business at the forefront of technological advancements in industrial applications.

Evaluate Cost-Effectiveness

When investing in an industrial laser cutting machine, evaluating cost-effectiveness is crucial to ensure you’re not only getting the best technology but also making a smart financial decision. A robust analysis of both initial costs and potential long-term savings can help you make a choice that benefits your business for years to come. Let’s break down the key aspects of cost-effectiveness in laser cutting.

Initial Investment vs. Long-Term Savings

The initial investment in a laser cutting machine can be substantial, especially if you're eyeing high-end models designed for precision and speed. However, it’s essential to consider the long-term savings these machines can bring through increased efficiency and reduced waste during the metal cutting process. A well-chosen industrial laser cutter can significantly lower operational costs over time, making it a wise investment despite its upfront price tag.

Moreover, many modern machines are equipped with features that enhance energy efficiency and reduce material consumption, which translates into ongoing savings. When comparing options, look at how quickly each machine cut metal compared to its competitors—this could save your business both time and money in the long run. Ultimately, understanding this balance between initial outlay and future gains will help you choose the right cutting machine laser for your production needs.

Maintenance Costs and Downtime

One of the hidden costs associated with any industrial machinery is maintenance; this is particularly true for complex systems like those found in advanced laser machinery. Regular upkeep is necessary to keep your machine running smoothly, but some models require more frequent maintenance than others—leading to higher overall costs over time. Be sure to factor in these potential expenses when evaluating different options for your metal cutting machine laser.

Downtime due to maintenance or unexpected repairs can also have a significant impact on productivity and profitability. An efficient industrial laser cutter minimizes downtime with reliable operation and easy access for servicing when needed; ensuring that it remains productive on the shop floor should be a top priority in your decision-making process. By carefully considering maintenance requirements alongside purchase price, you'll better understand how each option fits into your budget strategy.

ROI Considerations for Your Business

When assessing any investment—including an industrial laser cutting machine—the return on investment (ROI) is pivotal in determining whether it's worth pursuing. This involves not just calculating direct profit from increased output but also considering factors like improved quality control and reduced waste during production processes with advanced laser technology. Ideally, an effective cutting machine will pay for itself within its operational lifespan by enhancing both productivity and quality.

Additionally, exploring financing options or lease agreements may help spread out costs while still allowing you access to state-of-the-art equipment that boosts efficiency right away without breaking the bank upfront. Keep in mind that ROI isn't just about numbers; it's about how well the chosen technology aligns with your business goals—whether that's scaling up production or improving product quality through precise cuts made by an advanced industrial laser cutter. With careful planning around ROI considerations, you'll position yourself strategically within a competitive market landscape.

Research Reputable Manufacturers

When it comes to investing in an industrial laser cutting machine, selecting a reputable manufacturer is crucial. The right manufacturer not only ensures quality and reliability but also provides ongoing support and service that can make or break your experience with the equipment. A well-chosen cutting machine laser can significantly enhance your operations, so it's essential to do your homework.

Kiant Machinery: A Trusted Name

Kiant Machinery has established itself as a trusted name in the realm of industrial laser cutting machines. Known for their robust designs and innovative technology, their machines are engineered to deliver precision while handling various materials efficiently. Whether you need a metal cutting machine laser for intricate designs or high-volume production runs, Kiant offers solutions tailored to meet diverse needs.

Their commitment to quality is evident in every aspect of their laser machinery, making them a go-to choice for businesses looking for durability and performance. Additionally, Kiant’s customer service is often highlighted as exemplary, ensuring that clients receive comprehensive support from installation through maintenance. This level of reliability makes them a top contender when considering which industrial laser cutter will best serve your operations.

Comparing Competitors' Offerings

While Kiant Machinery stands out, it's essential to compare competitors' offerings to ensure you're making an informed decision regarding your laser cutting needs. Many manufacturers provide distinct features that cater to different aspects of metal cutting processes; some may excel in speed while others focus on precision or material versatility. Evaluating these differences will help you determine which machine cut metal aligns best with your production goals.

Additionally, consider factors such as warranty options, customer support availability, and the range of customization options offered by each brand. Some companies may offer hybrid models that combine CO2 and fiber technologies, enhancing flexibility for varied applications. By conducting thorough comparisons among manufacturers, you can identify the most suitable industrial laser cutting machine tailored specifically for your business requirements.

Customer Reviews and Case Studies

Customer reviews and case studies serve as invaluable resources when researching industrial laser cutters from various manufacturers. Hearing firsthand experiences from other businesses can provide insights into the performance and reliability of specific models over time—information that sales brochures simply can't convey fully. Look for reviews that discuss how well the laser cutting machine performs under different conditions and its effectiveness in achieving desired precision levels.

Case studies often highlight real-world applications where these machines have excelled or faced challenges; this context can help you gauge whether a particular model suits your operational needs effectively. Moreover, positive testimonials about after-sales support indicate how responsive manufacturers are when issues arise—a critical factor in maintaining productivity with any cutting machine laser investment. By reviewing this information diligently, you'll be better positioned to choose an industrial laser cutter that not only meets but exceeds expectations.

Training and Support Solutions

When investing in an industrial laser cutting machine, understanding the importance of training and support cannot be overstated. A cutting machine laser can be a significant asset to your manufacturing process, but without proper knowledge on how to use it effectively, you may not reap its full benefits. Comprehensive training ensures that your team is well-equipped to handle the intricacies of laser cutting, leading to enhanced productivity and reduced errors.

Importance of Comprehensive Training

Comprehensive training on your new metal cutting machine laser is crucial for several reasons. First, it empowers operators with the skills needed to maximize the machine's capabilities, ensuring they can perform tasks efficiently and safely. Second, proper training reduces the likelihood of costly mistakes that could arise from misunderstandings or misuse of the laser machinery, ultimately saving you time and money.

Moreover, a well-trained workforce can adapt more quickly to changes in production demands or material types. This flexibility is particularly important in industries where precision is key; knowing how to adjust settings on an industrial laser cutter can mean the difference between a flawless cut and a scrap piece of metal. Investing in thorough training not only enhances operational efficiency but also boosts employee confidence in using advanced technology.

After-Sales Support and Maintenance

After-sales support is another critical aspect when selecting your industrial laser cutting machine provider. Even with comprehensive training, issues may arise that require expert assistance or maintenance services for your cutting machine laser. A reliable manufacturer will offer ongoing support options such as troubleshooting assistance, spare parts availability, and regular maintenance checks to keep your metal cutting machine laser running smoothly.

Regular maintenance not only prolongs the life of your equipment but also ensures consistent performance over time. In industries where downtime translates directly into lost revenue, having access to quick after-sales support can make all the difference. Choosing a manufacturer with strong after-sales service guarantees you won’t be left stranded when problems occur.

Building a Long-Term Relationship

Establishing a long-term relationship with your industrial laser cutter supplier can yield numerous benefits beyond just purchasing equipment. By fostering this partnership, you gain access to valuable insights into future technology advancements that could enhance your production processes further—think upgrades or new features tailored for efficiency in metal cutting applications!

Additionally, ongoing communication allows for personalized support tailored specifically for your operation’s needs—whether it's specialized training sessions or custom maintenance schedules for optimal performance of your industrial laser machinery over time. Investing in this relationship means you're not just buying a product; you're securing a partner committed to helping you thrive in the competitive landscape of manufacturing.

Conclusion

In the fast-paced world of manufacturing, choosing the right industrial laser cutting machine can significantly impact your operations. From understanding your specific cutting needs to exploring the latest technology options, each factor plays a vital role in making an informed decision. As you navigate through this process, remember that a well-chosen laser cutting machine can enhance productivity and precision while reducing costs.

Recap of Key Factors in Your Decision

When selecting an industrial laser cutter, it's essential to assess material types and thicknesses that you'll be working with, as different machines excel in various applications. Production volume requirements should also guide your choice; whether you need a high-output machine cut metal or one designed for intricate designs, knowing your needs is crucial. Additionally, always consider precision and tolerance levels—these elements can make or break the quality of your final product when using a cutting machine laser.

The Role of Technology in Efficiency

The advancements in laser machinery have revolutionized how businesses approach metal cutting tasks. With options like CO2 and fiber laser technology available, understanding their advantages will help streamline operations and improve efficiency. Hybrid cutting machines combine the best features of both technologies, allowing for versatile applications that cater to diverse manufacturing needs—ultimately leading to enhanced productivity.

Making Informed Choices for Your Business

Investing time into researching reputable manufacturers is just as important as evaluating the machinery itself; brands like Kiant Machinery offer proven reliability and support for their industrial laser cutting machines. Don't overlook customer reviews and case studies—they provide valuable insights into how specific models perform under real-world conditions. By taking these steps, you’ll not only make an informed choice but also position your business to thrive with state-of-the-art technology tailored to meet your unique demands.