Introduction

Understanding Flatbed Laser Cutting Machines

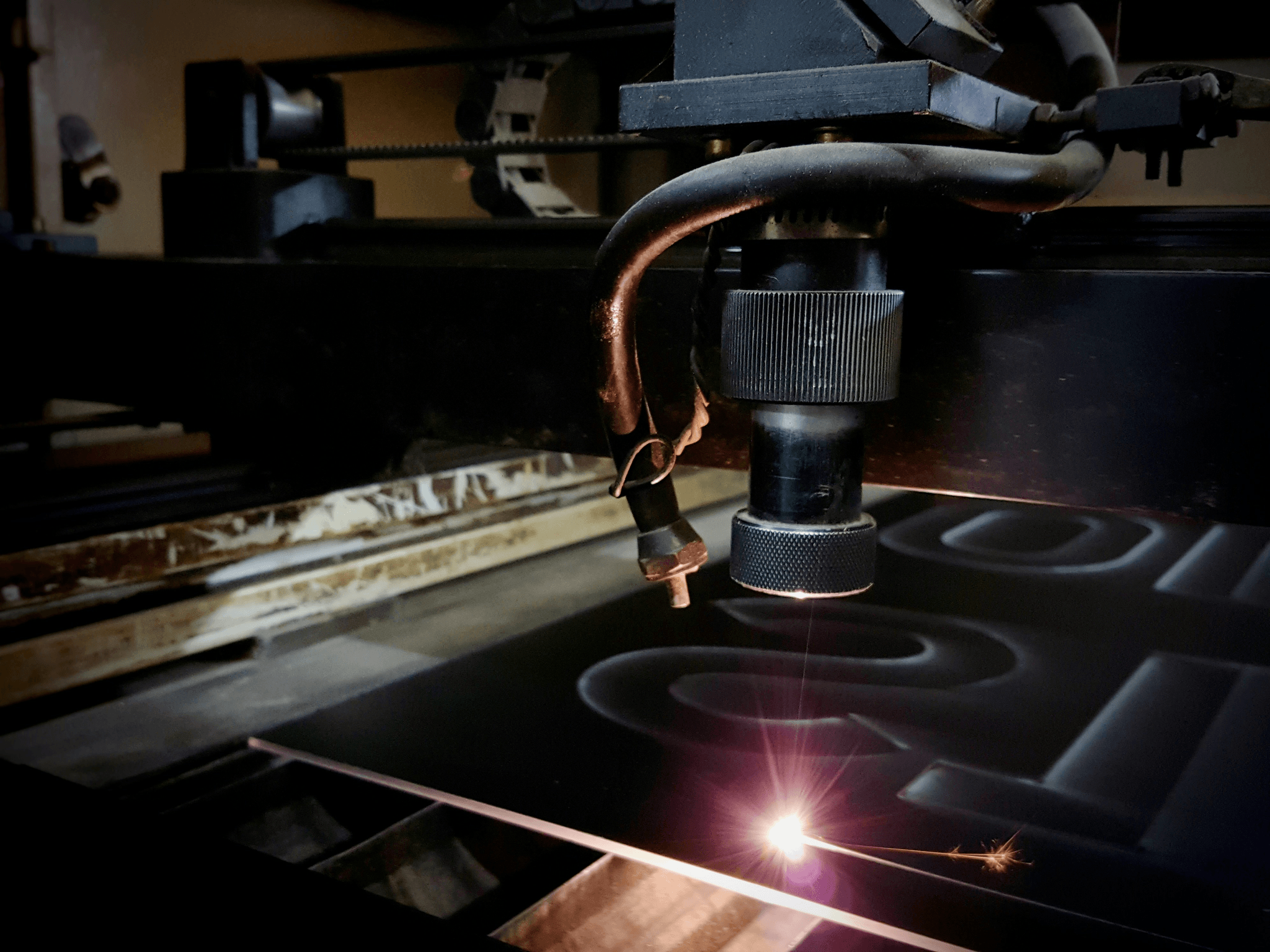

Flatbed laser cutting machines are designed to handle a variety of materials with incredible precision. These machines utilize high-powered lasers to melt or vaporize material, producing clean cuts without the need for physical contact. This non-invasive process is particularly beneficial for intricate designs and shapes found in metal tubes and pipes.

Benefits of Laser Cutting for Tube and Pipe

When it comes to cutting metal tubes, the advantages of using a laser cutting machine cannot be overstated. The speed at which a CNC tube laser cutting machine operates greatly reduces production times while maintaining high-quality cuts that minimize waste. Additionally, these machines can handle complex geometries that traditional methods struggle with, allowing for greater design flexibility in projects.

Key Features to Consider

Choosing the right cutting machine laser involves understanding several key features that can impact performance and efficiency. Factors such as power output, bed size, and software compatibility play crucial roles in determining whether a CNC laser pipe cutting machine meets your specific needs. Moreover, consider the ease of operation; a user-friendly interface on a CNC tube laser cutter can significantly enhance productivity in your workshop.

What is a Flatbed Laser Cutting Machine?

Flatbed laser cutting machines are revolutionizing the way industries approach metal fabrication, particularly when it comes to cutting tubes and pipes. These machines utilize a focused beam of light to slice through materials with precision and speed, making them indispensable in various sectors. As technology advances, the capabilities of these laser cutting machines continue to expand, providing manufacturers with innovative solutions for their metal cutting needs.

Definition and Functionality

A flatbed laser cutting machine is a type of CNC (Computer Numerical Control) equipment designed specifically for high-precision cutting tasks. This machine features a flat surface where sheets or tubular materials are placed, allowing the laser to cut through them effortlessly. With advanced software integration, operators can create intricate designs and patterns that would be difficult or impossible to achieve with traditional methods.

The primary functionality of this machine lies in its ability to deliver consistent results while minimizing waste material. By using a laser machine to cut metal tube or sheet, businesses can achieve cleaner cuts with reduced kerf width compared to conventional tools. This not only enhances the quality of the finished product but also contributes to overall cost savings by optimizing material usage.

How it Works for Tube and Pipe

When it comes to tube and pipe applications, CNC tube laser cutting machines offer unparalleled versatility and efficiency. The process begins with loading the material into the machine's feeding system, which automatically aligns it for precise cuts based on pre-programmed specifications. The focused laser beam then moves along predetermined paths, melting or vaporizing the metal as it travels, resulting in smooth edges without burrs.

CNC laser pipe cutting machines are particularly beneficial for complex geometries found in various industries such as automotive and aerospace manufacturing. By employing advanced motion control systems, these machines can manipulate both the angle of cut and position of the tube simultaneously—something manual methods simply cannot replicate efficiently. This capability allows manufacturers to create unique components tailored specifically for their projects.

Advantages over Traditional Cutting Methods

The advantages of using a cutting machine laser over traditional methods are numerous and compelling. First off, flatbed lasers provide exceptional precision; they can make cuts within fractions of a millimeter accuracy that manual saws struggle to match consistently. Additionally, because these machines operate at high speeds while maintaining quality output, they significantly reduce production times—allowing companies to meet tight deadlines without compromising on quality.

Another key advantage is flexibility; whether you need straight cuts or intricate designs on your metal products, CNC tube laser cutters can handle it all without needing multiple setups or tools like traditional methods would require. Furthermore, there's minimal heat affected zone (HAZ) during operation due to rapid cooling from surrounding air—this means less distortion in materials post-cutting compared with plasma or flame-cutting techniques.

In summary, investing in modern technology like CNC tube lasers not only enhances productivity but also opens up new avenues for creativity in design—all while ensuring cost-effectiveness remains at forefront concerns for manufacturers today!

The Technology Behind CNC Laser Cutting

In the world of modern manufacturing, CNC (Computer Numerical Control) technology has revolutionized the way we approach precision cutting. This innovative method allows for unparalleled accuracy and efficiency in processes like tube and pipe cutting. When you think about a laser machine to cut metal tube, you're really picturing a sophisticated system that can transform raw materials into finely crafted components with minimal waste.

Basics of CNC Technology

CNC technology operates by using computer software to control the movements of machinery, including laser cutting machines. This enables the cutting machine laser to execute intricate designs and specifications with remarkable consistency. Unlike traditional methods that rely on manual operation, CNC systems automate the process, significantly reducing human error and increasing production speed.

In a typical setup, a CNC tube laser cutter follows programmed instructions to manipulate its cutting head along multiple axes. This versatility allows it to handle various shapes and sizes of metal tubes efficiently. With such advanced capabilities, it's no wonder that industries are increasingly opting for cnc laser pipe cutting machines over older techniques.

Precision of CNC Tube Laser Cutting Machines

One of the standout features of cnc tube laser cutting machines is their extraordinary precision. These machines can achieve tolerances as tight as ±0.1 mm, ensuring that every cut is exact and meets stringent quality standards. This level of accuracy is crucial in industries like automotive manufacturing and aerospace, where even minor discrepancies can lead to significant issues down the line.

Moreover, the ability to program complex geometries means that manufacturers can create intricate designs without compromising on quality or speed. The result is not just a cleaner cut but also less material wastage—a win-win scenario for any business looking to maximize efficiency with their metal cutting machine investments. In essence, when you use a cnc tube laser cutter, you're investing in both quality and sustainability.

Comparing CNC to Manual Methods

When comparing cnc laser pipe cutting machines to manual methods, it's clear which option comes out on top in terms of efficiency and accuracy. Manual techniques often involve more labor-intensive processes that not only take longer but also increase the risk of inconsistencies in cuts—something no one wants when working with expensive materials like metal tubes.

Additionally, while manual methods may offer some flexibility for small-scale projects or one-off cuts, they simply can't match the scalability provided by automated systems like cnc tube laser cutters. With automation comes faster turnaround times; businesses can produce higher volumes without sacrificing quality or incurring additional costs associated with labor-intensive workarounds.

In conclusion, embracing technology such as cnc tube laser cutters not only streamlines operations but also enhances product quality across various sectors—making them an essential tool for modern manufacturers looking to stay competitive in today's fast-paced market.

Applications of Laser Cutting in Various Industries

Laser cutting technology has revolutionized various industries, providing unparalleled precision and efficiency. From construction to aerospace, the versatility of the laser machine to cut metal tubes is making waves. Here, we explore how different sectors are harnessing the power of laser cutting machines for their specific needs.

Construction and Architecture

In the construction and architecture fields, the demand for intricate designs and precise cuts is ever-increasing. The CNC tube laser cutting machine allows architects to bring their visions to life with remarkable accuracy. By utilizing a cutting machine laser, builders can efficiently create complex structural components that fit together seamlessly, reducing waste and saving time.

Moreover, using a CNC laser pipe cutting machine ensures that materials like steel and aluminum are cut with minimal distortion. This precision not only enhances the aesthetic appeal of buildings but also contributes to their structural integrity. As a result, construction firms are increasingly investing in metal cutting machines to meet modern architectural demands.

The benefits extend beyond just aesthetics; they also include improved safety on job sites due to fewer errors in material preparation. With a reliable CNC tube laser cutter at their disposal, contractors can focus on quality workmanship while minimizing delays. Ultimately, this technology is reshaping how construction professionals approach projects from concept to completion.

Automotive Manufacturing

The automotive industry has embraced laser cutting technology as a game-changer in manufacturing processes. Using a laser machine to cut metal tubes allows for high-speed production without compromising quality or accuracy. This capability is crucial for creating parts that must meet stringent safety standards while remaining cost-effective.

CNC tube laser cutters streamline operations by automating complex cuts that would be labor-intensive with traditional methods. Manufacturers can produce intricate components like exhaust systems or chassis parts quickly and efficiently using these advanced machines. As a result, automotive companies can respond swiftly to market demands while maintaining high production rates.

Additionally, the flexibility of CNC laser pipe cutting machines enables manufacturers to adapt designs easily without significant downtime or retooling costs. This adaptability is vital in an industry where innovation drives competitiveness and consumer satisfaction. Investing in advanced metal cutting machines not only boosts productivity but also fosters creativity within automotive design teams.

Aerospace and Defense

In aerospace and defense sectors, precision is paramount; even minor errors can lead to catastrophic failures or costly delays. Therefore, utilizing a CNC tube laser cutter becomes essential for producing critical components with exact specifications required by these industries. The ability of the cutting machine laser to achieve tight tolerances ensures that every piece fits perfectly within larger assemblies.

Moreover, lightweight materials are increasingly used in aircraft design for improved fuel efficiency; therefore, having efficient methods like CNC laser pipe cutting machines is crucial for processing these materials effectively without compromising strength or integrity. These advanced systems allow manufacturers to create complex geometries that traditional machining methods struggle with—making them indispensable tools in aerospace production lines.

Furthermore, as global regulations tighten around defense manufacturing processes regarding quality assurance and traceability, investing in reliable metal cutting machines becomes more than just an operational choice; it’s also about compliance with international standards. Adopting such technologies not only enhances operational capabilities but also positions companies favorably within competitive markets—an essential move given today's fast-paced industrial landscape.

Choosing the Right Laser Cutting Machine

Selecting the right laser cutting machine can feel like searching for a needle in a haystack, especially with so many options available. Whether you need a cutting machine laser for intricate designs or a robust CNC tube laser cutting machine for heavy-duty tasks, understanding your specific needs is crucial. Making an informed choice not only enhances productivity but also ensures that your investment pays off in the long run.

Factors to Consider for Your Needs

When choosing a metal cutting machine, several factors come into play. First and foremost, consider the material thickness and type you'll be working with; this will help determine whether you need a CNC laser pipe cutting machine or something more specialized. Additionally, evaluate the precision required for your projects—if you're dealing with tight tolerances, investing in a high-quality CNC tube laser cutter might be essential.

Another important factor is the size of the work area. If you're frequently working with larger metal tubes or pipes, you'll want to ensure that your chosen laser machine to cut metal tube can accommodate those dimensions comfortably. Lastly, don't overlook software compatibility; having a user-friendly interface can streamline operations and increase efficiency.

Kiant Machinery's Offerings

Kiant Machinery stands out in the world of laser cutting solutions by offering an impressive range of machines tailored to various needs. Their lineup includes advanced CNC tube laser cutters designed specifically for high-speed precision cutting of metal tubes and pipes. With features such as automatic loading systems and intuitive controls, Kiant’s machines make it easier than ever to get started on your projects.

Moreover, Kiant Machinery provides comprehensive support services that go beyond just selling equipment; they offer training programs that ensure users are well-versed in operating their new machinery efficiently. With options ranging from entry-level models perfect for small businesses to industrial-grade machines capable of handling large-scale production runs, there’s something for everyone at Kiant.

Cost vs. Efficiency

In today’s competitive market, balancing cost and efficiency is paramount when selecting a cutting machine laser for your operations. While it may be tempting to opt for cheaper models initially, investing in high-quality CNC tube laser cutting machines often leads to greater long-term savings through reduced waste and increased speed of production. Remember that downtime caused by unreliable machinery can quickly erode any initial cost benefits.

Additionally, consider operational costs such as maintenance and energy consumption when evaluating different models; some machines may have lower upfront costs but could prove expensive over time due to higher operational expenses. Ultimately, choosing an efficient metal cutting machine means looking beyond just price tags—it's about finding value that aligns with your business goals.

Maintenance and Support for Laser Cutting Equipment

Maintaining a laser cutting machine is crucial for ensuring optimal performance and longevity. Regular maintenance not only enhances the efficiency of your metal cutting machine but also minimizes downtime, which can be costly in a competitive environment. By investing in proper upkeep, you can ensure that your CNC tube laser cutting machine operates at peak capacity, delivering precision cuts every time.

Importance of Regular Maintenance

Regular maintenance is like a health check-up for your cutting machine laser; it keeps everything running smoothly and helps identify potential issues before they escalate. Neglecting maintenance can lead to increased wear and tear on components, resulting in costly repairs or even complete equipment failure. A well-maintained CNC laser pipe cutting machine will consistently produce high-quality results while extending its lifespan, making it a smart investment for any business.

Training and Support Services

Understanding how to operate your laser cutting machine effectively is just as important as the technology itself. Comprehensive training programs ensure that operators are well-versed in using the CNC tube laser cutter safely and efficiently, maximizing productivity while minimizing risks. Additionally, support services provide ongoing assistance to troubleshoot any issues that may arise during operation, ensuring that your metal cutting machine remains an asset rather than a headache.

Kiant Machinery's After-Sales Support

Kiant Machinery takes pride in offering exceptional after-sales support for all their products, including the advanced laser machines to cut metal tubes. Their dedicated team provides timely assistance, ensuring that any concerns regarding your CNC laser pipe cutting machine are addressed promptly. With Kiant’s after-sales service backing you up, you can focus on what really matters: producing top-notch cuts with confidence.

Conclusion

In wrapping up our exploration of laser cutting technology, it’s clear that the future holds exciting advancements for the industry. The evolution of the laser machine to cut metal tube and pipe has already transformed manufacturing processes, making them more efficient and precise. As innovations continue to emerge, we can expect even greater capabilities in CNC tube laser cutting machines and CNC laser pipe cutting machines.

The Future of Laser Cutting Technology

The trajectory for laser cutting technology is promising, with ongoing developments enhancing speed and accuracy. Emerging trends include automation integration and smart technology applications that will revolutionize how we think about metal cutting machines. With these advancements, the capabilities of a cutting machine laser will expand, allowing manufacturers to tackle more complex designs with ease.

Why Invest in a Metal Cutting Machine

Investing in a metal cutting machine is not just about keeping up with competition; it's about future-proofing your operations. A CNC tube laser cutter or a CNC laser pipe cutting machine can significantly reduce labor costs while increasing production efficiency and output quality. Additionally, the versatility offered by these machines allows businesses to diversify their offerings without investing heavily in multiple technologies.

Maximizing Efficiency with Kiant Machinery

Kiant Machinery stands out as a leader in providing high-quality solutions tailored to meet diverse manufacturing needs. Their range of CNC tube laser cutting machines offers advanced features designed to maximize operational efficiency while minimizing waste. By choosing Kiant Machinery's products, businesses can ensure they are equipped with top-tier tools that enhance productivity while maintaining cost-effectiveness.