Introduction

In the realm of modern manufacturing, metal laser cutting machines have emerged as indispensable tools for precision and efficiency. These advanced devices utilize focused laser beams to cut through various materials, making them a staple in industries that require high-quality fabrication. Among the different types of laser cutting machines available, flatbed laser cutting machines stand out for their versatility and capability to handle large sheets of material with ease.

Understanding Metal Laser Cutting Machines

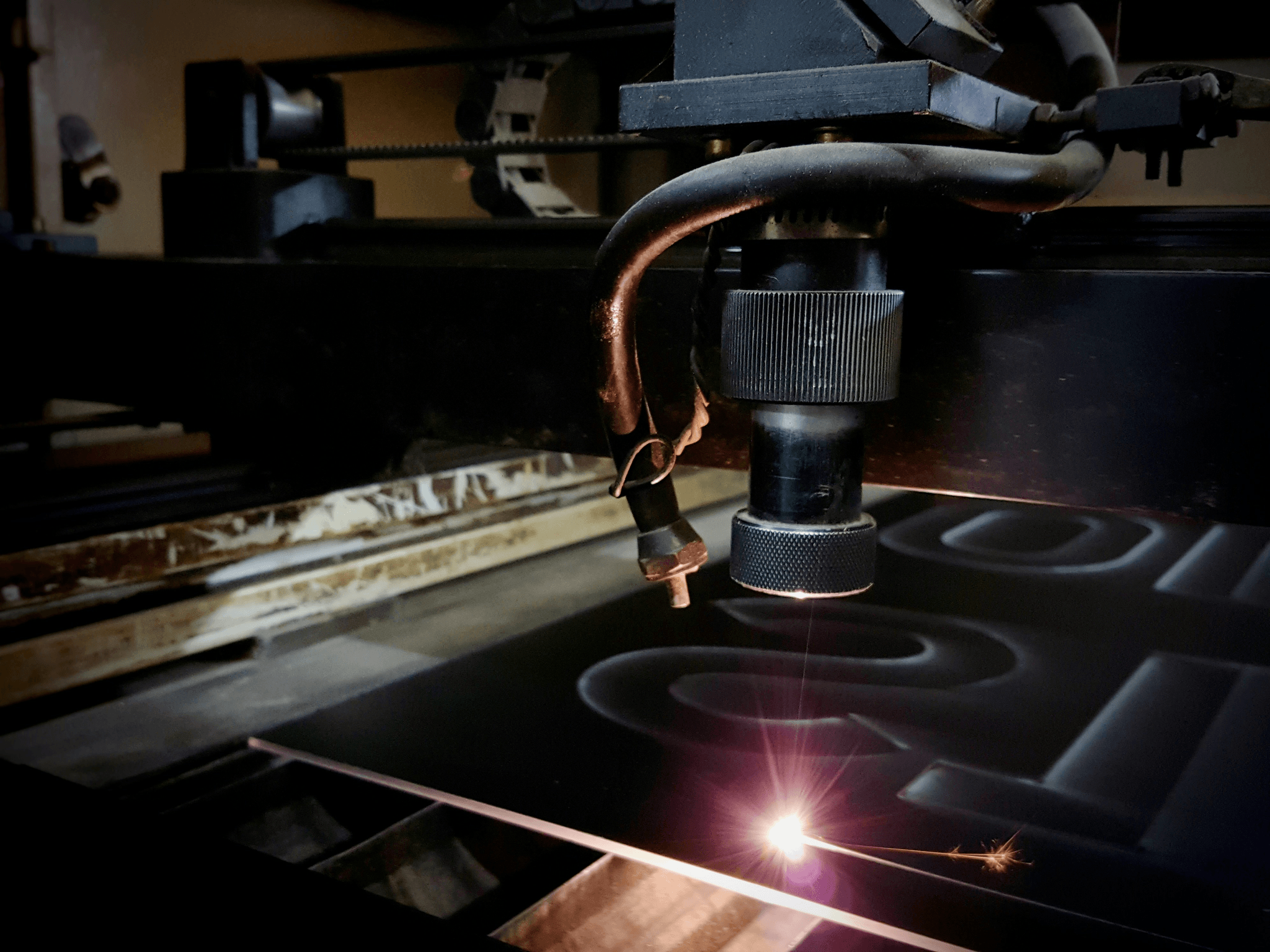

Metal laser cutting machines operate by directing a high-powered laser beam onto a workpiece, melting or vaporizing the material to create intricate designs and shapes. This technology allows for unparalleled accuracy compared to traditional cutting methods, reducing waste and increasing productivity in industrial settings. With options like fiber laser cutting machines and flatbed models, manufacturers can select the best equipment tailored to their specific needs.

Importance of Manufacturer Pricing

When considering an investment in a cutting machine laser, understanding manufacturer pricing is crucial for making informed decisions. Prices can vary significantly based on factors such as technology type, machine features, and brand reputation; thus, knowing what influences these costs helps businesses budget effectively. Ultimately, choosing a competitively priced industrial laser cutting machine can lead to substantial savings without sacrificing quality or performance.

Types of Laser Cutting Machines

There are several types of laser cutting machines available on the market today, each designed for particular applications and materials. Flatbed laser cutting machines are particularly favored for their ability to process large sheets efficiently while providing precise cuts across various metals. In contrast, fiber laser cutting machines excel at delivering rapid speeds and enhanced energy efficiency—making them ideal choices depending on production requirements and material types.

Overview of Flatbed Laser Cutting Machines

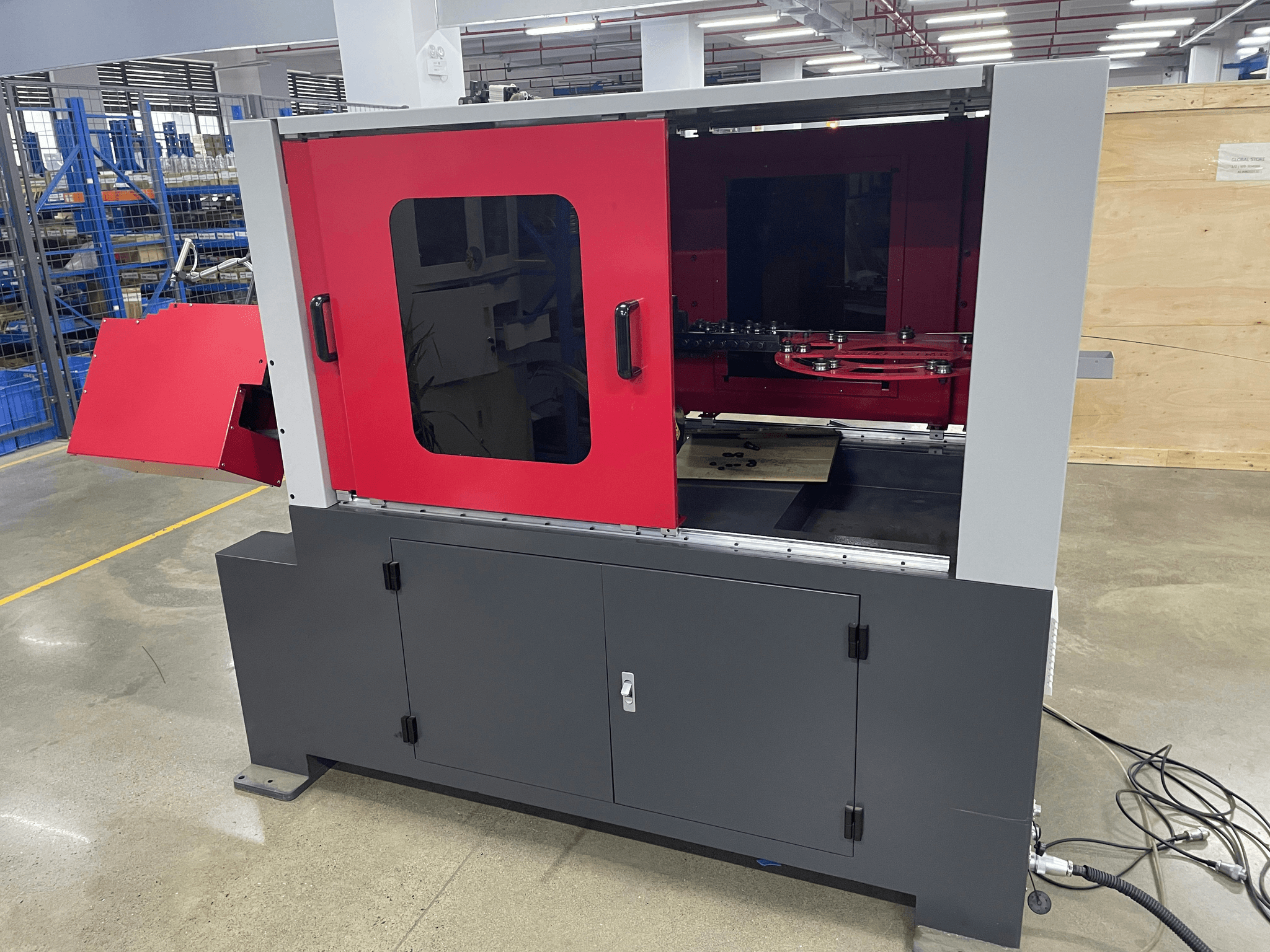

These machines utilize high-powered lasers to cut through a range of materials with precision and speed, making them ideal for both small-scale and large-scale production. Their design allows for easy loading and unloading of materials, which enhances workflow efficiency in manufacturing environments.

Features and Benefits

Flatbed laser cutting machines are equipped with several features that contribute to their effectiveness in the industrial sector. One significant advantage is their ability to handle large sheets of material, enabling users to maximize material usage while minimizing waste. Additionally, these machines often come with advanced software that allows for intricate designs and complex cuts, ensuring high-quality results every time.

The benefits extend beyond just cutting capabilities; flatbed laser cutting machines also require minimal maintenance compared to traditional cutting methods. With fewer moving parts than mechanical cutters, these laser machines offer reliability and longevity in demanding work environments. Furthermore, the precision of a laser cutting machine reduces the need for secondary processes like sanding or finishing, saving both time and resources.

Applications in Various Industries

Flatbed laser cutting machines are widely used across multiple industries due to their adaptability and efficiency. In the automotive sector, they play a crucial role in producing components such as brackets and panels with tight tolerances required for modern vehicles. Similarly, the aerospace industry relies on these machines for intricate part manufacturing where precision is paramount.

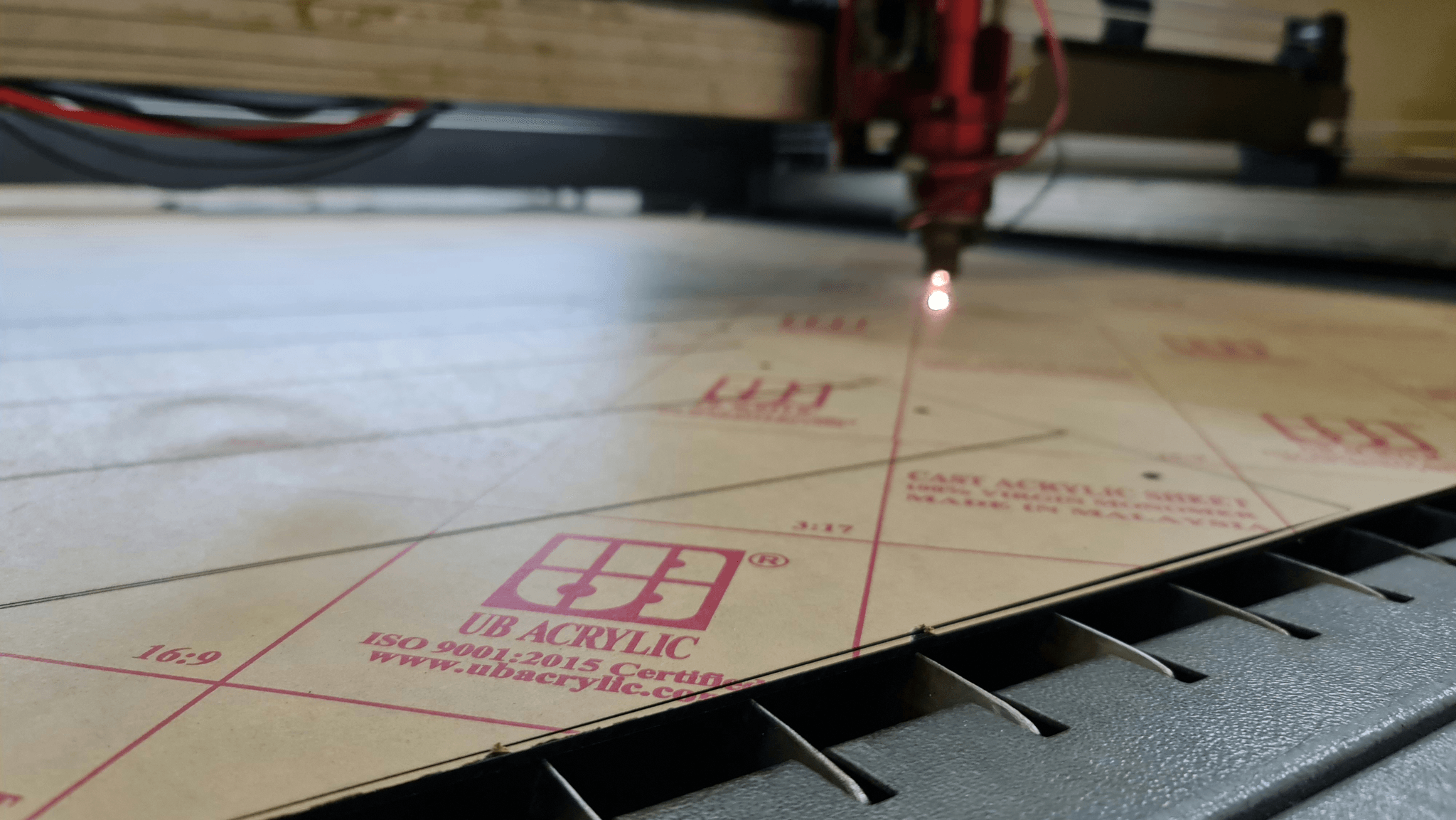

Beyond heavy industries, flatbed laser cutting technology finds its place in textiles, signage production, and even electronics manufacturing. For example, they can cut fabrics into complex patterns or engrave designs onto promotional materials at high speeds without compromising quality. This versatility makes flatbed lasers a preferred choice among manufacturers looking to innovate while maintaining cost-effectiveness.

Comparing Flatbed and Fiber Laser Cutting Machines

While both flatbed laser cutting machines and fiber laser cutting machines utilize lasers for material processing, they differ significantly in terms of technology and application suitability. Flatbed lasers typically use CO2 lasers that excel at cutting non-metallic materials like wood or acrylics effectively; however, they can also handle metals but may not be as efficient as fiber systems on thicker sheets. Fiber lasers shine when it comes to processing metals due to their higher energy density which translates into faster cuts with cleaner edges.

Another notable difference lies in operating costs; fiber laser systems tend to have lower energy consumption compared to their CO2 counterparts over time due to increased efficiency levels during operation. This can result in significant savings for businesses looking at long-term investments in an industrial laser cutting machine setup. Ultimately, choosing between a flatbed or fiber system will depend on specific project requirements—whether you prioritize versatility across different materials or specialized metal processing capabilities.

The Price Range of Industrial Laser Cutting Machines

When it comes to investing in an industrial laser cutting machine, understanding the price range is crucial for making an informed decision. Prices can vary significantly based on several factors, including the type and capabilities of the machine. Flatbed laser cutting machines often fall within a specific range due to their unique features and applications, but knowing what influences these costs helps in budgeting effectively.

Factors Influencing Costs

Several key factors influence the cost of laser cutting machines, particularly flatbed models and fiber laser cutting machines. First, the size and complexity of the machine play a significant role; larger machines with advanced technology tend to be more expensive. Additionally, features such as automation capabilities, precision levels, and brand reputation can also impact pricing—higher-end models often come with enhanced performance but at a premium cost.

Another factor includes the materials used in construction; robust materials increase durability but also contribute to higher prices. Furthermore, software compatibility and support services are essential considerations that can affect overall costs—cutting machine lasers equipped with advanced software may command higher prices due to their enhanced functionality. Lastly, geographic location and market demand can create variations in pricing across different regions.

Budgeting for a Cutting Machine Laser

Budgeting for a cutting machine laser requires careful planning and consideration of both upfront costs and long-term expenses. Start by defining your specific needs: will you primarily cut metals or softer materials? Understanding your requirements will help narrow down options while determining how much you’re willing to invest in flatbed or fiber laser cutting machines.

Once you have established your needs, consider additional expenses such as maintenance, consumables (like lenses and nozzles), and potential upgrades over time. It’s wise to allocate funds not just for purchasing but also for ongoing operational costs that accompany owning an industrial laser cutting machine. By adopting a comprehensive budgeting approach that encompasses all these aspects, you’ll be better positioned to make an investment that aligns with your financial strategy.

Cost vs. Value in Laser Cutting Machines

When evaluating cost versus value in laser cutting machines, it’s essential to look beyond just the price tag attached to flatbed or fiber laser cutting machines. Value encompasses performance metrics such as speed, precision, operational efficiency, and longevity—the right machine should provide substantial returns on investment through improved productivity over time.

Moreover, consider how well each model fits into your production processes; a less expensive option might end up costing more if it requires frequent repairs or lacks necessary features for your applications. Therefore, assessing value means weighing initial expenditures against potential savings gained from efficiency improvements or reduced material waste—this holistic view ensures you choose a solution that meets both budgetary constraints and operational goals.

Leading Manufacturers in the Market

When it comes to industrial laser cutting machines, the market is filled with a plethora of manufacturers vying for attention. Each company brings its own unique offerings, features, and pricing strategies to the table. Understanding these key players is essential for making an informed decision about which cutting machine laser best fits your needs.

Kiant Machinery: A Top Contender

Kiant Machinery stands out as a leading contender in the realm of flatbed laser cutting machines. Renowned for their high-quality engineering and innovative technology, they offer a range of models that cater to various industrial applications. Their commitment to customer satisfaction and robust after-sales support makes them a preferred choice among businesses looking for reliable laser cutting solutions.

One of the standout features of Kiant’s laser cutting machines is their versatility; they can handle different materials with precision and speed that often outpaces competitors. Moreover, their fiber laser cutting machine options are particularly popular due to their efficiency and lower operational costs compared to traditional models. With Kiant Machinery, businesses can expect not just a product but also a partnership that fosters growth through advanced technology.

Other Key Players in Laser Technology

While Kiant Machinery holds its ground firmly, several other key players also contribute significantly to the landscape of laser technology. Companies like Trumpf, Bystronic, and Amada have established themselves as formidable competitors by offering state-of-the-art industrial laser cutting machines designed for various sectors including automotive, aerospace, and metal fabrication. These manufacturers are known for pushing technological boundaries with innovative features like adaptive optics and real-time monitoring systems.

Each manufacturer has its strengths; Trumpf is celebrated for its robust build quality while Bystronic excels in user-friendly interfaces that simplify operation even for novice users. Meanwhile, Amada offers comprehensive service packages that ensure customers receive ongoing support long after purchase—an essential factor when considering investment in a cutting machine laser system.

Differentiating Factors Among Manufacturers

When evaluating different manufacturers of flatbed laser cutting machines or fiber laser cutting machines, several differentiating factors come into play beyond just price tags. The technology used in these industrial laser cutting machines can vary widely; some companies might focus on speed while others prioritize precision or material versatility. Understanding these nuances helps businesses align their specific needs with what each manufacturer offers.

Another critical factor is customer service and support; manufacturers who provide extensive training programs and responsive technical assistance often win over clients looking for long-term partnerships rather than one-off transactions. Additionally, customization options available from various manufacturers can greatly influence purchasing decisions—some may offer tailored solutions that fit perfectly into existing workflows while others stick to more standardized offerings.

In conclusion, navigating through the leading manufacturers in the market requires careful consideration of multiple factors including technology capabilities, customer support services, and customization options available with each industrial laser cutting machine on offer.

Choosing the Right Laser Machine for Your Needs

Selecting the right laser machine is akin to finding the perfect pair of shoes; it needs to fit your specific needs and provide comfort in performance. With various options available, particularly flatbed laser cutting machines and fiber laser cutting machines, understanding your requirements is essential. This section will guide you through assessing your cutting needs, exploring customization options, and considering maintenance and support.

Assessing Your Cutting Requirements

Before diving into the world of industrial laser cutting machines, it's crucial to evaluate what you actually need from a laser cutting machine. Are you primarily focused on precision cuts in metal or softer materials? Identifying the thickness of materials you'll be working with and the intricacy of designs will help narrow down whether a flatbed laser cutting machine or a fiber laser cutting machine is best suited for your projects.

Moreover, consider your production volume and speed requirements; some applications may demand high-speed operations that only certain models can handle efficiently. It’s also wise to think about future projects—will your needs evolve? Investing in a versatile cutting machine laser can save you time and money down the line.

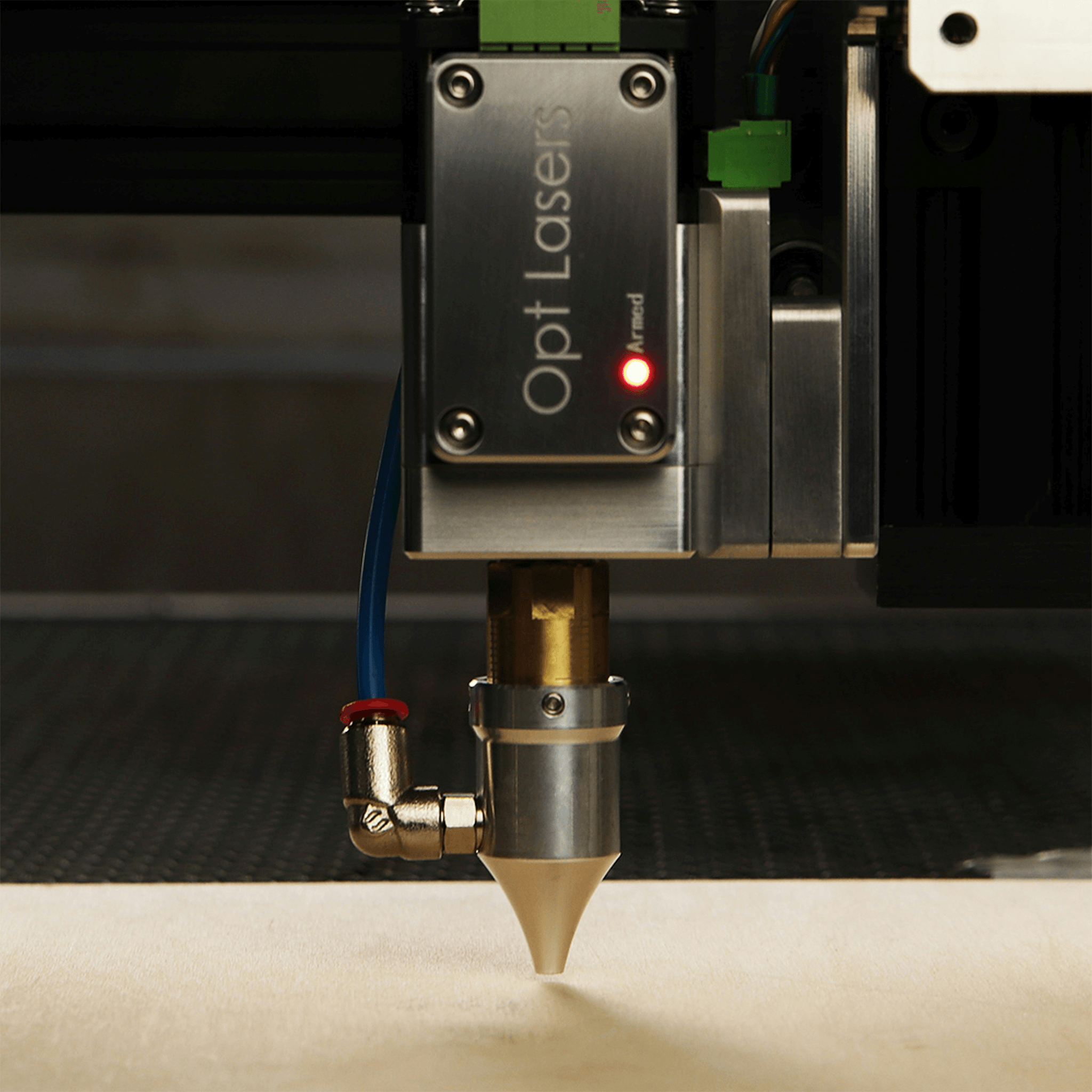

Customization Options Available

Customization is one of the standout features when it comes to modern laser machines. Many manufacturers offer bespoke solutions tailored to meet specific industry demands, ensuring that your flatbed laser cutting machines are equipped with features that enhance productivity and efficiency. Whether it's adding specialized software for design or integrating advanced cooling systems for prolonged use, there are numerous ways to make your industrial laser cutting machine uniquely yours.

Additionally, consider how customizable parts can affect maintenance costs and operational efficiency over time. You might want features like adjustable bed sizes or interchangeable nozzles for different materials; these can significantly influence both functionality and versatility in various applications. Always consult with manufacturers about available options before making a decision.

Maintenance and Support Considerations

When investing in a high-quality laser cutting machine, maintenance should be at the forefront of your mind—after all, an ounce of prevention is worth a pound of cure! Regular upkeep not only prolongs the life of flatbed laser cutting machines but also ensures consistent performance over time. Understanding what maintenance routines are necessary can help you avoid unexpected downtime that could cost both time and money.

It's equally important to evaluate the support offered by manufacturers post-purchase; reliable customer service can make all the difference when troubleshooting issues or sourcing replacement parts for fiber laser cutting machines or other models. Look for companies that provide comprehensive warranties along with training resources so you can get up-to-speed quickly on operating procedures as well as routine care guidelines.

In conclusion, choosing the right industrial laser cutting machine requires careful consideration across several factors—from assessing specific requirements to exploring customization possibilities and understanding ongoing maintenance needs. By taking these steps seriously, you'll ensure that you're not just buying equipment but investing in long-term productivity gains.

Future Trends in Laser Cutting Technology

The landscape of laser cutting technology is evolving at a rapid pace, driven by advancements that promise to reshape how industries approach manufacturing. As businesses seek more efficient and effective solutions, innovations in flatbed laser cutting machines and fiber laser cutting machines are leading the charge. From enhanced precision to new materials compatibility, the future looks bright for industrial laser cutting machines.

Innovations to Watch For

One of the most exciting innovations on the horizon is the development of hybrid laser systems that combine multiple cutting technologies into one machine. These advanced laser machines can handle a wider array of materials, making them incredibly versatile for various applications. Furthermore, improvements in software algorithms are enhancing the capabilities of these cutting machine lasers, allowing for more intricate designs and faster processing times.

Another trend gaining traction is the integration of artificial intelligence (AI) into laser cutting operations. AI can optimize cut paths and predict maintenance needs, which significantly reduces downtime and improves overall efficiency. As manufacturers adopt these smart technologies, we can expect flatbed laser cutting machines to become even more user-friendly while delivering higher-quality results.

Lastly, advancements in beam quality and power output are setting new standards for fiber laser cutting machines. With increased power comes improved speed and precision when working with thicker materials or complex geometries. This innovation not only enhances productivity but also opens up new possibilities for industries looking to push their manufacturing capabilities further.

The Impact of Automation

Automation is fundamentally changing how industrial laser cutting machines operate, making processes faster and less prone to human error. Automated loading and unloading systems are becoming standard features in modern flatbed laser cutting machines, allowing for continuous operation without manual intervention. This shift not only boosts efficiency but also frees up skilled workers to focus on more complex tasks that require human insight.

Moreover, robotics paired with advanced sensors enhance the operational capabilities of these laser machines by enabling real-time adjustments based on material conditions or unexpected variables during production runs. Such automated systems ensure consistent quality across all cuts while significantly reducing waste—an essential factor in today’s competitive market where every second counts.

As automation continues to evolve within the realm of fiber laser cutting technology, we can anticipate a future where entire production lines operate seamlessly without human oversight—transforming how companies approach both large-scale manufacturing and bespoke projects alike.

Sustainability in Industrial Laser Cutting

Sustainability has become a key consideration across all industries—and industrial laser cutting is no exception. Manufacturers are increasingly looking at ways to minimize waste generated during production processes while maximizing energy efficiency within their flatbed laser cutting machines. Innovations such as optimized cut patterns help reduce scrap material while ensuring precise cuts that meet stringent quality standards.

In addition to reducing waste at the source, there’s a growing emphasis on using eco-friendly materials compatible with modern fiber laser cutting techniques. As companies embrace sustainable practices throughout their supply chains, investing in environmentally friendly alternatives becomes not just an ethical choice but also a smart business strategy that appeals to environmentally conscious consumers.

Finally, advances in recycling technologies mean that even after products have reached their end-of-life stage they can be repurposed effectively through specialized industrial processes involving advanced lasers—creating a circular economy model within manufacturing sectors reliant on high-performance equipment like industrial lasers.

Conclusion

In the fast-evolving world of manufacturing, understanding the nuances of laser cutting technology is essential for making informed decisions. Flatbed laser cutting machines and fiber laser cutting machines each offer unique advantages that cater to different industrial needs. By considering factors such as application, cost, and manufacturer reputation, businesses can find the right laser machine to enhance their production capabilities.

Key Takeaways on Laser Cutting Machines

Laser cutting has revolutionized how materials are processed, providing precision and efficiency that traditional methods simply cannot match. The choice between flatbed laser cutting machines and other types hinges on specific requirements like material thickness and complexity of cuts needed. Additionally, understanding the price range of industrial laser cutting machines is crucial; it allows companies to balance budget constraints with the value offered by high-quality equipment.

Making the Best Investment in Machinery

Investing in a cutting machine laser requires careful consideration of both immediate needs and long-term goals. It's important to assess not just the upfront costs but also maintenance expenses and potential productivity gains over time. By choosing a reliable manufacturer known for quality support—like Kiant Machinery—businesses can ensure their investment pays off in efficiency and durability.

Final Thoughts on Kiant Machinery's Offerings

Kiant Machinery stands out as a leader in providing innovative solutions within the realm of industrial laser cutting machines. Their commitment to quality ensures that users benefit from advanced technology while receiving excellent customer support throughout their ownership experience. Ultimately, selecting a flatbed or fiber laser cutting machine from Kiant can lead to significant improvements in production processes, paving the way for future success.