Introduction

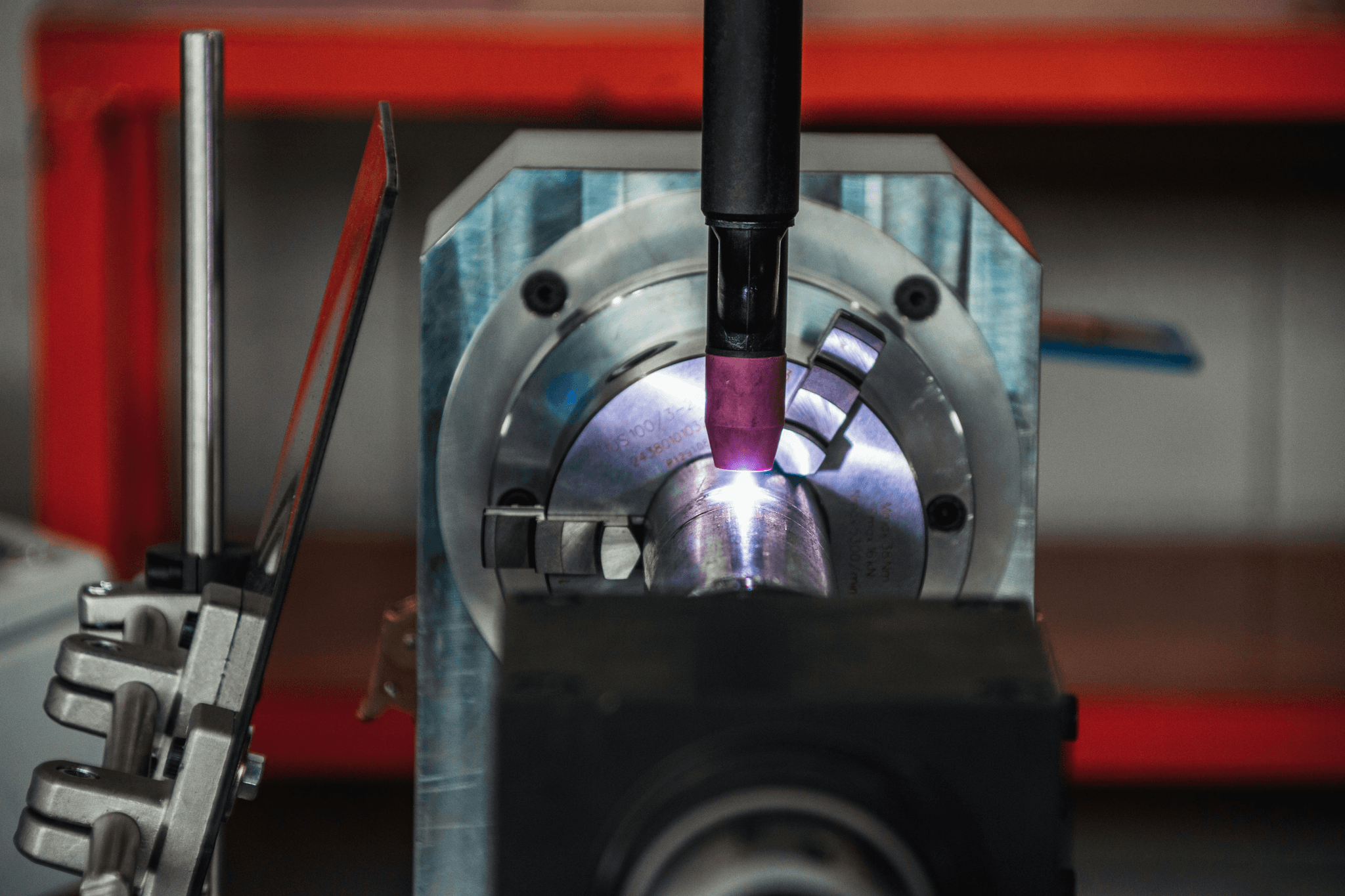

In the world of precision manufacturing, metal tube laser cutters have emerged as indispensable tools that combine speed, accuracy, and versatility. These machines, often referred to as industrial CNC laser cutters, are designed specifically to cut various types of metal tubes with remarkable precision. Understanding the available options and features is crucial for businesses looking to invest in a laser tube cutting machine that meets their specific needs.

Selecting the right equipment can significantly influence production efficiency and product quality. With numerous models on the market, including various tube laser cutting machines for sale, making an informed decision is essential. A well-chosen machine not only enhances productivity but also ensures compliance with safety standards and operational requirements.

When evaluating a tube laser cutting machine price, it's vital to consider key features that will impact your operations. Factors such as cutting speed, material compatibility, and automation capabilities play a significant role in determining the best fit for your business. By focusing on these essential aspects, you can confidently choose a machine that aligns with your production goals and budget constraints.

What to Look for in a Laser Cutter

When it comes to investing in a laser cutter, particularly an industrial CNC laser cutter, there are several key factors that can significantly impact your decision. The right machine can enhance your production capabilities and streamline your operations, so it’s crucial to understand what features truly matter. This section will guide you through performance metrics, pricing comparisons, and essential safety features that ensure compliance.

Performance Metrics for Industrial CNC Laser Cutters

Performance metrics are the lifeblood of any industrial CNC laser cutter. Factors such as cutting speed, precision, and material compatibility should be at the forefront of your evaluation process. For instance, a high-quality laser tube cutting machine should offer rapid cutting speeds without compromising on accuracy—this ensures that you maintain both productivity and quality in your projects.

Additionally, consider the maximum thickness and types of materials the tube laser cutting machine can handle. Machines that can work with a variety of metals like stainless steel or aluminum provide versatility essential for different applications. Ultimately, understanding these performance metrics will help you choose a laser cutter that meets both your current needs and future demands.

Comparing Tube Laser Cutting Machine Price

Price is often one of the most significant factors when selecting a tube laser cutting machine for sale. However, it's essential to look beyond just the sticker price; consider what you're getting for your investment. While some machines may have lower upfront costs, they might lack critical features or require more frequent maintenance—leading to higher long-term expenses.

To make an informed decision about tube laser cutting machine price, compare not only initial costs but also operational efficiency and potential return on investment (ROI). Investing in a more expensive model with superior technology could save money over time through reduced waste and increased production rates. Be sure to factor in warranties and support options as well; after all, peace of mind is priceless!

Essential Safety Features to Ensure Compliance

Safety should never take a backseat when evaluating an industrial CNC laser cutter; it's paramount for protecting both personnel and equipment. Ensure that any tube laser cutting machine you consider comes equipped with essential safety features such as emergency stop buttons and protective enclosures to minimize exposure during operation. These features are not just about compliance—they're about creating a safe working environment where employees feel secure.

Moreover, look for machines with advanced monitoring systems that can detect malfunctions or unsafe conditions before they lead to accidents or costly downtime. Regular safety audits should also be part of your operational routine; this keeps everyone aware of best practices while ensuring compliance with industry standards. Remember: investing in safety is investing in productivity!

Top Brands in Tube Laser Cutting Machines

When it comes to selecting the best tube laser cutting machine, knowing the top brands can make a world of difference. Each brand offers unique features, performance metrics, and price points that cater to different industrial needs. In this section, we’ll explore Kiant Machinery's offerings, highlight notable competitors in the market, and provide value comparisons among leading brands.

Exploring the Offerings from Kiant Machinery

Kiant Machinery has established itself as a frontrunner in the realm of industrial CNC laser cutters, offering a range of innovative models designed for precision and efficiency. Their laser tube cutting machines are renowned for their advanced technology that enables high-speed cutting with remarkable accuracy. Additionally, Kiant’s commitment to customer service ensures that clients receive ongoing support and training on their tube laser cutting machines for sale.

One standout feature of Kiant’s offerings is their customizable solutions tailored to meet specific industry demands. Whether you’re working with small or large diameter tubes, their machines can be configured to handle various materials with ease. This adaptability not only enhances productivity but also provides excellent value when considering tube laser cutting machine prices.

Notable Competitors in the Market

While Kiant Machinery is a leader in tube laser cutting technology, several other notable competitors also deserve attention. Brands like Trumpf and Bystronic offer robust options that cater to various industrial applications with impressive performance metrics. These companies have honed their expertise over decades, contributing significantly to innovations within the field of industrial CNC laser cutters.

Another contender worth mentioning is Mazak, known for its user-friendly interface and reliable machinery that appeals to both seasoned professionals and newcomers alike. Their focus on integrating automation into tube laser systems has made them a popular choice among manufacturers looking to streamline production processes without sacrificing quality. As you evaluate your options for a tube laser cutting machine for sale, these brands should definitely be on your radar.

Value Comparisons Among Leading Brands

When comparing value among leading brands in the tube laser cutting machine market, it’s essential to consider not just initial purchase price but also long-term operational costs and maintenance requirements. For instance, while some brands may offer lower upfront costs on their machines, they might lack essential safety features or require more frequent servicing—ultimately driving up expenses over time.

Kiant Machinery often stands out due to its competitive pricing combined with high-quality performance metrics across its range of industrial CNC laser cutters. When you factor in customer support services and warranty options offered by various manufacturers, Kiant frequently emerges as an attractive option for businesses seeking both affordability and reliability in their investments.

In conclusion, exploring offerings from top brands like Kiant Machinery alongside competitors such as Trumpf and Mazak will empower you with knowledge necessary for making an informed decision about your next investment in a tube laser cutting machine.

Benefits of Using a Laser Tube Cutting Machine

When it comes to cutting metal tubes, the advantages of using a laser tube cutting machine are hard to ignore. These machines offer unparalleled precision, speed, and cost-effectiveness that traditional methods simply cannot match. Investing in an industrial CNC laser cutter can elevate your production capabilities and streamline your operations.

Enhanced Precision and Accuracy in Cutting

One of the standout features of an industrial CNC laser cutter is its exceptional precision. Unlike traditional cutting methods that may leave room for error, a laser tube cutting machine delivers clean, precise cuts every time. This accuracy not only reduces waste but also ensures that components fit together perfectly, which is crucial for high-quality manufacturing.

With advanced technology at play, these machines can handle intricate designs and tight tolerances with ease. Whether you're working with thin-walled tubes or complex geometries, you can count on the consistent performance of a laser tube cutting machine. Ultimately, enhanced precision translates into better products and satisfied customers.

Increased Production Speed and Efficiency

Speed is the name of the game in today’s fast-paced manufacturing environment, and tube laser cutting machines excel in this area. The rapid processing capabilities of an industrial CNC laser cutter allow businesses to significantly increase their output without compromising quality. This efficiency means you can meet tight deadlines while maximizing productivity on the shop floor.

Moreover, these machines require less manual intervention compared to traditional methods, freeing up valuable labor resources for other tasks. As a result, you’ll find yourself not only saving time but also reducing operational costs associated with labor-intensive processes. When you invest in a tube laser cutting machine for sale, you're investing in a faster route to production success.

Cost-Effectiveness Over Traditional Methods

Cost considerations are always at the forefront when selecting equipment for your business operations. Fortunately, utilizing an industrial CNC laser cutter can lead to significant savings over time compared to conventional cutting techniques. Although initial investments like tube laser cutting machine price may seem steep upfront, the long-term benefits far outweigh these costs.

By minimizing material waste through precise cuts and reducing labor expenses due to automation, companies often see a quicker return on investment (ROI). Furthermore, lower maintenance costs associated with modern laser systems contribute to overall cost-effectiveness as well. In short, choosing a tube laser cutting machine not only boosts efficiency but also enhances your bottom line.

Maintenance Tips for Longevity

Maintaining your laser tube cutting machine is crucial for ensuring its long-term efficiency and reliability. Just like any high-performance equipment, an industrial CNC laser cutter requires regular care to keep it running smoothly. Following a structured maintenance plan can help you avoid costly repairs and extend the lifespan of your investment.

Routine Maintenance Practices

Routine maintenance practices are essential to keep your tube laser cutting machine in top shape. Start by regularly checking the alignment and calibration of the laser beam, as even minor misalignments can lead to significant inaccuracies in cuts. Additionally, cleaning the lenses and mirrors will ensure optimal performance, preventing debris buildup that can hinder cutting efficiency.

Don't forget about the mechanical components! Regularly inspect belts, gears, and bearings for wear and tear, lubricating them as necessary to prevent friction-related issues. Lastly, maintain a clean work environment around your industrial CNC laser cutter; dust and debris can compromise both performance and safety.

Troubleshooting Common Issues

Even with diligent maintenance, you may encounter some common issues with your laser tube cutting machine. One frequent problem is inconsistent cut quality; this could stem from various factors such as improper settings or worn-out components. If you notice this issue, check the parameters on your control panel first—adjusting speed or power settings might just do the trick!

Another common hiccup involves unexpected shutdowns during operation. This could be caused by overheating or electrical faults—so ensure that cooling systems are functioning correctly and that all connections are secure before calling for help. Taking time to troubleshoot these issues early on can save you from larger headaches down the road.

Importance of Professional Support

While routine maintenance and troubleshooting can often resolve minor problems, there are times when professional support becomes indispensable for your industrial CNC laser cutter's longevity. Complex issues may require specific expertise that only trained technicians possess; their knowledge ensures that repairs are done correctly without compromising future performance.

Moreover, professional service providers often have access to specialized tools and replacement parts specifically designed for tube laser cutting machines. Engaging with experts not only guarantees quality repairs but also provides peace of mind knowing that you're following industry standards for safety compliance—a crucial factor when operating high-powered machinery.

Lastly, consider establishing a service contract with a reputable provider who specializes in tube laser cutting machines available for sale; this proactive approach ensures regular check-ups tailored to your specific needs while keeping costs predictable over time.

Innovations in Laser Cutting Technology

The world of laser cutting technology is constantly evolving, and staying ahead means keeping an eye on the latest innovations. With advancements that push the boundaries of speed and efficiency, as well as the integration of automation in tube laser systems, manufacturers are witnessing remarkable transformations. These innovations not only enhance productivity but also redefine what’s possible with industrial CNC laser cutters.

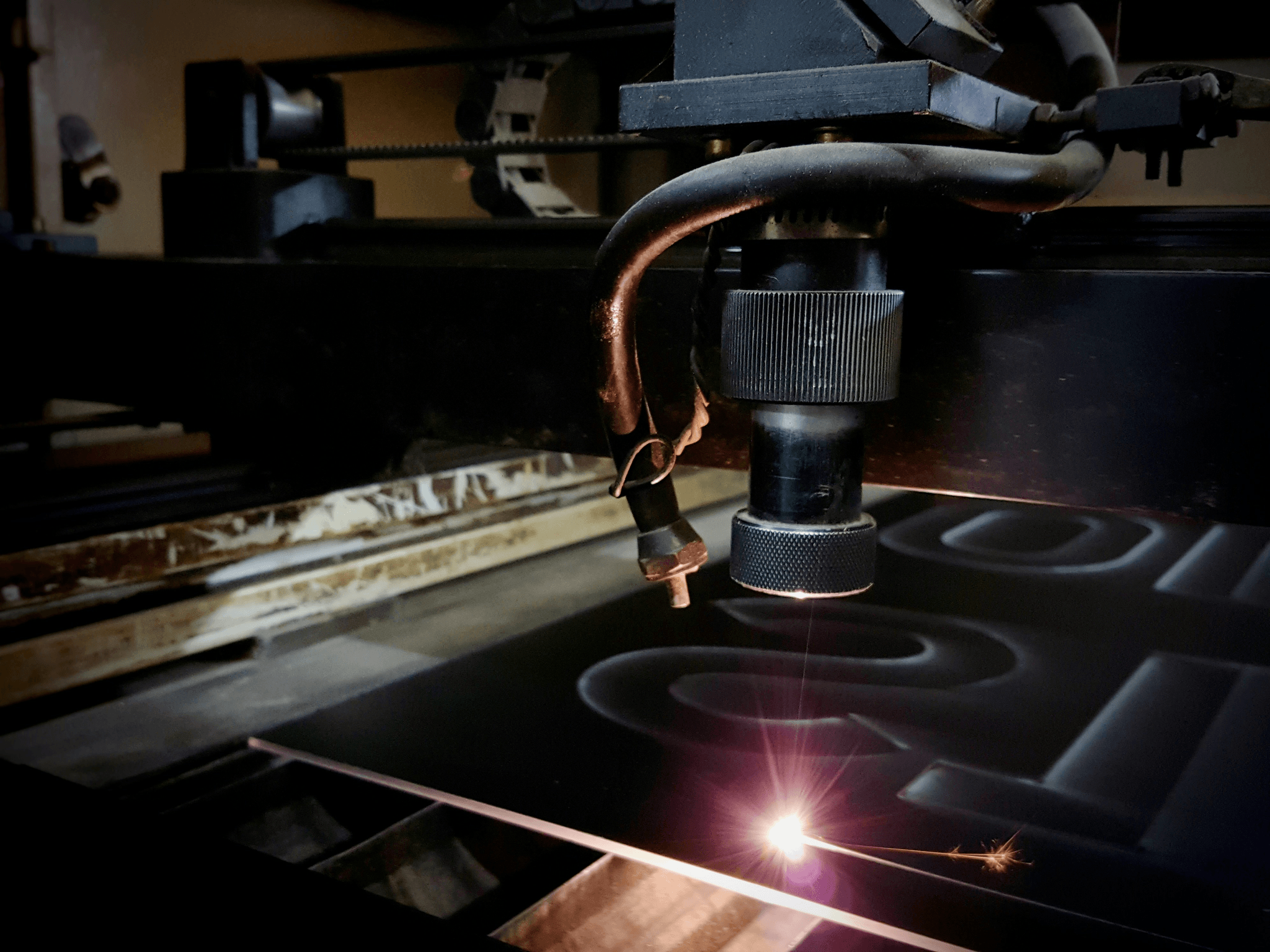

Advancements in Cutting Speed and Efficiency

Recent developments in laser technology have significantly increased the cutting speed and efficiency of machines, particularly for those looking at tube laser cutting machines. The introduction of high-powered lasers allows for faster processing times while maintaining precision—making it a game-changer for industries that rely on quick turnarounds. Additionally, improvements in software algorithms optimize cutting paths, reducing waste and ensuring that every inch of material is utilized effectively.

Efficiency isn't just about speed; it's also about energy consumption. Modern industrial CNC laser cutters are designed to be more energy-efficient than their predecessors, which translates to lower operational costs over time. This means that businesses can invest less in energy bills while enjoying a higher output from their tube laser cutting machine.

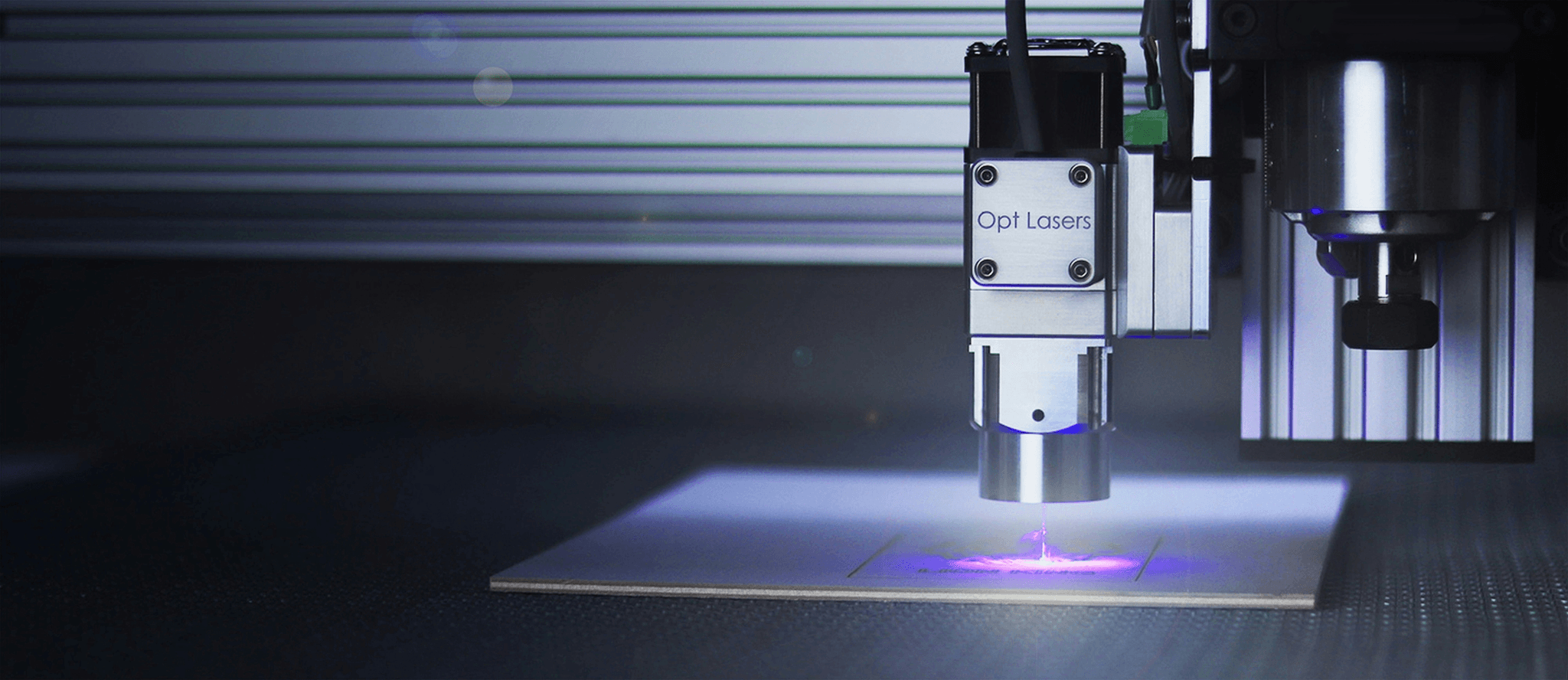

Integration of Automation in Tube Laser Systems

Automation is rapidly becoming a staple feature in advanced tube laser cutting machines, allowing for seamless operation with minimal human intervention. Automated loading and unloading systems streamline production processes, enabling manufacturers to run their operations continuously without downtime for manual handling. This integration not only boosts productivity but also reduces labor costs associated with manual processes.

Moreover, smart technologies like IoT (Internet of Things) are being incorporated into these systems to facilitate real-time monitoring and data analytics. This allows operators to track performance metrics closely, making it easier to spot inefficiencies or potential issues before they escalate into costly problems. As automation continues to evolve within the realm of industrial CNC laser cutters, businesses can expect even greater levels of efficiency and reliability from their tube laser cutting machines.

Future Trends to Watch Out For

As we look toward the future, several trends are poised to reshape the landscape of tube laser cutting technology significantly. One notable trend is the ongoing miniaturization of components within industrial CNC laser cutters—allowing for more compact designs without sacrificing power or performance capabilities. Smaller machines mean more flexibility in installation and operation spaces while still providing robust functionality.

Additionally, sustainability will play a crucial role moving forward; manufacturers are increasingly focusing on eco-friendly practices by developing machines that produce less waste and consume less energy during operation. The demand for greener solutions will likely drive innovation as companies strive to meet both regulatory requirements and consumer expectations regarding environmental responsibility.

Lastly, advancements in artificial intelligence (AI) will further enhance the capabilities of tube laser systems by enabling predictive maintenance features that anticipate equipment needs before breakdowns occur—saving time and money alike! Keeping an eye on these trends will be essential for anyone considering investing in a new tube laser cutting machine for sale.

Conclusion

In the world of manufacturing, selecting the right equipment can make or break your production line. A laser tube cutting machine is a significant investment that requires careful consideration of performance, safety features, and cost efficiency. By understanding your specific needs and the capabilities of various machines, you can make an informed decision that will enhance your operations.

Choosing the Best Tube Laser Cutting Machine

Look for an industrial CNC laser cutter that offers precision and speed tailored to your production requirements. Additionally, consider essential features such as automation capabilities and ease of use to ensure that you're not just getting a good deal but also a tool that enhances productivity.

Evaluating Your Budget and Needs

Budget considerations are crucial when searching for a tube laser cutting machine for sale. While it's tempting to go for the lowest price, remember that investing in quality often pays off in terms of reduced maintenance costs and increased efficiency over time. Evaluate your needs carefully; if high volume production is on the horizon, investing in a more advanced industrial CNC laser cutter may be worth it.

The Role of Kiant Machinery in Your Success

Kiant Machinery stands out as a reputable provider in the realm of tube laser cutting machines, offering innovative solutions tailored to diverse industrial needs. Their commitment to quality ensures you receive machinery that not only meets but exceeds expectations in precision and durability. By partnering with Kiant Machinery, you position yourself for success in an increasingly competitive market.