Introduction

In the world of manufacturing and fabrication, metal laser cutting has emerged as a game-changer, revolutionizing the way we approach precision cutting. This advanced technology utilizes lasers that cut metal with remarkable accuracy and efficiency, making it a preferred choice for various industries. As we delve into this topic, we will explore the significance of laser technology in modern machining and provide an overview of the cutting process that defines this innovative technique.

Understanding Metal Laser Cutting

Metal laser cutting is a process that employs focused laser beams to slice through materials with exceptional precision. By harnessing the power of lasers that cut metal, manufacturers can achieve intricate designs and complex shapes that traditional methods struggle to replicate. This process not only enhances productivity but also reduces material waste, making it an environmentally friendly option in today's manufacturing landscape.

Importance of Laser Technology

The importance of laser technology in industrial applications cannot be overstated; it offers unparalleled accuracy and speed compared to conventional cutting methods. Industrial laser machines have transformed how businesses operate by minimizing downtime and maximizing output quality. With advancements in this field, companies are increasingly investing in high-performance equipment like desktop laser cutters and industrial laser cutting machines to stay competitive.

Overview of the Cutting Process

The metal laser cutting process involves several key steps: from design creation using CAD software to the actual cutting phase where lasers are directed onto the material's surface. The precision achieved during this process is largely attributed to sophisticated control systems integrated within modern cutting machine lasers. As we progress through this guide, we'll unpack each step involved in metal laser cutting while highlighting essential safety protocols for operation.

What is Metal Laser Cutting?

Metal laser cutting is a modern technique that utilizes focused laser beams to slice through various types of metals with precision and efficiency. This innovative method has revolutionized the manufacturing industry, offering unparalleled accuracy compared to traditional cutting methods. Whether it's for intricate designs or large-scale production, lasers that cut metal have become the go-to solution for many businesses.

Definition of Metal Laser Cutting

At its core, metal laser cutting refers to the process of using a high-powered laser beam to cut through metal sheets or components. The technology harnesses the intense heat generated by the laser to melt or vaporize material in a controlled manner, resulting in clean edges and minimal waste. This method can be employed on a variety of metals, including steel, aluminum, and titanium, making it versatile for different applications.

How Lasers that Cut Metal Work

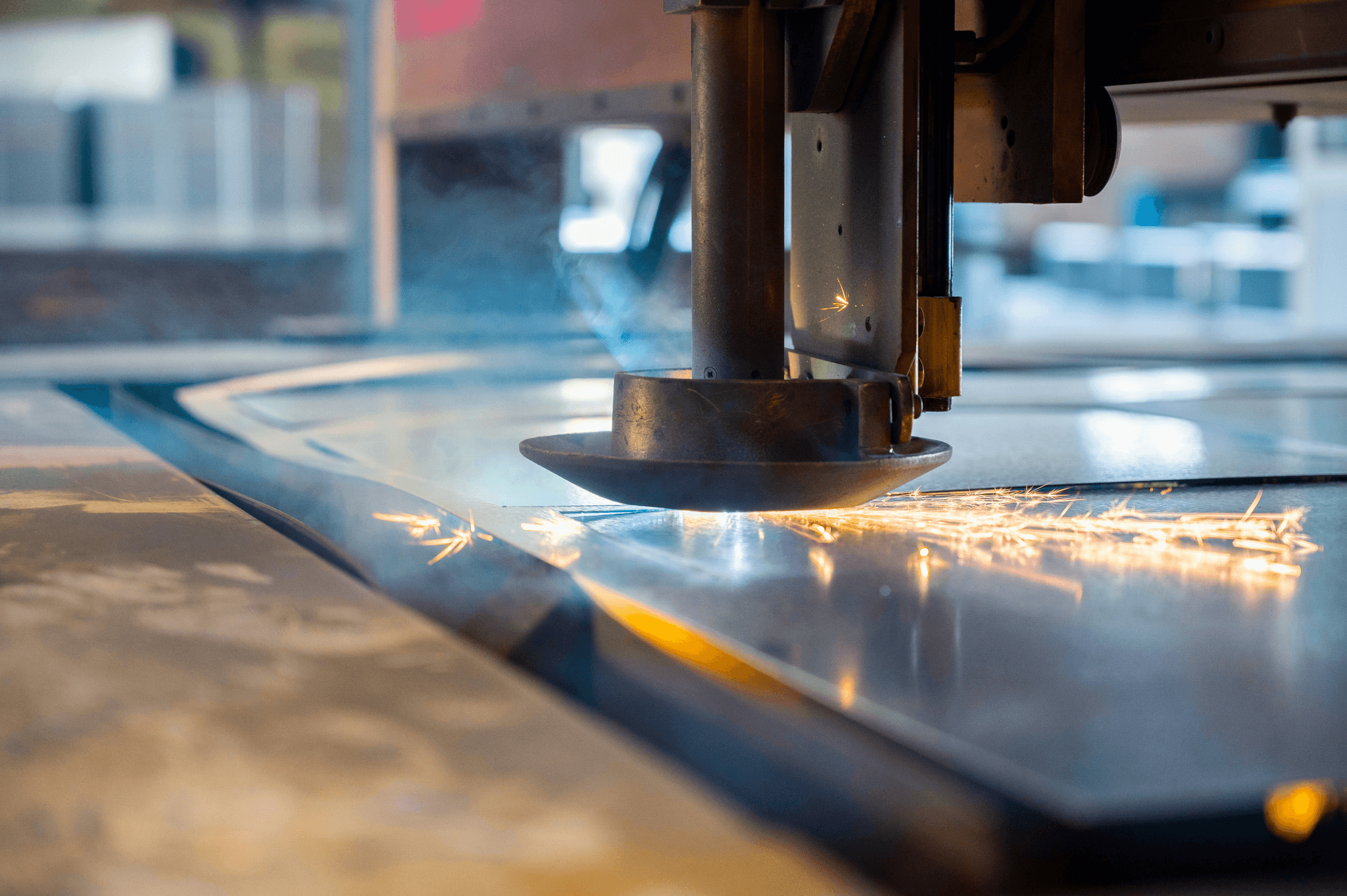

Lasers that cut metal operate by directing a concentrated beam of light onto the material surface, which causes rapid heating and melting at the point of contact. The process typically involves an industrial laser cutting machine equipped with mirrors or fiber optics to focus the beam accurately on the desired area. As the machine moves along predetermined paths, it either blows away molten material with a gas jet or allows it to fall away from the cut edge—ensuring smooth and precise cuts every time.

Benefits Over Traditional Cutting Methods

The advantages of using lasers over traditional cutting methods are numerous and compelling. For starters, metal laser cutters provide exceptional accuracy and repeatability—qualities that are essential in industries where precision is paramount. Additionally, these industrial laser machines reduce kerf (the width of material removed during cutting), leading to less waste and lower costs in materials over time; not to mention they often require less post-processing work due to their clean cuts! Furthermore, advancements in desktop laser cutters have made this technology accessible even for smaller shops looking for efficient solutions without breaking the bank on laser machine prices.

The Metal Laser Cutting Process

The metal laser cutting process is a sophisticated method that utilizes high-powered lasers to slice through various types of metal with remarkable precision. This technique has revolutionized manufacturing by offering speed and accuracy that traditional methods simply can't match. Understanding the intricacies of this process will help you appreciate the technology behind industrial laser cutting machines and their applications.

Steps Involved in the Process

The first step in metal laser cutting involves designing a digital model using computer-aided design (CAD) software, which serves as the blueprint for the cut. Once the design is finalized, it is transferred to an industrial laser cutting machine where it will guide the lasers that cut metal precisely along predetermined paths. The next phase includes setting up the machine, selecting appropriate materials, and adjusting parameters such as power, speed, and focus before initiating the cutting operation.

As the process unfolds, a focused beam from the laser interacts with the metal surface, heating it to melting or vaporization point while simultaneously blowing away molten material using a gas assist. After completing one section of cuts, operators often check for accuracy before moving on to subsequent sections to ensure quality control throughout production runs. Once finished, parts are typically deburred or cleaned up for final inspection before they are ready for assembly or shipping.

Types of Lasers Used in Cutting

When it comes to lasers that cut metal, different types cater to various applications based on material thickness and type. The most common types include CO2 lasers and fiber lasers; CO2 lasers excel at cutting thicker materials while fiber lasers are known for their efficiency with thinner metals and faster processing speeds. Industrial laser machines also employ solid-state lasers which provide excellent beam quality and can be used effectively on reflective materials like aluminum.

Each type of laser has its strengths depending on factors like energy consumption and operational costs—critical considerations when evaluating different options for your own setup or when searching for a desktop laser cutter suitable for smaller projects at home or in workshops. Understanding these differences helps businesses choose an optimal solution tailored to their specific needs without overspending on capabilities they may not require.

Safety Protocols During Operation

Safety protocols during operation are paramount when working with powerful industrial laser cutting machines due to potential hazards associated with high-intensity beams and flying debris from cuts. Operators should always wear appropriate personal protective equipment (PPE), including safety goggles specifically designed to filter harmful wavelengths emitted by lasers that cut metal during operation. Additionally, proper training on machine handling ensures operators understand emergency shutdown procedures as well as safe distance guidelines from active work areas.

Regular maintenance checks of machinery play an essential role in preventing accidents; worn-out components can lead to malfunctioning equipment posing risks not only to operators but also surrounding personnel in busy workshop environments where multiple machines may be running simultaneously. Furthermore, implementing clear signage around work areas reinforces awareness about potential hazards associated with metal laser cutters while promoting a culture of safety among all staff members involved in production processes.

Types of Metal Laser Cutting Machines

When it comes to metal laser cutting, the variety of machines available can be overwhelming. Understanding the different types of lasers that cut metal is crucial for selecting the right tool for your needs, whether you are in a large industrial setting or working from a small workshop. This section will explore industrial laser cutting machines, desktop laser cutters, and key features to consider when making your choice.

Industrial Laser Cutting Machines Explained

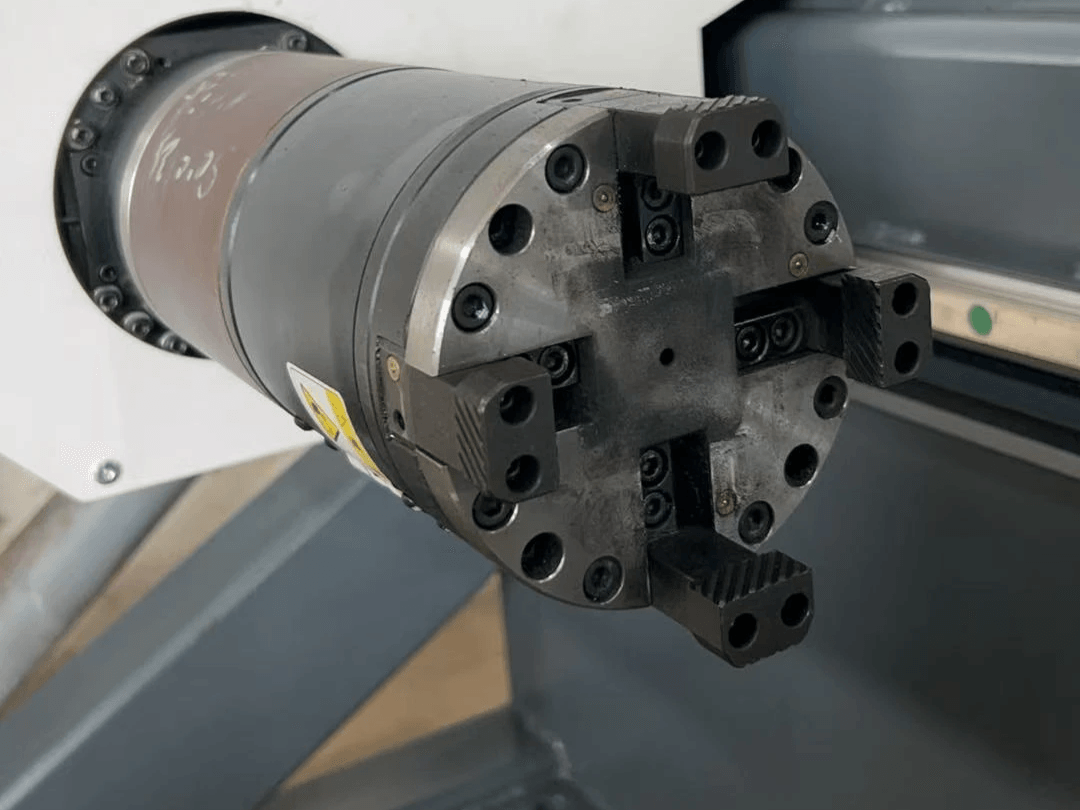

Industrial laser cutting machines are powerhouses designed for high-volume production and precision. These robust machines utilize advanced lasers that cut metal with incredible accuracy, making them essential in sectors like automotive and aerospace manufacturing. Due to their size and capabilities, they often come with a higher laser machine price but offer unmatched efficiency and speed compared to smaller alternatives.

These machines typically employ CO2 or fiber lasers, which allow them to handle various materials including steel, aluminum, and even exotic alloys. The ability to cut thicker materials at faster speeds makes industrial laser cutting machines a favorite among manufacturers looking to optimize their production lines. Investing in such equipment can lead directly to increased output and reduced operational costs over time.

Comparing Desktop Laser Cutters

On the other end of the spectrum are desktop laser cutters—compact yet capable tools ideal for hobbyists or small businesses. While not as powerful as their industrial counterparts, these machines still utilize effective lasers that cut metal with surprising finesse for thinner sheets or intricate designs. Their affordability makes them an attractive option for those looking to dip their toes into metalworking without breaking the bank on an industrial setup.

Desktop models typically feature user-friendly interfaces and are often compatible with various design software, allowing users more flexibility in creating custom pieces. However, potential buyers should pay close attention to specifications like maximum material thickness and power output when comparing options within this category. With numerous models available on the market today, finding a reliable metal laser cutter for sale has never been easier.

Key Features to Look For

When choosing between an industrial or desktop cutting machine laser, several key features should influence your decision-making process. First off is the power rating; higher wattage translates into faster cutting speeds and greater material thickness capabilities—critical factors if you plan on tackling heavier projects regularly. Additionally, consider the type of cooling system employed; efficient cooling mechanisms can prolong machine life by preventing overheating during extensive use.

Another vital aspect is software compatibility; ensure that your chosen machine can seamlessly integrate with design programs you intend to use for creating intricate designs or prototypes. Lastly, don’t overlook customer support options offered by manufacturers; robust support can make all the difference when troubleshooting issues down the line or seeking maintenance advice on your investment in an industrial laser machine or desktop cutter.

Leading Brands and Manufacturers

In the competitive landscape of metal laser cutting, several brands stand out for their innovation and reliability. Among these, Kiant Machinery has carved a niche for itself with its advanced industrial laser cutting machines that cater to various industries. Understanding the offerings from leading manufacturers helps potential buyers make informed decisions about their investment in lasers that cut metal.

Overview of Kiant Machinery

Kiant Machinery is renowned for producing high-quality industrial laser cutting machines designed to meet the demands of modern manufacturing. Their products emphasize precision, efficiency, and user-friendly interfaces, making them a top choice among professionals seeking reliable cutting machine lasers. With a commitment to innovation, Kiant Machinery continuously enhances its technology to stay ahead in the market.

The company’s range includes both large-scale industrial laser machines and more compact desktop laser cutters, catering to different operational needs. Their machines are equipped with advanced features like automated settings and real-time monitoring capabilities, ensuring optimal performance during operation. Additionally, Kiant's robust customer support enhances user experience by providing assistance throughout the lifecycle of their products.

Understanding Laser Machine Price

When it comes to investing in lasers that cut metal, understanding the price dynamics is crucial. The cost of a cutting machine laser can vary significantly based on various factors, making it essential for buyers to know what influences these prices. Whether you’re eyeing an industrial laser cutting machine or a more compact desktop laser cutter, being informed will help you make the best choice for your needs.

Factors Influencing Cost

Several elements contribute to the overall laser machine price, starting with the type of technology used in the industrial laser machines. For instance, CO2 lasers and fiber lasers come with different price tags due to their unique capabilities and applications in metal cutting. Additionally, features such as power output, precision levels, and software integration can further inflate or deflate costs in both industrial and desktop models.

Another significant factor is brand reputation; well-established manufacturers often charge premium prices for their reliability and support services. Maintenance requirements also play a role; machines that need frequent upkeep may seem cheaper upfront but can lead to higher long-term expenses. Lastly, market demand and competition can impact pricing trends; during peak demand periods, prices may rise as buyers scramble for quality metal laser cutters for sale.

Average Price Ranges for Different Models

When exploring average price ranges for various models of lasers that cut metal, it's important to categorize them effectively. Industrial laser cutting machines generally start around $50,000 and can go well over $500,000 depending on size and capabilities. On the other hand, desktop laser cutters are more budget-friendly options typically ranging from $2,000 to $20,000—ideal for small businesses or hobbyists looking to dabble in metal cutting without breaking the bank.

Mid-range options exist too; these machines often bridge the gap between entry-level desktop models and high-end industrial units. Expect these machines to fall within a range of $20,000 to $50,000 while offering improved features like enhanced speed and better precision compared to their lower-priced counterparts. Ultimately, your specific requirements will dictate which category best suits your needs when searching for a metal laser cutter for sale.

Cost-Benefit Analysis of Investment

Conducting a cost-benefit analysis before purchasing an industrial laser cutting machine is essential for making an informed decision. While initial costs might seem daunting—especially if you're considering high-end lasers that cut metal—the long-term benefits often outweigh these expenses significantly. Factors such as reduced material waste due to precise cuts and increased production efficiency can lead to substantial savings over time.

Moreover, investing in quality equipment ensures durability and reliability during operation; cheaper alternatives may save money upfront but could result in costly downtime or repairs later on. Additionally, consider how improved capabilities might enhance your product offerings or allow you greater flexibility in fulfilling customer demands—this potential increase in revenue should not be overlooked when evaluating investment returns on a cutting machine laser.

In conclusion, understanding the nuances behind laser machine prices empowers buyers with knowledge about their options while ensuring they make wise investments tailored specifically to their operational needs.

Conclusion

In conclusion, the world of metal laser cutting is rapidly evolving, bringing with it exciting advancements and opportunities. As industries continue to embrace precision and efficiency, the demand for cutting-edge technologies like lasers that cut metal will only grow. Understanding these trends can help businesses stay competitive and make informed decisions about their manufacturing processes.

Future Trends in Metal Laser Cutting

The future of metal laser cutting looks promising with innovations in technology and materials. Emerging trends include the development of more powerful industrial laser machines that enhance speed and precision while reducing waste. Additionally, advancements in automation and artificial intelligence are set to revolutionize how metal laser cutters operate, leading to increased efficiency and lower operational costs.

Choosing the Right Cutting Machine Laser

Selecting the right cutting machine laser is crucial for optimizing production capabilities. Factors such as material type, thickness, and desired precision should guide your choice between an industrial laser cutting machine or a desktop laser cutter. It's essential to assess your specific needs thoroughly; after all, investing in a suitable metal laser cutter for sale can significantly impact your operational success.

Finding a Reliable Metal Laser Cutter for Sale

When searching for a reliable metal laser cutter for sale, it's important to consider reputable manufacturers who prioritize quality and service support. Researching leading brands can provide insights into product performance and customer satisfaction ratings; this helps ensure you’re making a wise investment in an industrial laser cutting machine that meets your requirements. Don't forget to compare prices across models while factoring in long-term benefits—after all, a well-chosen machine can pay dividends down the line!