Introduction

In the world of modern construction, Framecad machines have become indispensable tools for efficient building practices. These innovative devices streamline the process of creating steel frames, making them a vital investment for contractors and builders alike. With a variety of options available, understanding the benefits and features of roll forming equipment is key to making an informed decision.

Why Framecad Machines Are Essential

Framecad machines are essential because they enable rapid and precise production of steel framing components, which are crucial in today's fast-paced construction industry. The ability to quickly adapt to project requirements while maintaining high-quality standards sets these machines apart from traditional methods. Moreover, with the growing demand for sustainable building practices, investing in a steel roll forming machine can significantly reduce waste and improve efficiency.

Benefits of Investing in Roll Forming Equipment

Investing in roll forming equipment offers numerous advantages that can enhance profitability and productivity on construction projects. For starters, these machines reduce labor costs by automating processes that would otherwise require multiple workers. Additionally, the durability and longevity of metal framing machines ensure that your investment pays off over time through lower maintenance costs and fewer replacements.

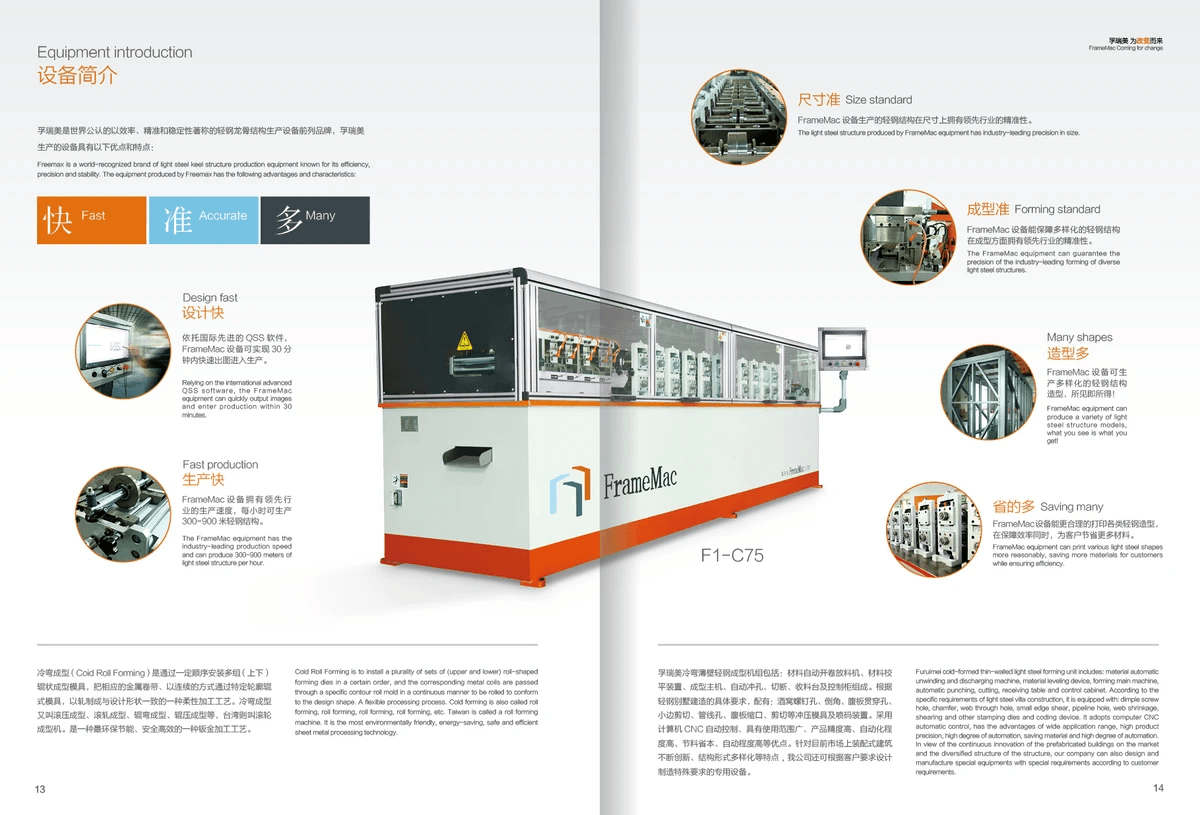

Overview of Framecad Machine Options

When exploring framecad machine options, you'll find a diverse range tailored to meet various project needs and budgets. From compact models suitable for small-scale operations to large-scale steel framing machines designed for extensive commercial projects, there's something for everyone. Understanding the different features and capabilities will help you choose the right framecad machine for sale that aligns with your business goals.

Understanding the Framecad Machine Variants

The Framecad machine variants cater to a variety of needs, ensuring that builders and manufacturers can find the right fit for their projects. From small-scale operations to large construction sites, understanding these machines will help you make an informed decision when looking for a framecad machine for sale.

Types of Steel Framing Machines

Steel framing machines come in several types, each designed to meet specific production requirements. For instance, some machines are tailored for residential construction, while others focus on commercial applications. Whether you're interested in a compact model or a more robust steel roll forming machine, there’s something out there that suits your needs and budget.

The most common types include automated cold roll forming machines and manual models that offer flexibility without sacrificing quality. Automated systems are perfect for high-volume production, while manual options allow for greater customization and control over the manufacturing process. Ultimately, selecting the right type of steel framing machine will depend on your project scope and desired output.

Features of Metal Framing Machines

When evaluating metal framing machines, it's essential to consider their features as they can significantly impact performance and efficiency. Most modern roll forming equipment includes advanced technology such as computer numerical control (CNC) systems that enhance precision during operation. These features not only streamline production but also minimize waste—an important factor when assessing roll forming machine price.

Additionally, many metal framing machines come equipped with adjustable settings for different material thicknesses and profiles. This versatility allows operators to produce various components without needing multiple machines or extensive retooling time. By understanding these features, you can select a framecad machine that aligns with your specific operational goals.

Comparing Different Roll Forming Equipment

With numerous options available in the market today, comparing different roll forming equipment is crucial before making any purchase decisions. When analyzing framecad machine prices across various models, consider factors such as build quality, warranty terms, service support from suppliers like Kiant Machinery, and overall user reviews from other buyers in your industry.

Moreover, it’s important to weigh not just initial costs but long-term savings associated with efficiency and durability in production capabilities—this is where cost vs value analysis comes into play! By investing in high-quality equipment upfront rather than opting for cheaper alternatives might save you money down the line due to fewer repairs and increased productivity rates.

In summary, understanding the various types of steel framing machines available will empower you when searching for a framecad machine for sale or evaluating different roll forming equipment options based on price versus value considerations.

Factors Influencing Framecad Machine Price

Various factors, such as the type of technology used, machine capabilities, and brand reputation, can significantly affect the roll forming machine price. Additionally, market demand and competition among suppliers also play a role in determining how much you’ll pay for your steel framing machine.

Key Elements That Affect Costs

The cost of a steel roll forming machine can vary widely based on several key elements. First off, the complexity of the metal framing machine's design and its production capabilities are major contributors to its price tag; advanced features typically come at a premium. Furthermore, brand reputation and after-sales support can also influence costs—machines from well-known manufacturers may be pricier but often provide better reliability and service.

Another critical factor is customization; if you need specific configurations or features tailored to your project needs, expect those modifications to impact your overall framecad machine price. The materials used in construction also matter; high-quality components may raise initial costs but can lead to greater durability and lower maintenance expenses over time. Finally, geographic location can affect shipping costs and local market conditions which could alter pricing dynamics.

Affordable Options in the Market

For those on a budget looking for a framecad machine for sale, there are plenty of affordable options available that still deliver quality performance. Many manufacturers offer entry-level models of roll forming equipment that maintain essential features without breaking the bank. Additionally, exploring second-hand markets or refurbished machines can yield significant savings while providing reliable functionality.

While it might be tempting to go for the cheapest option available, it’s essential to balance affordability with quality; investing in an inexpensive steel framing machine may lead to higher long-term costs due to repairs or inefficiencies down the line. Keep an eye out for promotions or financing options offered by suppliers as they can make acquiring high-quality equipment more feasible without sacrificing performance standards. Remember that being frugal doesn’t mean compromising on quality—just do your homework!

Cost vs. Value Analysis

When evaluating roll forming machine prices versus their value proposition, it's vital to consider both short-term costs and long-term benefits associated with each option available on the market today. A higher upfront investment in a robust steel roll forming machine often translates into enhanced productivity and reduced operational downtime due to fewer breakdowns over time—this is where value shines through!

Conducting a cost vs. value analysis involves assessing not only purchase prices but also factors like energy efficiency, ease of use, maintenance requirements, and resale potential down the road when considering metal framing machines in general. Ultimately, investing wisely means looking beyond sticker shock; prioritize machines that offer reliability alongside superior performance metrics while keeping operational expenses low over time.

Where to Find Quality Framecad Machines for Sale

Finding a quality Framecad machine for sale can be a daunting task, but it's essential for anyone looking to invest in roll forming equipment. With the right knowledge and resources, you can discover options that not only meet your needs but also fit your budget. Whether you're searching for a steel framing machine or a metal framing machine, understanding where to look is crucial.

Top Manufacturers and Suppliers

When it comes to sourcing a reliable framecad machine for sale, top manufacturers and suppliers should be at the forefront of your search. Companies like Framecad, BlueScope Steel, and other industry leaders offer a variety of roll forming machines that cater to different project requirements. These suppliers are known for their high-quality steel roll forming machines that combine innovation with durability, ensuring you get the best value for your investment.

In addition to established brands, don't overlook smaller manufacturers who may offer competitive pricing on their roll forming equipment. These companies often provide personalized service and may have unique features that larger brands lack. Always compare framecad machine prices across various suppliers to ensure you're making an informed decision.

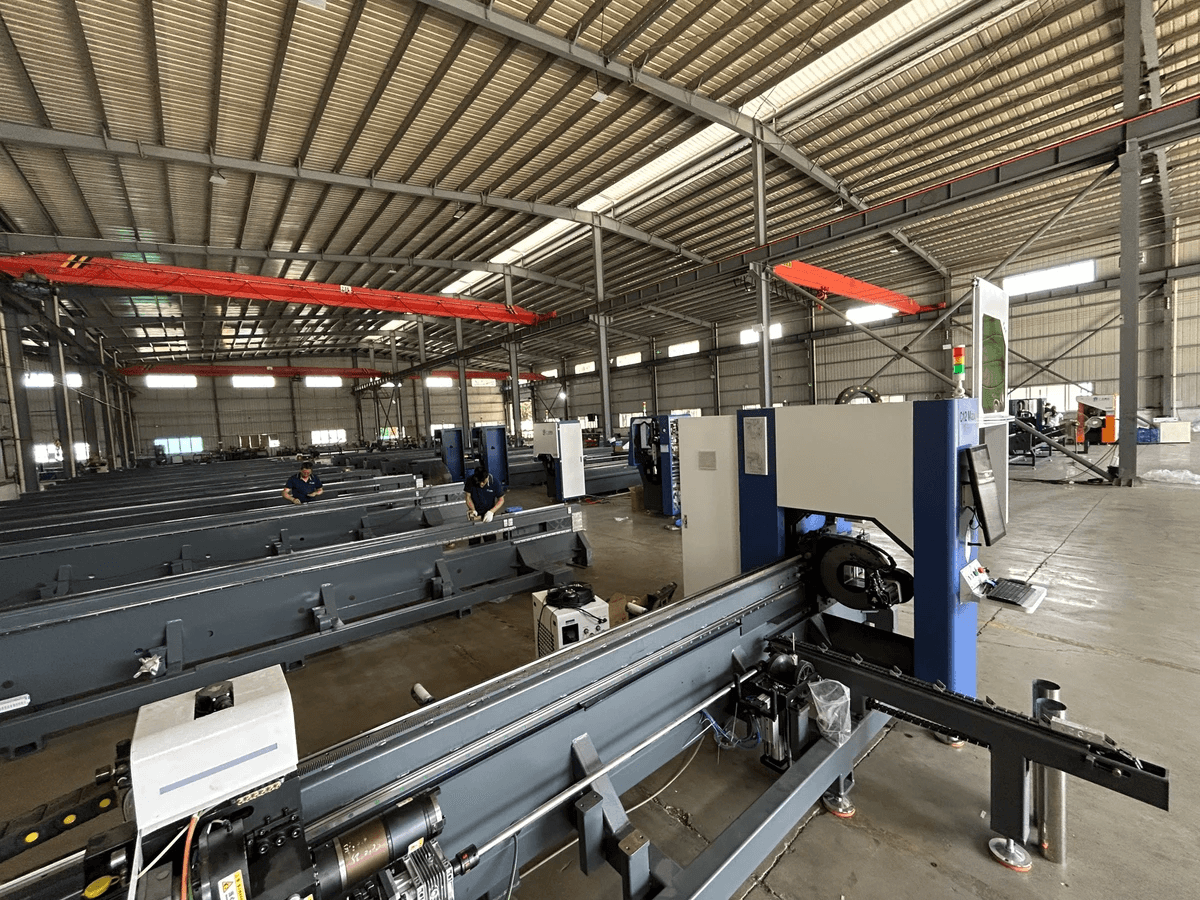

Exploring Kiant Machinery's Offerings

Kiant Machinery stands out as a reputable supplier in the realm of metal framing machines and roll forming equipment. Their extensive range includes advanced steel framing machines designed for efficiency and precision in construction projects. If you're on the hunt for a framecad machine for sale, Kiant Machinery's offerings are worth exploring due to their commitment to quality and customer satisfaction.

Moreover, Kiant Machinery provides detailed specifications and support services that help you understand which model best suits your needs. They also frequently update their inventory with the latest technologies in steel roll forming machines, ensuring you have access to cutting-edge solutions at competitive prices. Investing in a framecad machine from Kiant could significantly enhance your production capabilities while keeping costs manageable.

Online Marketplaces for Roll Forming Machines

In today's digital age, online marketplaces have become valuable resources when searching for a framecad machine for sale or any type of roll forming equipment. Websites like Alibaba, eBay, and Amazon offer an array of options from various sellers around the globe, allowing you to compare prices easily without leaving your home office. Just be sure to read reviews and check seller ratings before making any purchases; after all, you want assurance that you're investing in quality machinery.

Additionally, specialized industrial equipment platforms can provide insights into current market trends regarding steel framing machines and help you identify good deals on used or new models alike. Many sellers also offer warranties or return policies which can give you peace of mind with your purchase decision regarding framecad machine price points as well as overall value assessment.

By leveraging these resources effectively—whether directly through manufacturers like Kiant Machinery or via online marketplaces—you'll be well-equipped to find the perfect steel roll forming machine tailored specifically to your business needs.

Evaluating Performance and Efficiency

When it comes to investing in a framecad machine for sale, understanding the performance and efficiency of the equipment is crucial. High-performance equipment not only enhances productivity but also ensures that your projects are completed with precision and speed. Choosing a reliable steel roll forming machine can significantly reduce downtime and maintenance costs, making it a smart investment for any business.

Importance of High-Performance Equipment

High-performance equipment is vital in the competitive world of construction and manufacturing. A robust roll forming machine can handle various materials and complex designs, which increases versatility in project execution. Furthermore, investing in a quality metal framing machine means fewer interruptions during production, leading to higher overall efficiency.

Key Performance Indicators for Framecad Machines

To assess the effectiveness of your steel framing machine, several key performance indicators (KPIs) should be monitored regularly. These include production speed, material waste percentage, energy consumption, and maintenance frequency. Keeping track of these KPIs helps determine whether your framecad machine price reflects its value; after all, a high-performing roll forming equipment can save you money in the long run.

Long-Term Benefits of Investing in Quality

Investing in quality steel roll forming machines pays off not just immediately but also over time. Reliable machines tend to have longer lifespans and require less frequent repairs compared to their lower-quality counterparts. Additionally, as you gain experience working with efficient metal framing machines, you'll likely see an increase in output quality and customer satisfaction—two critical factors that contribute to business growth.

Maintenance Tips for Your Steel Roll Forming Machine

Keeping your steel roll forming machine in top shape is crucial for ensuring consistent performance and longevity. Regular maintenance not only enhances the efficiency of your roll forming equipment but also helps you avoid costly repairs down the line. By following a few simple practices, you can keep your framecad machine running smoothly and maintain its value over time.

Regular Maintenance Practices

To maximize the lifespan of your steel framing machine, establish a routine maintenance schedule that includes cleaning, lubrication, and inspections. Regularly check all moving parts for wear and tear, as well as ensure that all electrical connections are secure to prevent any unexpected downtime. Furthermore, keeping an eye on the roll forming machine price in relation to its performance can motivate you to invest in preventive measures that protect your investment.

In addition to these checks, make sure to clean the rollers and guides of your metal framing machine frequently to remove debris or buildup that could affect operation. Proper lubrication of mechanical components is essential; use high-quality lubricants recommended by manufacturers for optimal results. By adhering to these regular maintenance practices, you'll not only prolong the life of your framecad machine but also enhance its overall performance.

Troubleshooting Common Issues

Even with diligent upkeep, issues may arise with your steel roll forming machine from time to time. Common problems include misalignment of materials during processing or inconsistent thickness in rolled products; these can often be traced back to inadequate calibration or worn-out components. If you notice such discrepancies while operating your roll forming equipment, it’s wise to conduct a thorough inspection before assuming it's time for a costly repair.

Another frequent issue involves motor malfunctions or overheating; this could indicate an electrical problem or insufficient cooling mechanisms within the machinery itself. Keeping an eye on warning signs like unusual noises or vibrations can help you identify potential problems early on. Addressing these common issues promptly ensures that you maintain optimal performance from your framecad machine without incurring unnecessary expenses associated with repairs.

When to Seek Professional Help

While many maintenance tasks can be handled independently, there are times when professional intervention is necessary for complex issues related to your metal framing machine's functionality. If you've exhausted troubleshooting efforts without success—such as ongoing misalignments despite recalibration—it's best to consult a technician who specializes in roll forming machines. They possess expertise that can help diagnose underlying problems quickly and accurately.

Furthermore, if you're considering purchasing additional equipment or upgrading existing machinery within your setup, consulting professionals will provide insights into how new additions might impact overall operations and costs like framecad machine price adjustments over time due to enhanced capabilities. Recognizing when professional help is warranted will save both time and money while ensuring that your investments remain sound.

Investing in quality maintenance for your steel roll forming machines pays off significantly in terms of efficiency and durability—so don’t skimp! With regular care and timely professional support when needed, you’ll keep those framecad machines humming along smoothly for years ahead.

Conclusion

In the ever-evolving world of construction and manufacturing, making an informed purchase decision regarding a Framecad machine is crucial. With numerous options available, understanding the nuances of each steel framing machine will empower you to choose the right roll forming equipment for your specific needs. Whether you are looking for a budget-friendly roll forming machine price or willing to invest in high-end models, knowledge is your best ally.

Making an Informed Purchase Decision

When considering a framecad machine for sale, it's important to evaluate your production requirements and budget constraints carefully. The diverse range of steel roll forming machines on the market means that there's something suitable for every project size and scope. By comparing features and prices of different metal framing machines, you can ensure that your investment aligns with both current needs and future growth potential.

Maximizing Investment with Quality Equipment

Investing in quality roll forming equipment not only enhances productivity but also ensures longevity and reliability in performance. A well-maintained steel framing machine can yield impressive returns over time, especially when it comes to reducing downtime and maintenance costs. By prioritizing durability and efficiency in your choice of framecad machine price, you'll be setting yourself up for success in a competitive landscape.

The Future of Metal Framing Technology

As technology continues to advance, the future of metal framing looks promising with innovations enhancing efficiency and sustainability in construction practices. Emerging trends suggest that more customizable solutions will become available, allowing businesses to tailor their steel roll forming machines to specific project requirements seamlessly. Keeping an eye on these developments will ensure that your investment remains relevant as the industry evolves.