Introduction

In today's fast-paced manufacturing landscape, the demand for precision and efficiency has never been higher. Enter fiber laser technology, a game-changer that transforms how we approach metal cutting. With its unparalleled speed and accuracy, the laser cutting machine steel has become an essential tool for industries looking to elevate their production capabilities.

Understanding Fiber Laser Technology

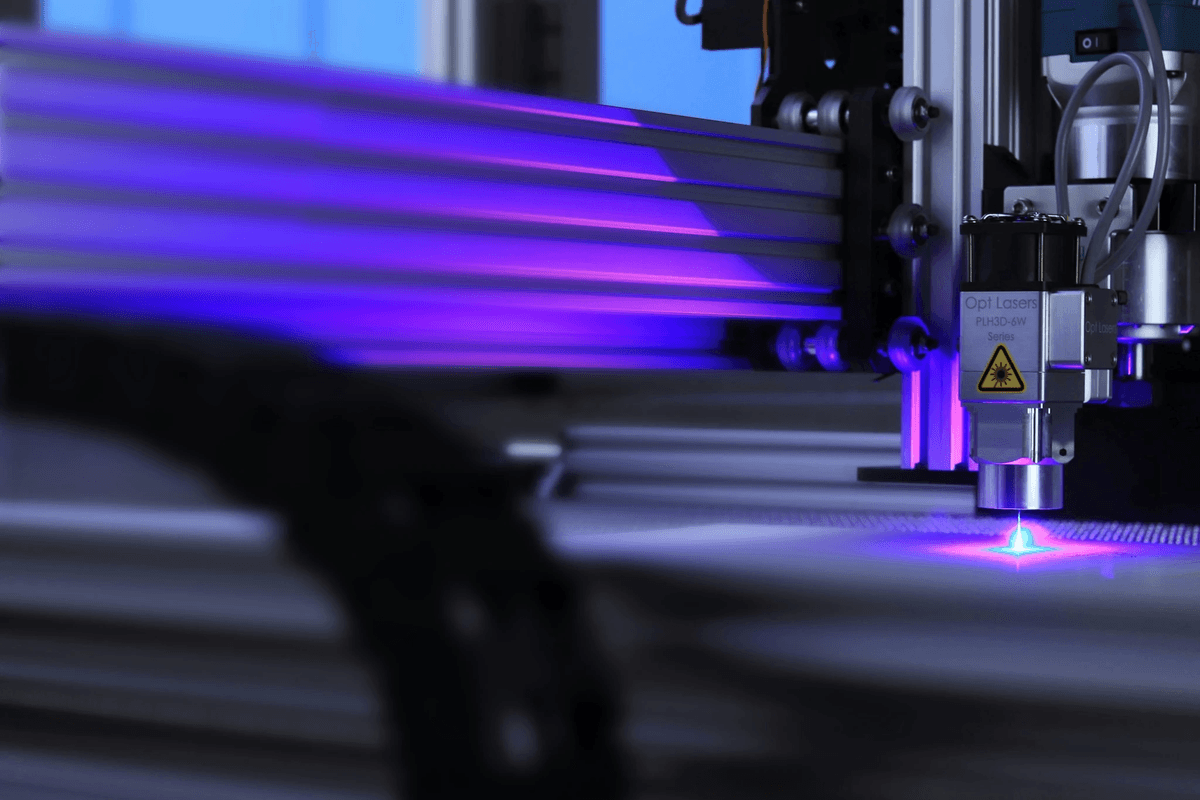

Fiber laser technology utilizes a high-powered beam of light to cut through various materials, especially metals. This advanced method employs optical fibers to generate and amplify the laser, resulting in a focused beam that can slice through steel with remarkable precision. The metal cutting laser cutter stands out for its ability to deliver clean edges and intricate designs, making it ideal for complex projects.

The Role of Kiant Machinery

Kiant Machinery is at the forefront of this technological revolution, providing top-of-the-line industrial laser cutters tailored to meet diverse manufacturing needs. With a commitment to innovation and quality, Kiant offers an extensive range of industrial laser cutting machines designed specifically for steel and other metals. Their expertise ensures that businesses can harness the full potential of metal cutting machines laser technology while maximizing productivity.

Advantages of Laser Cutting Machines

The advantages of using a laser cutter for metal are numerous; from reduced waste material to lower operational costs, these machines are designed for modern efficiency. Unlike traditional cutting methods, industrial laser machines provide unparalleled accuracy with minimal heat-affected zones, ensuring that your products maintain structural integrity even after processing. Moreover, the versatility of these machines allows them to handle various applications—from automotive parts to intricate art pieces—making them indispensable in any workshop or factory setting.

The Science Behind Laser Cutting

Laser cutting technology has revolutionized the way we approach metal fabrication, making it faster, more efficient, and incredibly precise. Understanding the science behind how these machines work is essential for anyone considering adding a laser cutter for metal to their operations. In this section, we will explore the mechanics of laser cutting, the various types of machines available, and the unique benefits offered by fiber laser technology.

How Laser Cutting Works

At its core, a laser cutting machine uses focused light beams to melt or vaporize material in a controlled manner. The process begins when a high-powered beam is generated and directed through optics onto the surface of the steel or other metals being cut. This intense energy creates heat that either melts away or burns through the material with extreme precision—resulting in clean edges without significant thermal distortion.

The operation of a metal cutting machine laser involves several key components: the laser source (often fiber-based), assist gas (which helps remove molten material), and a motion system that guides the beam along desired paths. This combination allows industrial laser cutters to achieve intricate designs and shapes with minimal waste. As such, industries ranging from automotive to aerospace increasingly rely on these advanced technologies for their manufacturing needs.

Types of Laser Cutting Machines

There are several types of industrial laser machines designed for different applications and materials. The most common include CO2 lasers, fiber lasers, and solid-state lasers—each offering unique advantages depending on your specific requirements. For instance, while CO2 lasers excel at cutting non-metal materials like wood or plastics, fiber lasers are more effective for steel and other metals due to their shorter wavelength.

When it comes to selecting a suitable option for your operations, consider what type of metal you’ll be working with most frequently; an industrial laser cutter specifically designed for metal will yield better results than one meant primarily for softer materials. Additionally, some machines are better suited for thicker materials while others excel at speed and precision on thinner sheets—making it crucial to match your choice with your production goals.

Benefits of Fiber Laser Technology

Fiber laser technology stands out as one of the most efficient methods available today for cutting metals like steel due to its superior beam quality and energy efficiency. Compared to traditional CO2 systems, fiber lasers consume less power while delivering faster cutting speeds—translating into lower operational costs over time when using an industrial laser cutting machine. Furthermore, they require less maintenance thanks to their solid-state design which eliminates many moving parts found in older systems.

Another significant advantage is that fiber lasers can cut through reflective materials such as aluminum without losing performance—a challenge often faced by other types of industrial laser cutters. This versatility makes them ideal not only as metal cutting machines but also as solutions that can adapt to various industry demands—from fabricating intricate components in electronics to large-scale structural applications in construction projects.

Kiant Machinery’s Product Range

Kiant Machinery offers an impressive range of laser cutting machines designed to meet the diverse needs of various industries. From compact models for small-scale operations to robust industrial laser cutters capable of handling heavy-duty tasks, their product lineup caters to every requirement. Whether you're looking for a laser cutter for metal or a specialized industrial laser cutting machine, Kiant has you covered.

Overview of Laser Cutting Equipment

Kiant Machinery's laser cutting equipment is engineered with precision and efficiency in mind, making it ideal for working with materials like steel and other metals. Their offerings include advanced metal cutting machines that leverage fiber laser technology, ensuring high-quality cuts with minimal waste. With options ranging from entry-level models to high-performance industrial laser machines, there's something for everyone in their product range.

Features of Kiant's Industrial Laser Cutter

The industrial laser cutter from Kiant boasts several standout features that set it apart from the competition. Equipped with state-of-the-art technology, this metal cutting laser cutter delivers exceptional speed and accuracy, allowing users to achieve intricate designs without compromising on quality. Additionally, its user-friendly interface and automated settings make operating the machine a breeze—perfect for both seasoned professionals and newcomers alike.

Applications of Laser Cutting Machines

Laser cutting machines have found applications across numerous industries due to their versatility and efficiency. In manufacturing sectors such as automotive, aerospace, and construction, these machines are indispensable for tasks like creating components from steel sheets or intricate designs in various metals. With a reliable industrial laser cutter at your disposal, the possibilities are virtually endless—from prototyping to mass production.

Choosing the Right Laser Cutter for Metal

Selecting the right laser cutter for metal is crucial for optimizing your manufacturing processes. With a plethora of options available, it’s essential to consider various factors that can impact performance, efficiency, and cost-effectiveness. By understanding your specific needs and comparing different models, you can make an informed decision that aligns with your production goals.

Factors to Consider

When choosing a laser cutting machine steel, several key factors come into play. First and foremost is the material thickness; different machines are designed to handle various gauges of metal, so knowing what you'll be cutting is vital. Additionally, consider the power output of the industrial laser cutter—higher wattage typically means faster cutting speeds and better performance on thicker materials.

Another factor to weigh is the operational environment; some industrial laser cutting machines are built for heavy-duty use in demanding settings while others may be more suited for lighter applications. Maintenance requirements also vary; some models may require more upkeep than others, impacting long-term costs. Lastly, think about software compatibility and ease of use; a user-friendly interface can significantly enhance productivity.

Comparing Machine Specifications

Once you've identified your needs, it’s time to dive into comparing machine specifications among available options like the metal cutting laser cutter or an industrial laser cutting machine. Look at parameters such as maximum sheet size, speed (measured in inches per minute), and precision levels—these will directly affect your workflow efficiency. Pay attention to cooling systems as well; effective cooling can prolong machine life and maintain optimal performance during extended operations.

Don't overlook features like automation capabilities or integration with existing systems; these can streamline processes significantly in high-volume production environments. Moreover, check if the machine supports various types of materials beyond just steel—flexibility can save you from future equipment purchases as your business evolves. Each specification should align with your unique operational requirements to ensure you're investing wisely.

Industry-Specific Solutions

Different industries have unique demands when it comes to metal fabrication, making industry-specific solutions essential in selecting a laser cutter for metal applications. For instance, automotive manufacturers often require high-speed precision cuts for intricate designs while aerospace industries might prioritize lightweight materials with stringent tolerances—your choice should reflect these nuances accordingly.

Moreover, sectors like construction may benefit from robust machines capable of handling thicker metals efficiently using advanced technologies found in modern industrial laser machines. Understanding these industry standards helps tailor your selection process towards machines that not only meet but exceed expectations in specific environments—a critical factor when aiming for competitive advantage.

In summary, taking time to assess factors such as material type and thickness along with comparing specifications will guide you toward selecting the optimal industrial laser cutter tailored to your needs while considering industry-specific solutions ensures that you stay ahead in today’s competitive landscape.

Efficiency and Cost-Effectiveness

In the competitive landscape of manufacturing, efficiency and cost-effectiveness are paramount. The integration of a laser cutting machine steel into production processes can significantly reduce operational costs while enhancing overall productivity. By investing in an industrial laser cutter, businesses can achieve remarkable savings and output, ensuring they stay ahead in the market.

Reducing Operational Costs

One of the most compelling advantages of using a metal cutting laser cutter is its ability to minimize waste. Traditional cutting methods often lead to significant material loss, whereas an industrial laser cutting machine precisely cuts materials with minimal kerf width. This efficiency not only conserves valuable resources but also reduces costs associated with purchasing additional raw materials.

Moreover, industrial laser machines require less maintenance compared to conventional equipment, further driving down operational expenses. With fewer moving parts and a more streamlined design, these machines experience less wear and tear over time. As businesses adopt laser cutters for metal applications, they find that maintenance schedules become less frequent and costly.

Lastly, energy consumption is another area where metal cutting machine lasers shine. Compared to older technologies that consume excessive power during operation, modern fiber lasers are designed for energy efficiency. This translates into lower electricity bills for manufacturers who rely on these advanced systems for their production needs.

Enhancing Production Speed

When it comes to production speed, nothing beats the capabilities of an industrial laser cutter. These machines can cut through various metals at impressive speeds without compromising precision or quality. For example, a laser steel cutting machine can operate at rates that traditional methods simply cannot match.

The rapid processing capabilities allow manufacturers to increase their throughput significantly; jobs that once took hours or even days can now be completed in mere minutes with a metal cutting laser cutter on hand. This speed not only boosts productivity but also enables companies to take on more projects simultaneously—an essential factor in today's fast-paced market.

Furthermore, the automation features found in many modern industrial laser cutting machines streamline workflows by reducing manual intervention requirements. With automated loading and unloading systems integrated into these machines, manufacturers enjoy seamless operations that enhance both efficiency and safety within their facilities.

Long-Term Investment in Laser Technology

Investing in a high-quality industrial laser cutter is not just about immediate gains; it's also about long-term value creation for businesses looking to future-proof their operations. The durability and reliability of these machines mean they often outlast traditional equipment by years—making them a wise investment choice for savvy manufacturers seeking longevity.

Additionally, as technology continues to advance rapidly within the realm of metal fabrication, owning an advanced metal cutting machine laser ensures companies remain competitive as new applications emerge over time. These versatile tools adapt easily to evolving industry demands without requiring significant additional investments or upgrades down the line.

Finally, choosing Kiant Machinery's range of industrial laser machines means you’re not just purchasing equipment; you’re investing in ongoing support and innovation from experts dedicated to helping your business thrive in an ever-changing landscape.

Support and Services Offered by Kiant Machinery

When investing in an industrial laser cutter, it's essential to have robust support and services to ensure your operations run smoothly. Kiant Machinery understands this need and offers comprehensive assistance to its customers, from installation and training to ongoing after-sales support. With a focus on customer satisfaction, Kiant is committed to helping you maximize the potential of your laser cutting machine steel.

Installation and Training

The installation of a metal cutting machine laser can be a complex process, but Kiant Machinery makes it seamless. Their experienced technicians handle the setup of your industrial laser cutting machine, ensuring that everything is calibrated correctly for optimal performance. Additionally, they provide thorough training sessions for your team, equipping them with the necessary skills to operate the laser cutter for metal efficiently.

Training doesn't just stop at installation; it’s an ongoing commitment at Kiant Machinery. They offer refresher courses and updates whenever new features or technologies are introduced in their industrial laser machines. This dedication ensures that your staff remains proficient in using the latest advancements in laser technology.

After-Sales Support

Once you’ve invested in a laser steel cutting machine from Kiant Machinery, their relationship with you doesn’t end there; it’s just the beginning! Their after-sales support team is always on standby to address any technical issues or questions that may arise during operation. This proactive approach helps minimize downtime and keeps your production line running smoothly.

Kiant also provides regular maintenance checks as part of their after-sales service package, ensuring that your metal cutting laser cutter operates at peak efficiency throughout its lifespan. These services are vital for preventing unexpected breakdowns that could disrupt your operations and lead to costly delays.

Customer Success Stories

Kiant Machinery has a proven track record of transforming businesses through its advanced industrial laser cutters. Numerous customers have reported significant improvements in their production capabilities after switching to Kiant's metal cutting machines lasers. From small workshops to large manufacturing plants, success stories abound where companies have increased productivity while reducing operational costs thanks to their investment in fiber laser technology.

One notable example involves a manufacturer who upgraded from traditional methods to an industrial laser cutting machine provided by Kiant. They experienced not only faster processing times but also enhanced precision—allowing them greater flexibility in meeting customer demands while maintaining high-quality standards.

Conclusion

In the rapidly evolving landscape of manufacturing, laser cutting machines stand out as a beacon of innovation and efficiency. With advancements in technology, particularly in fiber laser systems, these machines are becoming increasingly sophisticated and accessible. As industries strive for precision and speed, the future of laser cutting is poised to reshape production processes across various sectors.

The Future of Laser Cutting Machines

The future of laser cutting machines is bright, driven by continuous technological advancements that enhance performance and versatility. Innovations in industrial laser cutters are leading to improved energy efficiency and reduced operational costs, making them an attractive option for businesses looking to optimize their metal fabrication processes. As industries embrace automation and smart manufacturing practices, the capabilities of metal cutting laser cutters will expand further, paving the way for unprecedented levels of productivity.

Why Choose Kiant Machinery for Your Needs

Our extensive range of products includes top-of-the-line laser cutters for metal that are designed to meet diverse application requirements while ensuring superior performance. With a commitment to customer satisfaction and ongoing support, Kiant Machinery stands out as a partner you can trust for all your metal cutting machine laser solutions.

Transforming Manufacturing with Laser Technology

Laser technology is not just transforming how we cut materials; it's redefining the entire manufacturing landscape. The precision offered by industrial laser machines allows manufacturers to achieve intricate designs with minimal waste, leading to sustainable practices that benefit both business and environment alike. By integrating advanced features into our industrial laser cutter offerings, Kiant Machinery empowers businesses to elevate their production capabilities while embracing the future of manufacturing.