Introduction

In the world of modern manufacturing, the tube laser cutting machine stands out as a revolutionary tool that enhances productivity and precision. This advanced laser cutting technology has transformed traditional metal cutting processes, enabling manufacturers to achieve intricate designs and high-quality finishes with ease. As industries continue to evolve, understanding the capabilities and advantages of laser cutting machinery becomes essential for staying competitive.

Understanding the Tube Laser Cutting Machine

A tube laser cutting machine is specifically designed to cut various shapes and sizes of tubes and pipes using high-powered lasers. Unlike conventional metal cutting machines that rely on mechanical blades or other methods, this innovative technology utilizes focused laser beams to achieve clean and precise cuts with minimal material waste. The functionality of a cutting machine laser allows for complex geometries that would be challenging or impossible with traditional techniques.

Benefits of Laser Cutting Technology

The benefits of laser cutting technology are numerous, making it an attractive option for manufacturers across diverse sectors. First and foremost, precision is a hallmark of any quality metal cutting machine laser; it ensures that every cut meets exact specifications without compromising on quality. Additionally, the speed and efficiency offered by a laser cutting machine streamline production processes, allowing businesses to meet tight deadlines while maintaining high standards.

Key Applications of Tube Laser Cutting

Tube laser cutting has found its niche in various industries due to its versatility and effectiveness in handling different materials such as steel, aluminum, and brass. From automotive components to architectural structures, the applications are vast and varied—each benefiting from the unique capabilities offered by this advanced technology. Moreover, case studies highlight how companies have enhanced their design capabilities through innovative use of tube laser cutting machines, leading to improved product offerings and customer satisfaction.

What is a Tube Laser Cutting Machine?

When it comes to precision and versatility in cutting, the tube laser cutting machine takes the spotlight. This advanced technology uses focused laser beams to cut through various materials, especially metals, with incredible accuracy. Essentially, it transforms solid metal into intricate shapes and designs that would be nearly impossible to achieve with traditional methods.

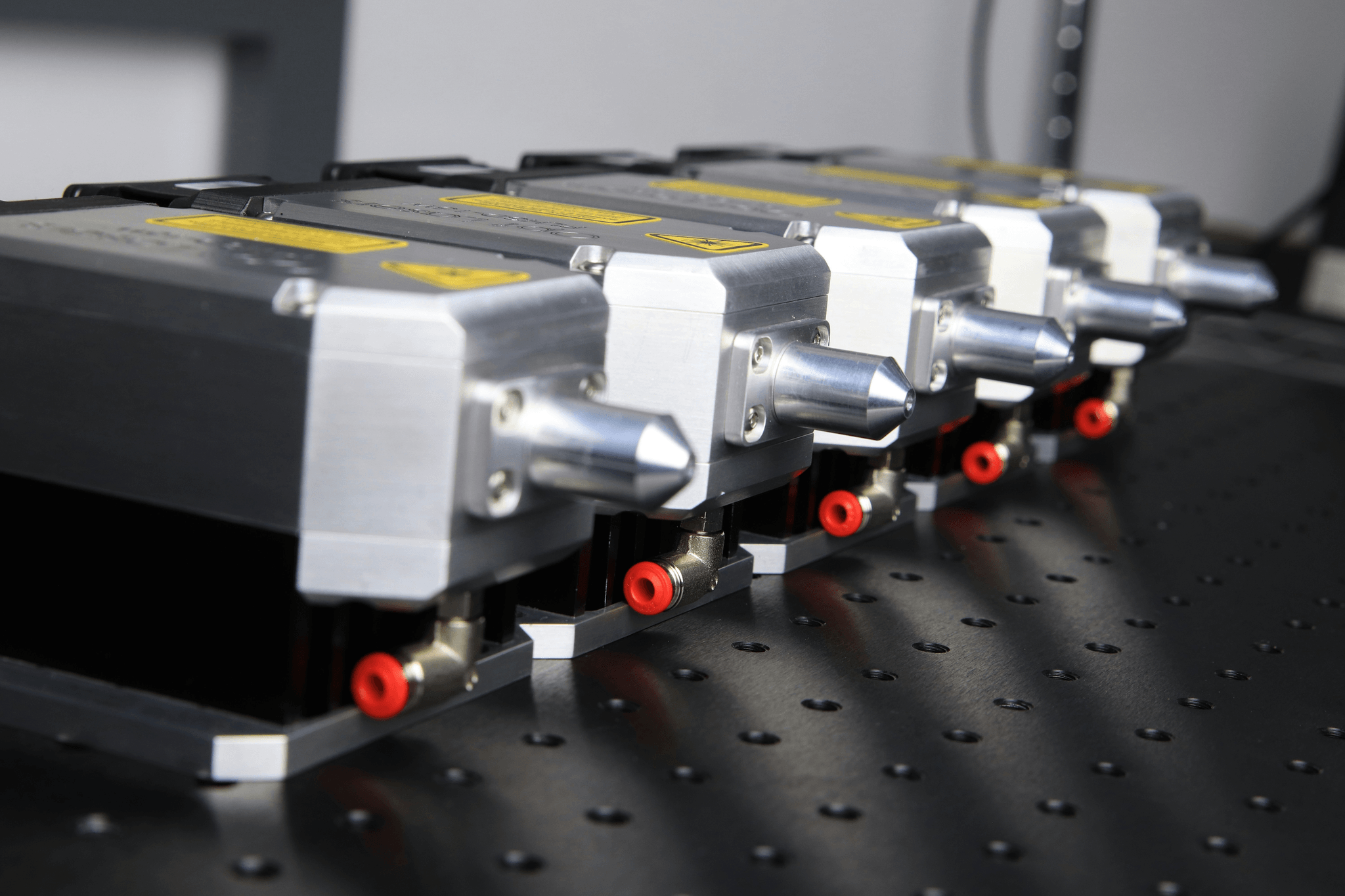

Definition and Functionality

A tube laser cutting machine is a specialized type of laser cutting machine designed specifically for processing tubular materials. It utilizes high-powered lasers to slice through metal tubes and profiles with exceptional precision, making it ideal for applications in industries like automotive, aerospace, and construction. The functionality of these machines allows for complex cuts including notches, holes, and even decorative patterns without compromising the structural integrity of the material.

How It Differs from Traditional Cutting Methods

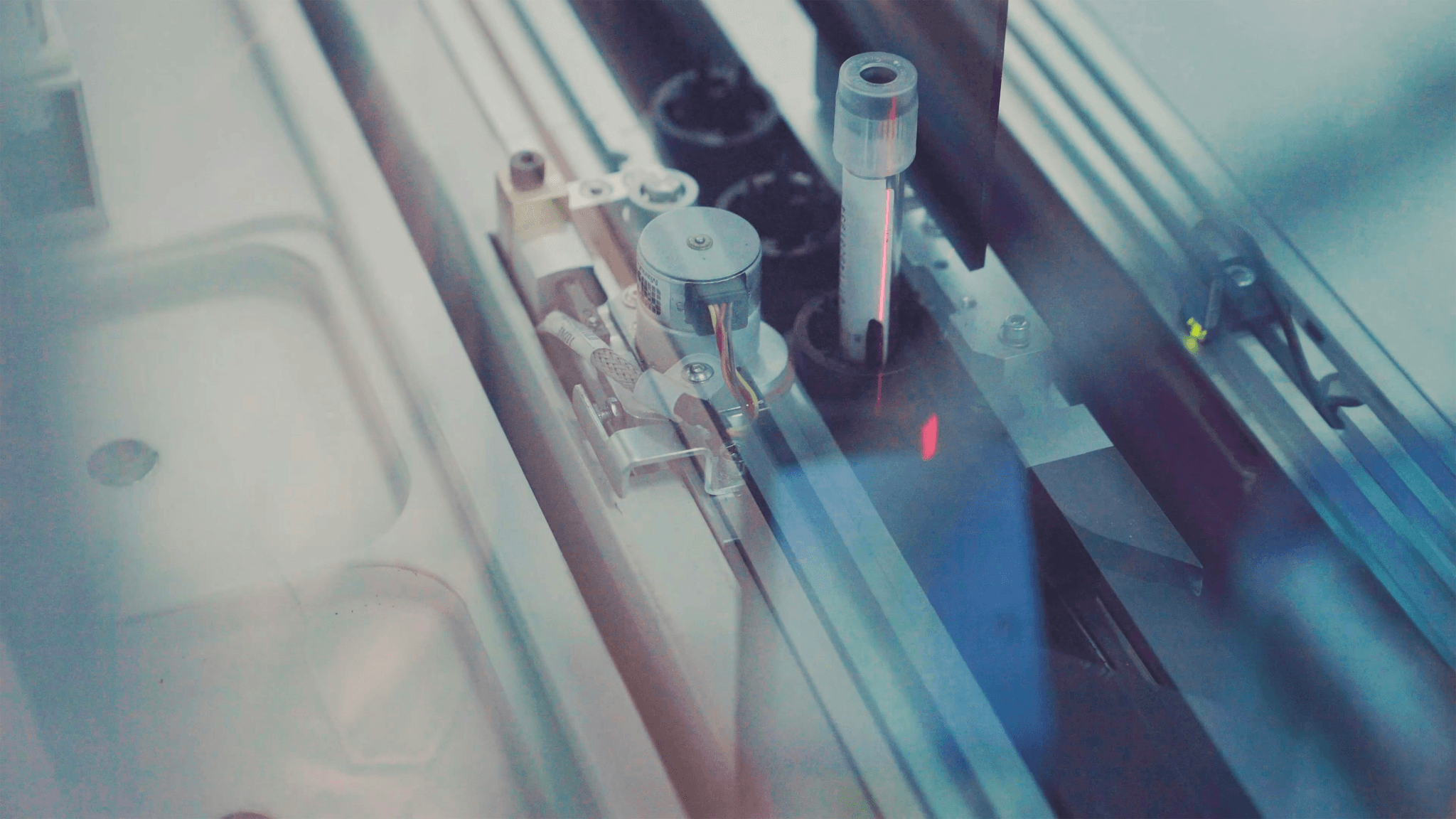

Unlike traditional cutting methods such as saws or plasma cutters that can leave rough edges or require extensive finishing work, a tube laser cutting machine delivers clean cuts right off the bat. The precision of laser technology minimizes material waste by ensuring each cut is exact and tailored to specifications. Additionally, while traditional methods may struggle with intricate designs or thicker materials, a metal cutting machine laser can handle both effortlessly due to its advanced capabilities.

Overview of the Technology Behind Laser Cutting

At its core, the technology behind laser cutting involves directing a concentrated beam of light onto the material's surface until it melts or vaporizes away. This process is controlled by computer numerical control (CNC) systems that allow for intricate programming and automation in metal cutting machines. By harnessing this sophisticated technology found in modern laser machinery, manufacturers can achieve high-speed production without sacrificing quality—a game-changer in today's fast-paced industrial landscape.

Advantages of Using Laser Cutting Machines

These machines have revolutionized the way industries approach metal fabrication, offering a level of precision and versatility that traditional methods simply cannot match. With their ability to streamline production processes, tube laser cutting machines have become indispensable in various sectors.

Precision and Accuracy in Metal Cutting

One of the standout features of a tube laser cutting machine is its unparalleled precision and accuracy in metal cutting. Unlike conventional methods that can suffer from human error or mechanical limitations, laser cutting technology delivers clean, exact cuts every time. This high level of accuracy minimizes waste and ensures that components fit together perfectly during assembly, enhancing the overall quality of the final product.

Moreover, the precision offered by a laser cutting machine allows for intricate designs that were previously difficult or impossible to achieve with traditional metal cutting machines. The focused laser beam can cut through materials with remarkable detail, making it ideal for complex shapes and patterns needed in various applications. As industries continue to demand higher standards for quality and design, investing in a reliable metal cutting machine laser becomes increasingly essential.

Versatility Across Various Materials

Another significant advantage of using laser machinery is its versatility across different materials. Tube laser cutting machines can efficiently process not only metals like steel and aluminum but also non-metal materials such as plastics and wood. This flexibility enables manufacturers to diversify their product offerings without needing multiple specialized machines.

Additionally, the adaptability of a laser cutting machine means that it can handle varying thicknesses and types of materials without compromising on performance or quality. Whether you're working with thin sheets or thicker plates, these advanced metal cutting machines deliver consistent results across all material types. This versatility ultimately streamlines production lines by reducing downtime associated with changing tools or setups for different materials.

Speed and Efficiency in Production

Speed is another critical factor where tube laser cutting machines excel compared to traditional methods. The rapid processing capabilities of these machines allow manufacturers to significantly increase their output while maintaining high-quality standards—perfect for meeting tight deadlines in competitive markets. With less time spent on setup and adjustments, businesses can focus on scaling their operations more effectively.

Furthermore, the efficiency provided by a laser cutting machine translates into cost savings over time. By minimizing material waste through precise cuts and reducing labor costs due to faster processing times, companies can enjoy improved profit margins while still delivering top-notch products to customers. In an age where efficiency is paramount for success, investing in advanced metal cutting machinery becomes not just an option but a necessity.

Selecting the Right Laser Cutting Machine

Choosing the right tube laser cutting machine is crucial for maximizing efficiency and productivity in your operations. With a plethora of options available, it’s essential to know what features will best suit your needs. This section will guide you through the key factors to consider, how to compare various models and brands, and highlight what makes Kiant Machinery a standout choice in the market.

Factors to Consider When Choosing

When selecting a laser cutting machine, the first consideration should be the materials you intend to cut. Different machines have varying capabilities when it comes to thickness and type of material; some excel with metals while others may handle plastics or composites better. Additionally, think about the size of parts you’ll be working with—larger components may require a more robust metal cutting machine laser that can accommodate bigger dimensions.

Another vital factor is precision and speed; these attributes directly impact production time and quality of cuts. If your projects require intricate designs or tight tolerances, investing in a high-precision tube laser cutting machine is non-negotiable. Lastly, consider your budget not just for initial purchase costs but also for maintenance and operational expenses over time.

Comparing Different Models and Brands

With so many options on the market, comparing different models can feel overwhelming—but it doesn’t have to be! Start by looking at customer reviews and case studies that showcase how various laser cutting machines perform in real-world applications. Pay attention to aspects such as ease of use, software compatibility, and after-sales support offered by each brand.

It’s also wise to evaluate energy efficiency since this can significantly affect operating costs in the long run. Some metal cutting machines are designed with advanced technology that reduces power consumption while maintaining performance levels—definitely something worth considering! By making side-by-side comparisons based on these criteria, you’ll be better equipped to make an informed decision.

How Kiant Machinery Stands Out in the Market

Kiant Machinery has carved out a niche for itself within the competitive landscape of laser machinery by offering state-of-the-art tube laser cutting machines tailored for various industrial needs. Their equipment boasts impressive accuracy rates coupled with user-friendly interfaces that simplify operation—even for those new to laser cutting technology!

Moreover, Kiant Machinery prioritizes customer service; they provide comprehensive training programs along with ongoing support that ensures your team can effectively operate their metal cutting machine lasers without hitches or hiccups along the way. With their commitment to innovation and quality assurance, it's no wonder they stand out as a leading choice among businesses looking for reliable solutions in laser cutting.

Tube Laser Cutting Machine Applications

The versatility of the tube laser cutting machine has led to its adoption across various industries, revolutionizing traditional metal cutting processes. From automotive to aerospace and furniture design, laser cutting technology is proving indispensable for modern manufacturing. As businesses seek efficiency and precision, the demand for advanced metal cutting machines continues to rise.

Industries Utilizing Laser Cutting Technology

Numerous industries have embraced the benefits of laser cutting, leveraging the capabilities of metal cutting machine lasers to enhance their production processes. In the automotive sector, manufacturers utilize tube laser cutting machines for creating intricate parts that require high precision and minimal waste. Similarly, in architecture and construction, laser machinery is employed to cut complex designs into steel beams and other materials, facilitating innovative structural solutions.

The aerospace industry is another significant beneficiary of laser cutting technology; it requires components that meet stringent safety standards while maintaining lightweight characteristics. The medical field also utilizes these machines for creating specialized instruments with exact specifications. Overall, the adaptability of laser cutting machines allows various sectors to innovate and improve their product offerings significantly.

Case Studies of Successful Implementations

One notable case study involves a leading automotive manufacturer that integrated a tube laser cutting machine into its production line to streamline operations. By replacing traditional methods with advanced laser technology, they achieved a 30% reduction in material waste while increasing production speed by 25%. This implementation not only improved efficiency but also elevated product quality through enhanced precision in metal parts fabrication.

Another example can be found in the furniture industry where a designer utilized a laser cutting machine to create custom pieces tailored to client specifications quickly. By harnessing the capabilities of a metal cutting machine laser, they were able to produce intricate patterns on wood and metal surfaces that would have been nearly impossible using conventional methods. These success stories highlight how adopting innovative technologies like tube lasers can lead to impressive outcomes across diverse fields.

Enhancing Design Capabilities with Laser Technology

Laser technology has transformed design capabilities by enabling designers and engineers to explore more complex geometries without compromising on quality or efficiency. With a tube laser cutting machine at their disposal, professionals can experiment with unique shapes and patterns that enhance both aesthetics and functionality in their products. This level of creativity fosters innovation across industries as businesses seek distinctive designs that set them apart from competitors.

Moreover, the flexibility offered by these machines allows for rapid prototyping—essentially speeding up the development process from concept to finished product significantly. Designers can quickly iterate on ideas using advanced software integrated with their metal cutting machines before finalizing designs for production runs. This synergy between creativity and technology ensures businesses remain competitive in an ever-evolving market landscape.

Maintenance and Best Practices for Laser Cutting

Maintaining a tube laser cutting machine is crucial for ensuring optimal performance and longevity. Regular upkeep not only enhances the efficiency of your metal cutting machines but also helps in preventing costly breakdowns. By following a few best practices, you can keep your laser cutting machine running smoothly and effectively.

Routine Maintenance Tips

Routine maintenance is vital for any laser cutting machine to operate at peak performance. Start with regular cleaning of the optics, as dust and debris can significantly affect the quality of the cut. Additionally, check the alignment of mirrors and lenses frequently; misalignment can lead to poor cuts and increased wear on the cutting machine laser.

Another essential aspect is inspecting the cooling system; maintaining proper coolant levels prevents overheating, which can damage components within your metal cutting machine laser. It's also wise to keep an eye on belts, gears, and other moving parts—regular lubrication will ensure smooth operation and reduce friction wear. Lastly, don’t forget about software updates; keeping your laser machinery’s software current maximizes functionality and introduces new features that enhance productivity.

Common Issues and Troubleshooting

Even with diligent maintenance, issues may arise with your tube laser cutting machine from time to time. One common problem is inconsistent cut quality, which could stem from worn-out nozzles or improper focus settings—always ensure that these are in top shape before starting a project. If you notice excessive smoke or residue during operation, it may indicate that you're using incorrect settings or materials that aren't compatible with your metal cutting machines.

If you encounter error codes on your control panel, refer to the manufacturer's manual for troubleshooting guidance specific to your model of laser cutting machine. Another frequent issue could be mechanical failures due to lack of lubrication or failure in electrical components; regular inspections will help catch these problems early before they escalate into major repairs.

Ensuring Longevity of Your Cutting Machine Laser

To ensure the longevity of your laser cutting equipment, investing time in preventive measures pays off significantly over time. Create a maintenance schedule that outlines routine checks for all critical components—this habit can save you both money and headaches down the line when unexpected failures occur in your metal cutting machines.

Moreover, training operators on best practices while using a tube laser cutting machine ensures they're aware of how their actions affect equipment lifespan; proper handling goes a long way in reducing wear-and-tear on sensitive parts like lenses and mirrors. Lastly, consider keeping an inventory of essential spare parts on hand so you're prepared when minor issues arise—this proactive approach minimizes downtime while maximizing productivity across all operations involving metal cutting machine lasers.

Conclusion

In the rapidly evolving world of manufacturing, the tube laser cutting machine stands out as a beacon of innovation and efficiency. This advanced tool not only enhances precision in metal cutting but also brings versatility to various industries. As we move forward, understanding these innovations will be crucial for businesses looking to stay competitive.

Innovations in Tube Laser Cutting Technology

Recent advancements in tube laser cutting technology have introduced features like automated loading systems and advanced software integration that streamline operations. These innovations allow for more complex designs and shapes to be cut with unmatched precision, making metal cutting machines increasingly efficient. Moreover, improvements in laser sources have enhanced energy efficiency, reducing operational costs while maintaining high-quality output.

Future Trends in Laser Machinery

The future of laser machinery is bright, with trends leaning towards increased automation and connectivity through Industry 4.0 technologies. Expect to see more smart features that allow for real-time monitoring and data analysis, which can optimize production processes significantly. Additionally, the integration of artificial intelligence will likely enhance decision-making capabilities within metal cutting machine laser operations, paving the way for even greater efficiency.

Why Choose Kiant Machinery for Your Needs

When it comes to selecting a reliable tube laser cutting machine, Kiant Machinery emerges as a top contender due to its commitment to quality and customer satisfaction. Their range of laser cutting machines is designed with state-of-the-art technology that ensures precision and durability across various applications. With an extensive support system and a reputation built on excellence, choosing Kiant means investing in the future of your metal cutting endeavors.