Introduction

In the world of fabrication and design, understanding the various laser cutter types is essential for achieving optimal results. Whether you're a hobbyist or a business owner, selecting the right cutting machine laser can significantly impact your productivity and creativity. With options ranging from CO2 laser cutters to fiber laser cutting machines, knowing which one suits your needs best is crucial for success.

Understanding Laser Cutter Types

Laser cutter types vary widely in functionality and application, each offering unique advantages based on the materials being processed. For instance, metal cutting laser cutters are specifically designed for precision tasks involving metals, while engraving laser cutting machines excel at detailed designs on softer materials like wood or acrylic. Familiarizing yourself with these distinctions will empower you to make informed decisions tailored to your specific projects.

Importance of Choosing the Right Machine

Choosing the right machine is not merely a matter of preference; it can dictate the efficiency and quality of your work. The wrong choice could lead to increased operating costs or subpar results that tarnish your reputation in the market. Investing time in understanding different options, such as fiber laser engravers versus CO2 laser cutters, ensures you find a solution that aligns with both your immediate needs and long-term goals.

Key Features to Consider

When selecting a cutting machine laser, several key features should be at the forefront of your decision-making process. Factors such as power output, speed capabilities, and compatibility with various materials are essential for optimizing performance in diverse applications. Additionally, consider aspects like ease of use and maintenance requirements to ensure that your investment supports seamless operations over time.

Assessing Your Cutting Needs

This section will help you navigate the essential factors that dictate which machine will best serve your purposes. By evaluating material types, production volume, and precision requirements, you can ensure that your investment aligns with your operational goals.

Material Types and Thickness

Different laser cutter types excel at cutting various materials, so identifying what you'll be working with is critical. CO2 laser cutters are fantastic for non-metal materials like wood and acrylic, while metal cutting laser cutters are designed specifically for thicker metals such as steel and aluminum. If you're considering a fiber laser cutting machine or an engraving laser cutting machine, keep in mind their strengths in both speed and accuracy when dealing with diverse materials.

Thickness also plays a significant role in determining which machine to choose; some machines can handle thicker materials better than others. For example, while a fiber laser engraver is excellent for intricate designs on thinner metals, it may struggle with thicker substrates compared to a robust metal cutting machine laser. Thus, knowing the thickness of the materials you'll be working with allows you to narrow down the options effectively.

Production Volume and Speed

Next up is assessing your production volume and speed requirements—this will significantly influence which type of cutting machine laser suits you best. If you're operating in a high-volume environment where speed is essential, investing in a fiber laser cutting machine might be ideal due to its rapid processing capabilities compared to traditional CO2 lasers. On the other hand, if you're focused more on small-scale projects or custom jobs, an engraving laser cutting machine could provide the flexibility you need without sacrificing quality.

Understanding how quickly you need to produce cuts can also impact long-term costs; faster machines often come with higher initial investments but can lead to lower operational costs over time due to increased efficiency. Additionally, consider how often you'll need to change settings or switch between different material types—this could affect overall productivity as well. Thus, aligning your output expectations with the capabilities of various laser cutter types ensures smoother operations down the line.

Precision and Detail Requirements

Finally, let's talk about precision and detail requirements—after all, not all projects are created equal! If you're working on intricate designs or fine details that demand high accuracy, choosing a fiber laser engraver or an advanced CO2 laser cutter would likely meet those needs effectively due to their superior focus capabilities. These machines can achieve remarkable detail levels that make them perfect for applications ranging from jewelry making to detailed signage.

However, if you're primarily focused on larger cuts where detail isn't as critical (think signage or structural components), then opting for a more robust metal cutting machine laser may suffice without breaking the bank on precision features you won’t fully utilize. It's essential to weigh these factors carefully; after all, investing in unnecessary capabilities could lead to overspending without any real benefit! Ultimately, understanding your precision needs helps ensure that whichever type of laser cutter you choose aligns perfectly with what you aim to achieve.

Exploring Different Laser Cutter Types

Overview of CO2 Laser Cutters

CO2 laser cutters are among the most popular laser cutter types, especially for non-metal materials like wood, acrylic, and paper. These machines use a gas mixture that includes carbon dioxide to produce a high-powered beam capable of cutting through various substrates with precision. With their ability to handle intricate designs and detailed engravings, CO2 laser cutters are a go-to option for artists and manufacturers alike.

One of the key features of CO2 laser cutters is their affordability compared to other metal cutting machines. They also tend to have lower operating costs due to less expensive maintenance needs.

Benefits of Fiber Laser Cutting Machines

Fiber laser cutting machines are revolutionizing the industry with their efficiency and power when it comes to metal processing. Unlike traditional CO2 lasers, fiber lasers utilize solid-state technology that allows them to cut through metals such as stainless steel and aluminum with remarkable speed and accuracy. This makes them ideal for high-volume production environments where precision is non-negotiable.

Another standout feature of fiber lasers is their low maintenance requirements; they don't require regular alignment or gas refills like some other types do. Additionally, these machines offer better energy efficiency, translating into cost savings over time—an appealing factor for small businesses looking at long-term investments in equipment. If you're focused on metal applications or need a robust solution for intricate designs on tougher materials, a fiber laser engraver might just be your best bet.

Versatility of Engraving Laser Cutting Machines

Engraving laser cutting machines bring creativity into play by allowing users to etch detailed designs onto various surfaces beyond just cutting them apart. These versatile tools can handle everything from wood and leather to glass and stone—making them perfect for personalized items or promotional products that require unique touches. Their adaptability means you can easily shift from one material type to another without needing extensive setup changes.

Moreover, engraving capabilities add another layer of functionality; businesses can create custom signage or decorative pieces that stand out in any market space without sacrificing quality or speed. This versatility also means engraving machines often serve dual purposes: as both engraving tools and standard cutting machine lasers—perfect for maximizing your investment! So if you're looking at different laser cutter types with an eye on creativity as well as functionality, an engraving laser cutting machine should definitely be on your radar.

Evaluating Costs and Budget

When it comes to investing in a laser cutting machine, understanding the financial implications is crucial. Different laser cutter types come with varying price tags, and while it’s tempting to go for the lowest initial investment, long-term value should be the guiding star of your decision-making process. A well-chosen metal cutting laser cutter can pay for itself over time through increased efficiency and reduced operational costs.

Initial Investment vs. Long-term Value

The initial cost of a cutting machine laser can be daunting, especially when you’re eyeing high-quality options like fiber laser cutting machines or CO2 laser cutters. However, it’s essential to weigh that upfront expense against what you’ll gain in productivity and reliability down the line. For instance, investing in a robust engraving laser cutting machine may mean higher upfront costs but will often lead to lower maintenance needs and longer lifespan—translating into greater long-term savings.

Operating Costs and Maintenance

Operating costs are another critical factor to consider when evaluating different laser cutter types. The efficiency of your metal cutting machine laser will directly impact electricity consumption; more advanced models often use less power while delivering superior results. Additionally, maintenance costs can vary significantly between a fiber laser engraver and other models; understanding these differences can help you budget wisely.

Regular maintenance is key to keeping your equipment running smoothly and avoiding costly repairs down the road. A CO2 laser cutter might require different upkeep compared to a fiber laser cutting machine, so familiarize yourself with what each type entails before making your choice. In short, knowing these variables allows you to make an informed decision that fits both your operational needs and budget constraints.

Financing Options for Small Businesses

For small businesses looking at various metal cutting laser cutter options but feeling overwhelmed by the initial investment, financing solutions are available that can ease this burden considerably. Equipment financing allows you to spread out payments over time rather than paying a lump sum upfront—making those shiny new engraving laser cutting machines feel much more attainable!

Additionally, many manufacturers offer leasing options or payment plans tailored specifically for small business owners looking to invest in reliable technology without breaking the bank right away. By exploring these financing avenues, you not only secure essential equipment but also maintain cash flow for other operational necessities.

Brand Reputation and Reliability

When investing in a laser cutting machine, brand reputation and reliability are paramount. The world of laser cutter types is vast, with different manufacturers offering various models tailored for specific applications. A well-regarded brand often signifies quality and durability, ensuring that your metal cutting laser cutter will perform consistently over time.

Notable Brands to Consider

Several brands stand out in the realm of laser cutters, each known for their unique strengths. For instance, companies like Epilog and Trotec are renowned for their CO2 laser cutters, which excel in engraving and cutting non-metal materials. On the other hand, brands like Trumpf and Bystronic have made their mark with fiber laser cutting machines that dominate the metal cutting landscape due to their speed and efficiency.

In addition to these industry giants, there are also emerging brands that have started to make waves in the market. These newer players often offer competitive pricing while maintaining high standards of quality in their engraving laser cutting machines or metal cutting machines lasers. It’s essential to research these options thoroughly to find a brand that aligns with your specific needs.

Importance of Customer Support

Customer support can make or break your experience with any machinery purchase, especially when dealing with complex equipment like a fiber laser engraver or CO2 laser cutter. When issues arise—be it technical difficulties or operational queries—having access to responsive customer support is crucial for minimizing downtime and ensuring smooth operations. Brands that prioritize customer service tend to foster long-term relationships with their clients, providing peace of mind as you invest in your business's future.

Moreover, effective customer support extends beyond just troubleshooting; it includes training on how to operate your new machine efficiently. Many reputable companies offer comprehensive training programs for users of their metal cutting machines lasers or engraving laser cutting machines, ensuring you can maximize the capabilities of your investment from day one.

Reviews and Testimonials

Nothing speaks louder than the voices of those who have already walked the path you're considering; reviews and testimonials provide invaluable insights into real-world experiences with various laser cutter types. Customers often share detailed accounts of how well a particular fiber laser cutting machine performed on specific projects or how reliable a CO2 laser cutter has been over time under demanding conditions.

Reading through reviews can also help you identify potential red flags regarding performance issues or customer service shortcomings associated with certain brands or models. Additionally, testimonials from businesses similar to yours can guide you toward making an informed decision about which engraving laser cutting machine will suit your needs best.

Case Studies and Applications

Laser cutting technology has transformed various industries, showcasing the versatility and efficiency of different laser cutter types. From industrial processes to creative applications, understanding how these machines are utilized can provide valuable insights for potential buyers. In this section, we explore real-world examples that highlight the capabilities of metal cutting laser cutters, fiber laser engravers, and CO2 laser cutters.

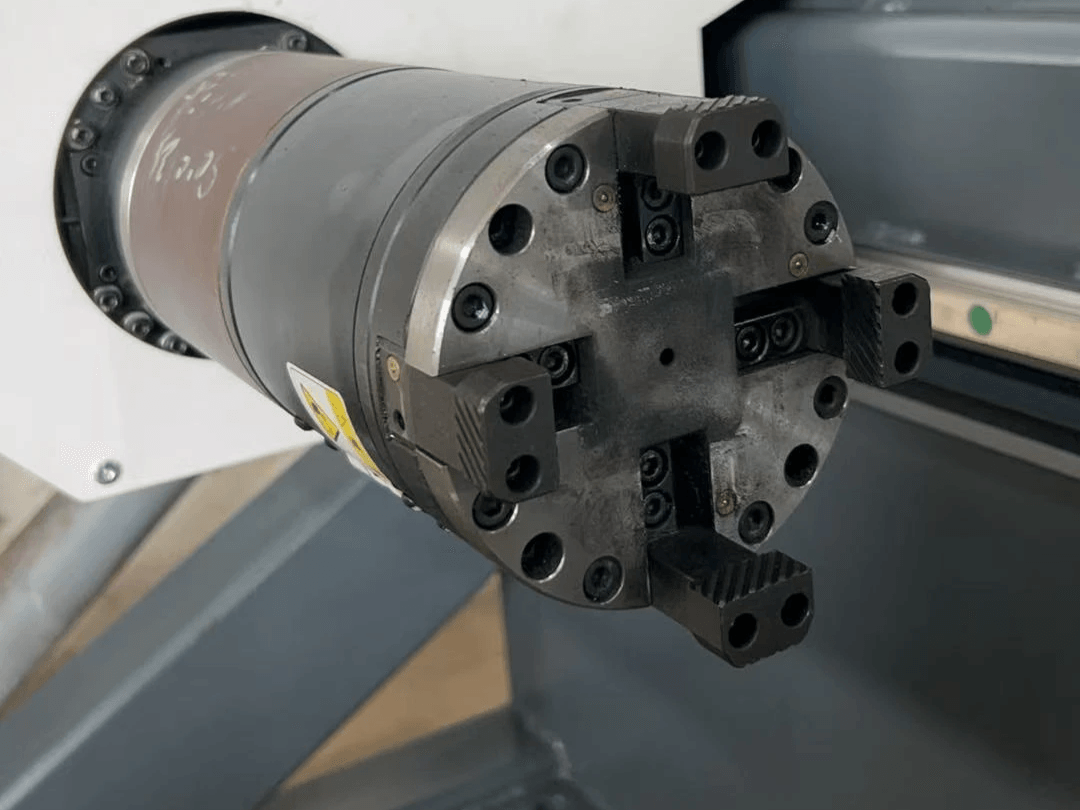

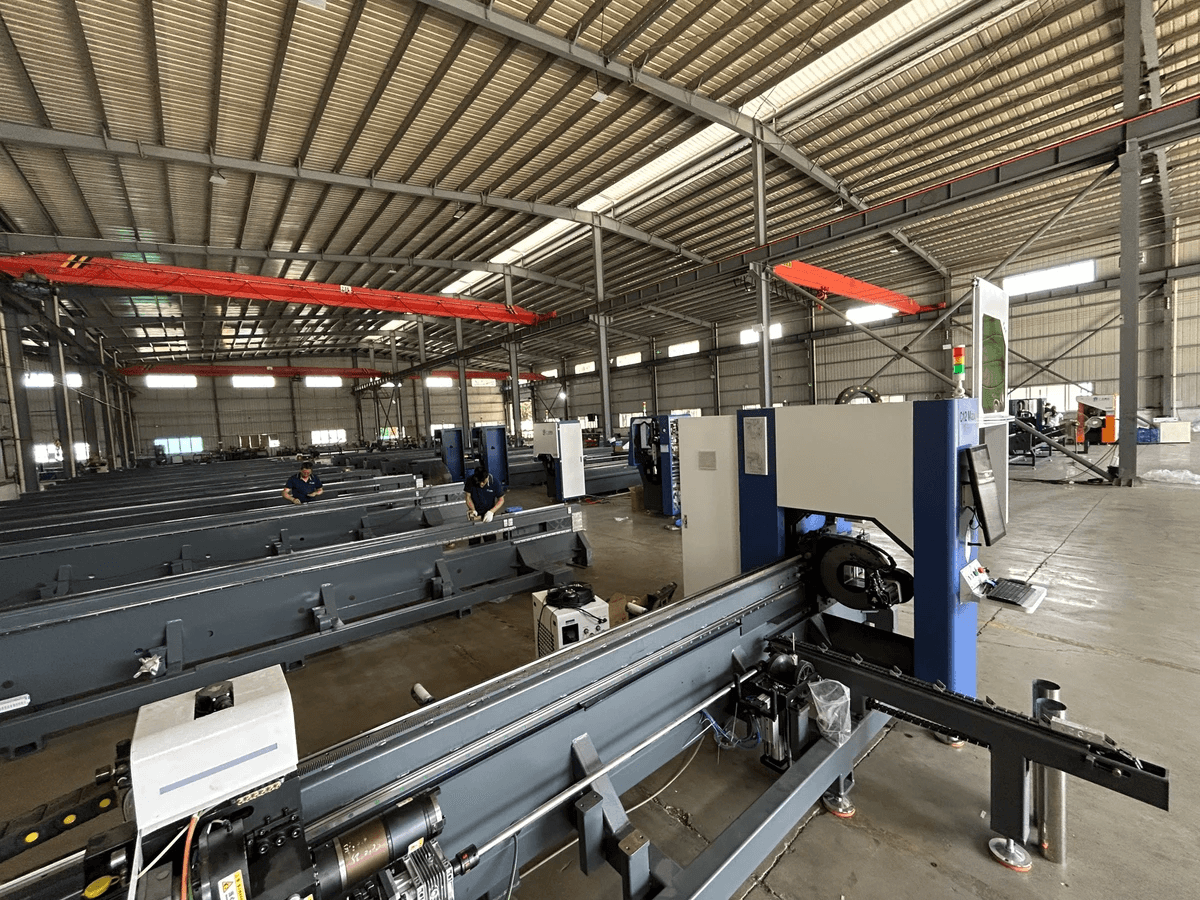

NAROO's Role in Industrial Processes

NAROO is a prime example of how a company effectively leverages laser cutter types to streamline its manufacturing processes. By integrating a metal cutting machine laser into their production line, they have significantly improved precision and reduced waste. The efficiency gained from using a fiber laser cutting machine allows NAROO to produce high-quality products while meeting tight deadlines.

The company's choice of an engraving laser cutting machine also plays a crucial role in customizing products for clients. This flexibility not only enhances customer satisfaction but also opens new revenue streams by offering bespoke solutions. As NAROO continues to innovate with its machinery choices, it sets a benchmark for other businesses looking to optimize their operations with advanced technology.

Metal Cutting Laser Cutter Success Stories

One notable case involves an automotive parts manufacturer that adopted a fiber laser cutting machine to enhance its production capabilities. With the ability to cut through thick metals with exceptional speed and accuracy, they were able to reduce lead times dramatically while maintaining stringent quality standards.

Another success story features a small fabrication shop that transitioned from traditional methods to using a CO2 laser cutter for their projects. This shift not only improved their operational efficiency but also allowed them to take on more complex designs that were previously unfeasible with older equipment. The investment in modern technology has paid off handsomely as they expand their client base and increase profitability.

Innovations in Fiber Laser Engravers

Fiber laser engravers are at the forefront of innovation in the world of engraving technology! These machines are increasingly being adopted for applications ranging from intricate jewelry designs to durable industrial markings on metal surfaces. Their ability to deliver high-precision engravings at remarkable speeds makes them an attractive option for businesses aiming for both quality and efficiency.

Recent advancements have led to more compact and user-friendly models that cater specifically to small businesses or hobbyists looking for an engraving solution without sacrificing performance. Additionally, integration with software tools allows operators greater control over design parameters, further enhancing creativity in product development. As innovations continue within this space, fiber lasers stand poised as essential tools across various industries needing reliable engraving solutions.