Introduction

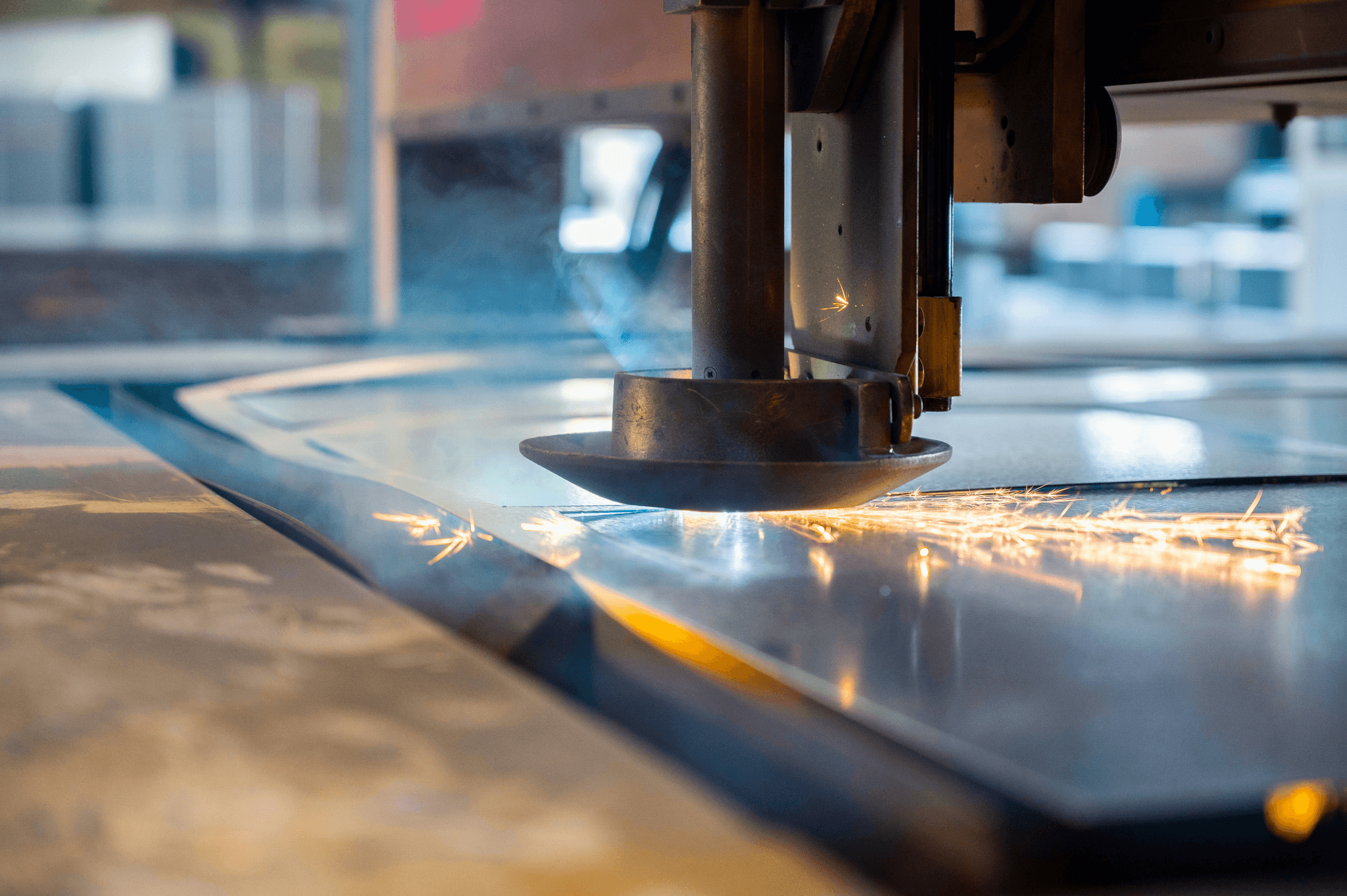

In the ever-evolving landscape of manufacturing, the rise of iron cutting laser machines has marked a significant shift in how industries approach metal fabrication. These advanced tools leverage cutting-edge technology to deliver precision and efficiency, reshaping the way we think about traditional metalworking processes. As businesses seek to enhance productivity and reduce waste, the adoption of laser cutting technology is becoming not just beneficial but essential.

The Rise of Iron Cutting Laser Machines

The popularity of industrial laser cutters has surged in recent years, driven by their unparalleled ability to cut through various metals with incredible accuracy. Iron cutting laser machines are at the forefront of this revolution, offering solutions that cater to both small-scale operations and large manufacturing facilities alike. With advancements in laser cutting technology, these machines are now more accessible than ever, allowing businesses to streamline their production lines while maintaining high-quality standards.

Key Benefits of Laser Cutting Technology

One of the standout advantages of using a metal cutting laser cutter is its remarkable precision; even intricate designs can be executed flawlessly without compromising on quality. Additionally, industrial laser cutting machines boast impressive speed and efficiency compared to traditional methods, significantly reducing turnaround times for projects. Furthermore, these versatile cutting machine lasers can handle a wide range of materials beyond iron, making them an invaluable asset for any modern workshop.

How to Choose the Right Laser Cutting Machine

Selecting the right laser cutting machine involves considering several factors tailored to your specific needs—such as material type and thickness you plan to work with. It's essential to evaluate features like power output and speed capabilities when comparing different models; this will ensure you invest in an industrial laser cutter that aligns with your production goals. Ultimately, understanding your requirements will help you make an informed decision that maximizes both efficiency and cost-effectiveness for your operations.

Understanding Laser Cutting Basics

Laser cutting technology has revolutionized the manufacturing landscape, offering unparalleled precision and efficiency. By utilizing high-powered lasers, industrial laser cutters can slice through various materials, including metals, with ease. This section will delve into the fundamentals of laser cutting, its various types, and the specific advantages of metal cutting laser cutters.

What is Laser Cutting Technology

At its core, laser cutting is a process that employs focused light beams to cut or engrave materials with extreme precision. The technology works by directing a high-intensity beam from a laser source onto the workpiece, which melts or vaporizes the material along a predetermined path. This method not only provides clean cuts but also minimizes waste and enhances overall production efficiency compared to traditional cutting methods.

The versatility of laser cutting makes it suitable for various applications across different industries. From intricate designs in art to robust components in automotive manufacturing, iron cutting laser machines can tackle diverse tasks effectively. Moreover, advancements in technology have led to more sophisticated industrial laser cutting machines that incorporate automation and smart features for improved performance.

Types of Laser Cutting Machines

The most common varieties include CO2 lasers and fiber lasers; each has its unique strengths tailored to specific applications. CO2 lasers are excellent for non-metal materials like wood or acrylic, while fiber lasers excel in metal processing due to their higher energy density.

Industrial laser cutters also vary based on their design and functionality—some are designed for flat sheet metal while others cater specifically to 3D objects or tubes. Additionally, there are hybrid systems that combine multiple technologies for enhanced versatility in metal processing tasks. When choosing an industrial laser cutting machine, consider factors such as material type and thickness as well as production volume requirements.

Advantages of Metal Cutting Laser Cutters

Metal cutting laser cutters offer several advantages that set them apart from traditional methods like plasma or mechanical cutting techniques. First and foremost is their precision; these machines can achieve tolerances as tight as ±0.001 inches (±0.025 mm), making them ideal for intricate designs requiring high accuracy—something essential in industries like aerospace or automotive manufacturing.

Speed is another significant benefit; industrial laser cutters operate at remarkable rates without compromising quality during cuts—allowing manufacturers to increase productivity significantly while reducing lead times on projects. Furthermore, these machines generate minimal heat-affected zones (HAZ), which means less distortion in the final product compared to other thermal processes.

Lastly, the versatility offered by metal cutting machine lasers cannot be overstated; they can efficiently process various types of metals—from stainless steel to aluminum—and even handle complex geometries with ease! This adaptability makes iron cutting laser machines an invaluable asset in modern manufacturing environments where flexibility is key.

Essential Features of Iron Cutting Laser Machines

These machines are designed to deliver superior performance in precision, speed, and versatility—qualities that are crucial for any industrial operation. Let's dive into what makes these machines stand out in the realm of laser cutting technology.

Precision and Accuracy in Cutting

Precision is the hallmark of any quality laser cutting machine, particularly when it comes to an iron cutting laser machine. The ability to achieve intricate designs with minimal tolerance is vital for industries that require exact specifications. With a metal cutting laser cutter, you can expect cuts that not only meet but often exceed industry standards, ensuring each component fits perfectly into your projects.

The advanced optics and control systems integrated into these industrial laser cutters allow for exceptional accuracy during the cutting process. This means less material waste and reduced costs—a win-win situation for manufacturers looking to optimize their operations. Ultimately, whether you're dealing with delicate components or heavy-duty materials, precision remains a key feature that defines the effectiveness of any industrial laser cutting machine.

Speed and Efficiency of Industrial Laser Cutters

In today’s fast-paced manufacturing environment, speed is king—and that's where an industrial laser cutter shines bright! An iron cutting laser machine offers rapid processing speeds that traditional methods simply can't match. This efficiency translates into shorter lead times and higher production rates, allowing businesses to meet customer demands without compromising quality.

Moreover, these machines are engineered for continuous operation with minimal downtime; they can handle high-volume tasks while maintaining consistent performance levels. The result? Increased productivity without sacrificing accuracy or detail in every cut made by your metal cutting machine laser. When time is money in manufacturing, investing in a high-speed industrial laser cutter can drastically improve your bottom line.

Versatility in Material Processing

Versatility is another essential feature that sets iron cutting laser machines apart from other types of equipment on the market today. These machines are not limited to just one type of material; they excel at processing various metals including steel, aluminum, brass, and more! This flexibility allows manufacturers to diversify their product offerings while maintaining high-quality standards across different applications.

Additionally, modern industrial laser cutting machines come equipped with adjustable settings tailored for different materials and thicknesses—making them adaptable to various project requirements without needing extensive reconfiguration or setup time. Whether you’re working on small intricate parts or larger structural components, a metal cutting laser cutter provides unparalleled adaptability throughout your production processes.

Key Technologies Behind Laser Cutting

In the realm of laser cutting, understanding the underlying technologies is crucial for selecting the right industrial laser cutter for your needs. The efficiency and effectiveness of an iron cutting laser machine are influenced significantly by its technological components. This section will delve into CO2 versus fiber laser technology, advanced control systems, and the integration with automation and robotics.

CO2 vs. Fiber Laser Technology

CO2 lasers have been a staple in industrial settings for decades, offering excellent beam quality and efficiency when cutting thicker materials like steel or aluminum. On the other hand, fiber lasers are gaining traction due to their higher energy efficiency and ability to cut reflective materials with ease, making them ideal for modern iron cutting laser machines.

The choice between these two types often boils down to your specific needs: if you require versatility across various metals, a fiber laser might be your best bet; however, if you're focused on thicker metals at high speeds, a CO2 system could serve you better. Additionally, maintenance costs can be lower for fiber lasers since they don’t require mirrors that need regular alignment or replacement like CO2 lasers do. Ultimately, understanding these differences can help you make an informed decision when investing in an industrial laser cutting machine.

Advanced Control Systems and Software

Advanced control systems play a pivotal role in enhancing the precision of any metal cutting machine laser setup. These systems enable operators to fine-tune parameters such as speed, power levels, and focus position with remarkable accuracy—resulting in cleaner cuts with less material wastage. Moreover, sophisticated software solutions allow for seamless integration of design files directly into the cutting machine's operations.

With features like real-time monitoring and automated adjustments based on feedback from sensors within the industrial laser cutter itself, users can achieve optimal results consistently over time. This level of sophistication not only boosts productivity but also minimizes downtime caused by manual errors or miscalculations during operation. As industries continue evolving toward higher standards of quality control and efficiency, investing in a state-of-the-art control system becomes increasingly essential.

Integration with Automation and Robotics

The integration of automation and robotics into iron cutting laser machines marks a significant leap forward in manufacturing capabilities. By automating routine tasks such as loading materials or unloading finished products from the metal cutting machine laser setup, companies can significantly enhance productivity while reducing labor costs associated with manual handling processes. This not only streamlines operations but also allows skilled workers to focus on more complex tasks that require human intervention.

Moreover, robotic arms equipped with advanced sensors can work alongside industrial laser cutters to ensure precise placement during multi-step processes or intricate designs that demand high accuracy levels throughout production runs—making it easier than ever to achieve consistent results across various projects! As industries embrace this trend toward automation coupled with powerful industrial laser cutting machines; they are setting themselves up for long-term success driven by innovation.

Maintenance and Support for Laser Cutting Machines

When it comes to keeping your iron cutting laser machine in top-notch condition, maintenance plays a crucial role. Regular upkeep not only extends the lifespan of your industrial laser cutter but also ensures optimal performance during metal cutting operations. Ignoring routine maintenance can lead to costly downtime and repairs, which is the last thing any business wants.

Importance of Routine Maintenance

Routine maintenance for your laser cutting machine is essential for several reasons. First, it helps maintain precision and accuracy—key attributes of any reliable industrial laser cutting machine. Second, regular checks can prevent minor issues from escalating into major problems, saving you both time and money in the long run.

Moreover, an iron cutting laser machine that undergoes consistent maintenance will operate more efficiently, resulting in faster production times and reduced waste material. This efficiency translates directly into cost savings for businesses that rely on metal cutting laser cutters for their manufacturing processes. Ultimately, a well-maintained industrial laser cutter is a more profitable investment.

Available Support from Kiant Machinery

Kiant Machinery offers comprehensive support services tailored specifically for users of their industrial laser cutting machines. From initial setup to ongoing maintenance plans, they provide the resources needed to ensure your metal cutting machine laser operates smoothly at all times. Their team of experts is just a phone call away when you need assistance or advice regarding your iron cutting laser machine.

In addition to technical support, Kiant Machinery provides training sessions that empower users to maximize the capabilities of their equipment effectively. Understanding how to operate an industrial laser cutter proficiently can enhance productivity while minimizing errors during operation. With Kiant's support at your fingertips, you'll feel confident navigating any challenges that may arise.

Troubleshooting Common Issues

Even with routine maintenance and exceptional support from Kiant Machinery, issues can still crop up with an industrial laser cutter from time to time. Common problems include misalignment or inconsistent cuts; however, these are often straightforward to resolve with some basic troubleshooting steps. First things first: always consult the user manual before diving into repairs or adjustments on your metal cutting laser cutter.

If you find yourself facing persistent issues despite following recommended practices, don’t hesitate to reach out for professional help from Kiant's support team—they’re trained specifically in addressing concerns related to their products like the iron cutting laser machine you own! Remember that timely intervention can prevent small glitches from turning into bigger headaches down the line.

Future Trends in Laser Cutting Technology

The landscape of laser cutting technology is evolving rapidly, with innovations that promise to enhance efficiency and versatility. As industries demand more precision and speed, the development of advanced iron cutting laser machines is paving the way for the future. These innovations not only improve operational capabilities but also redefine what we can achieve with industrial laser cutting machines.

Innovations in Laser Cutting Machines

One of the most exciting innovations in laser cutting technology is the advent of high-powered fiber lasers that significantly increase cutting speeds while maintaining quality. The latest models of metal cutting laser cutters are equipped with advanced optics and beam management systems, allowing them to handle thicker materials with ease. Additionally, improvements in user interfaces and automation features make modern industrial laser cutters more intuitive and easier to operate than ever before.

These advancements mean that businesses can expect higher throughput from their iron cutting laser machines without sacrificing precision. The integration of real-time monitoring systems also ensures consistent performance, reducing downtime caused by mechanical failures or misalignments. As manufacturers continue to push the boundaries of what these machines can do, we can anticipate even more groundbreaking developments on the horizon.

The Growing Role of AI in Manufacturing

Artificial Intelligence (AI) is becoming a game-changer in manufacturing processes, particularly within the realm of industrial laser cutting machines. By leveraging AI algorithms, these machines can optimize their operations based on real-time data analysis, leading to improved accuracy and reduced waste during metal processing tasks. This not only enhances productivity but also allows for predictive maintenance schedules that minimize unexpected breakdowns.

Moreover, AI-driven software enables operators to simulate cuts before executing them on actual materials, ensuring optimal paths are chosen for efficiency and minimal resource use. As machine learning continues to evolve, we will likely see even smarter metal cutting machine lasers capable of adapting their settings based on previous job performance or material characteristics automatically. This transformative shift towards AI integration promises a future where human error is significantly reduced while maximizing output.

Sustainability in Laser Cutting Processes

Sustainability has become a crucial focus across all industries, and laser cutting technology is no exception. Modern iron cutting laser machines are designed with energy efficiency in mind; they consume less power compared to traditional methods while delivering superior results. Additionally, advancements in material recycling processes allow for better utilization of scrap material generated during cuts.

The eco-friendly aspect doesn’t stop there; many new industrial laser cutters utilize gases that have a lower environmental impact than those used previously. Furthermore, companies are increasingly adopting practices such as closed-loop water cooling systems to minimize water usage during operations—a win-win for both business efficiency and environmental stewardship. As sustainability becomes an integral part of manufacturing strategies worldwide, it’s clear that metal cutting processes will continue evolving toward greener practices.

Conclusion

In the ever-evolving landscape of manufacturing, iron cutting laser machines have emerged as game-changers. Their ability to deliver precision and efficiency makes them indispensable in various industries. As we wrap up our exploration, let's focus on maximizing efficiency, choosing the right machinery, and what the future holds for laser cutting technology.

Maximizing Efficiency with Iron Cutting Lasers

To truly maximize efficiency with an iron cutting laser machine, understanding its capabilities is crucial. These machines not only provide high-speed processing but also ensure minimal waste through precise cuts—an essential factor in today's cost-conscious market. By integrating advanced software and automation, businesses can streamline their operations and enhance productivity like never before.

Investing in an industrial laser cutter means investing in a future where speed meets accuracy. The versatility of a metal cutting laser cutter allows you to tackle various projects without needing multiple machines, saving both time and resources. Ultimately, optimizing your workflow with a cutting machine laser will lead to significant improvements in output quality and operational costs.

Choosing Kiant Machinery for Your Needs

When it comes to selecting the right equipment for your business, Kiant Machinery stands out as a reliable choice for industrial laser cutting machines. Their extensive range of products is designed to meet diverse needs—whether you're looking for precision or speed in your metal cutting machine laser operations. Plus, their commitment to customer support ensures that you’re never left hanging when challenges arise.

Kiant Machinery not only provides top-notch iron cutting laser machines but also offers tailored solutions based on your specific requirements. This personalized approach helps businesses maximize their investment while ensuring they have access to the latest technology available in the market today. With Kiant by your side, you can rest assured that you're equipped with the best tools for success.

The Future of Laser Cutting in Industry

As we look ahead into the future of industrial laser cutting technology, it's clear that innovation will continue to drive this field forward at breakneck speed. Emerging trends like artificial intelligence are set to revolutionize how these systems operate—enhancing their capabilities beyond what we can currently imagine. Expect smarter machines that can self-optimize based on real-time data inputs from production lines.

Sustainability is another critical trend shaping the future landscape of metal cutting processes; manufacturers are increasingly seeking eco-friendly solutions without compromising performance or quality standards. This shift towards greener technologies will likely influence how businesses approach their manufacturing strategies moving forward—leading us toward a more sustainable industrial environment overall.

In conclusion, embracing advanced iron cutting laser technology today positions companies at the forefront of tomorrow's manufacturing innovations—a thrilling prospect indeed!