Introduction

In the world of construction, light gauge steel framing has emerged as a game-changer, offering a robust alternative to traditional building materials. This innovative approach utilizes thin sheets of steel to create durable structures that can withstand the test of time and environmental challenges. With the rise of advanced technologies and machinery, the efficiency and effectiveness of light gauge metal framing have reached new heights, paving the way for modern construction practices.

Understanding Light Gauge Steel Framing

Light gauge steel framing is a construction method that employs thin-walled steel sections to form structural frameworks for buildings. These components are designed with precision, making them lightweight yet incredibly strong, which is essential in creating resilient structures. By utilizing a light steel structure machine, builders can fabricate these components with remarkable accuracy and speed, ensuring high-quality results in every project.

Advantages of Steel Framing Systems

One of the primary advantages of steel framing systems is their superior strength-to-weight ratio compared to traditional wood framing. This means that buildings constructed with light gauge steel can support heavier loads while remaining lighter overall, allowing for more design flexibility and reducing foundation costs. Additionally, steel's resistance to pests and rot significantly enhances longevity, making it an appealing choice for both residential and commercial applications.

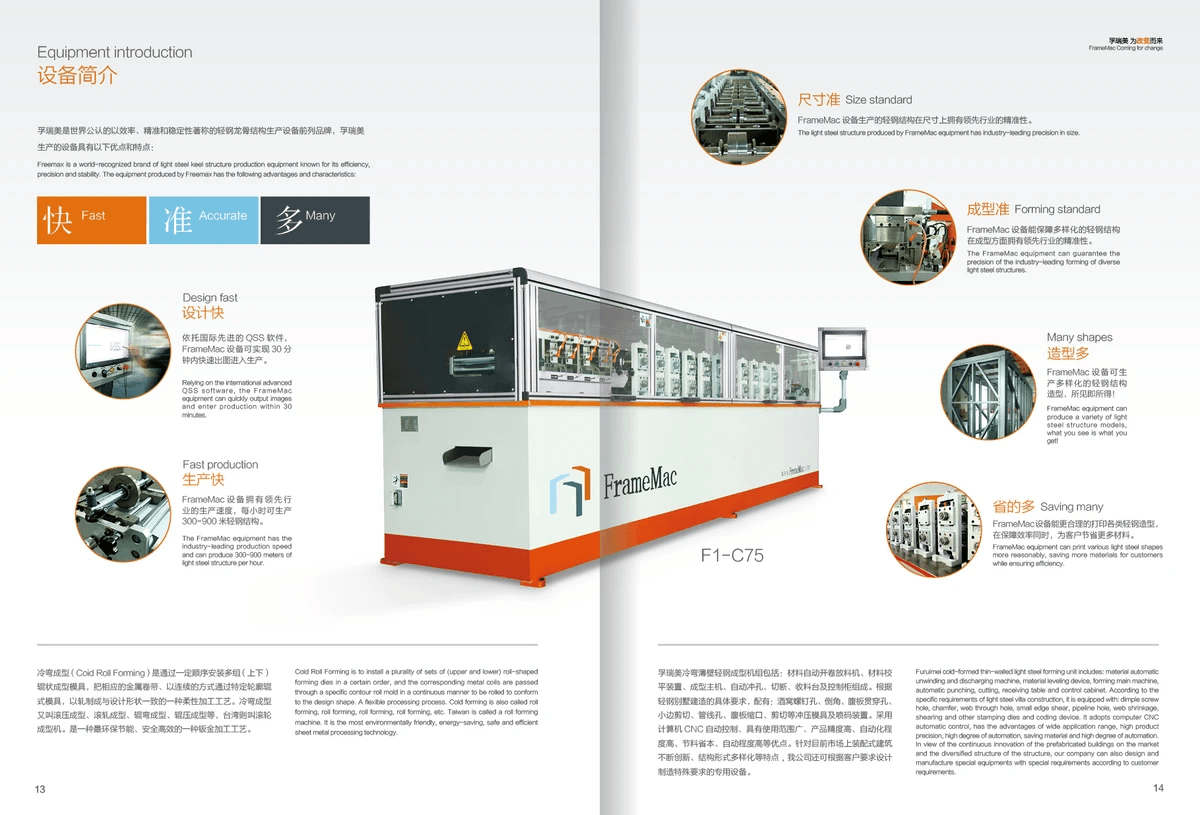

How Kiant Machinery Innovates the Industry

Kiant Machinery stands at the forefront of innovation in the light gauge metal framing industry by providing cutting-edge equipment tailored for modern construction needs. Their state-of-the-art light steel structure machines not only streamline production but also ensure high precision in manufacturing processes. By focusing on efficiency and quality assurance, Kiant Machinery empowers builders and contractors to achieve greater productivity while maintaining exceptional standards in their projects.

The Basics of Light Gauge Steel Framing

Light gauge steel framing is revolutionizing the construction industry, providing a durable and efficient alternative to traditional building methods. This innovative approach utilizes thin sheets of steel to create a strong framework for buildings, making it an ideal choice for both residential and commercial projects. Understanding the components and benefits of light gauge steel framing is essential for anyone looking to enhance their construction practices.

Definition and Components of Light Gauge Steel

Light gauge steel refers to cold-formed steel sections that are manufactured in various shapes and sizes, typically used in wall systems, roofs, and floors. The primary components include studs, tracks, and braces that together form a robust framework capable of supporting significant loads while remaining lightweight. This versatility allows builders to create complex structures efficiently using specialized equipment like the light steel structure machine.

Comparing Light Gauge Metal Framing and Wood

When comparing light gauge metal framing with wood, several advantages emerge that make steel a preferred choice for many builders. Unlike wood, which can warp or rot over time, light gauge metal framing provides superior stability and longevity under varying environmental conditions. Additionally, the use of a steel framing system often results in reduced maintenance costs over time compared to traditional wooden structures.

Key Features of the Steel Framing System

One standout feature of light gauge metal framing is its resistance to pests such as termites—an issue that can plague wooden frames significantly. Moreover, the precision manufacturing processes employed by leading steel frame manufacturers ensure consistent quality and performance across all components. Lastly, integrating advanced technology into the design of a steel framing machine enhances efficiency during both production and installation phases, streamlining overall project timelines.

The Role of Steel Frame Manufacturers

In the world of construction, steel frame manufacturers play a pivotal role in ensuring the success of any project that utilizes light gauge steel framing. These manufacturers not only supply essential materials but also provide the technology and expertise necessary to implement efficient and effective steel framing systems. With the right partnership, builders can enhance their operations and achieve remarkable results.

Choosing Reliable Steel Frame Manufacturers

When it comes to selecting a reliable steel frame manufacturer, several factors should be considered to ensure quality and performance. First, look for manufacturers with a proven track record in producing light gauge metal framing products that meet industry standards. Additionally, customer reviews and testimonials can provide valuable insights into their reliability and product quality, helping you make an informed choice about your light steel structure machine provider.

Moreover, it's essential to evaluate the range of products offered by potential manufacturers. A reputable manufacturer should provide various options for light gauge steel framing systems tailored to different project needs. This flexibility not only streamlines your purchasing process but also allows for customization that can lead to better overall project outcomes.

Importance of Quality Assurance in Manufacturing

Quality assurance is critical in manufacturing light gauge metal framing components, as it directly impacts the durability and safety of the final structure. Steel frame manufacturers must adhere to stringent quality control processes throughout production to ensure that every piece meets specified standards before reaching construction sites. This commitment to quality reduces risks associated with structural failures or costly repairs down the line.

Additionally, investing in high-quality materials from reputable manufacturers enhances the integrity of your projects while optimizing performance when using a steel framing machine. By prioritizing quality assurance during manufacturing, builders can achieve greater peace of mind knowing that their structures are built on solid foundations—literally! This attention to detail ultimately translates into long-term cost savings by minimizing maintenance needs over time.

How Manufacturers Enhance Project Efficiency

Steel frame manufacturers contribute significantly to enhancing project efficiency through innovative practices and technologies designed specifically for light gauge steel framing applications. By providing advanced machinery like automated light steel structure machines, they enable faster production times while reducing labor costs associated with manual assembly processes. This efficiency allows contractors to complete projects on schedule without sacrificing quality or safety.

Furthermore, many manufacturers offer comprehensive support services such as training programs for operators of their equipment—ensuring everyone involved understands how best to utilize these machines effectively within a given project scope. Such investment in operator education fosters smoother workflows on-site and minimizes downtime caused by operational errors or misunderstandings about equipment usage.

Lastly, collaboration between builders and reliable steel frame manufacturers fosters an environment where continuous improvement is prioritized throughout all phases—from design through installation—ultimately leading toward enhanced productivity across entire projects involving light gauge metal framing systems.

Selecting the Right Light Steel Structure Machine

Choosing the right light steel structure machine is crucial for any project involving light gauge steel framing. The efficiency, durability, and quality of your steel framing system largely depend on the equipment you select. With a variety of machines available, understanding your options can lead to better decision-making and ultimately enhance your construction processes.

Types of Light Steel Structure Machines Available

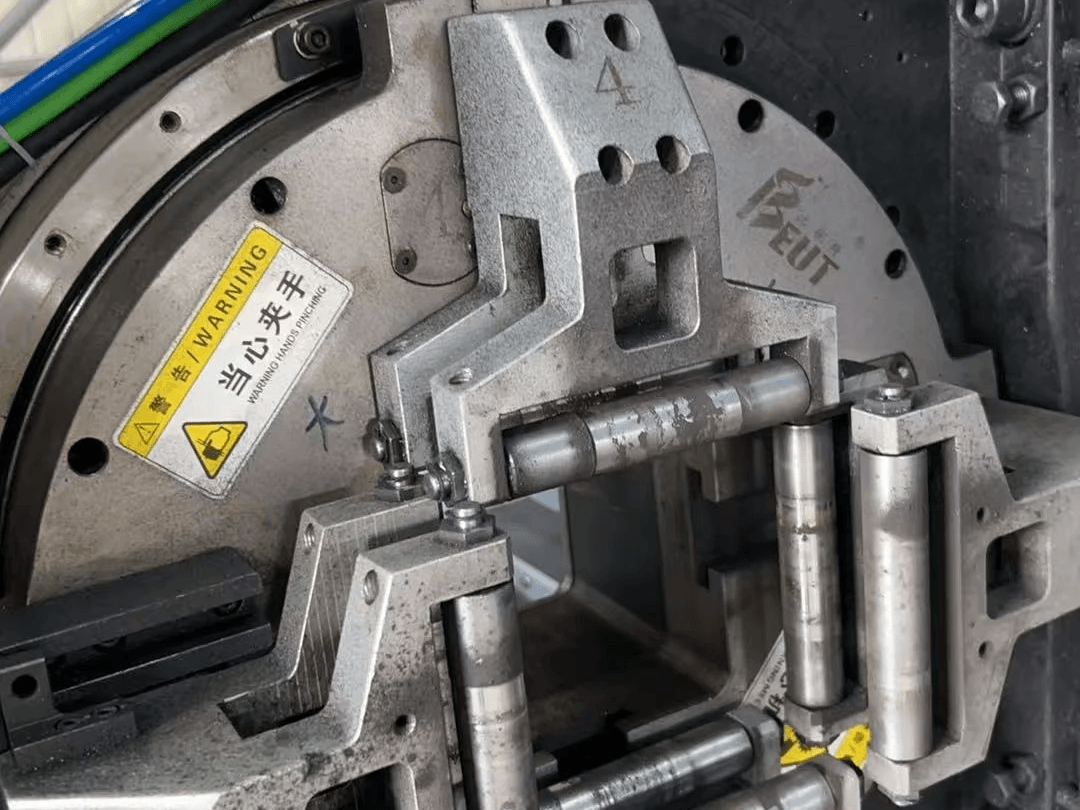

There are several types of light steel structure machines on the market, each designed to cater to specific needs in light gauge metal framing. These include roll forming machines, which create steel sections from coils; CNC cutting machines that ensure precision in component sizes; and automated assembly systems that streamline the construction process. By familiarizing yourself with these options, you can identify which type best suits your project requirements and workflow.

Factors to Consider When Choosing Equipment

When selecting a light steel structure machine, several factors should guide your decision-making process. First, consider the production capacity—how much output you need based on project demands will influence your choice significantly. Additionally, evaluate the ease of use and maintenance requirements; a user-friendly machine reduces training time and operational hiccups while minimizing downtime due to repairs or adjustments.

Equally important is compatibility with existing systems or materials—ensure that your chosen equipment integrates seamlessly into your current setup without major modifications. Finally, budget constraints must be factored in as well; investing in high-quality machinery may initially seem costly but can lead to long-term savings through increased efficiency and reduced waste.

Why Kiant Machinery Stands Out

Kiant Machinery distinguishes itself from other steel frame manufacturers by offering innovative solutions tailored specifically for light gauge metal framing applications. Their commitment to quality ensures that each light steel structure machine is built with durability in mind while maintaining high-performance standards essential for modern construction projects. Furthermore, Kiant's customer-centric approach means they provide comprehensive support—from initial consultation through installation—to ensure clients maximize their investment.

Additionally, Kiant Machinery’s advanced technology enhances productivity by automating processes that traditionally required manual labor, thus reducing human error and improving overall efficiency within the steel framing system. With an extensive range of customizable options available, clients can find a solution that perfectly aligns with their unique needs while benefiting from ongoing advancements in machinery technology.

Installation and Setup of Steel Framing Machines

Installing a light steel structure machine is a crucial step in ensuring the efficiency and effectiveness of your light gauge steel framing projects. Proper preparation can significantly reduce downtime and make the setup process smoother. This section will guide you through the essential steps for preparing your site, setting up your equipment, and addressing potential challenges.

Preparing Your Site for Installation

Before the arrival of your steel framing machine, it's vital to assess and prepare your installation site thoroughly. Start by ensuring that the area is clear of debris, obstacles, and any materials that could impede access or operation. Additionally, consider factors such as power supply availability, space for maneuvering the light gauge metal framing equipment, and proximity to materials needed for construction activities.

Next, ensure that you have a solid foundation for your light steel structure machine. The surface should be level to prevent any operational issues during use; an uneven base can lead to inaccuracies in framing assembly. Finally, confirm that all necessary tools are on-site and ready for use during installation—having everything at hand will save time later on.

Step-by-Step Guide to Machine Setup

Setting up a steel framing machine involves several methodical steps to ensure it operates efficiently from day one. First, carefully unpack all components of the light gauge steel framing system according to the manufacturer's instructions—this includes checking for any damage during shipping. Once unpacked, position each part according to your prepared layout plan while considering accessibility for maintenance.

Next, connect power sources and safety features as outlined in the user manual provided by your chosen steel frame manufacturers. It's crucial to follow these guidelines meticulously since improper setup can lead to safety hazards or equipment malfunction down the line. After connecting everything securely, run initial tests on various settings before commencing full-scale operations with your light gauge metal framing projects.

Lastly, don’t forget about calibration! Adjusting settings based on material specifications ensures precision cuts and joints throughout construction phases—this is where investing in quality machinery pays off significantly in terms of project efficiency.

Common Challenges and How to Overcome Them

While installing a light steel structure machine may seem straightforward, several common challenges can arise during this phase that requires quick thinking and problem-solving skills. One frequent issue is misalignment between components; this often occurs when measurements aren't accurately taken prior to setup or when surfaces are not level enough—a situation easily remedied by double-checking measurements beforehand.

Another challenge could involve electrical connections not being compatible with local standards or unexpected power surges affecting machine performance; always consult with electrical professionals if you're uncertain about wiring requirements specific to your region or machinery type used by different steel frame manufacturers.

Lastly, training staff adequately before operating new machines minimizes risks associated with inexperienced handling; consider scheduling training sessions led by experts like those from Kiant Machinery who provide comprehensive support tailored specifically for their equipment users—because nothing beats hands-on learning when it comes down to mastering technology!

Training and Support for Steel Framing Systems

In the world of light gauge steel framing, having the right training and support can make all the difference. A well-trained workforce is essential for maximizing the efficiency and safety of using a light steel structure machine. Moreover, ongoing support ensures that any hiccups in operations are swiftly addressed, allowing projects to stay on track and within budget.

The Importance of Proper Training

Proper training in using a light gauge steel framing system is paramount for several reasons. First, it helps workers understand the intricacies of operating a steel framing machine, minimizing errors that could lead to costly mistakes or delays. Second, with comprehensive training programs, employees become adept at recognizing potential issues before they escalate into significant problems, enhancing overall project efficiency.

Furthermore, trained personnel are more confident and capable when handling complex tasks associated with light gauge metal framing. This confidence translates into higher productivity levels and better quality outcomes in construction projects. In an industry where precision is key, investing in training pays dividends by ensuring that the team is well-versed in best practices and safety protocols.

Kiant Machinery’s Training Programs

Kiant Machinery takes pride in offering robust training programs tailored specifically for users of their light steel structure machines. These programs cover everything from basic operation to advanced techniques for optimizing the use of their innovative steel framing systems. Participants engage in hands-on learning experiences that equip them with practical skills needed to navigate challenges confidently.

In addition to technical skills, Kiant's training also emphasizes safety procedures essential for working with steel framing machines. This focus on safety not only protects employees but also safeguards valuable equipment from unnecessary wear or damage during operations. By fostering a culture of continuous learning and improvement, Kiant Machinery positions its clients for long-term success in their construction endeavors.

After-Sales Support: Keeping Your Business Running

After-sales support is crucial for maintaining operational efficiency when utilizing light gauge metal framing systems from reputable steel frame manufacturers like Kiant Machinery. Their commitment doesn’t end once a sale is made; instead, they provide ongoing assistance to ensure clients get the most out of their investment in machinery. Whether it’s troubleshooting issues or providing spare parts quickly, reliable after-sales support keeps businesses running smoothly.

Kiant Machinery understands that every moment counts on a job site; therefore, they offer responsive customer service designed to address concerns promptly and effectively. This level of dedication not only enhances customer satisfaction but also builds trust between manufacturers and their clients over time. With such dependable support at hand, businesses can focus on what truly matters—delivering high-quality projects efficiently.

Conclusion

As we wrap up our exploration of light gauge steel framing, it's clear that this innovative building method is not just a passing trend; it’s shaping the future of construction. With its lightweight yet robust characteristics, light gauge metal framing offers a sustainable and efficient alternative to traditional materials. The continued advancements in technology, particularly through companies like Kiant Machinery, ensure that the steel framing system will only get better, pushing the boundaries of what’s possible in modern architecture.

The Future of Light Gauge Steel Framing

The future of light gauge steel framing looks incredibly promising as more builders recognize its advantages over conventional materials. With ongoing innovations in design and manufacturing processes, light steel structure machines are becoming more sophisticated and user-friendly. This evolution not only enhances structural integrity but also supports eco-friendly practices by reducing waste and improving energy efficiency.

Cost Benefits of Investing in Machinery

Investing in high-quality machinery for light gauge metal framing can yield substantial cost benefits over time. While the initial investment might seem significant, the durability and low maintenance needs of steel framing systems lead to long-term savings on repairs and replacements. Moreover, with efficient production capabilities from advanced steel frame manufacturers, projects can be completed faster, further maximizing profitability.

Enhancing Efficiency with Kiant Machinery Solutions

Kiant Machinery stands out as a leader in providing cutting-edge solutions for the construction industry with their range of advanced light steel structure machines. Their commitment to quality and innovation ensures that users benefit from enhanced operational efficiency and reduced downtime during projects. By choosing Kiant's equipment, businesses can streamline their processes while enjoying comprehensive training and support that keeps them ahead in a competitive market.