Introduction

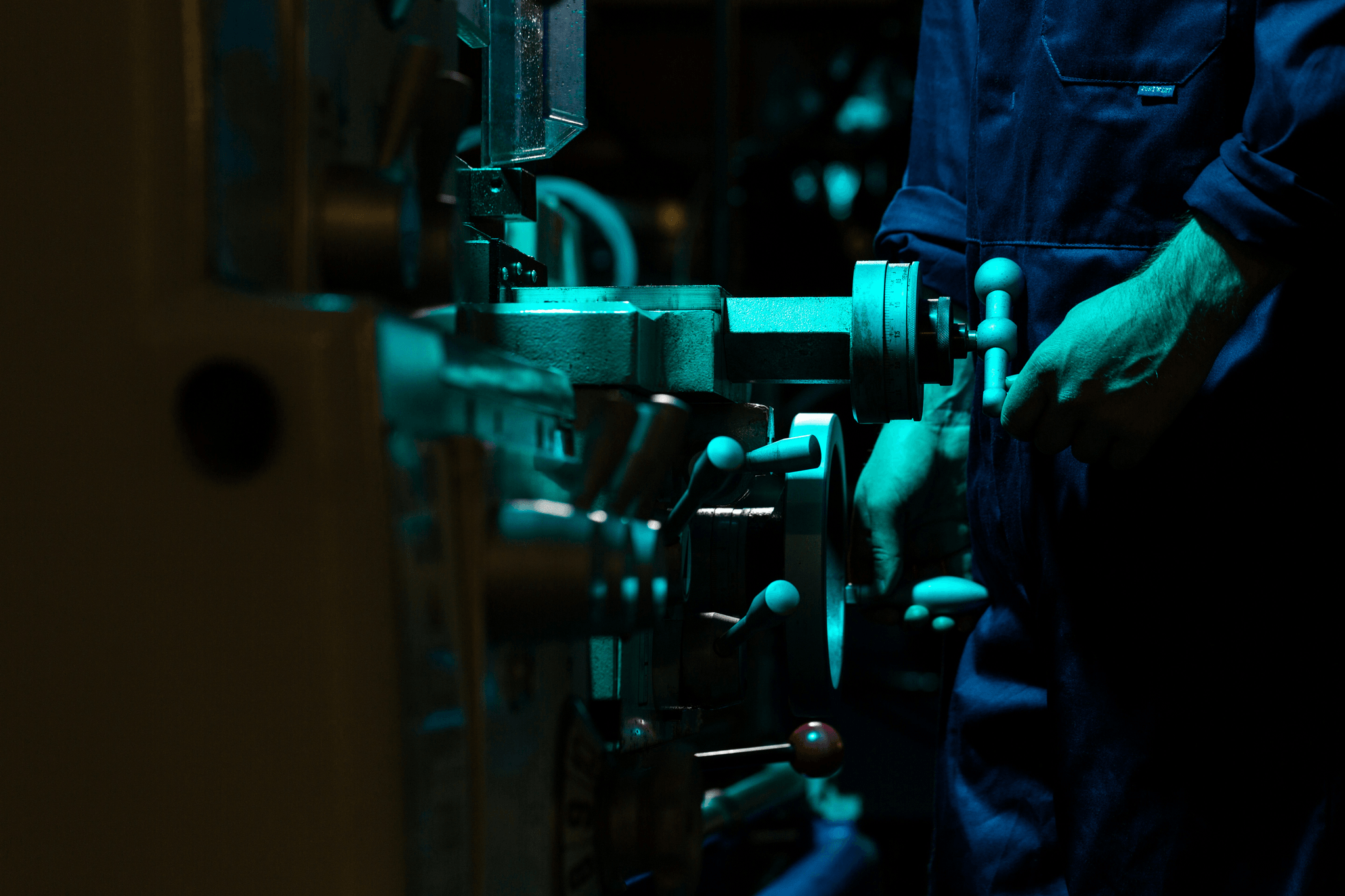

In the world of metal fabrication, pipe laser cutters have revolutionized how we approach cutting tasks. These machines combine precision and speed, making them indispensable in various industries. Understanding how to cut iron pipe efficiently with a metal pipe laser cutting machine can significantly enhance productivity and reduce waste.

Understanding Pipe Laser Cutters

Pipe laser cutters are specialized tools designed to cut through metal pipes with remarkable accuracy. Unlike traditional methods that might leave rough edges or require additional finishing work, these advanced machines use focused laser beams to achieve clean cuts in a fraction of the time. By utilizing a flatbed laser cutting machine specifically designed for pipes, operators can ensure consistent results across different materials and thicknesses.

Advantages of Using a Laser Cutter

For starters, these machines offer unparalleled precision; they can create intricate designs and complex shapes without compromising the integrity of the material. Furthermore, they minimize material waste—an essential factor for businesses looking to optimize their production processes while keeping costs down.

Key Components of Laser Cutting Machines

A typical metal pipe laser cutting machine consists of several key components that work together seamlessly to deliver high-quality cuts. The most crucial element is the laser source itself, which generates the beam used for cutting; this is often complemented by optics that focus and direct the beam onto the material being cut. Additionally, features like motion control systems and cooling mechanisms play vital roles in ensuring efficiency and longevity in operations involving framing machines or other industrial applications.

What is a Pipe Laser Cutter?

Pipe laser cutters are specialized machines designed to cut metal pipes with exceptional precision and efficiency. These machines utilize laser technology to achieve clean cuts, making them a preferred choice in various industries. By harnessing the power of focused light, these devices can create intricate designs and shapes that traditional cutting methods often struggle to reproduce.

Definition and Functionality

A pipe laser cutter is a type of laser cutting machine specifically engineered for processing cylindrical materials like metal pipes and tubes. It employs a high-powered laser beam that melts or vaporizes the material along a predetermined path, resulting in precise cuts with minimal waste. This functionality is essential for applications requiring accuracy, such as automotive parts manufacturing or structural steel fabrication.

How it Differs from Traditional Cutting

When considering how to cut iron pipe, the advantages of using a metal pipe laser cutting machine become evident compared to traditional methods like saws or plasma cutters. Traditional cutting techniques often leave rough edges and require additional finishing work, while laser cutting produces smooth edges right off the bat. Moreover, pipe laser cutters can handle complex geometries effortlessly—something flatbed laser cutting machines may find challenging with irregular shapes.

Applications of Pipe Laser Cutters

The versatility of pipe laser cutters allows them to be employed across various sectors including construction, automotive, and aerospace industries. For instance, they are commonly used in creating custom frames for vehicles or intricate piping systems in commercial buildings—demonstrating their capability in both functional and aesthetic applications. As businesses increasingly seek efficient solutions for how to cut iron pipe accurately, investing in advanced cutting lasers for sale has become crucial for staying competitive in today's market.

How to Cut Iron Pipe with Precision

Cutting iron pipe with precision is essential for ensuring structural integrity and achieving clean edges. Whether you're using a metal pipe laser cutting machine or a traditional saw, the right approach can make all the difference. This section will guide you through selecting the best equipment, effective cutting techniques, and common challenges you might face.

Choosing the Right Equipment

A metal pipe laser cutting machine offers unparalleled precision compared to conventional methods, making it a popular choice among professionals. Additionally, if your projects require versatility, consider investing in a flatbed laser cutting machine that can handle various materials and shapes effortlessly.

Choosing between different types of machines can be daunting; however, understanding your specific needs will simplify the decision-making process. For example, if you're primarily working with steel pipes, a dedicated laser cutting machine for steel may provide better results than a general-purpose cutter. Always ensure that your chosen framing machine complements your workflow and meets industry standards for safety and efficiency.

Techniques for Effective Cutting

Once you've selected your equipment, mastering effective cutting techniques is next on the agenda for how to cut iron pipe accurately. Begin by securing the pipe in place using clamps or fixtures; this ensures stability during the cutting process and minimizes vibrations that could lead to inaccuracies. Furthermore, always take time to adjust settings on your metal pipe laser cutting machine according to material thickness and desired cut quality.

Another technique involves utilizing proper feed rates and power settings on your laser cutter; these adjustments can significantly impact edge quality and minimize waste material. For intricate designs or tight tolerances, consider performing test cuts on scrap pieces before executing final cuts on valuable materials. These practices not only enhance precision but also extend the life of your equipment by reducing unnecessary strain.

Common Challenges in Pipe Cutting

Despite advancements in technology like metal pipe laser cutting machines, challenges still arise when figuring out how to cut iron pipe effectively. One common issue is warping due to heat generated during the cutting process; this can compromise both appearance and functionality of finished products. To combat this challenge, ensure proper cooling systems are integrated into your setup or select slower feed rates when working with thicker pipes.

Another challenge involves aligning cuts accurately on longer pipes—this is where using a flatbed laser cutting machine can offer advantages over traditional methods by providing more extensive support surfaces for alignment checks. Finally, be prepared for potential issues related to material inconsistencies or impurities that may affect cut quality; regular inspections of raw materials before use help mitigate these risks effectively.

Features of Metal Pipe Laser Cutting Machines

Metal pipe laser cutting machines have revolutionized the way we approach cutting tasks, especially when it comes to materials like steel. These machines utilize advanced technology to deliver unparalleled precision and efficiency. Understanding the core technology behind these devices is crucial for anyone looking to enhance their cutting capabilities.

Core Technology in Laser Cutting

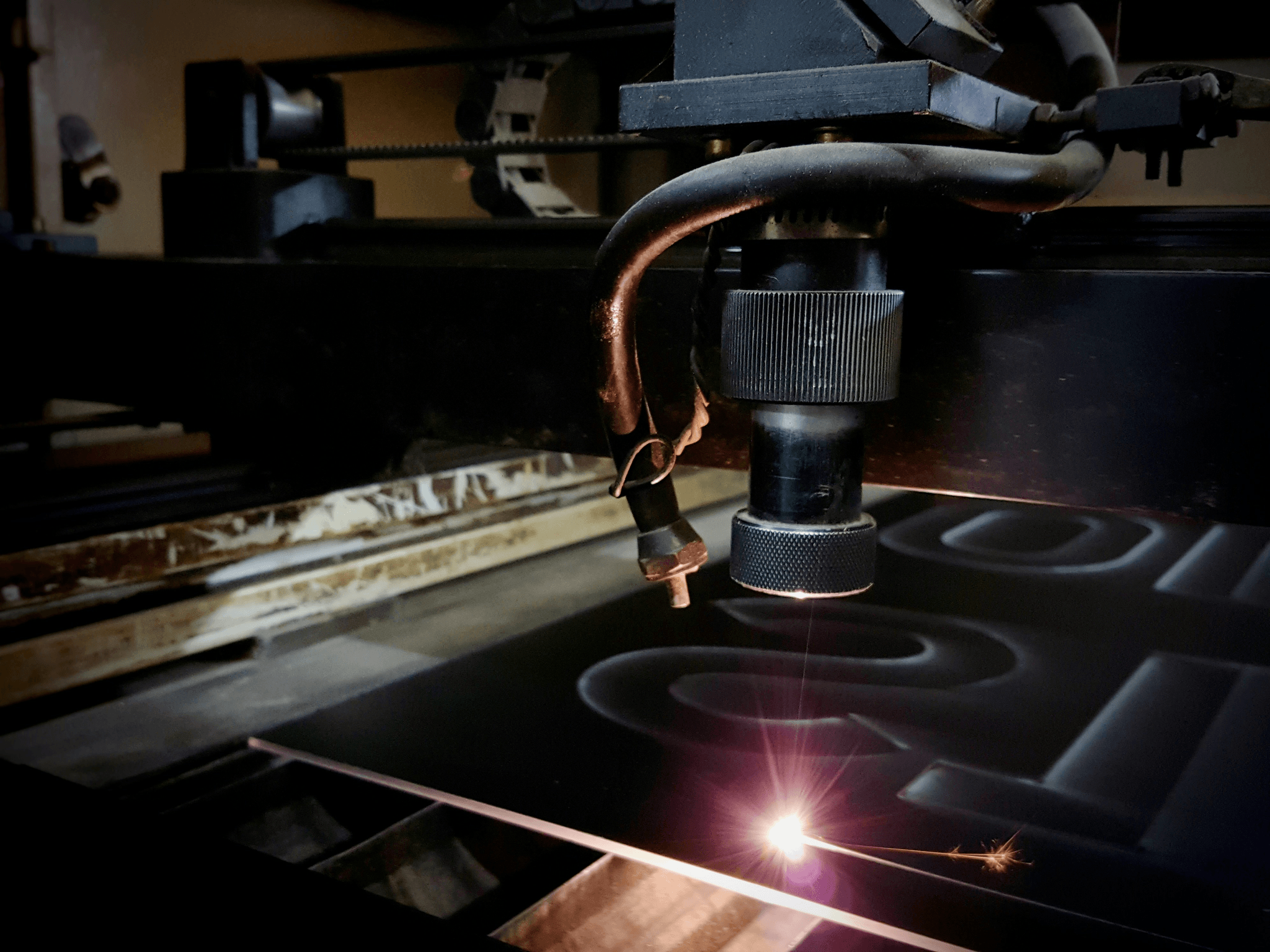

At the heart of a metal pipe laser cutting machine lies a high-powered laser beam that is generated and focused through a series of mirrors and lenses. This beam can cut through various materials, including iron pipes, with remarkable accuracy by melting or vaporizing the material at the point of contact. The integration of CNC (Computer Numerical Control) systems allows for intricate designs and patterns, making it easier than ever to learn how to cut iron pipe effectively.

The core technology also includes features such as adjustable focus and speed settings, enabling operators to tailor their cuts according to specific project requirements. This flexibility is essential when working with different thicknesses or types of steel, ensuring optimal results every time. Additionally, modern laser cutters often come equipped with software that simplifies design input, allowing for seamless transitions from design to execution.

Advantages of Laser Cutting Machines for Steel

Laser cutting machines for steel offer numerous advantages over traditional methods such as plasma or oxy-fuel cutting. One significant benefit is the cleaner cuts produced by lasers; there’s minimal slag or burr formation, which means less post-processing work is required after cutting iron pipes or other metal components. This not only saves time but also reduces material waste—an essential factor in today’s eco-conscious manufacturing environment.

Another advantage lies in the precision that these machines provide; they can achieve tolerances as tight as ±0.1 mm without compromising speed or quality. This accuracy translates into better fitting parts and reduced assembly times in projects requiring multiple components cut from metal pipes or sheets. Moreover, laser cutters are versatile tools capable of handling complex geometries that would be challenging for conventional methods.

Comparing Flatbed Laser Cutting Machines

When comparing flatbed laser cutting machines with other types like tube lasers or handheld cutters, it's essential to consider their unique strengths and weaknesses. Flatbed laser cutting machines are designed primarily for flat materials but can be adapted for specific applications involving pipes if equipped correctly—this adaptability makes them a popular choice among manufacturers looking to maximize their equipment's utility.

However, while flatbed models may excel in speed and efficiency on flat surfaces, dedicated pipe lasers are often more effective when it comes specifically to tubular shapes like iron pipes due to their tailored design features such as rotating clamps and specialized nozzles. Understanding these differences helps businesses decide whether investing in a framing machine designed specifically for tubes might be more beneficial than relying solely on flatbed options.

In conclusion, whether you're exploring how to cut iron pipe efficiently or considering various types of metal pipe laser cutting machines available on the market today, understanding these features will guide you toward making informed decisions about your equipment investments.

Choosing the Right Framing Machine

Selecting the appropriate framing machine is crucial for achieving precision and efficiency in your projects. With various options available, it’s essential to understand the specific needs of your tasks, including how to cut iron pipe effectively. A well-chosen framing machine can enhance your workflow and ensure high-quality results.

Factors to Consider when Selecting a Framing Machine

When choosing a framing machine, consider factors such as material compatibility, cutting speed, and ease of use. If you frequently work with metal pipe laser cutting machines or need a laser cutting machine for steel, ensure that the framing machine can handle these materials efficiently. Additionally, think about the size of the workspace; larger machines may offer more capabilities but require more space.

Another vital factor is precision; look for a framing machine known for its accuracy in cuts. This is particularly important when you’re figuring out how to cut iron pipe without compromising on quality. Lastly, consider your budget and whether investing in advanced features will provide long-term benefits for your operations.

Popular Models and Their Features

Several popular models stand out in the market today for their reliability and performance in metal fabrication tasks. The XYZ Framer 3000 is renowned for its robust construction and ability to handle various materials seamlessly, making it ideal for users who often deal with flatbed laser cutting machines. Another excellent choice is the ABC Precision Cutter which boasts advanced technology designed specifically for laser cutting applications.

These models often come equipped with features like programmable settings, user-friendly interfaces, and enhanced safety measures that make them suitable even for beginners learning how to cut iron pipe effectively. Additionally, many modern machines offer integration capabilities with other equipment like CAD software which streamlines workflows significantly.

Maintenance Tips for Longevity

To maximize the lifespan of your framing machine, regular maintenance should be part of your routine practices. Start by keeping all moving parts clean and lubricated; this not only helps maintain performance but also prevents wear over time—especially important when using a metal pipe laser cutting machine or any laser cutting machine for steel applications.

Check alignment frequently to ensure accurate cuts every time you operate the machinery; misalignment can lead to costly mistakes when working on projects requiring precise measurements such as those involving flatbed laser cutting machines. Lastly, always refer to manufacturer guidelines regarding scheduled maintenance checks; adhering to these recommendations will help you avoid unexpected breakdowns and keep your equipment running smoothly.

Where to Find Cutting Lasers for Sale

Finding the right cutting lasers for sale can be a daunting task, especially with the variety of options available in the market today. Whether you're searching for a metal pipe laser cutting machine or a flatbed laser cutting machine, knowing where to look can make all the difference. In this section, we’ll explore top brands, compare online and local suppliers, and help you evaluate price and quality.

Top Brands in the Market

When it comes to purchasing a laser cutting machine for steel, several brands stand out due to their reliability and innovation. Companies like Trumpf, Bystronic, and Amada are renowned for their advanced technology and high-quality machines tailored for various applications including how to cut iron pipe effectively. Each of these brands offers unique features in their metal pipe laser cutting machines that cater to different needs—from precision cutting to speed.

Additionally, newer players like FiberLaserTech are making waves with cost-effective solutions that don’t compromise on quality. It’s essential to research each brand's reputation by checking customer reviews and testimonials before making your decision on which framing machine or metal pipe laser cutter suits your requirements best.

Online vs. Local Suppliers

Deciding between online versus local suppliers is another crucial step when hunting for cutting lasers for sale. Online platforms often provide a broader selection of products at competitive prices due to lower overhead costs; however, purchasing locally allows you to inspect machinery firsthand and receive immediate support from sales representatives who understand how to cut iron pipe effectively.

Local suppliers might offer demo units or training sessions on using equipment such as flatbed laser cutting machines more efficiently. On the other hand, online shopping provides convenience—many reputable websites now feature customer service chat options that can help answer your questions about specific models or techniques related to effective pipe cutting.

Evaluating Price and Quality

When evaluating price versus quality in your search for a metal pipe laser cutting machine, it's essential not just to look at initial costs but also consider long-term value. Higher-priced models may offer enhanced features like faster processing speeds or better energy efficiency that could save you money over time while ensuring precise cuts when learning how to cut iron pipe.

It’s also wise to compare warranties and support services offered by manufacturers; sometimes cheaper options come with limited support that could lead you into trouble down the line if issues arise with your framing machine or flatbed laser cutter. Ultimately, investing in a high-quality machine from a reputable brand will pay off through increased productivity and reduced operational headaches.

Conclusion

In the rapidly evolving world of manufacturing, pipe cutting technology is on the brink of a revolution. The integration of advanced laser cutting machines is reshaping how industries approach tasks like how to cut iron pipe with precision and efficiency. With innovations in metal pipe laser cutting machines, the future looks bright for those seeking speed and accuracy in their operations.

The Future of Pipe Cutting Technology

The future of pipe cutting technology is undeniably exciting, with advancements that promise to enhance productivity and reduce waste. Innovations such as automated flatbed laser cutting machines are paving the way for more efficient processes, allowing manufacturers to handle various materials including steel with greater ease. As these technologies continue to evolve, we can expect even more robust solutions that streamline operations and minimize downtime.

Why Kiant Machinery Stands Out in the Industry

Their commitment to quality and innovation sets them apart from competitors, offering top-notch metal pipe laser cutting machines designed for versatility and durability. By focusing on customer needs and providing exceptional support, Kiant Machinery has made a name for itself as a go-to source for cutting lasers for sale that meet diverse industrial requirements.

Enhancing Efficiency with Laser Cutting Solutions

Investing in a laser cutting machine for steel not only boosts operational efficiency but also enhances overall product quality. With features tailored specifically for precision tasks like how to cut iron pipe, these machines significantly reduce material waste while improving turnaround times. As companies increasingly adopt these advanced technologies, they position themselves at the forefront of their industries—ready to tackle any challenge that comes their way.