Introduction

In the ever-evolving landscape of manufacturing, laser cutting technology has emerged as a transformative force, revolutionizing the way metal components are produced. From intricate designs to high-volume production runs, the right laser cutting machine can significantly enhance operational capabilities and product quality.

Importance of Laser Cutting Technology

Laser cutting technology stands at the forefront of industrial processes, providing unmatched accuracy and versatility for a myriad of applications. Traditional methods often fall short in terms of precision and speed, making the adoption of advanced metal cutting machines essential for competitive businesses. With capabilities ranging from simple shapes to complex geometries, these machines have become vital for maintaining productivity and meeting customer demands in today's fast-paced market.

Advantages of Fiber Laser for Metal Tubes

Their ability to cut through various metals with exceptional speed and minimal heat-affected zones results in cleaner edges and reduced post-processing requirements. Moreover, fiber lasers require less maintenance than traditional iron laser cutting machines while delivering superior energy efficiency—making them an attractive option for any business looking to optimize its metal cutting processes.

How to Choose the Right Machine

Choosing the right metal cutting machine is crucial for achieving desired outcomes while staying within budget constraints. Factors such as material thickness, production volume, and specific application requirements should be carefully considered when selecting a laser machine. Additionally, understanding features like automation capabilities and software integration can help streamline operations—ensuring that your investment in a metal cutting laser cutter pays off in the long run.

Overview of Fiber Laser Cutting Machines

In the realm of modern manufacturing, fiber laser cutting machines have emerged as a game changer. These machines utilize advanced technology to deliver precise cuts in metal, making them indispensable for industries that rely on high-quality metal components. With their efficiency and versatility, fiber lasers are quickly becoming the go-to choice over traditional methods like CO2 laser cutters.

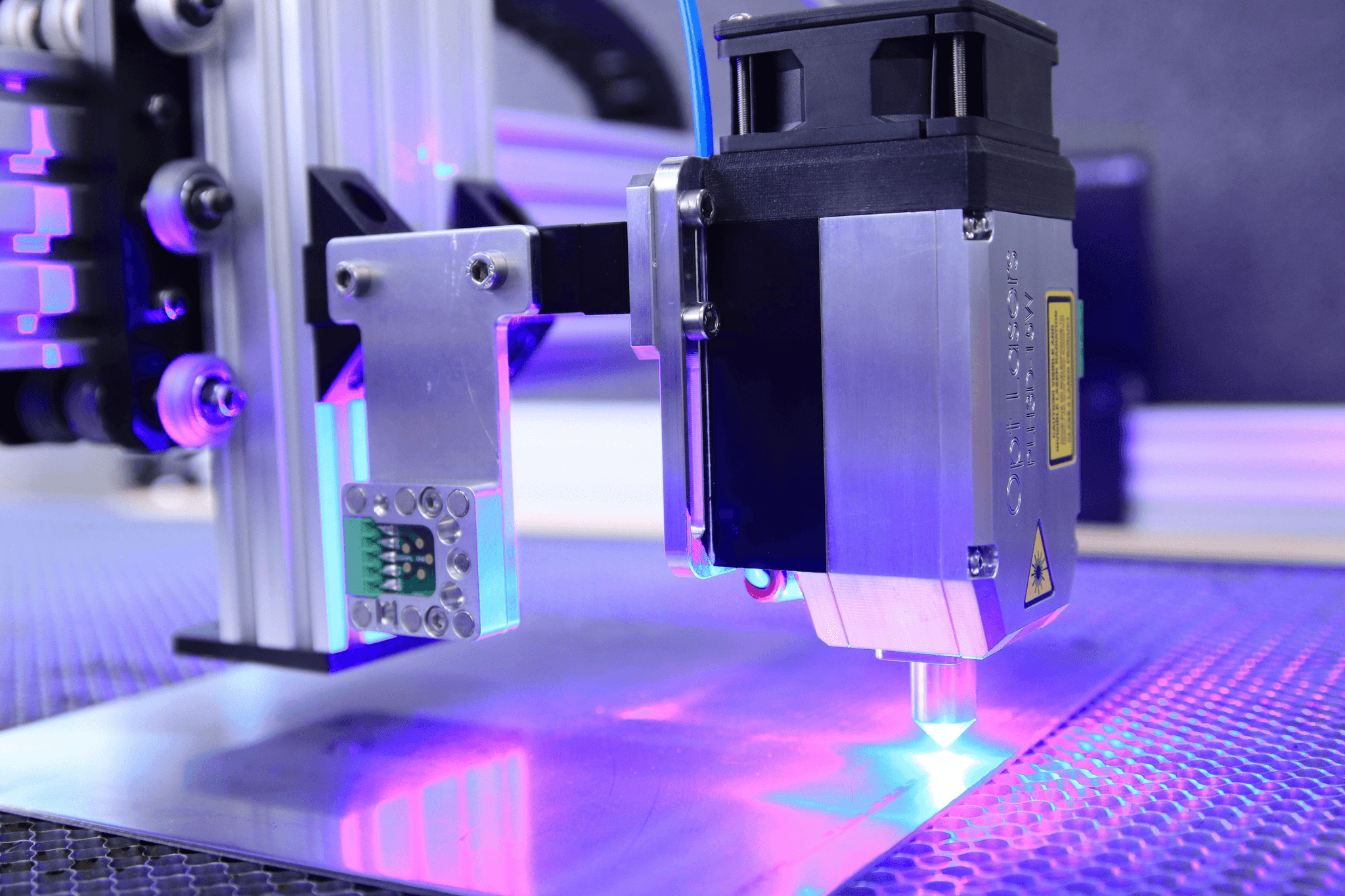

What is a Fiber Laser Cutting Machine?

A fiber laser cutting machine is a type of metal cutting machine that employs a solid-state laser to cut various materials, particularly metals. Unlike conventional CO2 laser cutters, which use gas to generate the laser beam, fiber lasers utilize optical fibers doped with rare-earth elements to produce a highly focused beam of light. This innovative approach allows for superior energy efficiency and faster cutting speeds, making it ideal for applications requiring intricate designs or rapid production.

Key Features and Benefits

One of the standout features of fiber laser cutting machines is their ability to cut through thick materials with remarkable precision and speed. They are equipped with advanced optics that provide excellent beam quality and focusability, leading to cleaner cuts and reduced waste material. Additionally, these metal cutting machines have lower operating costs compared to traditional iron laser cutting machines due to their energy efficiency and minimal maintenance requirements.

Another significant benefit is their versatility; fiber lasers can easily switch between different materials such as stainless steel, aluminum, and even non-metallic materials like plastics or wood when properly configured. The integration of automation features further enhances productivity by streamlining operations in busy workshops or factories. Overall, investing in a metal cutting machine laser can significantly boost operational efficiency while delivering exceptional results.

Comparison with CO2 Laser Cutters

When comparing fiber lasers with CO2 laser cutters, several key differences emerge that highlight why many manufacturers prefer the former for metal processing tasks. First off, fiber lasers generally offer better beam quality than CO2 systems; this translates into finer cuts at higher speeds without compromising on accuracy—an essential factor when dealing with intricate designs or tight tolerances in parts manufacturing.

Moreover, while both types can handle various materials effectively, fiber lasers excel specifically in cutting reflective metals like copper and brass—materials that often pose challenges for conventional CO2 setups due to reflection issues during processing. Lastly, from an operational standpoint, the lower power consumption of fiber lasers leads not only to cost savings but also reduces environmental impact—a win-win situation for businesses looking to optimize both performance and sustainability.

Top Picks for Best Fiber Laser Cutting Machines

Kiant Machinery’s Advanced Laser Tube Cutters

Kiant Machinery has made a name for itself with its advanced laser tube cutters, designed specifically for high-speed metal cutting applications. These machines are equipped with state-of-the-art technology that allows for exceptional accuracy when dealing with various tube sizes and materials. The iron laser cutting machine from Kiant boasts features such as automatic loading systems and intelligent software integration, ensuring seamless operation in any fabrication shop.

One of the key advantages of Kiant's metal cutting machine is its ability to handle complex geometries without compromising on speed or quality. This makes it an ideal choice for businesses looking to maximize productivity while minimizing waste. With a focus on user-friendly interfaces and robust after-sales support, investing in a Kiant laser machine is a smart move for any serious metal fabricator.

Trumpf TruLaser Series for Metal Cutting

The Trumpf TruLaser Series stands out as one of the most versatile options available in the market today. Known for its reliability and high performance, this series offers several models tailored to different needs within metal fabrication industries. Whether you’re working with thick steel or intricate designs, this metal cutting laser cutter ensures precision cuts every time.

What sets Trumpf apart is its innovative technology that combines speed with exceptional beam quality—features that are crucial when considering a laser cutting machine for various materials. Moreover, Trumpf offers extensive training programs to help operators get accustomed to using their machines effectively. If you’re considering an investment in a top-tier metal cutting machine laser, look no further than the TruLaser Series; it’s built to last.

Bystronic Bysprint Fiber for Precision Cutting

For those who prioritize precision above all else, the Bystronic Bysprint Fiber is hard to beat. This laser machine excels at delivering clean cuts on even the most challenging materials while maintaining high-speed operations—perfectly suited for industries requiring meticulous attention to detail like aerospace or automotive manufacturing. The Bysprint Fiber's advanced features include dynamic focusing capabilities that adjust automatically based on material thickness.

Additionally, Bystronic's commitment to energy efficiency means that this fiber laser cutter not only performs well but also reduces operational costs over time—an essential factor when evaluating your investment options in a metal cutting machine. Their robust customer support further ensures that you will have assistance whenever needed during your production processes. With Bystronic’s Bysprint Fiber, you can achieve unparalleled results without breaking the bank on maintenance or energy consumption.

Performance vs. Cost: Finding the Right Balance

When it comes to investing in a metal cutting machine, performance and cost are two sides of the same coin. A high-performance iron laser cutting machine might come with a hefty price tag, but it can also deliver exceptional results that justify the investment. Striking the right balance between these factors is crucial for businesses looking to optimize their operations without breaking the bank.

Analyzing Cost-Effectiveness

Cost-effectiveness is not just about the initial purchase price of your metal cutting laser cutter; it encompasses long-term savings and productivity gains as well. A fiber laser cutting machine often has lower operational costs compared to traditional CO2 laser cutters, thanks to its energy efficiency and reduced maintenance needs. By analyzing total cost of ownership over time, businesses can determine which laser machine will provide better value while delivering optimal performance.

Maintenance and Operating Costs

Maintenance plays a significant role in the overall cost of running a metal cutting machine laser system. Fiber lasers generally require less upkeep than their CO2 counterparts, leading to lower operating costs over time—a significant consideration for any savvy business owner. Additionally, understanding how frequently parts need replacement or servicing can help you budget effectively and avoid unexpected expenses down the line.

ROI Considerations for Metal Cutting Machines

When evaluating ROI for your new iron laser cutting machine, it's essential to look beyond just purchase price and consider factors like production speed, quality of cuts, and versatility across various applications. A high-quality metal cutting machine can lead to increased productivity, reduced waste, and ultimately higher profits—making it easier to justify its initial investment over time. By carefully assessing these elements alongside financial metrics, companies can make informed decisions that align with their strategic goals.

Applications of Fiber Laser Cutting in Industries

Fiber laser cutting technology has revolutionized various industries by providing precise and efficient metal cutting solutions. Its versatility allows for the production of intricate designs and complex shapes, making it an essential tool in modern manufacturing. From construction to aerospace, the applications of fiber laser cutting machines are vast and impactful.

Metal Fabrication and Construction

In the realm of metal fabrication and construction, fiber laser cutting machines are indispensable for their ability to handle a wide range of materials with ease. These metal cutting machines offer exceptional speed and accuracy, allowing fabricators to produce components that meet stringent industry standards. Whether it's beams, brackets, or custom parts, an iron laser cutting machine can streamline processes while reducing waste.

The durability of materials processed via a metal cutting machine laser means that components can withstand harsh environments without compromising structural integrity. Additionally, the efficiency provided by these laser machines translates into faster project completion times—an invaluable asset in competitive construction markets. As companies increasingly adopt advanced technologies like fiber lasers, they gain a significant edge over those relying on traditional methods like CO2 laser cutters.

Automotive Industry Uses

The automotive industry is another sector that has greatly benefited from advancements in fiber laser technology. Metal cutting lasers allow manufacturers to create precise parts with minimal tolerance errors—crucial for vehicle safety and performance standards. From chassis components to intricate engine parts, using a metal cutting machine ensures high-quality production while optimizing material usage.

Moreover, as electric vehicles become more prevalent, the demand for lightweight yet strong materials has surged; this is where an iron laser cutting machine shines due to its ability to cut advanced alloys efficiently. The speed at which these machines operate also aids in rapid prototyping—a key factor in today's fast-paced automotive market where innovation is vital. By leveraging fiber lasers instead of traditional methods like CO2 laser cutters, automotive manufacturers can enhance productivity without sacrificing quality.

Aerospace Applications for Metal Cutting

Aerospace applications require unparalleled precision and reliability; hence the adoption of fiber laser technology has been transformative within this field. The capability of a metal cutting machine to create complex geometries while maintaining strict tolerances makes it ideal for producing critical aircraft components such as frames and fuselage sections. An iron laser cutting machine not only meets but often exceeds industry requirements for safety and performance.

Furthermore, these advanced machines facilitate the use of lightweight materials essential for fuel efficiency—a top priority in aerospace engineering today. With their reduced operational costs compared to traditional methods like CO2 laser cutters, companies can invest savings back into research and development efforts aimed at creating even more innovative aircraft designs. As aerospace continues evolving toward greater sustainability goals, fiber lasers will undoubtedly play a pivotal role in shaping its future.

Advanced Features to Look For

When investing in a metal cutting machine, it's essential to consider advanced features that enhance productivity and safety. Automation and software integration can significantly streamline operations, while robust safety features protect operators during the laser cutting process. Additionally, after-sales support and training ensure your team is well-equipped to maximize the machine's potential.

Automation and Software Integration

Automation is revolutionizing the landscape of metal cutting machines, particularly with iron laser cutting machines. Advanced software integration allows for seamless operation, enabling users to program complex cuts with ease and precision. This not only enhances efficiency but also reduces human error, making the metal cutting laser cutter a reliable choice for high-volume production.

Moreover, modern automation features can include automatic loading and unloading systems that save time and labor costs. When selecting a laser machine, look for models that offer compatibility with industry-standard CAD/CAM software for streamlined design-to-production workflows. Ultimately, an automated system will not only boost your output but also provide a competitive edge in today's fast-paced manufacturing environment.

Safety Features in Metal Cutting Machines

Safety should always be a top priority when operating any metal cutting machine laser technology. The best iron laser cutting machines come equipped with advanced safety features such as enclosed work areas, emergency stop buttons, and protective interlocks that prevent unauthorized access during operation. These measures help create a safer working environment for operators while maintaining compliance with industry regulations.

In addition to physical safety mechanisms, some modern metal cutting machines incorporate smart technology that monitors performance metrics in real-time. This allows for immediate alerts if any irregularities are detected during operation—ensuring quick responses to potential hazards before they escalate into serious issues. Investing in a laser cutting machine with robust safety features not only protects your workforce but also minimizes downtime due to accidents or equipment failures.

After-Sales Support and Training with Kiant Machinery

When it comes to purchasing a metal cutting machine like the Kiant Machinery models, after-sales support can make all the difference in ensuring long-term satisfaction. Comprehensive training programs help operators understand how to utilize their new iron laser cutting machine effectively while maximizing its capabilities through specialized techniques tailored for different applications. This investment in education can lead to significant improvements in production quality and efficiency.

Moreover, reliable after-sales support means you have access to expert assistance whenever issues arise or maintenance is required on your metal cutting laser cutter. Having dedicated customer service representatives who understand your specific needs ensures that you won't be left hanging when challenges occur—keeping your production line running smoothly at all times! Ultimately, choosing a manufacturer like Kiant Machinery provides peace of mind knowing you have ongoing support as you navigate the world of advanced metal fabrication.

Conclusion

In the fast-paced world of manufacturing, choosing the right laser machine can make all the difference in maximizing efficiency and productivity. With advancements in technology, particularly fiber laser cutting machines, businesses can significantly enhance their metal processing capabilities. By investing in a high-quality metal cutting machine laser, companies can streamline operations and achieve superior results.

Maximizing Efficiency with the Right Laser Machine

The key to maximizing efficiency lies in selecting an iron laser cutting machine that aligns with your specific needs. A well-chosen metal cutting machine not only reduces waste but also speeds up production times, allowing for more projects to be completed on schedule. Additionally, features like automation and software integration can elevate your operations to new heights, making your metal cutting laser cutter an invaluable asset.

The Future of Metal Cutting Technology

As industries continue to evolve, so too does the technology behind metal cutting machines. The future holds exciting possibilities for innovations such as enhanced precision and speed in fiber laser systems compared to traditional CO2 laser cutters. These advancements will likely lead to even more efficient processes and applications across various sectors—from automotive manufacturing to aerospace engineering—ensuring that businesses remain competitive in a rapidly changing marketplace.

Final Thoughts on Choosing a Fiber Laser Machine

When it comes down to it, choosing a fiber laser machine involves careful consideration of factors like performance, cost-effectiveness, and after-sales support from manufacturers like Kiant Machinery. Each business has unique requirements; thus, understanding your specific needs will guide you toward the best metal cutting machine for your operation. Ultimately, investing in the right equipment today will pave the way for greater success tomorrow.