Introduction

In today's fast-paced industrial landscape, automated laser cutting is revolutionizing how products are manufactured and designed. This cutting-edge technology enhances efficiency, precision, and customization across various sectors, making it an indispensable tool for modern manufacturing. As industries increasingly adopt laser cutting machines, the transformation in production capabilities is nothing short of remarkable.

How Automated Laser Cutting Transforms Industries

Automated laser cutting has become a game-changer for many industries by streamlining processes and enhancing product quality. With the ability to cut through materials with unparalleled precision, the cutting machine laser significantly reduces errors and rework in production lines. This transformation not only boosts productivity but also allows businesses to meet diverse customer demands with ease.

The Rise of Cutting Machines in Manufacturing

The rise of cutting machines in manufacturing can be attributed to advancements in technology that have made automated cutting more accessible than ever before. Companies are increasingly investing in sophisticated laser cutting machines that offer speed and accuracy, enabling them to stay competitive in a global market. As these machines evolve, they continue to play a pivotal role in reshaping manufacturing practices across various sectors.

Benefits of Customized Laser Cutting Techniques

Customized laser cutting techniques provide businesses with the flexibility to create unique designs tailored to specific needs. By utilizing design for laser cutting principles, manufacturers can optimize their production processes while minimizing waste and maximizing material use. The ability to implement custom laser cutting solutions not only enhances creativity but also drives innovation within industries looking for distinct competitive advantages.

The Technology Behind Automated Laser Cutting

Automated laser cutting is revolutionizing the way industries approach precision and efficiency in their manufacturing processes. Understanding the intricate workings of laser cutting machines is essential to appreciate their impact on modern production methods. These machines utilize focused beams of light to cut through various materials, offering unparalleled accuracy and speed.

Understanding Laser Cutting Machines

Laser cutting machines are sophisticated tools that harness the power of concentrated light to slice through materials with extreme precision. At their core, these machines employ a high-powered laser beam directed onto a workpiece, which melts or vaporizes the material along a predetermined path. This automated cutting process allows for complex designs that are often impossible to achieve with traditional cutting methods, making it an invaluable asset in many industries.

The versatility of a laser cutting machine is another significant advantage; it can handle various materials such as metals, plastics, wood, and more. By adjusting parameters like speed and power settings, operators can customize the process for different applications—perfect for businesses looking to implement custom laser cutting solutions tailored to their needs. As technology advances, these machines continue to evolve, incorporating features like CNC (Computer Numerical Control) for enhanced automation and user-friendliness.

Innovations in Cutting Laser Metal

Innovations in cutting laser metal have significantly improved both the efficiency and quality of industrial manufacturing processes. Advanced technologies such as fiber lasers have emerged as game-changers in this field; they provide increased energy efficiency while delivering superior cut quality compared to traditional CO2 lasers. This shift not only reduces operational costs but also enhances production capabilities across various sectors.

Furthermore, developments in software integration allow for more sophisticated design for laser cutting processes. These programs enable manufacturers to optimize their designs before production begins—minimizing errors and maximizing material usage during automated cutting operations. As industries continue pushing boundaries with innovative applications of laser technology, we can expect even greater advancements that will redefine what's possible in metal fabrication.

Role of Precision in Design for Laser Cutting

Precision plays a pivotal role in design for laser cutting; it ensures that every component fits together seamlessly during assembly or installation phases. The accuracy offered by automated laser cutting techniques allows designers to push creative boundaries without compromising functionality or structural integrity—leading to innovative products that stand out in competitive markets. This level of precision not only enhances aesthetic appeal but also contributes significantly to overall product performance.

Moreover, achieving high levels of precision requires an understanding of both the material properties being used and the capabilities of the chosen cutting machine laser technology. Designers must consider factors such as kerf width (the width of material removed by the cut) when creating models intended for automated processing; this ensures optimal results without unnecessary waste or additional rework down the line. In essence, meticulous attention paid during the design phase translates directly into higher-quality outcomes during production—a win-win scenario for manufacturers embracing custom laser cutting solutions.

Applications Across Various Industries

Automated laser cutting technology is revolutionizing various sectors by enhancing efficiency and precision. From automotive manufacturing to aerospace components and even furniture design, the versatility of cutting machines is reshaping traditional practices. Each application highlights the benefits of laser cutting machines in producing high-quality results tailored to specific industry needs.

Automotive Manufacturing Efficiency

In the automotive industry, automated laser cutting plays a crucial role in streamlining production processes. By utilizing cutting machine lasers, manufacturers can achieve remarkable precision in creating parts that fit perfectly within complex assemblies. This efficiency not only speeds up production but also reduces labor costs, allowing companies to allocate resources more effectively while maintaining high standards of quality.

The ability to implement custom laser cutting techniques means that automotive manufacturers can adapt designs for laser cutting based on evolving market demands. Whether it's creating intricate patterns or optimizing component shapes, automated cutting ensures that every piece meets stringent specifications. As a result, the automotive sector benefits from reduced waste and improved turnaround times, driving competitiveness in a rapidly changing landscape.

Aerospace Components and Quality Control

Aerospace manufacturing requires an unwavering commitment to quality control, where even minor defects can have catastrophic consequences. Automated laser cutting provides an exceptional solution by ensuring precise cuts and consistent quality across all components produced. Cutting laser metal with extreme accuracy allows manufacturers to meet rigorous safety standards while minimizing material waste.

The integration of advanced design for laser cutting techniques enables aerospace engineers to create lightweight yet durable parts tailored for optimal performance. This capability not only enhances aircraft efficiency but also contributes to fuel savings and lower emissions—key considerations in today's environmentally conscious market. With automated systems continuously monitoring quality during production, aerospace companies can confidently deliver components that exceed regulatory requirements.

Customized Solutions in Furniture Design

The furniture industry has seen a significant transformation thanks to automated laser cutting technology, which offers endless possibilities for customization. Designers are now able to create intricate patterns and unique shapes with unparalleled precision using state-of-the-art laser cutting machines. This level of customization allows furniture makers to cater directly to consumer preferences while maintaining high productivity levels.

Moreover, custom laser cutting facilitates the use of diverse materials beyond traditional wood products—think acrylics or metals—enabling designers to push creative boundaries further than ever before. The result is a stunning array of bespoke furniture pieces that reflect individual styles and tastes while still being cost-effective due to minimized material waste from precise cuts made by automated systems. As this trend continues, we can anticipate even more innovative designs emerging from this synergy between technology and creativity.

Economic Advantages of Automated Cutting

Automated laser cutting is revolutionizing the way industries approach manufacturing, offering substantial economic advantages that are hard to ignore. By implementing cutting machines laser technology, businesses can streamline operations, reduce overhead costs, and ultimately boost profitability. The precision and efficiency of laser cutting machines not only enhance production but also create a competitive edge in the market.

Reducing Labor Costs Through Automation

One of the most significant benefits of automated cutting is the reduction in labor costs. Traditional manufacturing processes require a sizable workforce for tasks such as measuring, marking, and manual cutting; however, with automated laser cutting systems in place, these tasks can be executed with minimal human intervention. This shift not only reduces wage expenses but also allows skilled workers to focus on more complex tasks that require human ingenuity.

Moreover, automated laser cutting machines operate continuously without fatigue or breaks, increasing overall productivity. The efficiency gained from using a cutting machine laser means companies can complete projects faster than ever before. This rapid turnaround not only saves money but also improves customer satisfaction through timely deliveries.

Minimizing Material Waste with Precision Cutting

Another compelling economic advantage of automated laser cutting is its ability to minimize material waste significantly. Unlike traditional methods that often lead to excess scrap material due to inaccuracies in cuts and measurements, design for laser cutting allows for highly precise operations that optimize material usage. By leveraging advanced technologies in cutting laser metal processes, manufacturers can achieve tighter tolerances and more efficient layouts.

This precision translates into cost savings as less raw material is wasted during production runs. For industries where materials are expensive or subject to market fluctuations, this advantage becomes even more critical. Companies embracing custom laser cutting techniques find themselves not only saving money on materials but also enhancing their sustainability efforts by reducing their environmental footprint.

Long-Term Financial Impact of Laser Cutting

The long-term financial impact of investing in automated laser cutting technology cannot be overstated. While the initial investment may seem daunting for some businesses, the return on investment (ROI) becomes apparent over time through reduced operational costs and increased output quality. As companies realize savings from lower labor costs and minimized waste, they can reinvest those funds into further innovations or expansions.

Additionally, companies utilizing advanced automated cutting solutions often experience fewer errors and defects in their products due to the high precision offered by modern equipment like laser cutting machines. This leads to lower rework rates and improved product quality—factors that positively influence customer loyalty and brand reputation over time. Ultimately, investing in state-of-the-art automated systems stands as a smart strategy for businesses looking toward sustainable growth.

Kiant Machinery: A Leader in Laser Cutting Solutions

Kiant Machinery stands at the forefront of the automated laser cutting industry, providing innovative solutions that cater to diverse manufacturing needs. With a robust lineup of cutting machines, Kiant has redefined efficiency and precision in laser cutting technology. Their commitment to excellence ensures that businesses can achieve optimal results with their laser cutting machines.

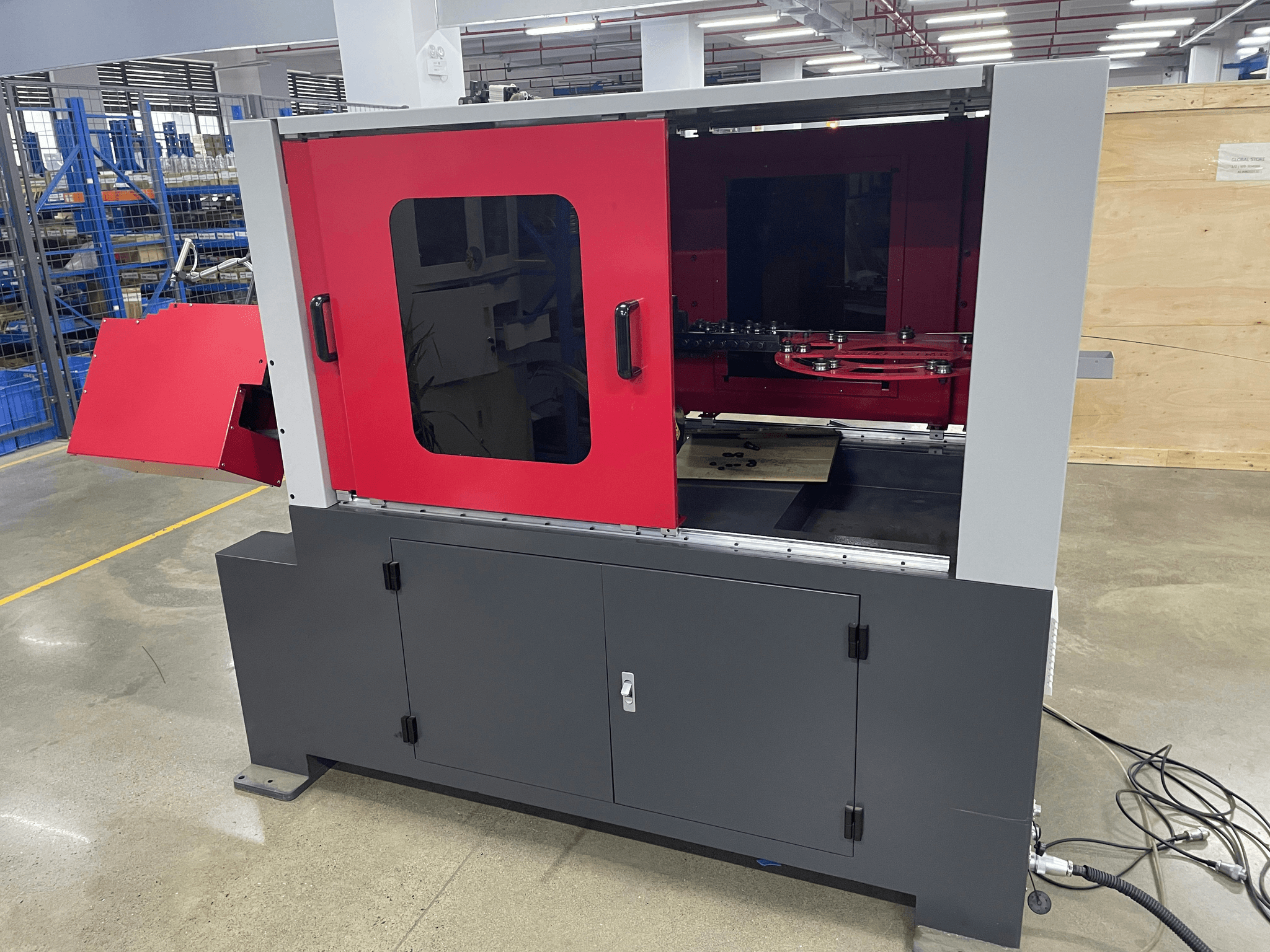

Overview of Kiant Machinery Products

Kiant Machinery offers a comprehensive range of products designed for automated laser cutting applications. From high-powered cutting lasers for metal to versatile machines capable of handling various materials, their product line is tailored for maximum performance. Each laser cutting machine is engineered with advanced technology, ensuring reliability and precision in every cut.

Benefits of Kiant's Custom Laser Cutting Services

One of the standout features of Kiant Machinery is their custom laser cutting services, which allow clients to tailor solutions specifically to their design for laser cutting needs. This flexibility enables businesses to create unique components that meet exact specifications while benefiting from the efficiency of automated cutting processes. Additionally, Kiant’s expertise in customized solutions helps clients reduce lead times and enhance productivity without compromising quality.

Support and Training for Effective Implementation

To ensure successful integration of their products, Kiant Machinery provides extensive support and training for all customers investing in automated laser cutting systems. Their dedicated team offers hands-on training sessions that cover everything from basic operation to advanced techniques in using the cutting machine laser effectively. This commitment to customer education not only enhances user confidence but also maximizes the return on investment by ensuring optimal use of the equipment.

Future Trends in Laser Cutting Technology

The landscape of automated laser cutting is evolving rapidly, driven by technological advancements and changing industry needs. As businesses seek greater efficiency and customization, innovations in laser cutting machines are paving the way for smarter manufacturing processes. Understanding these trends is essential for industries aiming to stay competitive and meet customer demands.

The Role of AI in Automated Cutting

Artificial Intelligence (AI) is set to revolutionize the realm of automated cutting by enhancing the capabilities of laser cutting machines. With AI-driven algorithms, these machines can analyze design for laser cutting with unprecedented accuracy, optimizing paths and minimizing waste during production. This not only speeds up the process but also ensures that each cut is executed with precision, leading to higher quality outcomes.

Furthermore, AI can facilitate predictive maintenance for cutting machines laser, reducing downtime and extending equipment lifespan. By monitoring performance metrics in real-time, manufacturers can anticipate issues before they arise, ensuring smooth operations. This integration of AI into automated cutting processes signifies a shift towards more intelligent manufacturing systems that prioritize efficiency and reliability.

Sustainable Practices in Laser Cutting

As industries become increasingly aware of their environmental impact, sustainable practices in laser cutting are gaining traction. Automated laser cutting technology allows for precise cuts that minimize material waste—making it an eco-friendly alternative to traditional methods. By employing custom laser cutting techniques that optimize material usage, companies can significantly reduce their carbon footprint while maintaining high-quality production standards.

Moreover, advancements in energy-efficient laser cutting machines contribute to sustainability efforts by lowering energy consumption during operation. Manufacturers are now able to implement strategies that align with green initiatives while still achieving cost savings through reduced operational expenses. Embracing these sustainable practices not only appeals to environmentally conscious consumers but also positions companies as leaders in responsible manufacturing.

Predictions for Industry Evolution

The future of automated laser cutting looks promising as we anticipate several key developments over the coming years. First off, we expect a surge in demand for customized solutions across various sectors; businesses will increasingly turn to advanced technologies like automated cutting to meet unique client specifications efficiently. As customization becomes the norm rather than the exception, innovations in design for laser cutting will play a pivotal role.

Additionally, we foresee enhanced collaboration between different technologies such as robotics and IoT (Internet of Things) within the realm of automated laser systems. This convergence will create smarter factories where interconnected devices communicate seamlessly—ultimately driving productivity levels higher than ever before. Finally, as industries continue embracing automation trends like these, investment opportunities will flourish; companies looking to grow must consider integrating state-of-the-art solutions like advanced cutting machine lasers into their operations.

Conclusion

In the ever-evolving landscape of manufacturing, automated laser cutting stands out as a game-changer. By integrating cutting machine laser technology into production processes, industries can achieve unprecedented efficiency and precision. The advancements in design for laser cutting not only streamline operations but also enhance product quality across various sectors.

Maximizing Efficiency with Automated Laser Cutting

Automated laser cutting significantly boosts operational efficiency by minimizing human error and speeding up production times. The precision offered by cutting laser metal ensures that each cut is exact, reducing the need for costly rework or material wastage. As businesses embrace these innovations, they are finding that investing in a laser cutting machine can lead to remarkable improvements in throughput and overall productivity.

The Future of Custom Laser Cutting Solutions

The future of custom laser cutting solutions is bright, with ongoing advancements promising even greater capabilities. Innovations such as AI integration are set to revolutionize how we approach automated cutting, allowing for smarter designs and more adaptive manufacturing processes. This evolution will empower industries to create bespoke products tailored precisely to customer needs while maintaining high levels of efficiency.

Investing in Cutting Machines for Growth

Investing in advanced cutting machines is not just a trend; it's a strategic move towards sustainable growth in manufacturing sectors. Companies that adopt automated laser cutting technologies position themselves at the forefront of innovation, gaining competitive advantages through enhanced productivity and reduced costs. As the demand for customized solutions rises, those who invest wisely in these technologies will likely see significant returns on their investment over time.