Introduction

In the ever-evolving world of manufacturing, fiber laser cutting technology stands out as a game changer, particularly for those in metal fabrication. With its precision and efficiency, the sheet metal cutting laser machine has become a preferred choice for businesses looking to enhance their production capabilities. Understanding this technology is crucial, as it directly impacts the quality of your projects and your bottom line.

Understanding Fiber Laser Cutting Technology

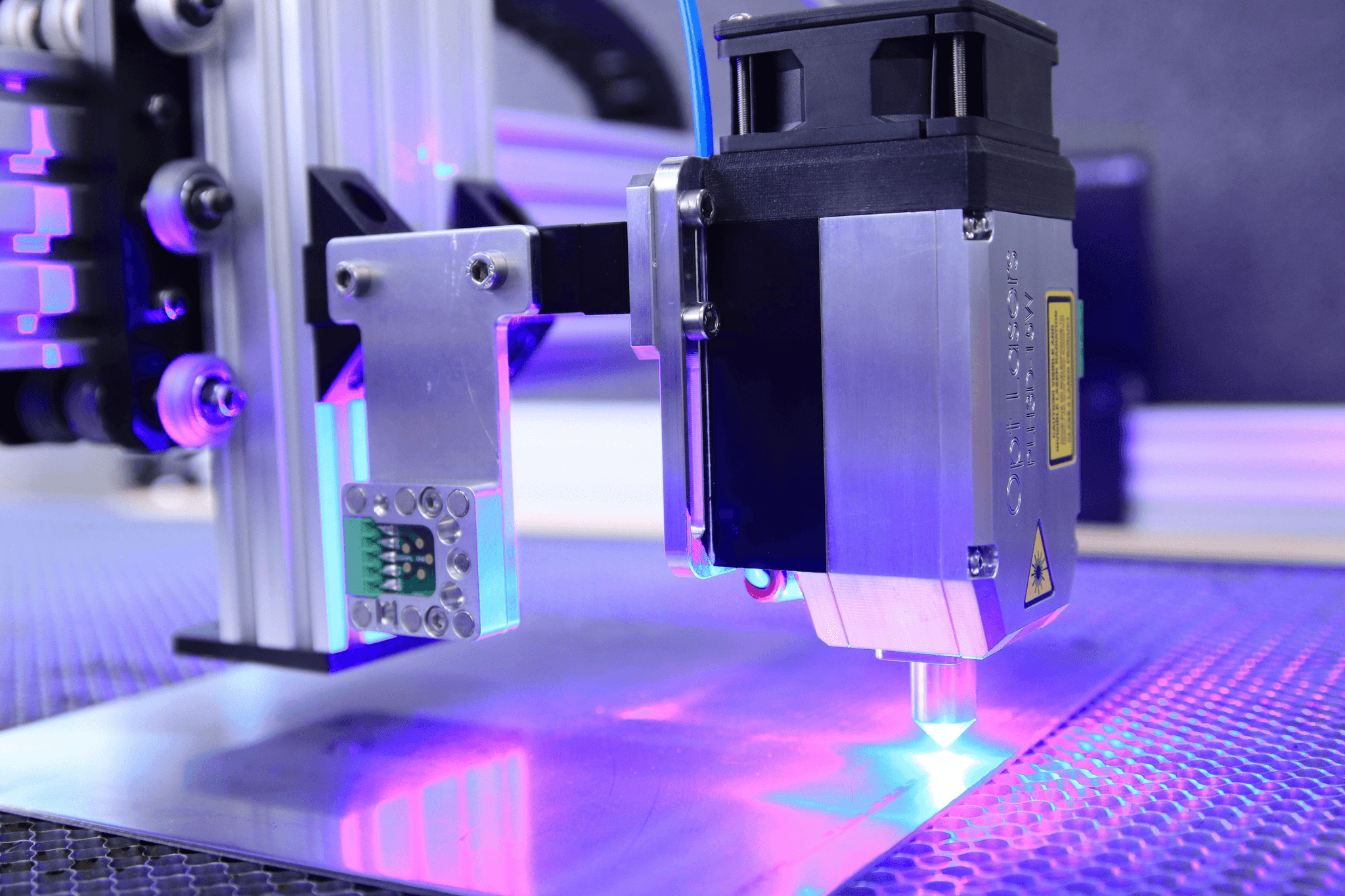

Fiber laser cutting utilizes advanced laser technology to deliver exceptional results in cutting various metals. By focusing a high-intensity beam onto the material, it can achieve intricate designs with remarkable accuracy. This method not only improves speed but also minimizes waste—making it a top choice for modern cutting machine lasers.

Importance of Choosing the Right Machine

Selecting the right laser cutting machine is paramount for optimizing production processes and meeting specific project requirements. A well-chosen cutting laser metal device can drastically reduce operational costs while enhancing quality control. Therefore, understanding your needs and evaluating different options ensures you invest wisely in a machine that aligns with your goals.

Overview of the Top Machines

The market offers an impressive array of fiber laser cutting machines designed to cater to diverse needs within metal fabrication. From industry leaders like Trumpf and Bystronic to innovative solutions from Kiant Machinery, each machine brings unique features that can elevate your operations. In this guide, we will explore these top contenders, helping you make an informed decision on which sheet metal cutting laser machine best suits your business.

What is a Fiber Laser Cutting Machine?

Fiber laser cutting machines have revolutionized the world of metal fabrication, providing high-speed, precise cutting solutions for various industries. Unlike traditional cutting methods, these machines utilize advanced fiber laser technology to achieve exceptional results. Understanding how this technology works and its benefits can help businesses make informed decisions about their manufacturing processes.

Explanation of Fiber Laser Technology

At the heart of a fiber laser cutting machine lies fiber laser technology, which generates a high-intensity beam of light through optical fibers doped with rare-earth elements. This method allows for a more efficient conversion of electrical energy into light, resulting in superior beam quality and power density compared to other types of lasers. The focused beam can easily cut through various materials, making it an ideal choice for sheet metal cutting laser machines.

Benefits of Using a Laser Cutting Machine

The advantages of using a laser cutting machine are numerous and impactful on productivity and efficiency. First and foremost, these machines offer unparalleled precision; they can create intricate designs without compromising the integrity of the material being cut. Additionally, a cutting machine laser provides faster processing speeds than traditional methods while producing minimal waste—making it both cost-effective and environmentally friendly.

Moreover, the versatility of laser cutting means that it can handle different materials such as steel, aluminum, and brass with ease. This adaptability makes it an essential tool in many workshops and factories specializing in metal fabrication. Ultimately, investing in a sheet metal cutting laser machine not only enhances production capabilities but also elevates the quality of finished products.

Common Applications in Metal Fabrication

Laser cutting has become integral to various applications within the metal fabrication sector due to its efficiency and precision. Industries such as automotive manufacturing frequently use these machines for creating complex parts that require exact measurements and clean edges—qualities that are challenging to achieve with conventional methods. Furthermore, architectural firms utilize laser-cut components for decorative elements or structural pieces that demand both aesthetic appeal and strength.

Another common application includes custom signage production where intricate designs need sharp details without any rough edges left behind after cutting—a feat easily accomplished by using a powerful cutting laser metal setup. Additionally, aerospace companies rely on these advanced systems for producing lightweight yet durable components crucial for aircraft performance and safety standards.

In summary, fiber laser technology has transformed how industries approach metal fabrication by offering unmatched precision, speed, and versatility across various applications—from automotive parts to artistic creations.

Key Features to Consider

This section will delve into the crucial aspects you should evaluate, including power and performance specifications, size and material capacity, as well as software compatibility. Each of these factors plays a significant role in determining the efficiency and effectiveness of your laser cutting endeavors.

Power and Performance Specifications

Power is one of the most critical specifications when selecting a cutting machine laser. Generally measured in watts, the power output directly correlates with the thickness of materials you can cut and the speed at which you can perform those cuts. A higher wattage typically allows for faster cutting speeds and better performance on thicker materials, making it essential to consider your specific needs before committing to a laser cutting machine.

Performance goes hand-in-hand with power; it’s not just about how much energy your sheet metal cutting laser machine can deliver but also how effectively it utilizes that energy. Look for features such as pulse frequency control and beam quality, which can significantly impact the precision of your cuts. Understanding these power dynamics will help ensure that your investment in a cutting laser metal technology pays off in both efficiency and quality.

Size and Material Capacity

The size of your chosen laser cutting machine is another vital factor that cannot be overlooked. Larger machines offer increased workspace for handling bigger sheets of material, which is particularly beneficial if you're working with extensive projects or high-volume production runs. However, you must also consider the physical space available in your facility; balancing capacity with practicality is key when selecting a sheet metal cutting laser machine.

Material capacity varies between different models; some machines excel at processing thinner materials while others are designed for more robust applications. Ensure that the machine you choose aligns with the types of metals you'll be working with most frequently—be it stainless steel, aluminum, or carbon steel—to maximize its utility over time. The right balance between size and material capacity will lead to more efficient operations within your fabrication processes.

Software and Compatibility

In today’s tech-savvy world, software compatibility has become increasingly important when selecting a laser cutting machine. The best machines come equipped with sophisticated software that not only streamlines operations but also integrates seamlessly with existing systems like CAD/CAM programs used in design processes. Investing in a model that offers robust software capabilities ensures smoother workflows from design conception through to final production.

Moreover, consider whether the software allows for easy updates or additional features down the line; this flexibility can save you money on future upgrades or new functionalities as technology evolves within the industry. Compatibility extends beyond just software—ensure that any attachments or additional tools required for specific tasks are readily available for your chosen model too! By prioritizing these elements, you'll secure an efficient setup capable of meeting both current demands and future challenges.

Top Fiber Laser Cutting Machines for Metal Fabrication

Trumpf TruLaser Series: Industry Leader

The Trumpf TruLaser Series is often regarded as the gold standard in sheet metal cutting laser machines. Known for their exceptional precision and reliability, these machines deliver outstanding performance across various applications. Whether you need to cut intricate designs or handle larger sheets, the TruLaser series excels with its advanced technology and user-friendly interface.

One standout feature is its high-speed cutting capabilities paired with remarkable cut quality, ensuring that every piece meets stringent standards. The integration of smart software solutions allows operators to optimize production processes efficiently, making it a favorite among manufacturers looking for speed without sacrificing quality. For businesses focused on maximizing productivity while maintaining high standards in laser cutting, investing in a Trumpf machine is a no-brainer.

Bystronic ByStar Fiber: Versatile and Efficient

Next up is the Bystronic ByStar Fiber, which has earned its reputation as one of the most versatile and efficient cutting machines on the market today. This machine offers an impressive range of power options suited for various materials and thicknesses—making it ideal for any metal fabrication shop looking to diversify its offerings. With its ability to easily switch between different types of cuts and materials, it stands out as an adaptable solution in an ever-evolving industry.

The ByStar Fiber also boasts innovative automation features that enhance productivity while reducing labor costs associated with manual operations. Its advanced laser technology ensures superior cut quality on both thin and thick sheets alike, providing a competitive edge for businesses that prioritize precision in their work. If you're seeking a reliable partner in your production line that can handle diverse tasks effortlessly, this machine should be at the top of your list.

Kiant Machinery's Advanced Laser Solutions

Lastly, we have Kiant Machinery's advanced laser solutions—an emerging player that's gaining traction among fabricators looking for cost-effective alternatives without compromising on performance. Their sheet metal cutting laser machines offer robust capabilities tailored specifically for small to medium-sized enterprises aiming to enhance their manufacturing processes without breaking the bank. These systems are designed with simplicity in mind while still delivering impressive results when it comes to cutting laser metal.

Kiant Machinery prides itself on providing excellent customer support alongside their innovative products; they ensure users are well-equipped to maximize their investment over time through training and maintenance services. Furthermore, these machines come equipped with intuitive software that simplifies operation—making them accessible even for those new to using a cutting machine laser effectively! For budget-conscious businesses eager to step into modern manufacturing techniques without overspending upfront, Kiant Machinery presents an appealing option worth considering.

Comparing Cutting Speed and Quality

When it comes to selecting the right cutting machine laser for your metal fabrication needs, understanding the balance between speed and quality is essential. Different machines excel in different areas, and knowing how they stack up can help you make an informed decision. In this section, we will delve into the speed metrics of leading machines, the trade-offs between precision and speed, and how various materials interact with these powerful tools.

Speed Metrics of Leading Machines

Speed is often a top priority for businesses looking to maximize productivity with their sheet metal cutting laser machine. The cutting speed of these machines is typically measured in meters per minute (m/min), with some high-end models capable of reaching speeds over 100 m/min. However, it's important to note that while faster speeds can lead to increased output, they may not always result in the best quality cuts—an aspect that should not be overlooked when evaluating a laser cutting machine.

Different manufacturers provide varying specifications on their cutting machines; for instance, Trumpf's TruLaser series boasts impressive acceleration rates and rapid positioning capabilities. Bystronic's ByStar Fiber also shines in this area with its ability to maintain efficiency at high speeds without compromising on performance. When comparing options, consider both the maximum speed ratings and real-world performance data from users to ensure you choose a machine that aligns with your operational goals.

Quality of Cuts: Precision vs. Speed

While speed is crucial in a competitive environment, quality should never take a backseat when it comes to selecting a cutting laser metal solution. Many users find themselves at a crossroads: opting for higher speeds can sometimes lead to rougher edges or less precise cuts on certain materials—especially thicker metals or those requiring intricate designs. Therefore, it's vital to assess how each machine balances speed against cut quality.

High-quality lasers are designed not just for rapid operation but also for delivering clean edges and minimal dross formation—features that ultimately save time during post-processing stages like deburring or finishing work. For example, machines equipped with advanced beam technology can enhance cut quality even at higher speeds by providing more consistent energy distribution across the material being processed. Thus, evaluating user feedback on cut quality at various speeds can provide valuable insights into which laser cutting machine will meet your specific requirements.

Material Interaction: Analyzing the Differences

The interaction between different materials and your chosen sheet metal cutting laser machine is another critical factor affecting both speed and quality outcomes. Various metals react differently under laser exposure; for instance, stainless steel may require specific settings compared to aluminum or mild steel due to differences in thermal conductivity and melting points. Understanding these interactions helps operators optimize their processes for each material type.

Additionally, some advanced models come equipped with adaptive technologies that automatically adjust parameters based on material type and thickness—greatly simplifying setup times while ensuring optimal results across diverse applications. This adaptability not only improves efficiency but also enhances overall production consistency when working with multiple materials over time. Ultimately, analyzing how well each cutting machine laser handles different materials will aid you in selecting one that meets your production demands effectively.

Cost-Effectiveness and ROI

When considering a sheet metal cutting laser machine, it's crucial to weigh the initial investment against potential long-term gains. While the upfront cost of a high-quality laser cutting machine can be significant, the efficiency and precision they offer often lead to substantial savings over time. Companies that invest in advanced cutting machines typically see improvements in production speed and reduced waste, translating into better profitability.

Initial Investment vs. Long-Term Gains

The initial investment for a cutting machine laser can be daunting, but savvy businesses recognize it as an investment rather than just an expense. High-performance laser cutting machines are designed to last, providing consistent output that enhances productivity over the years. Ultimately, companies often find that their return on investment (ROI) from increased efficiency and lower operational costs far outweighs the initial financial commitment.

Maintenance Costs and Considerations

Maintenance costs for a laser cutting machine are another vital aspect to consider in your ROI calculations. Regular upkeep is essential to ensure optimal performance and longevity of your sheet metal cutting laser machine; however, these costs are generally manageable compared to traditional machining methods. Furthermore, many manufacturers offer support packages that can help mitigate unexpected expenses and keep your cutting laser metal operating smoothly.

The Value of Efficient Production

Efficient production is where the true value of investing in a high-quality laser cutting machine shines through. With faster cut speeds and superior quality cuts, businesses can fulfill orders more quickly while maintaining high standards—leading to happier customers and repeat business. In today’s competitive landscape, adopting advanced technologies like a state-of-the-art sheet metal cutting laser machine not only boosts productivity but also positions companies favorably against competitors who may still rely on outdated methods.

Conclusion

In the rapidly evolving world of manufacturing, selecting the right sheet metal cutting laser machine can significantly impact your operational efficiency and product quality. The decision-making process should involve careful consideration of your specific needs, including the types of materials you work with and the volume of production required. Ultimately, investing in a cutting machine laser that aligns with your business goals will yield substantial returns.

Selecting the Best Machine for Your Needs

Choosing the ideal laser cutting machine hinges on understanding your unique requirements and how they align with available technologies. Consider factors such as power output, material thickness capabilities, and software compatibility to ensure optimal performance. With various models on the market, it's essential to evaluate each option's features against your production demands to find a perfect fit.

Importance of Reliable After-Sales Support

Once you've invested in a cutting laser metal solution, reliable after-sales support becomes invaluable to maintaining productivity and minimizing downtime. A trustworthy manufacturer should provide comprehensive service agreements that include training, maintenance, and troubleshooting assistance. This support not only enhances the longevity of your investment but also ensures that you can maximize the benefits of advanced technology like fiber laser cutting.

Future Trends in Laser Cutting Technology

The landscape of laser cutting technology is continually advancing with innovations aimed at improving speed, precision, and efficiency in sheet metal fabrication. Emerging trends include automation integration and artificial intelligence enhancements that promise to streamline operations further while reducing human error. By staying informed about these developments, businesses can leverage new capabilities that keep them competitive in an ever-evolving market.