Introduction

In the ever-evolving landscape of metal manufacturing, roll forming machinery stands out as a crucial player. This technology not only enhances production efficiency but also ensures precision in creating components for various applications, particularly in the roofing industry. As businesses seek to optimize their operations, understanding the significance of metal roof forming machines for sale becomes essential.

Why Roll Forming Machinery Matters

Roll forming machinery is integral to modern manufacturing, offering a streamlined approach to producing high-quality metal products. With its ability to create complex shapes and profiles with minimal waste, this equipment is vital for companies aiming to improve their bottom line. The demand for durable and efficient roll forming products continues to rise, making it imperative for manufacturers to invest in reliable machinery.

Exploring Metal Manufacturing Trends

The metal manufacturing sector is witnessing exciting trends driven by advancements in technology and changing consumer demands. From automation integration to sustainable practices, these trends are reshaping how businesses operate and compete in the market. As more companies look for metal roofing machines for sale that align with these innovations, staying informed about industry shifts is key.

Your Guide to Online Shopping for Equipment

Navigating the online marketplace for roll forming machinery can be overwhelming without a solid strategy. Knowing where to find reputable sellers and understanding product specifications are crucial steps toward making an informed purchase decision. This guide aims to simplify your shopping experience by highlighting essential factors when searching for a metal roll forming machine that meets your needs.

Understanding Roll Forming Machinery

When it comes to metal manufacturing, roll forming machinery stands out as a crucial player in producing high-quality components efficiently. This innovative process involves continuously shaping metal sheets into desired profiles, making it ideal for various applications, especially in the construction sector. Whether you're looking for a metal roofing machine for sale or exploring other roll forming products, understanding the fundamentals can significantly impact your purchasing decision.

Basics of Roll Forming Process

The roll forming process begins with feeding a flat strip of metal into a series of rollers that gradually shape it into the desired profile. Each roller is meticulously designed to bend and form the material progressively, ensuring precision and consistency throughout production. This method not only enhances efficiency but also reduces waste compared to traditional manufacturing techniques, making roll forming machinery an attractive option for businesses aiming to optimize their operations.

Various Types of Roll Forming Machinery

Roll forming machinery comes in various types tailored to meet specific needs within the metal manufacturing industry. From standard metal roll forming machines that produce simple shapes to more advanced systems capable of creating complex profiles, there’s a machine suited for every application. If you’re on the hunt for a metal roofing machine for sale, you’ll find options ranging from portable models perfect for smaller projects to heavy-duty machines designed for large-scale production.

Benefits of Using Roll Forming Products

Investing in roll forming products offers numerous advantages that can elevate your manufacturing capabilities. One significant benefit is the ability to produce high volumes with minimal labor costs while maintaining exceptional quality standards—an essential factor in today’s competitive market. Additionally, products made through this method often exhibit superior strength and durability, making them ideal choices for applications like roofing where longevity is paramount.

Top Manufacturers for Roll Forming Equipment

When it comes to roll forming machinery, the market is filled with a variety of manufacturers that cater to the growing demands of metal manufacturing. Each brand offers unique features and capabilities, making it essential for buyers to understand their options. In this section, we'll explore some of the top manufacturers in the industry, starting with Kiant Machinery, a name synonymous with quality and innovation.

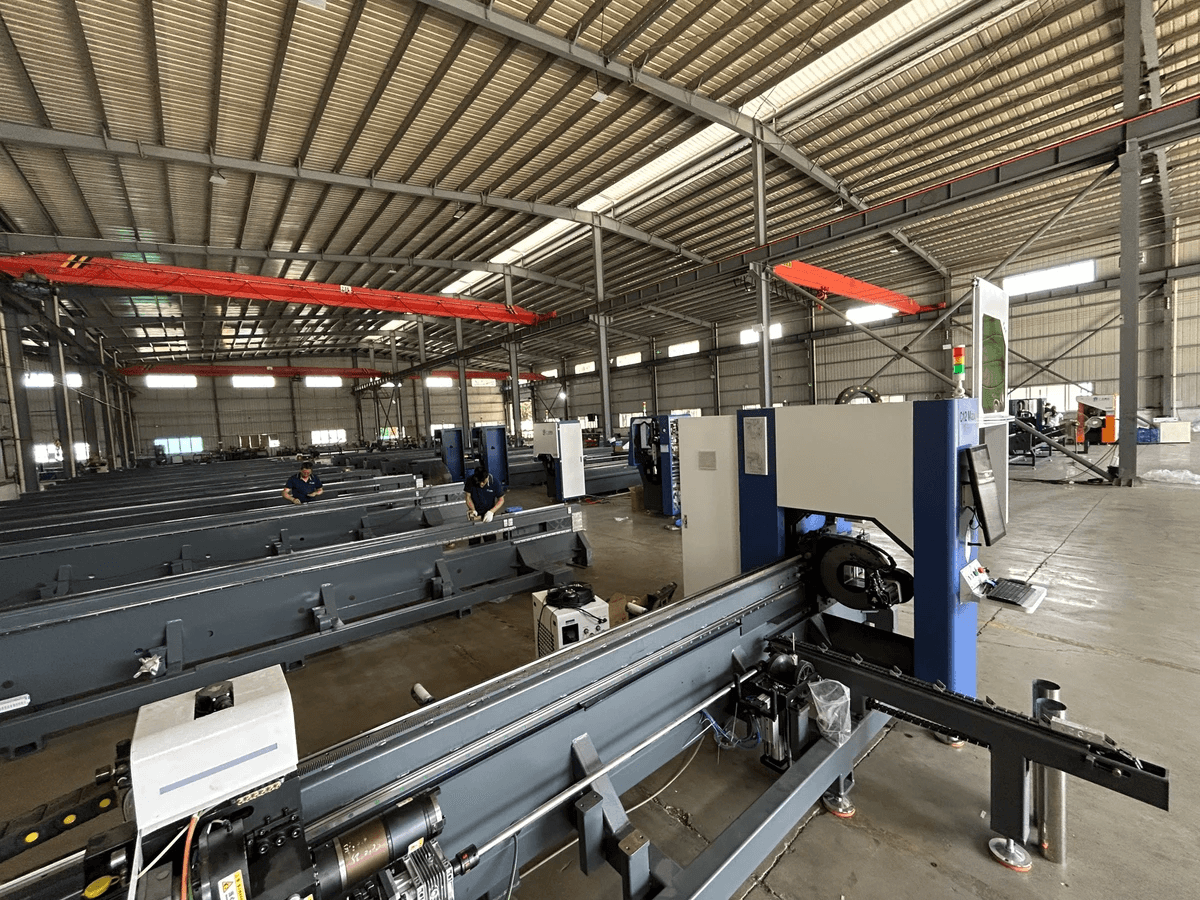

Kiant Machinery: Leading the Industry

Kiant Machinery has established itself as a leader in roll forming products, particularly in metal roofing machines. Known for their robust designs and cutting-edge technology, they offer a range of metal roof forming machines for sale that meet diverse industry needs. Their commitment to customer satisfaction and product reliability makes them a go-to choice for businesses looking to invest in high-quality roll forming machinery.

One standout feature of Kiant Machinery is their focus on customization; they understand that different projects require different solutions. Whether you need a standard metal roll forming machine or something tailored specifically for your operation, Kiant has you covered. With an impressive track record and numerous satisfied clients, it's no wonder they are often at the forefront of discussions about metal manufacturing equipment.

Other Notable Names in Metal Roofing Machines

While Kiant Machinery takes center stage, several other notable brands also make waves in the world of roll forming machinery. Companies like Bradbury Group and Samco Machinery have built strong reputations by delivering reliable and efficient metal roofing machines for sale across various markets. These manufacturers are recognized for their innovative approaches and dedication to producing durable equipment that stands up to rigorous use.

In addition to these well-known brands, emerging players are also entering the market with fresh ideas and competitive pricing on metal roll forming machines. This influx of new companies fosters healthy competition while driving technological advancements within the sector. Buyers now have more choices than ever when selecting machinery tailored to their specific needs.

Comparative Analysis of Different Brands

When comparing various brands offering roll forming equipment, several factors come into play: price point, durability, technology integration, and after-sales support are just a few considerations worth noting. While Kiant Machinery excels in customization options and customer service, other brands may offer superior pricing or faster delivery times on standard models like metal roofing machines or general-purpose metal roll forming machines.

It's crucial for potential buyers to conduct thorough research before making any commitments; reading reviews can provide insight into each manufacturer’s strengths and weaknesses related to specific models or types of machinery available on the market today. Additionally, attending trade shows or industry events can give you hands-on experience with different products before deciding which brand aligns best with your business goals.

Ultimately, investing time into understanding these top manufacturers will pay off when it comes time to purchase your next piece of roll forming machinery—ensuring you find not just any machine but one that elevates your production capabilities significantly!

Key Features to Look for in Equipment

When diving into the world of roll forming machinery, it’s essential to consider various features that can significantly impact your production efficiency and product quality. Whether you're eyeing a metal roofing machine for sale or exploring other roll forming products, understanding these key specifications will help you make an informed decision. Let’s break down what you should look for in a metal roll forming machine.

Essential Specifications for Metal Roofing Machine

The essential specifications of a metal roofing machine can make or break your manufacturing process. First, pay attention to the thickness and width capacity; different projects may require varying material sizes, so flexibility is crucial. Additionally, consider the speed of operation—higher speeds can lead to increased productivity but ensure that quality isn’t compromised in the pursuit of efficiency.

Another vital specification is the power source; hydraulic versus electric options each have their pros and cons depending on your facility's needs. Moreover, check if the machine offers programmable controls or automation features—these enhancements can streamline operations and reduce labor costs significantly. Ultimately, ensuring these essential specifications align with your production goals will set you up for success with your new roll forming machinery.

Importance of Durability and Reliability

Durability and reliability are paramount when investing in any piece of equipment, particularly in metal manufacturing where machinery endures constant wear and tear. A robust metal roofing machine for sale should be constructed from high-quality materials that withstand harsh working conditions while delivering consistent performance over time. Choosing reliable equipment not only minimizes downtime but also enhances safety on the production floor.

Furthermore, consider manufacturers who offer warranties or guarantees on their roll forming products; this indicates confidence in their machinery's durability. Regular maintenance is another aspect to ensure longevity—opt for machines that are easy to service or come with comprehensive support services from manufacturers like Kiant Machinery. In essence, prioritizing durability and reliability will safeguard your investment in roll forming machinery against unexpected failures.

Innovations in Roll Forming Technology

The landscape of roll forming technology is continuously evolving, offering exciting innovations that enhance efficiency and product quality in metal manufacturing processes. For instance, advancements such as servo-driven systems allow for precise control over speed and torque during operations—a game-changer when producing intricate designs with a metal roof forming machine for sale. These innovations not only improve output but also reduce waste by optimizing material usage throughout the process.

Another notable trend is the integration of smart technology into roll forming machines; think IoT capabilities that enable real-time monitoring and diagnostics via mobile devices or computers. This level of connectivity ensures manufacturers can promptly address issues before they escalate into costly downtimes or defects in products like metal roofing sheets. Embracing these technological advancements means staying ahead of competitors while maximizing productivity with modern roll forming products.

Where to Shop Online for Machinery

In the digital age, finding the right roll forming machinery has never been easier. With a plethora of online platforms dedicated to metal manufacturing equipment, you can shop from the comfort of your office or workshop. Whether you're searching for a metal roof forming machine for sale or specific roll forming products, knowing where to look is essential.

Evaluating Customer Reviews and Ratings

Customer reviews are invaluable when shopping for any type of machinery, including metal roofing machines for sale. They provide real-world insights into performance, durability, and customer service experiences that can help guide your decision-making process. Look specifically for feedback on the reliability of the roll forming machinery and how well it meets production expectations.

Be wary of overly positive reviews; they may be biased or incentivized by sellers looking to boost their ratings artificially. Instead, focus on balanced reviews that highlight both strengths and weaknesses of specific models—this will give you a clearer picture of what to expect from your potential purchase. A thorough evaluation will empower you to choose a metal roll forming machine that aligns with your operational goals.

Tips for Finding the Best Deals

Finding great deals on roll forming machinery doesn't have to feel like searching for a needle in a haystack; it just requires some savvy shopping strategies! Start by subscribing to newsletters from reputable suppliers; they often share exclusive discounts or promotions on their latest metal roofing machines for sale. Additionally, consider joining industry forums where members frequently post about sales events or clearance items—it's an excellent way to snag bargains!

Timing is also crucial; many companies offer significant discounts during trade shows or end-of-season sales as they clear out older inventory in favor of new models. Don't hesitate to negotiate prices directly with sellers—many are willing to work with you if they see you're serious about making a purchase! By employing these tips, you'll increase your chances of landing high-quality equipment at competitive prices.

After-Sales Support and Maintenance

Investing in roll forming machinery is just the beginning of your journey in metal manufacturing. After purchasing your equipment, proper after-sales support and maintenance become crucial to ensure long-term performance and efficiency. A reliable support system can help you troubleshoot issues, optimize operations, and extend the lifespan of your metal roofing machine for sale.

Importance of Service and Support

When you invest in a metal roll forming machine, having access to excellent service and support is essential. This ensures that if any issues arise, you won't be left stranded without assistance. Prompt support can minimize downtime, allowing you to keep production running smoothly while maximizing the benefits of your roll forming products.

Moreover, good after-sales service often includes regular check-ups or maintenance schedules that can prevent minor issues from becoming major headaches down the line. Manufacturers like Kiant Machinery understand this importance and strive to provide comprehensive support for their clients. With a solid service framework in place, businesses can focus on growth rather than worrying about equipment failures.

Training Options Offered by Kiant Machinery

Kiant Machinery goes above and beyond by offering training options for users of their metal roofing machines for sale. Understanding how to operate roll forming machinery efficiently not only boosts productivity but also enhances safety within the workplace. Their training programs cover everything from basic operation techniques to advanced troubleshooting skills.

This investment in training ensures that all employees are well-versed in using the machinery effectively, which translates into fewer errors during production runs. Plus, trained operators are more confident when handling complex tasks associated with metal manufacturing processes. By equipping your team with the right knowledge, you set them—and your business—up for success.

Long-term Maintenance Tips for Machinery

To keep your roll forming products performing at their best over time, implementing a robust maintenance plan is essential. Regularly scheduled inspections will help identify potential issues before they escalate into costly repairs or downtime scenarios with your metal roll forming machine. Simple tasks like cleaning components or checking fluid levels can make a significant difference in longevity.

Additionally, adhering to manufacturer guidelines regarding lubrication schedules and part replacements ensures optimal performance throughout the life cycle of your equipment. Don't forget about keeping an eye on wear-and-tear indicators; these early warning signs can save you from unexpected breakdowns later on! With proactive maintenance practices in place, you'll reap the rewards of investing in quality machinery while enjoying peace of mind knowing you're prepared for anything.

Conclusion

In the world of metal manufacturing, the right roll forming machinery can be a game changer. By investing in high-quality equipment, businesses can maximize efficiency and ensure that their production processes run smoothly. Whether you’re searching for a metal roof forming machine for sale or exploring other roll forming products, making informed decisions is crucial for success.

Maximizing Efficiency with the Right Equipment

Selecting the right metal roofing machine for sale not only streamlines operations but also reduces waste and enhances productivity. With advancements in technology, modern metal roll forming machines offer features that optimize speed and precision, ensuring you get the most out of your investment.

Investing in Quality for Long-Term Growth

When considering options like a metal roofing machine for sale, quality should never be compromised. Investing in durable and reliable roll forming products will pay off in the long run by minimizing downtime and maintenance costs. Choosing reputable brands ensures that your equipment can withstand the rigors of daily use while supporting your business's growth trajectory.

Navigating the Online Shopping Experience

Shopping online for roll forming machinery has never been easier, but it does come with its challenges. To find the best deals on metal manufacturing equipment, it's essential to evaluate customer reviews and compare different models effectively. With a bit of research and patience, you can navigate through countless listings to discover the perfect metal roll forming machine that meets your needs without breaking the bank.