Introduction

In the world of metal fabrication, roll forming equipment stands out as a pivotal player, transforming flat sheets into intricate shapes with precision and efficiency. These machines are specifically designed for sheet metal roll forming, allowing metal manufacturers to create components that are not only structurally sound but also aesthetically pleasing. As industries evolve, the demand for versatile and efficient machines to cut metal has surged, making roll forming machines an essential part of modern manufacturing.

What is Roll Forming Equipment?

Roll forming equipment consists of a series of rollers that gradually shape flat sheet metal into desired profiles through a continuous bending process. This method is particularly effective for producing long lengths of uniform cross-sections, which can be used in various applications ranging from automotive parts to building materials. The versatility and efficiency of form rolling machines make them a go-to choice for many metal manufacturers looking to optimize their production processes.

Benefits of Sheet Metal Roll Forming Machines

One significant advantage of sheet metal roll forming machines is their ability to produce high volumes with minimal waste, making them an economical choice for large-scale production runs. Additionally, these machines offer superior repeatability and consistency in product quality, ensuring that every piece meets exact specifications. With the capability to work with various materials and thicknesses, roll forming equipment provides unmatched flexibility in sheet metal fabrication.

Overview of the Roll Forming Process

The roll forming process begins with feeding flat sheets into the machine where they pass through a series of rollers that gradually shape them into the desired profile. Each roller is strategically positioned to apply pressure at specific angles, allowing for precise shaping without compromising material integrity. This continuous flow not only speeds up production but also reduces labor costs associated with manual handling or alternative machining methods like cutting or stamping.

Understanding Roll Forming Machines

Roll forming machines are essential tools in the world of sheet metal fabrication, enabling manufacturers to create complex shapes efficiently and accurately. These machines operate by passing a continuous strip of metal through a series of rollers, progressively shaping it into the desired profile. Understanding the types, features, and applications of roll forming machines is crucial for any metal manufacturer looking to optimize their production processes.

Types of Roll Forming Equipment

There are several types of roll forming equipment available to suit various manufacturing needs. Standard roll forming machines are commonly used for producing simple profiles like channels or angles, while more advanced systems can handle intricate designs with multiple bends and curves. For specialized tasks, there are also dedicated machines to cut metal at specific lengths or integrate additional processes like punching or welding.

Another popular type is the high-speed roll forming machine, which significantly increases production rates without sacrificing quality. These machines often feature advanced automation capabilities that allow for quick changeovers and reduced downtime between runs. Additionally, portable roll formers cater to on-site fabrication needs, making them ideal for construction projects where space and mobility are considerations.

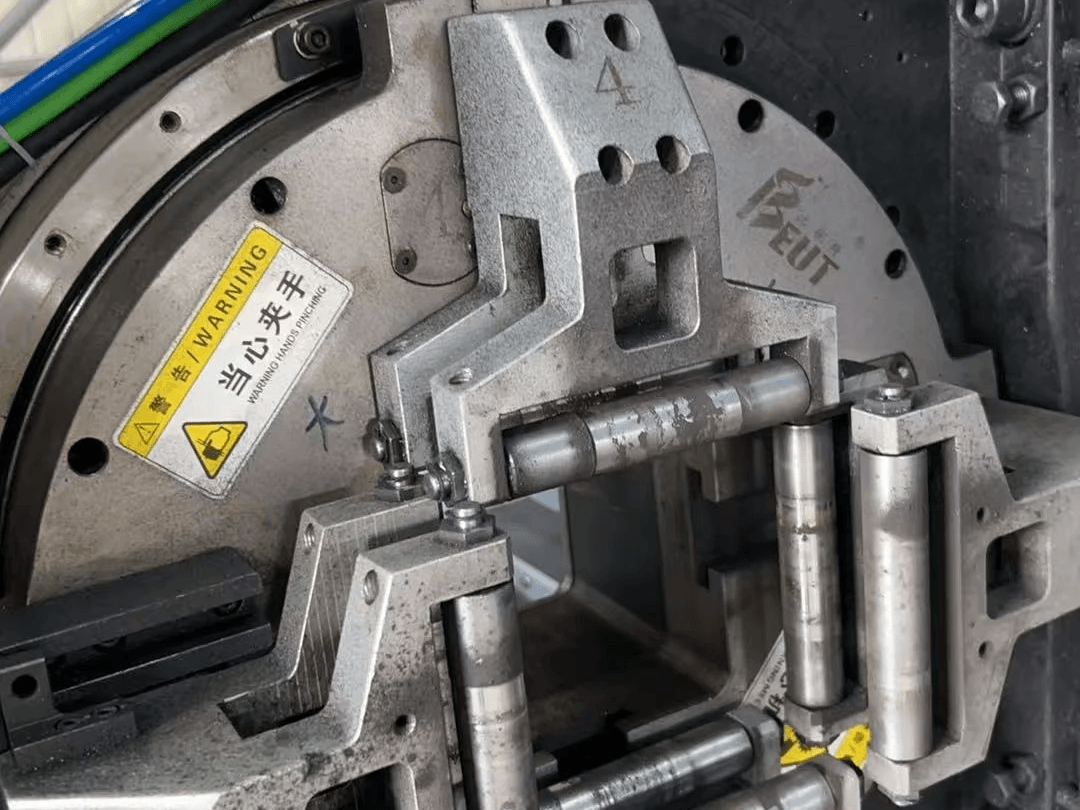

Key Features of Form Rolling Machines

Form rolling machines come packed with features designed to enhance productivity and precision in sheet metal fabrication. One key feature is adjustable roller spacing, which allows operators to customize the machine settings based on material thickness and desired profile shape. This flexibility ensures that manufacturers can work with various materials while maintaining high-quality standards.

Another notable feature is integrated control systems that monitor performance metrics in real-time, providing valuable data for optimizing operations. Many modern roll forming machines also include safety mechanisms such as automatic shut-off systems and emergency stops to protect operators during use. Furthermore, some units offer modular designs that enable easy upgrades as technology evolves or production needs change.

Applications in Metal Fabrication

The applications of sheet metal roll forming machines span a wide range of industries due to their versatility and efficiency in creating custom profiles. In construction, these machines produce components like roofing panels, wall studs, and track systems essential for building frameworks. Additionally, they play a crucial role in manufacturing automotive parts such as brackets and reinforcements that require precise dimensions.

In the HVAC industry, roll formed products like ductwork components ensure optimal airflow efficiency while being lightweight yet durable enough for long-term use. Other applications include furniture manufacturing where decorative elements made from rolled sheet metal add both aesthetic appeal and structural integrity to products. Overall, form rolling machines contribute significantly to advancements in metal forming technologies across various sectors.

Selecting the Right Roll Forming Machine

Choosing the right roll forming machine is crucial for metal manufacturers aiming to optimize their sheet metal fabrication processes. With a variety of machines available, understanding your specific needs can make all the difference in efficiency and output quality. This section will guide you through essential factors to consider, comparisons of different machines to cut metal, and available customization options.

Factors to Consider for Metal Manufacturers

When selecting a roll forming machine, several factors come into play that can impact your operations significantly. First and foremost, consider the material thickness and type you’ll be working with; sheet metal roll forming machines vary in their capacity to handle different gauges of metal. Additionally, think about production volume—higher output demands may necessitate more advanced features or larger machines to cut metal efficiently.

Another critical factor is the machine's speed and precision in rolling machining; faster doesn’t always mean better if it sacrifices accuracy. Look for features like adjustable speeds or automated controls that enhance both speed and precision during the metal forming process. Lastly, take into account your budget—not just for the initial purchase but also ongoing maintenance costs associated with operating a form rolling machine.

Comparing Different Machines to Cut Metal

With so many options on the market, comparing various machines to cut metal can feel overwhelming but is essential for making an informed decision. Start by examining specifications such as maximum width and thickness capabilities; these will determine what types of sheet metal fabrication projects you can undertake effectively. Next, assess additional features like integrated safety systems or user-friendly interfaces that make operation smoother for your team.

You should also look into reviews and testimonials from other metal manufacturers who have used these machines; real-world feedback can provide valuable insights into reliability and performance over time. Don’t forget about after-sales support—having access to knowledgeable technicians can save you headaches down the line when issues arise with your roll forming machine. By weighing these aspects carefully against your production needs, you'll find a machine that meets both quality standards and operational efficiency.

Customization Options for Your Needs

Customization is where things get exciting in choosing a roll forming machine tailored specifically for your operations! Many manufacturers offer options ranging from specialized tooling setups to software integrations that streamline production workflows in sheet metal fabrication processes. If you're producing unique profiles or components regularly, investing in customizable solutions ensures versatility without compromising efficiency.

Consider whether you need add-ons like automatic coil feeders or programmable controls that allow operators to switch between product lines seamlessly—these enhancements can significantly boost productivity levels when working with various types of sheet metals. Furthermore, don’t hesitate to discuss specific requirements with suppliers; they often have experience developing bespoke solutions tailored precisely to meet unique manufacturing challenges faced by clients like you.

Innovations in Roll Forming Technology

The world of roll forming technology is constantly evolving, and recent innovations are making waves in the sheet metal fabrication industry. From advanced rolling machining techniques to the integration of smart features, these developments are enhancing the capabilities of sheet metal roll forming machines. As a result, metal manufacturers are finding new ways to improve efficiency and product quality while reducing costs.

Advances in Rolling Machining Techniques

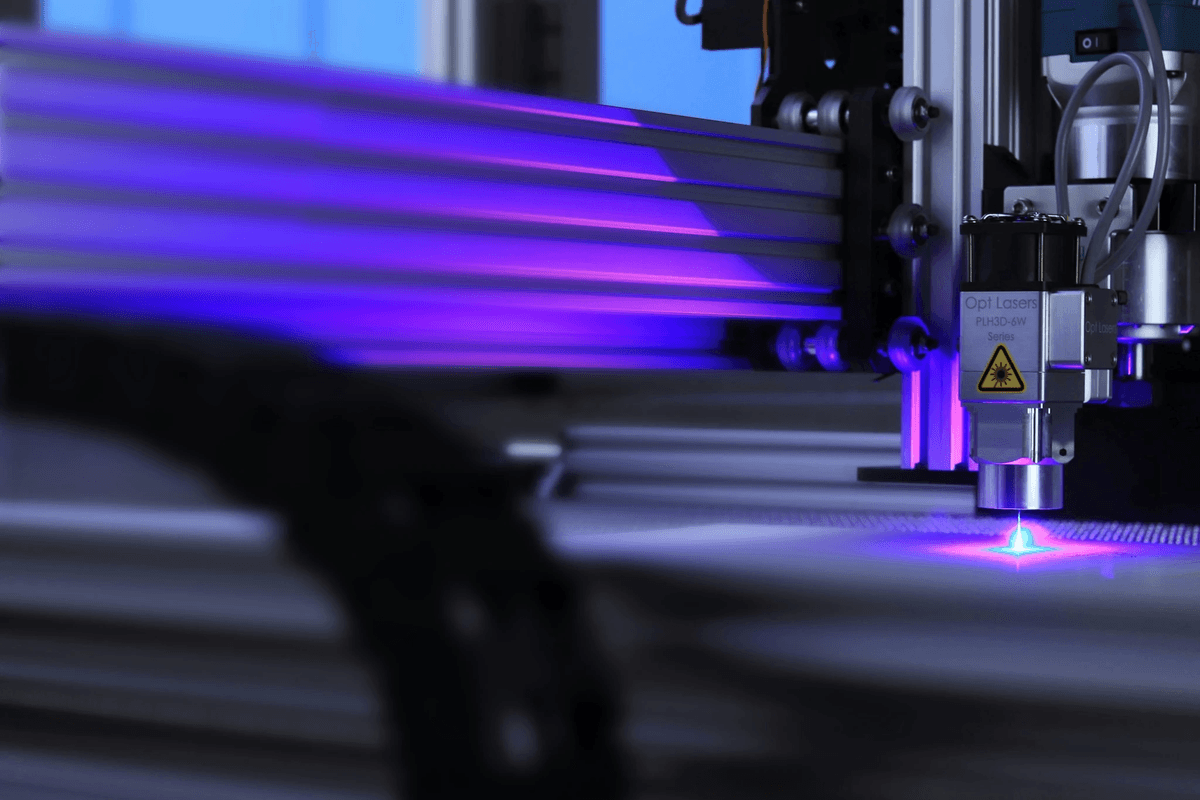

Recent advancements in rolling machining techniques have transformed how form rolling machines operate. For instance, improvements in tooling and die design have led to greater precision and consistency in the production of complex shapes. Additionally, the use of high-strength materials has increased the durability and lifespan of these machines to cut metal, resulting in less downtime for maintenance.

Another notable advancement is the introduction of hybrid technologies that combine traditional roll forming with other processes like laser cutting or welding. This integration allows for more versatile applications within sheet metal fabrication, enabling manufacturers to produce intricate designs without sacrificing speed or efficiency. Overall, these innovations not only enhance productivity but also open up new avenues for creativity in metal forming.

Automation and Smart Features in Machines

Automation is revolutionizing how roll forming machines operate, bringing significant improvements to efficiency and accuracy. Modern sheet metal roll forming machines now come equipped with smart features such as real-time monitoring systems that track production metrics and alert operators to potential issues before they escalate. This proactive approach minimizes downtime and helps maintain optimal performance levels throughout the manufacturing process.

Moreover, automated setups allow for quicker changeovers between different product lines or specifications, catering to diverse customer needs without extensive manual intervention. The implementation of robotics further streamlines operations by handling repetitive tasks such as material loading or unloading—freeing up human resources for more skilled activities within sheet metal fabrication environments. In short, automation is setting a new standard for productivity among metal manufacturers.

Impact of Technology on Production Efficiency

The impact of technology on production efficiency cannot be overstated; it has fundamentally reshaped how businesses approach their manufacturing processes. With enhanced rolling machining capabilities and smart machine integration, companies can achieve higher output rates while maintaining superior quality control over their products made using form rolling machines. This shift not only increases profitability but also positions manufacturers favorably within competitive markets.

Furthermore, data analytics derived from advanced machinery enable manufacturers to make informed decisions based on real-time performance insights—leading to continuous improvement strategies that optimize workflows across all stages of production. As a result, businesses can respond swiftly to changing market demands while minimizing waste associated with inefficient practices commonly found in traditional methods used by some older machines to cut metal. Ultimately, embracing these technological advancements is crucial for any forward-thinking company looking to thrive in today’s fast-paced manufacturing landscape.

The Role of Kiant Machinery in the Industry

Kiant Machinery has made a significant mark in the roll forming sector, offering a diverse range of solutions tailored to meet the needs of metal manufacturers. Their commitment to innovation ensures that their sheet metal roll forming machines are not just efficient but also adaptable to various applications. By focusing on quality and performance, Kiant positions itself as a leader in the competitive landscape of sheet metal fabrication.

Overview of Kiant Machinery’s Offerings

Kiant Machinery specializes in providing state-of-the-art roll forming machines designed for high precision and durability. Their offerings include advanced form rolling machines that cater to a variety of industries, ensuring that every metal manufacturer finds a suitable solution for their specific needs. From machines to cut metal with intricate designs to robust systems capable of handling large volumes, Kiant’s product lineup is impressive and comprehensive.

Benefits of Choosing Kiant for Roll Forming

Choosing Kiant Machinery for your roll forming needs means investing in quality and reliability. Their sheet metal roll forming machines come equipped with innovative technology that enhances production efficiency while reducing waste during the metal forming process. Additionally, customers benefit from customized options tailored specifically to their operational requirements, making it easier than ever for manufacturers to optimize their workflows.

Customer Support and After-Sales Service

One standout feature of Kiant Machinery is its exceptional customer support and after-sales service, which sets it apart from competitors in the industry. They understand that operating form rolling machines requires ongoing assistance and guidance; hence they offer comprehensive training resources and technical support for all clients. This commitment ensures that every user can maximize the potential of their sheet metal roll forming machines while minimizing downtime due to maintenance or operational issues.

Best Practices for Operating Roll Forming Equipment

Operating sheet metal roll forming machines effectively requires attention to safety, maintenance, and training. By following best practices in these areas, metal manufacturers can enhance productivity and ensure a safe working environment. This section will delve into essential guidelines that every operator should know.

Safety Guidelines for Operators

Safety is paramount when working with roll forming machines. Operators must wear appropriate personal protective equipment (PPE) such as gloves, goggles, and steel-toed boots to minimize the risk of injury during sheet metal fabrication processes. Additionally, it’s crucial to conduct regular safety audits and ensure that all emergency stops are functioning correctly on the form rolling machine.

Operators should also be trained to identify potential hazards associated with rolling machining and understand how to mitigate risks effectively. Keeping work areas tidy can prevent accidents caused by slips or trips over tools and materials used in metal forming operations. Lastly, always follow the manufacturer’s guidelines regarding operational limits and maintenance schedules for machines to cut metal safely.

Maintenance Tips for Longevity

Regular maintenance is key to extending the lifespan of your roll forming machine. Establishing a routine inspection schedule helps catch minor issues before they escalate into costly repairs or downtime in production lines using sheet metal roll forming machines. Key components such as gears, rollers, and bearings should be regularly lubricated according to the manufacturer's specifications.

In addition to lubrication, operators should monitor alignment settings frequently since misalignment can lead to defects in production quality during sheet metal fabrication processes. Cleaning debris from the machine regularly prevents buildup that could hinder performance or cause mechanical failure over time. By implementing these maintenance tips consistently, you’ll ensure your form rolling machine runs smoothly and efficiently.

Training Resources for Efficient Use

Investing in proper training resources is vital for maximizing efficiency when operating machines to cut metal like roll forming equipment. New operators should undergo comprehensive training programs that cover both theoretical knowledge and hands-on practice with sheet metal roll forming machines. This ensures they understand not only how to operate the machinery but also how it integrates into larger manufacturing processes.

Utilizing online courses or workshops provided by industry experts can significantly enhance skill levels among staff members involved in metal manufacturing operations. Additionally, creating a mentorship program where experienced operators guide newcomers fosters a culture of continuous learning within your facility focused on sheet metal fabrication techniques. Remember: well-trained personnel are key assets that contribute significantly toward achieving high productivity rates while minimizing errors.

Conclusion

In conclusion, understanding the capabilities and benefits of sheet metal roll forming machines is crucial for any metal manufacturer aiming to enhance their production efficiency. These machines not only streamline the sheet metal fabrication process but also provide versatility in producing various shapes and forms. By leveraging advanced rolling machining techniques, manufacturers can achieve high precision and quality in their outputs.

Key Takeaways on Roll Forming Machines

Roll forming machines are essential tools in the realm of metal forming, offering a continuous method to shape materials into desired profiles. The flexibility of these machines to accommodate different types of metals makes them invaluable for diverse applications in industries ranging from automotive to construction. Remember, investing in high-quality form rolling machines can lead to significant improvements in production speed and cost-effectiveness.

Future Trends in Metal Forming

Looking ahead, the landscape of sheet metal fabrication is poised for exciting advancements driven by automation and smart technology integration. The emergence of IoT-enabled roll forming machines will likely enhance real-time monitoring and predictive maintenance capabilities, further optimizing operational efficiency for metal manufacturers. Additionally, as sustainability becomes a focal point, innovations aimed at reducing waste during the roll forming process will gain traction.

Why Choose Kiant Machinery for Your Needs

When it comes to selecting a partner for your roll forming machine needs, Kiant Machinery stands out with its commitment to quality and customer satisfaction. Their extensive range of sheet metal roll forming machines is designed with cutting-edge technology that caters specifically to the unique demands of modern manufacturing processes. With exceptional customer support and after-sales service, choosing Kiant Machinery ensures you have a reliable ally as you navigate the world of metal fabrication.