Introduction

In the world of manufacturing and fabrication, precision is paramount, and a sheet metal laser cutter has become an indispensable tool. Whether you're a small business owner or part of a large industrial operation, investing in a cutting machine laser can significantly enhance efficiency and accuracy in your projects. With the rise of fiber laser technology, choosing the right laser cutting machine has never been more crucial for staying competitive.

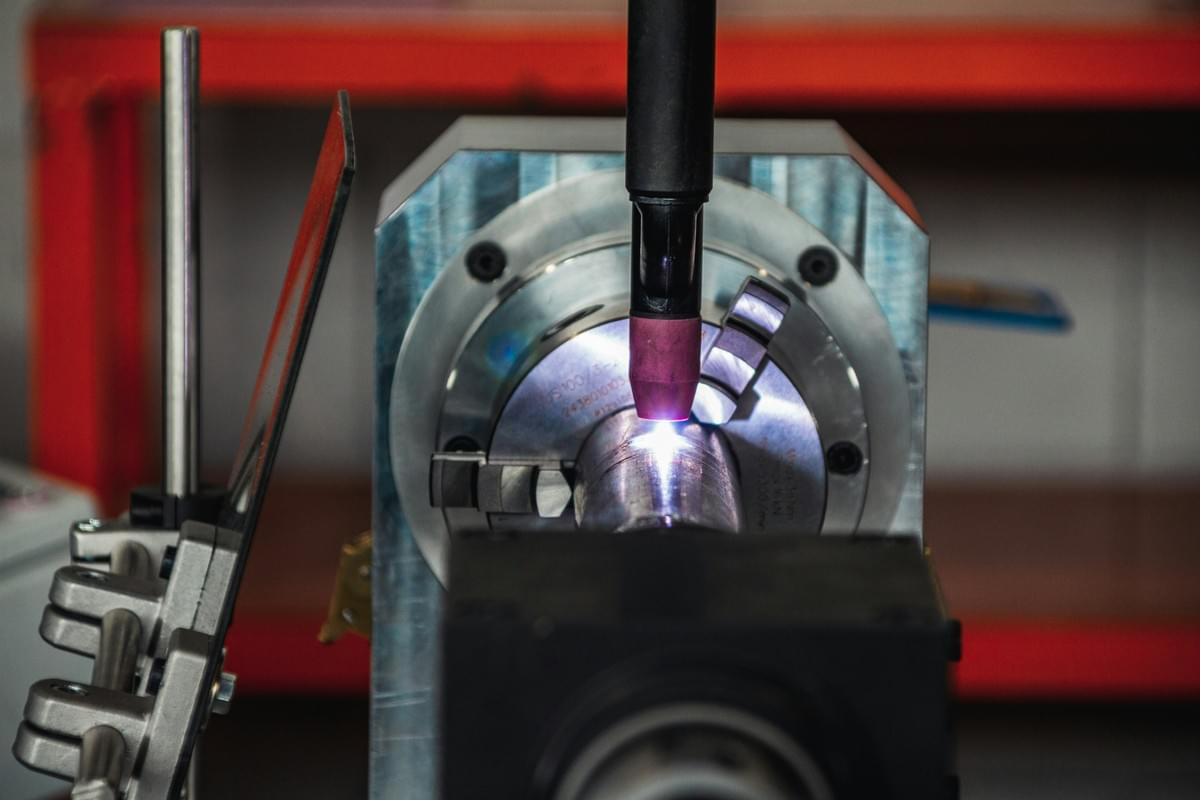

Why Choose a Sheet Metal Laser Cutter

Unlike traditional methods that may leave rough edges or require extensive finishing work, laser cutting provides clean and precise cuts every time. This level of accuracy not only saves time but also reduces material waste, making it an ideal choice for anyone looking to optimize their operations.

Benefits of Fiber Laser Technology

Fiber lasers are revolutionizing the industry with their unparalleled speed and performance compared to CO2 lasers. They offer higher energy efficiency and require less maintenance due to fewer moving parts, translating into lower operational costs over time. By utilizing fiber laser technology in your wholesale iron sheet laser cutting machine, you can achieve faster turnaround times while maintaining exceptional quality in your cuts.

Key Features to Look For

When selecting a laser machinery system for your needs, certain features should be at the forefront of your decision-making process. Look for options that offer high-speed cutting capabilities along with advanced software for easy operation and integration into existing workflows. Additionally, consider machines with robust safety features and excellent customer support to ensure you get the most out of your investment in a cutting machine laser.

Top Manufacturers of Laser Cutting Machines

Selecting the right manufacturer is crucial for ensuring you get a reliable and efficient cutting machine laser that meets your specific needs. In this section, we’ll explore some of the top players in the industry—Kiant Machinery, Trumpf, and Bystronic—each known for their unique contributions to laser machinery.

Kiant Machinery: Leading the Charge

Kiant Machinery has carved out a reputation as a leader in fiber laser technology, particularly when it comes to wholesale iron sheet laser cutting machines. Their commitment to quality and precision makes them a go-to choice for businesses looking to enhance their cutting capabilities. With advanced features like high-speed processing and automated operations, Kiant's machines are designed to meet the demands of modern manufacturing environments.

Not only does Kiant focus on performance, but they also prioritize user-friendly interfaces that simplify operation for technicians at any skill level. Their range of laser cutting machines caters to various industries, ensuring that you can find a model tailored specifically for your needs. If you’re considering investing in a fiber laser machine, Kiant Machinery should definitely be on your radar.

Trumpf: Innovation in Cutting Solutions

Trumpf is synonymous with innovation in the world of laser cutting machines. Known for their pioneering spirit, they have continuously developed solutions that push the envelope on speed and efficiency in laser cutting applications. Their state-of-the-art fiber lasers are particularly renowned for their energy efficiency and minimal maintenance requirements—features that make them highly sought after by companies looking to optimize production processes.

What sets Trumpf apart is not just their technology but also their dedication to customer service and support. They offer extensive training programs and resources that ensure users can maximize their investment in Trumpf's cutting machine lasers effectively. If you're serious about entering or enhancing your position in industries like automotive or aerospace with top-notch precision equipment, look no further than Trumpf.

Bystronic: Precision Meets Performance

Their fiber lasers are engineered with advanced optics and control systems that allow for incredibly accurate cuts even at high speeds—perfectly suited for intricate designs often required by fabricators today. This level of precision ensures minimal waste material during production runs while maintaining cost-effectiveness.

Moreover, Bystronic’s commitment extends beyond just providing excellent equipment; they also focus on integrating automation into their systems which enhances overall productivity even further. This makes them an ideal choice if you're looking into wholesale iron sheet laser cutting machines with added features like automatic loading systems or intelligent software solutions that streamline operations seamlessly.

Understanding Fiber Laser vs. CO2 Laser

In the world of laser cutting, two technologies have emerged as the frontrunners: fiber lasers and CO2 lasers. Each has its unique advantages and applications, making them suitable for different industries and tasks. Understanding these differences is crucial when selecting a cutting machine laser that aligns with your specific needs.

Fiber Lasers: The New Frontier

Fiber lasers are revolutionizing the laser cutting landscape with their exceptional speed and efficiency. Utilizing solid-state technology, these lasers produce a beam that is highly concentrated, allowing for precise cuts in various materials, including metals like steel and aluminum. The rise of fiber laser technology has made it a favorite among manufacturers looking for a wholesale iron sheet laser cutting machine that delivers both performance and cost-effectiveness.

One of the standout features of fiber lasers is their ability to cut through thicker materials faster than traditional methods. This capability not only enhances productivity but also reduces operational costs over time—a critical consideration for businesses aiming to optimize their manufacturing processes. As industries continue to evolve, fiber lasers are becoming essential tools in modern fabrication shops.

Additionally, fiber laser machinery typically requires less maintenance than CO2 systems due to fewer moving parts and no gas requirements. This reliability translates into reduced downtime, ensuring that your operations run smoothly without unexpected interruptions. With these advantages combined, it's clear why many companies are making the switch to fiber technology.

CO2 Lasers: Traditional Powerhouses

On the other side of the spectrum lies CO2 lasers—long-standing champions in the world of laser cutting machinery. These systems have been around for decades and have proven their mettle in various applications from engraving to cutting softer materials like wood and plastics. While they may not be as fast as their fiber counterparts when it comes to metalwork, they still hold significant value in specific niches.

CO2 lasers excel at delivering high-quality cuts with excellent edge finishes on non-metal materials, making them indispensable in signage production or artistic endeavors where detail matters most. Their versatility allows users to tackle a broad range of projects using one machine—an appealing factor for smaller shops or those just starting out with laser technology.

However, it's important to note that while CO2 machines can handle certain tasks effectively, they may come with higher operational costs due to gas consumption and more frequent maintenance needs compared to fiber systems. In choosing between these two technologies, understanding your primary applications will help you make an informed decision about which type of laser machine fits best into your workflow.

Choosing the Right Technology for Your Needs

Selecting between a fiber laser and a CO2 laser ultimately boils down to your specific requirements and budget constraints within your industry context. If you're primarily focused on metal fabrication or require high-speed processing capabilities—especially when dealing with thicker materials—a wholesale iron sheet laser cutting machine utilizing fiber technology would be an ideal choice.

Conversely, if your projects lean towards softer materials or intricate designs requiring detailed engraving work, investing in a CO2 system might serve you better despite its limitations on metalwork efficiency. Evaluating factors such as material types you'll be working with, expected production volumes, and long-term operational costs will guide you toward making an optimal selection.

Ultimately, whether you opt for advanced fiber technology or stick with tried-and-true CO2 systems should align closely with your business goals and project demands—ensuring that every cut counts toward greater productivity and profitability in your operations.

Applications of Laser Cutting in Industry

Laser cutting technology has revolutionized various industries by enhancing precision, efficiency, and customization. From automotive assembly lines to intricate aerospace components, the versatility of laser machinery is unmatched. Let’s explore how different sectors are leveraging this cutting-edge technology to meet their unique demands.

Automotive Industry: Efficiency on the Line

In the automotive industry, laser cutting plays a pivotal role in streamlining production processes. Manufacturers utilize fiber laser systems for their speed and accuracy, enabling them to cut through various materials with minimal waste. The wholesale iron sheet laser cutting machine is particularly popular here, as it allows for high-volume production while maintaining exceptional quality standards.

Laser cutting machines also facilitate complex designs that traditional methods struggle to achieve. This capability not only enhances vehicle aesthetics but also contributes to lightweight structures that improve fuel efficiency. In an industry where every second counts on the assembly line, investing in advanced laser technology can significantly boost productivity.

Moreover, maintenance requirements for these cutting machines are generally lower compared to conventional methods. This reliability means fewer downtimes and more time spent producing high-quality automotive parts that meet stringent safety regulations.

Aerospace Sector: Cutting Edge Solutions

The aerospace sector demands precision and reliability like no other industry, making fiber lasers an ideal choice for manufacturing aircraft components. Laser cutting technology allows for intricate designs and tight tolerances necessary for parts such as fuselage sections and engine mounts. With a wholesale iron sheet laser cutting machine in play, manufacturers can efficiently process large sheets of material into complex shapes without compromising quality.

Additionally, the ability to cut lightweight materials like aluminum and titanium with ease helps reduce overall aircraft weight—an essential factor in fuel efficiency and performance. The precision offered by laser machinery ensures that even the smallest components are crafted with meticulous attention to detail.

As regulations tighten around safety standards in aviation, adopting advanced technologies like laser cutting becomes imperative for compliance while maintaining competitive advantages in production costs and timelines.

Signage and Fabrication: Customization Made Easy

When it comes to signage and fabrication, customization is key—and that's where laser machines truly shine! Businesses rely on laser cutting technology to create bespoke signs that stand out from the crowd due to their intricate designs and vibrant finishes. Whether it’s a simple logo or a complex architectural feature, a reliable laser cutting machine can handle any request with finesse.

The flexibility of fiber lasers allows fabricators to work with various materials such as wood, acrylics, metals, and more—perfect for creating eye-catching displays or functional signage solutions tailored specifically for clients’ needs. By utilizing wholesale iron sheet laser cutting machines alongside other equipment in their arsenal, businesses can streamline their operations while offering unparalleled customization options.

Furthermore, quick turnaround times are essential in this fast-paced market; hence investing in efficient laser machinery ensures projects are completed promptly without sacrificing quality or creativity.

Evaluating Performance and Efficiency

When investing in a laser cutting machine, performance and efficiency are paramount. The right machine can greatly enhance productivity while minimizing costs. Understanding key aspects such as speed, accuracy, cost-effectiveness, and maintenance will help you make an informed decision.

Speed and Accuracy in Cutting

Speed is often the name of the game in laser cutting, especially in high-demand environments like manufacturing or fabrication shops. A top-tier fiber laser can cut through materials at lightning speed without compromising on precision, making it ideal for applications requiring intricate designs or tight tolerances. The accuracy of a cutting machine laser is vital; even minor deviations can lead to waste and increased operational costs.

With advancements in technology, modern laser machinery offers remarkable consistency across various materials, including iron sheets. This means that whether you're working with thick or thin stock, you can expect reliable results every time you fire up your wholesale iron sheet laser cutting machine. Ultimately, investing in a fast and accurate laser cutting machine allows businesses to stay competitive while delivering high-quality products.

Cost-Effectiveness of Cutting Machine Laser

Cost-effectiveness is another crucial factor when evaluating your options for a laser cutting machine. While initial investments can be significant—especially for advanced fiber lasers—the long-term savings from reduced material waste and lower operational costs often outweigh these upfront expenses. Efficient energy consumption also plays a role; fiber lasers typically use less power compared to traditional CO2 lasers.

Moreover, the versatility of modern laser machines means they can handle various tasks without needing multiple machines for different applications. This adaptability not only saves on capital expenditures but also reduces the need for extensive training on multiple types of equipment. When considering your budget for a wholesale iron sheet laser cutting machine, remember that cost-effectiveness encompasses both immediate purchase price and ongoing operational expenses.

Maintenance Requirements and Reliability

Maintenance requirements are essential to consider when choosing your next laser cutting solution. Fiber lasers generally require less maintenance than their CO2 counterparts due to fewer moving parts and longer-lasting components—this translates into less downtime and greater reliability over time. By selecting a dependable cutting machine laser model that minimizes maintenance needs, you can maximize productivity.

Additionally, ensuring that your chosen equipment has readily available parts will further enhance reliability; downtime waiting for repairs or replacements can be detrimental to any operation's bottom line. Regular servicing by qualified technicians will keep your equipment running smoothly while extending its lifespan significantly—a must when investing in expensive machinery like fiber lasers or other types of laser machinery used for industrial applications.

In summary, evaluating performance through speed and accuracy alongside cost-effectiveness and maintenance needs will guide you toward making an informed decision about your next investment in a wholesale iron sheet laser cutting machine.

Where to Buy and Find Deals

Finding the right place to buy a wholesale iron sheet laser cutting machine can be just as important as choosing the machine itself. With numerous options available, it’s essential to weigh the pros and cons of each source. Whether you're looking for competitive prices or specialized support, understanding your buying options will help you make an informed decision.

Wholesale Iron Sheet Laser Cutting Machine Options

When searching for a wholesale iron sheet laser cutting machine, consider reaching out to manufacturers directly. Many manufacturers offer bulk purchasing options that can significantly reduce costs, especially if you're planning to buy multiple machines or accessories. Additionally, attending industry trade shows can connect you with suppliers offering exclusive deals on laser cutting machinery.

Another avenue is exploring online marketplaces specializing in industrial equipment where you can find competitive pricing on various models of laser cutting machines. These platforms often feature user reviews and ratings that provide valuable insights into performance and reliability before making your purchase. Don’t forget about local wholesalers who may have stock available at discounted rates; sometimes the best deals are hidden in plain sight!

Online Retailers vs. Local Distributors

The debate between online retailers and local distributors for purchasing a laser cutting machine is ongoing among buyers in the industry. Online retailers typically offer a broader selection of products, including fiber lasers and CO2 lasers, often at lower prices due to reduced overhead costs. However, local distributors can provide personalized service, allowing you to see the machinery firsthand and receive tailored advice based on your specific needs.

Moreover, dealing with local distributors means you may have easier access to after-sales support and maintenance services for your cutting machine laser. This relationship can be crucial when troubleshooting issues or needing replacement parts quickly without waiting for shipping from an online retailer. Ultimately, it boils down to weighing convenience against personalized service – both avenues have their merits!

Tips for Getting the Best Prices

To snag the best prices on a wholesale iron sheet laser cutting machine, timing is everything! Keep an eye out for seasonal sales events or manufacturer promotions that could save you a significant amount of money on your purchase. Additionally, don’t hesitate to negotiate with sellers – many are willing to provide discounts if they believe it will lead to a sale.

Another smart strategy is leveraging group buying power; teaming up with other businesses looking for similar equipment might secure bulk discounts from suppliers eager to make larger sales volumes. Also consider checking multiple sources before committing; comparing prices across different platforms ensures you're getting the most bang for your buck when investing in laser machinery!

Conclusion

In wrapping up our exploration of laser cutting technology, it's clear that the choice of a laser cutting machine is a significant investment for any business. Whether you’re looking for a wholesale iron sheet laser cutting machine or exploring options for fiber laser models, understanding your needs is paramount. The benefits of fiber lasers, coupled with the performance and efficiency they offer, make them an attractive option in today’s competitive landscape.

Summary of Key Considerations

When selecting a laser cutting machine, consider factors such as speed, accuracy, and maintenance requirements. The efficiency of a cutting machine laser can significantly impact your production line's output and cost-effectiveness. Additionally, weighing the pros and cons of fiber lasers versus traditional CO2 lasers will help you make an informed decision tailored to your specific applications.

Future Trends in Laser Cutting Technology

The future of laser cutting technology is bright and filled with innovations that promise to enhance productivity and precision further. Advancements in automation and artificial intelligence are set to revolutionize how we approach tasks like programming and operation within laser machinery. Moreover, the demand for eco-friendly solutions will likely drive more manufacturers toward developing energy-efficient models that utilize fiber laser technology.

Final Thoughts on Your Cutting Machine Journey

Embarking on your journey to acquire a new laser cutting machine can be both exciting and daunting. As you navigate through various options—be it wholesale iron sheet laser cutting machines or advanced fiber lasers—stay focused on your unique needs and budget constraints. With the right knowledge at hand, you're well-equipped to make an informed choice that aligns perfectly with your business goals.