Introduction

In the realm of modern manufacturing, the flatbed laser cutter machine has emerged as a transformative tool, revolutionizing how materials are processed. This technology employs high-powered lasers to cut through various substrates with remarkable speed and precision, making it an essential component in numerous industrial applications. From intricate designs in textiles to robust components in metalworking, laser cutting is reshaping production lines around the globe.

Overview of Laser Cutting Technology

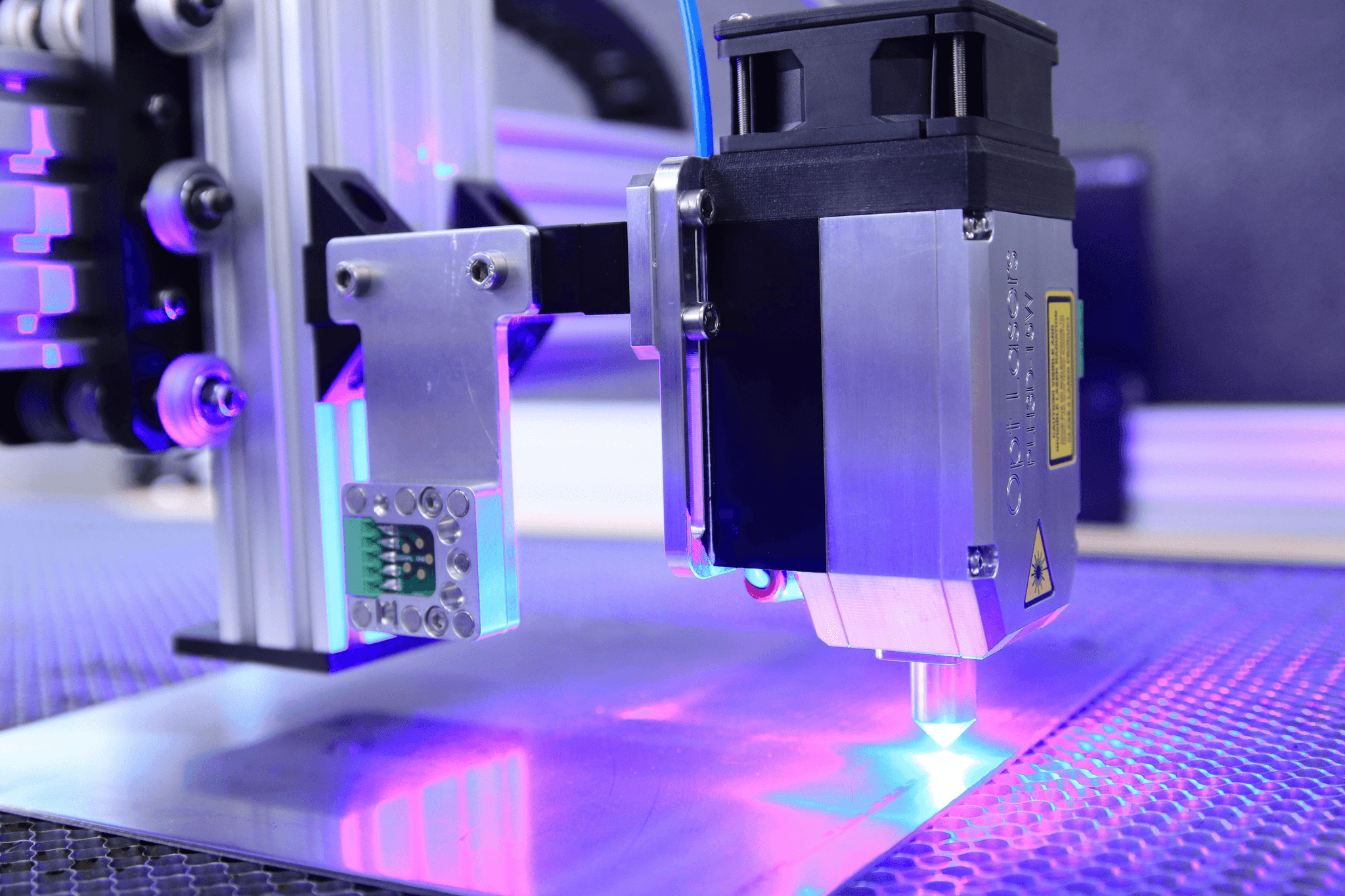

Laser cutting technology harnesses focused light beams to achieve clean and accurate cuts in a multitude of materials. The process involves directing a high-energy laser through optics to melt or vaporize the material being cut, resulting in minimal waste and exceptional edge quality. With advancements such as fiber laser cutting machines, industries can now enjoy greater efficiency and effectiveness than ever before.

Importance of Precision in Cutting

The unparalleled accuracy of a metal cutting laser cutter ensures that each piece meets exact specifications, reducing rework and material wastage. In a competitive market where time and resources are precious, investing in a reliable cutting machine laser can provide businesses with a crucial edge.

Applications of Flatbed Laser Cutters

Flatbed laser cutters find their applications across diverse sectors including automotive, aerospace, fashion, and signage industries. These industrial laser cutting machines are adept at handling everything from delicate fabrics to heavy metals with ease and finesse. As companies continue to seek innovative solutions for their production challenges, the versatility of flatbed laser cutter machines positions them as indispensable assets on the factory floor.

What is a Flatbed Laser Cutter Machine

Definition and Functionality

A flatbed laser cutter machine is an advanced tool that employs focused laser beams to slice through materials with unparalleled precision. Unlike traditional cutting methods, which may involve blades or other mechanical means, this cutting machine laser operates by vaporizing the material at the point of contact. The result? Clean edges and minimal waste, making it an essential asset for industries that prioritize quality and efficiency.

The functionality of a flatbed laser cutter extends beyond just cutting; it also allows for engraving and marking on various surfaces. This versatility makes it particularly valuable in sectors such as automotive, aerospace, and signage manufacturing. By utilizing computer numerical control (CNC) technology, operators can program complex designs that the machine executes flawlessly—ensuring consistency across production runs.

Key Components of Laser Cutting Machines

Understanding the key components of an industrial laser cutting machine is crucial for anyone looking to invest in this technology. At its core, a flatbed laser cutter consists of several essential parts: the laser source (often CO2 or fiber), the optics system that focuses the beam, and a motion system that moves either the material or the laser head to achieve precise cuts.

Additionally, these machines are equipped with cooling systems to maintain optimal operating temperatures during prolonged use—ensuring longevity and performance stability. The user interface plays a pivotal role as well; intuitive controls allow operators to set parameters quickly without extensive training on complex machinery.

Types of Flatbed Laser Cutters

There are several types of flatbed laser cutters available on the market today, each designed for specific applications and materials. The most common include CO2 lasers and fiber lasers; while CO2 lasers excel in cutting non-metal materials like wood and acrylics, fiber lasers shine when it comes to metal cutting applications due to their higher energy efficiency and speed.

Another classification involves power levels—ranging from low-power models suitable for thin sheets to high-power metal cutting machines designed for thicker materials like stainless steel or aluminum. When selecting a type of flatbed laser cutter machine, it's essential to consider your specific needs regarding material types, thicknesses, and desired production speed.

Advantages of Using a Laser Cutting Machine

Laser cutting technology has revolutionized the manufacturing landscape, offering numerous benefits that traditional cutting methods simply can't match. The flatbed laser cutter machine stands out for its ability to deliver high precision and versatility across various applications, making it an invaluable tool in many industries. Let’s dive into some of the key advantages of using a laser cutting machine.

Precision and Accuracy in Cutting

One of the most significant advantages of a flatbed laser cutter machine is its unparalleled precision and accuracy in cutting materials. With advanced optics and computer-controlled systems, these industrial laser cutting machines can achieve intricate designs with minimal tolerances, ensuring that every cut is exactly where it should be. Whether you're dealing with metal or other materials, the precision offered by a metal cutting laser cutter enhances product quality and reduces waste.

Moreover, this level of accuracy means less need for secondary processes like sanding or finishing, which can save both time and resources. The fine beam produced by a fiber laser cutting machine allows for clean edges without burrs or rough spots, further emphasizing its effectiveness in high-stakes applications such as aerospace or automotive manufacturing. Ultimately, when precision matters most, a cutting machine laser is the ideal choice.

Versatility Across Various Materials

Another compelling advantage of using a laser cutting machine is its versatility across different materials. Flatbed laser cutters are adept at processing not just metals but also plastics, wood, glass, and textiles—making them suitable for diverse sectors from fashion to engineering. This adaptability allows businesses to streamline their operations by consolidating multiple machines into one powerful industrial laser cutting machine.

The ability to switch between materials without significant downtime means that companies can respond quickly to changing market demands or custom orders with ease. Additionally, advancements in technology have made it possible for fiber laser cutting machines to handle thicker materials while maintaining speed and efficiency—further broadening their applicability across various industries. In short, whether you’re crafting delicate designs or heavy-duty components, there’s likely a metal cutting machine laser that fits your needs perfectly.

Cost-Effectiveness for Production

Cost-effectiveness is another major benefit associated with utilizing a flatbed laser cutter machine in production processes. Although the initial investment may seem substantial compared to traditional methods, the long-term savings on labor costs and material waste quickly add up when using an efficient cutting machine laser. The high-speed capabilities of these machines mean they can produce more parts in less time—maximizing output while minimizing operational costs.

Additionally, because these systems require less manual intervention due to their automation features, businesses can reduce labor costs significantly over time while reallocating skilled workers to more complex tasks that require human oversight. Moreover, precise cuts lead to fewer errors and scrap materials during production runs—a win-win situation for any manufacturing operation looking to improve profitability without sacrificing quality standards. In essence, investing in advanced technology like an industrial metal cutting laser cutter not only boosts productivity but also enhances overall financial performance.

Materials Suitable for Laser Cutting

When it comes to laser cutting, the choice of materials is crucial for achieving optimal results. A flatbed laser cutter machine can handle a variety of substances, transforming them into precise parts and components for numerous applications. Understanding which materials work best with an industrial laser cutting machine can significantly improve productivity and efficiency.

Common Materials for Industrial Laser Cutting

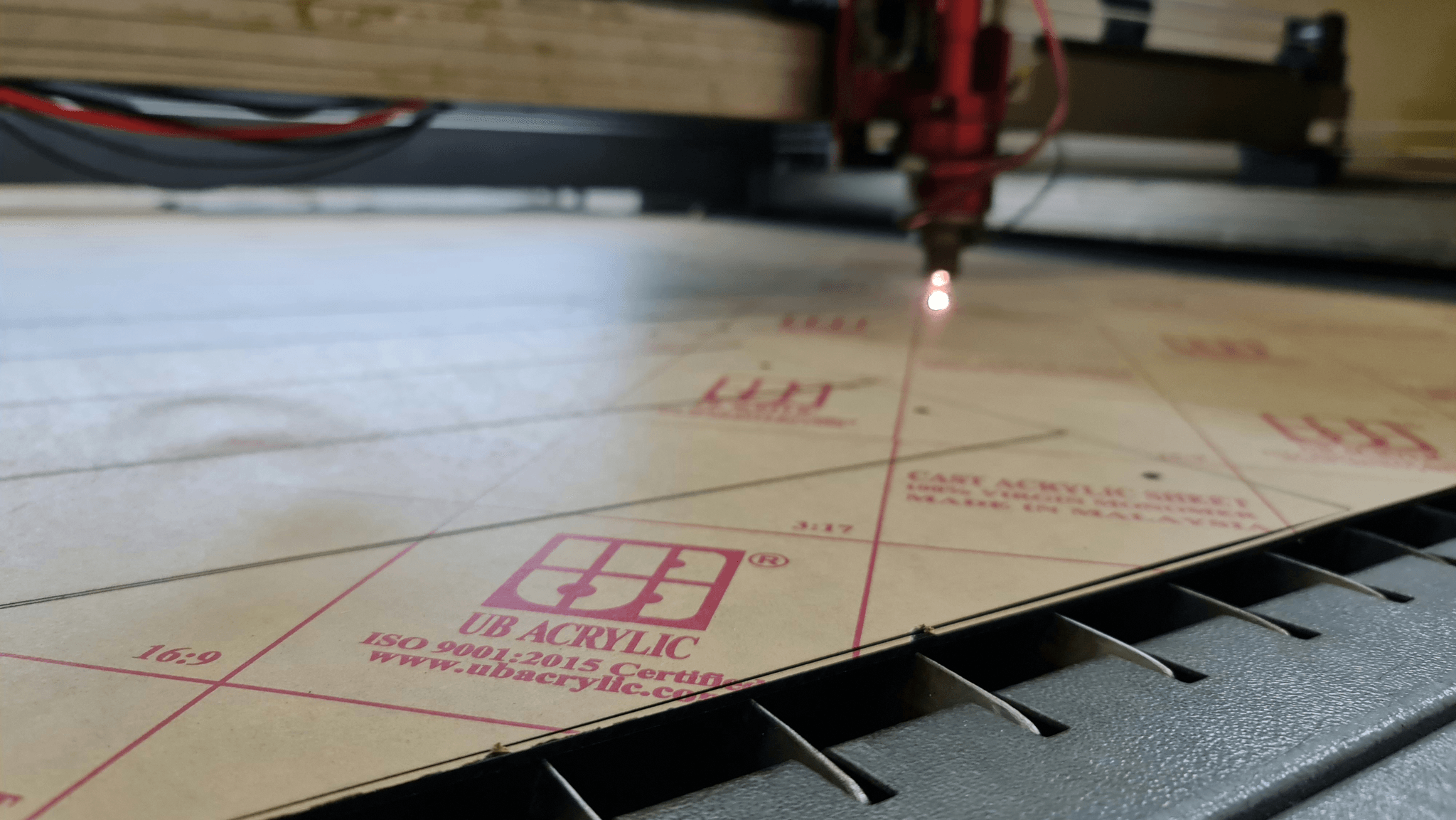

Flatbed laser cutter machines excel at processing a range of common materials, including acrylic, wood, and textiles. Acrylic is particularly favored due to its clean cuts and vibrant finishes, making it perfect for signage and display items. Additionally, wood offers versatility in design while maintaining structural integrity when cut with a metal cutting machine laser or a fiber laser cutting machine.

In the textile industry, the ability to create intricate patterns without fraying edges is another advantage of using a cutting machine laser. This precision allows manufacturers to produce high-quality garments and upholstery efficiently. With advancements in technology, even composite materials are now being explored for industrial laser cutting applications.

Specialized Applications in Metal Cutting

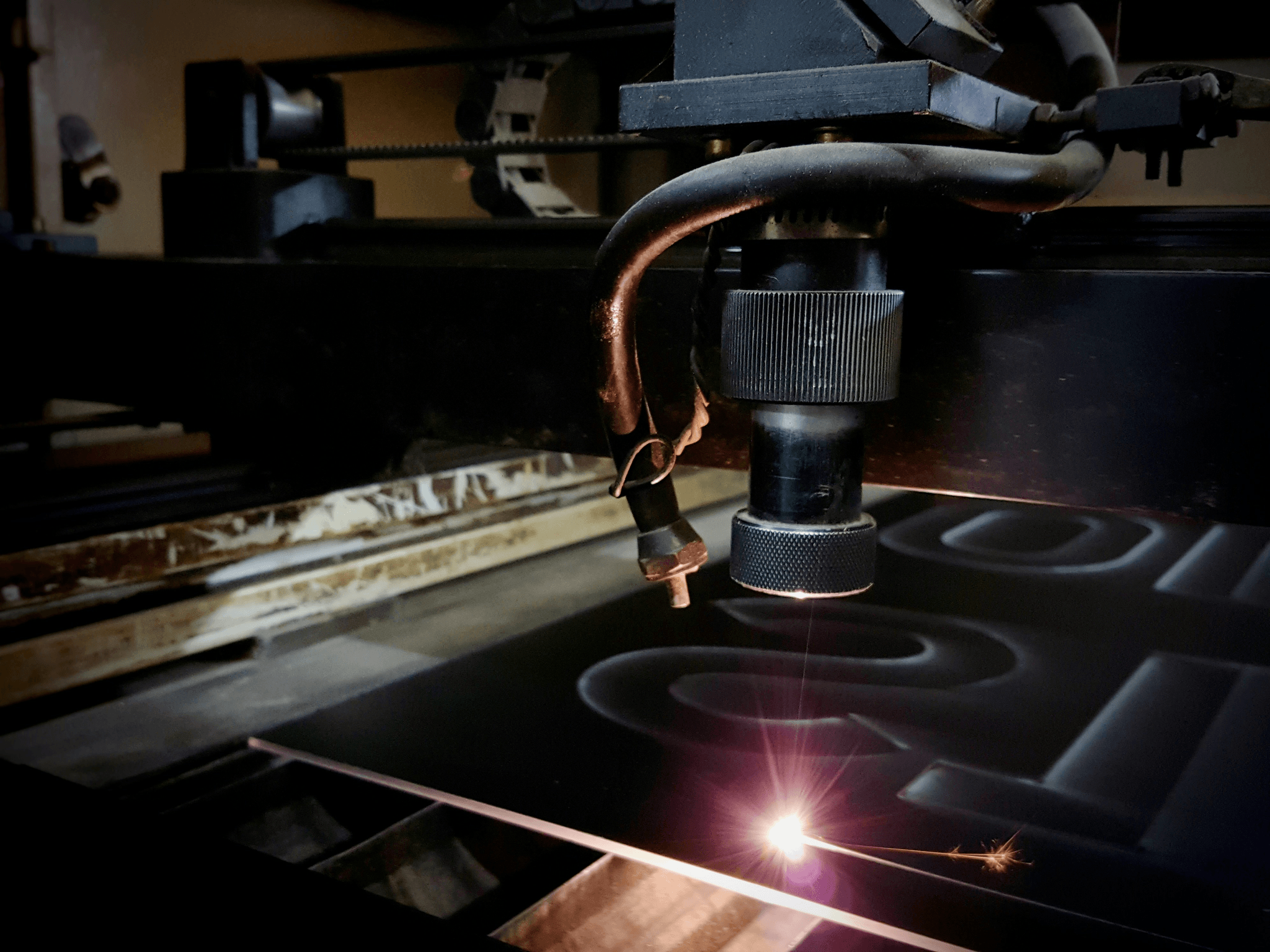

Metal cutting presents unique challenges that require specialized solutions from metal cutting laser cutters. These machines can handle various metals such as stainless steel, aluminum, and brass with remarkable precision. The capabilities of a metal cutting machine laser enable manufacturers to produce intricate designs that would be difficult or impossible with traditional machining methods.

In specialized applications like aerospace or automotive manufacturing, where tolerances must be incredibly tight, the use of advanced flatbed laser cutter machines becomes indispensable. They ensure consistent quality across high-volume production runs while minimizing waste material during the process. As industries continue to evolve, innovations in metal cutting technology will further enhance these capabilities.

Innovations in Fiber Laser Cutting Technology

Fiber laser cutting technology has revolutionized how we approach material processing in recent years. Unlike traditional CO2 lasers, fiber lasers offer higher efficiency and faster processing speeds while maintaining exceptional beam quality—perfect for both thick and thin materials alike. This innovation has made fiber lasers increasingly popular among manufacturers looking to optimize their operations with a reliable flatbed laser cutter machine.

Moreover, advancements in software integration have allowed operators to program complex cuts more easily than ever before—reducing setup times dramatically on an industrial scale! With continuous improvements in fiber technology's energy consumption rates compared to other methods like CO2 lasers or plasma cutters, businesses are seeing significant cost savings alongside enhanced performance metrics.

In summary, selecting suitable materials is essential when using any type of cutting machine laser; understanding their properties ensures optimal results across various applications—from intricate designs on textiles all the way through heavy-duty metal fabrication processes!

Selecting the Right Laser Cutting Machine

Choosing the right laser cutting machine can feel like navigating a labyrinth of options, but fear not! Understanding the nuances between various models can lead you to the perfect flatbed laser cutter machine for your needs. From precision to material compatibility, several factors play a pivotal role in making this decision.

Factors to Consider in Choosing a Machine

When selecting an industrial laser cutting machine, consider its intended use and production volume. The power of the laser, typically measured in watts, directly influences the thickness of materials it can cut—higher wattage is ideal for thicker metals. Additionally, look into features such as speed settings and software compatibility that may enhance your cutting efficiency and precision.

Another crucial factor is the type of materials you plan to cut with your metal cutting machine laser. Different machines excel at different materials; for instance, fiber laser cutting machines are exceptional for metals but might struggle with softer materials like plastics or wood. Lastly, don’t overlook maintenance requirements; some machines demand more upkeep than others, which can impact long-term costs and productivity.

Comparing Metal Cutting Laser Cutters

When comparing metal cutting laser cutters, start by examining their specifications and capabilities side-by-side. Look for features such as beam quality and focusability—these can greatly affect cut quality and speed during operation. Additionally, consider user-friendly interfaces; a straightforward control system allows operators to maximize their efficiency with minimal training.

Another aspect worth considering is customer support from manufacturers or suppliers when investing in a cutting machine laser. Reliable after-sales support ensures that any issues encountered during operation are resolved swiftly without disrupting production schedules. Finally, assess the overall cost-effectiveness of each option; sometimes spending a bit more upfront on a high-quality flatbed laser cutter machine pays off through increased durability and lower operational costs over time.

Kiant Machinery: Leading Solutions Provider

Kiant Machinery stands out as a leading solutions provider in the realm of laser technology with its wide range of advanced flatbed laser cutter machines tailored for various applications. Their commitment to innovation ensures that customers have access to state-of-the-art equipment designed for precision metal cutting while maintaining cost-effectiveness in production processes. With expert guidance available throughout your purchasing journey, Kiant Machinery simplifies selecting an industrial laser cutting machine that aligns perfectly with your operational needs.

Additionally, Kiant Machinery offers robust training programs designed to empower operators with essential skills needed for optimal performance of their new equipment—ensuring you get the most out of your investment right from day one! With ongoing support and maintenance services at hand, partnering with Kiant means you're not just buying machinery; you're investing in a long-term relationship dedicated to advancing your business's success.

Maintenance and Best Practices

Maintaining a flatbed laser cutter machine is not just about keeping it clean; it's a crucial part of ensuring optimal performance and longevity. Regular maintenance can prevent unexpected breakdowns, which can be costly in terms of both time and money. By adhering to a structured maintenance schedule, operators can maximize the efficiency of their industrial laser cutting machines.

Importance of Regular Maintenance

Regular maintenance for your metal cutting laser cutter is essential for several reasons. First, it ensures that the cutting machine laser operates at peak efficiency, reducing waste and improving precision during operations. Second, it extends the lifespan of the equipment by identifying potential issues before they escalate into costly repairs or replacements.

Additionally, neglecting maintenance can lead to decreased quality in cuts, which could impact the overall production process. A well-maintained flatbed laser cutter machine will consistently deliver high-quality results across various materials, making it indispensable for any manufacturing operation. Ultimately, regular upkeep is an investment in productivity and profitability.

Tips for Optimizing Laser Cutter Performance

To get the most out of your fiber laser cutting machine, consider implementing these practical tips for optimization. First and foremost, ensure that your cutting machine laser is calibrated correctly; this involves setting the right power levels and speeds based on material type and thickness to achieve optimal results. Regularly check alignment as well; even minor misalignments can lead to subpar cuts.

Another key aspect is keeping your workspace clean and organized to avoid debris accumulation around your metal cutting machine laser. Dust or particles can interfere with performance or even damage sensitive components over time. Lastly, always keep an eye on consumables like lenses and nozzles—replacing them when necessary will help maintain clarity and focus during operations.

Training and Support from Kiant Machinery

When investing in a flatbed laser cutter machine from Kiant Machinery, you’re not just purchasing equipment; you're gaining access to comprehensive training and support services designed to maximize your investment’s return. Kiant Machinery offers specialized training programs that cover everything from basic operation to advanced troubleshooting techniques for industrial laser cutting machines.

Moreover, ongoing support ensures that any questions or issues are promptly addressed by knowledgeable professionals who understand the intricacies of metal cutting machines lasers like no one else does. This commitment helps operators become proficient in using their machinery efficiently while minimizing downtime due to operational errors or misunderstandings.

In conclusion, proper maintenance practices combined with expert training from Kiant Machinery will significantly enhance the performance of any flatbed laser cutter machine while ensuring smooth operations throughout its lifecycle.

Conclusion

In the ever-evolving landscape of manufacturing, the flatbed laser cutter machine has emerged as a game-changer, revolutionizing how industries approach cutting processes. The precision and versatility of laser cutting technology have not only enhanced production efficiency but also allowed for intricate designs that were once deemed impossible with traditional methods. As businesses strive to meet the demands of modern consumers, embracing industrial laser cutting machines becomes essential for staying competitive.

Transforming Industries with Laser Cutting

Laser cutting technology is fundamentally transforming various industries by providing unparalleled precision and adaptability. From automotive to aerospace, the ability to use a metal cutting laser cutter offers manufacturers a way to produce complex components with minimal waste. This efficiency in production not only reduces costs but also accelerates time-to-market, giving companies a significant edge in their respective fields.

Future Trends in Laser Technology

Looking ahead, advancements in fiber laser cutting machines are poised to redefine what’s possible within the realm of laser technology. With ongoing innovations focusing on speed and energy efficiency, future metal cutting machines will likely become even more powerful while using less energy. Additionally, developments in automation and artificial intelligence will enhance the capabilities of these cutting machines, allowing for smarter manufacturing processes that can adapt in real-time.

How Kiant Machinery Supports Your Operations

Kiant Machinery stands at the forefront of this technological revolution by offering top-of-the-line flatbed laser cutter machines tailored to meet diverse industrial needs. Their commitment to quality ensures that each metal cutting machine laser delivers exceptional performance and reliability, empowering businesses to achieve their production goals efficiently. With comprehensive training and support services available, Kiant Machinery not only equips you with advanced equipment but also ensures your team is fully prepared to maximize its potential.