Introduction

In the ever-evolving landscape of construction, understanding LGS framing solutions is becoming increasingly vital. Light Gauge Steel (LGS) has emerged as a preferred choice for builders and architects alike, thanks to its unique properties and versatility. But what exactly is LGS building technology? This introduction will explore the benefits of Light Gauge Steel, the role of LGS production machines, and why this innovative material is reshaping modern construction.

Understanding LGS Framing Solutions

LGS framing solutions represent a modern approach to construction that utilizes thin-walled steel sections to create structural frameworks. These systems are lightweight yet incredibly strong, making them ideal for various applications in residential and commercial buildings. By embracing what LGS stands for in construction—efficiency, durability, and sustainability—builders can achieve remarkable results that traditional materials simply cannot match.

Benefits of Light Gauge Steel

One of the standout benefits of Light Gauge Steel is its resistance to common issues like rot, pests, and fire hazards that plague conventional wood framing. Additionally, LGS offers significant weight savings without compromising structural integrity, which translates into lower transportation costs and easier handling on-site. As we delve deeper into what is the production machine used for crafting this material, it becomes clear that these machines enhance productivity while maintaining high-quality standards.

The Role of LGS Production Machines

The efficiency of LGS production machines is crucial in transforming raw steel into usable components for construction projects. These machines are designed with advanced technology to ensure precision cutting and shaping of steel sheets into various profiles needed for framing systems. Understanding what is the production machine involved in this process helps highlight how automation and innovation contribute to maximizing efficiency in building with Light Gauge Steel.

What is LGS Building Technology?

LGS building technology has emerged as a revolutionary approach in the construction industry, primarily utilizing light gauge steel (LGS) for various structural applications. This innovative method offers a flexible, durable, and efficient alternative to traditional building materials. By integrating advanced LGS production machines, builders can streamline their processes while enhancing overall project quality.

Overview of Light Gauge Steel

Light gauge steel is a type of framing material made from thin sheets of steel that are cold-formed into structural shapes. This process results in lightweight yet strong components that can be easily transported and assembled on-site. The versatility of LGS makes it suitable for residential, commercial, and industrial construction projects alike.

As we delve deeper into what LGS stands for in construction, it becomes clear that this material is not just about strength but also about efficiency and sustainability. Light gauge steel’s manufacturing process allows for reduced waste and lower energy consumption compared to traditional materials like wood or concrete. With the advent of modern LGS production machines, the fabrication process has become even more precise and efficient.

Advantages Over Traditional Materials

One of the primary advantages of light gauge steel over traditional materials is its impressive strength-to-weight ratio. This characteristic allows for lighter structures without compromising durability or safety standards. Additionally, LGS is resistant to pests such as termites and does not warp or shrink like wood over time.

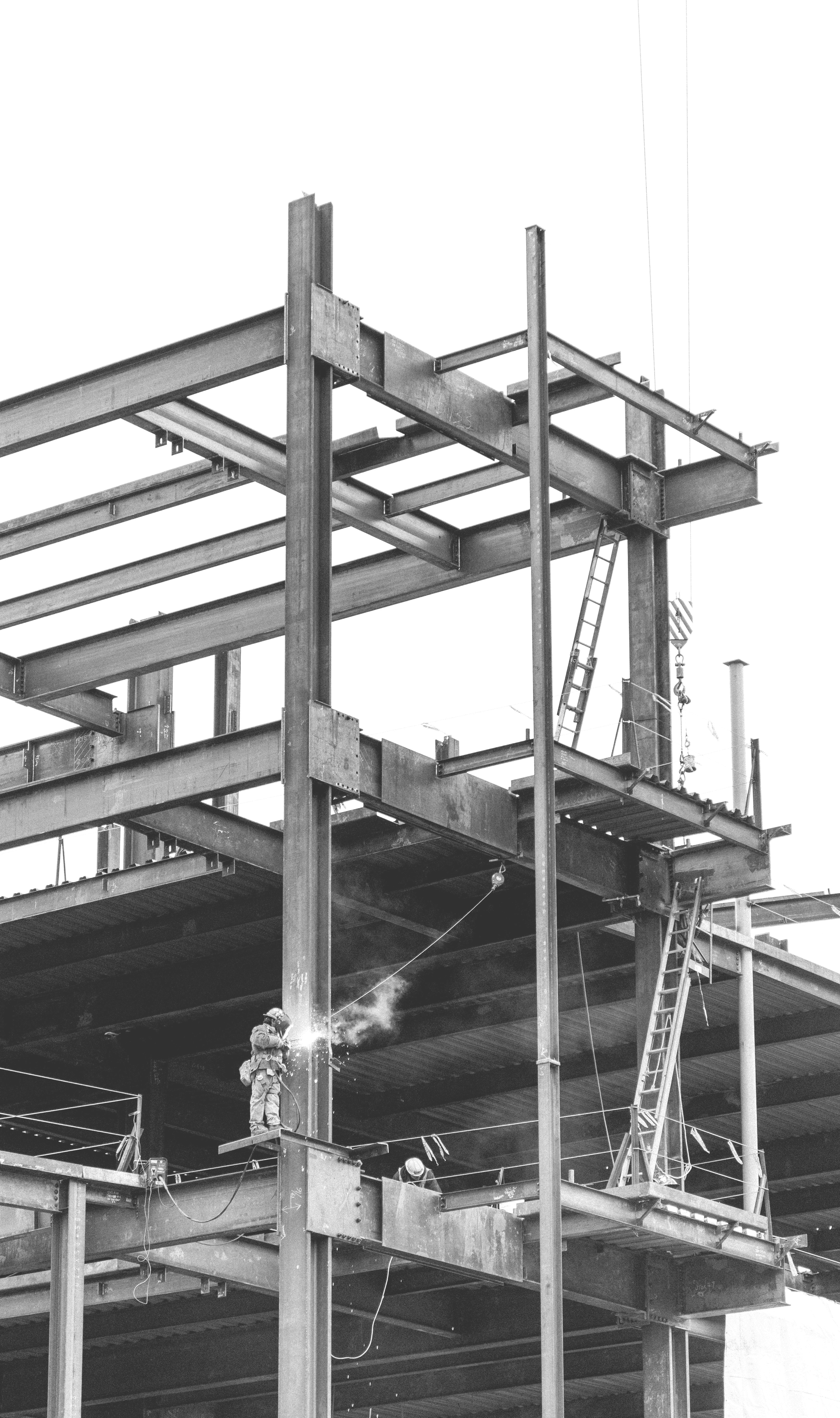

Another benefit lies in the speed of construction; with the use of advanced LGS production machines, builders can significantly reduce labor costs and project timelines. The prefabrication capabilities offered by these machines enable quicker assembly on-site, minimizing delays caused by weather or other unforeseen factors. Moreover, light gauge steel's recyclability contributes positively to sustainable building practices—a growing concern within the industry.

Applications in Modern Construction

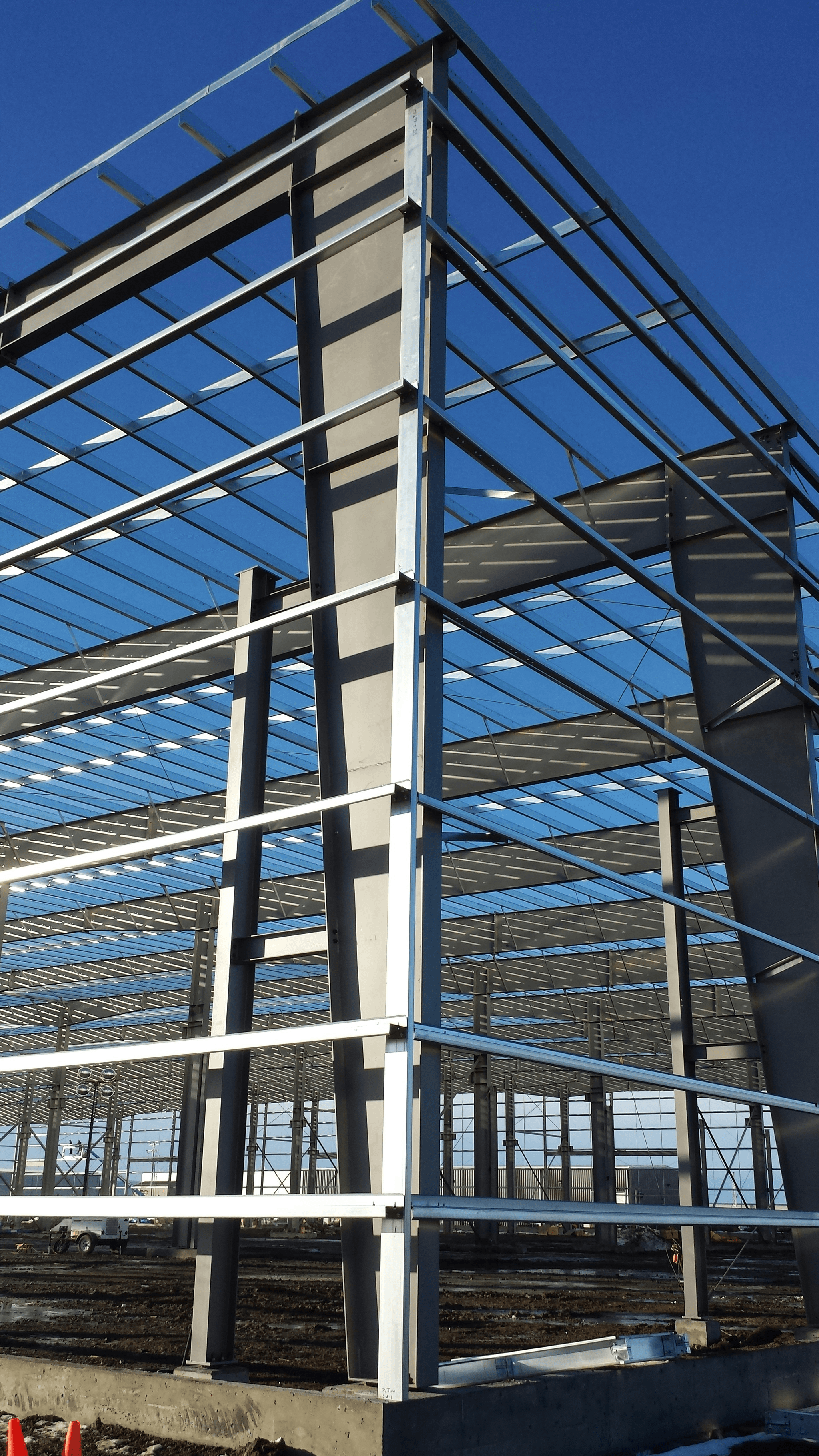

The versatility of light gauge steel lends itself to numerous applications across various sectors in modern construction. From residential homes to large commercial buildings and even industrial warehouses, LGS has proven effective in meeting diverse design requirements while maintaining structural integrity. Its adaptability allows architects to push creative boundaries without sacrificing performance.

In addition to its use in framing systems, light gauge steel can also be found in roofing systems, wall panels, and even flooring solutions—demonstrating its multifaceted nature within construction projects. As we explore what is the production machine behind this technology, it's essential to recognize how these innovations are transforming conventional building methods into more streamlined processes that enhance productivity.

With an increasing emphasis on sustainability and efficiency within the construction sector today, it’s clear that light gauge steel will continue playing a pivotal role moving forward—especially when combined with cutting-edge machinery designed specifically for its production needs.

What Does LGS Stand for in Construction?

When it comes to construction, LGS stands for Light Gauge Steel. This innovative material is gaining traction in the building industry due to its lightweight nature and structural integrity. Understanding what LGS means is crucial for anyone involved in modern construction practices.

Definition of LGS

Light Gauge Steel (LGS) refers to steel sections that are formed into thin sheets and used primarily in framing, roofing, and wall systems. These sections are typically less than 3mm thick, making them lighter than traditional steel but still strong enough to support various structures. In summary, LGS is a game-changer that combines strength with ease of handling.

Common Misconceptions

Many people mistakenly believe that LGS lacks the strength needed for substantial construction projects, equating “light” with “weak.” However, the reality is that when engineered correctly using advanced lgs production machines, Light Gauge Steel can withstand significant loads and stresses. Additionally, some think that LGS is only suitable for residential buildings; in fact, it’s widely used in commercial applications as well.

Importance in Structural Engineering

The importance of LGS in structural engineering cannot be overstated; it offers flexibility and durability while minimizing the overall weight of a structure. This allows architects and engineers to design more innovative buildings without compromising safety or performance standards. Moreover, using what is known as LGS building technology enables faster construction times and reduced labor costs—benefits that appeal to contractors everywhere.

What is the Production Machine?

When it comes to LGS building technology, understanding the production machine is crucial. The LGS production machine is designed specifically for creating light gauge steel components that are essential in modern construction. These machines streamline the manufacturing process, making it faster and more efficient while maintaining high-quality standards.

Types of LGS Production Machines

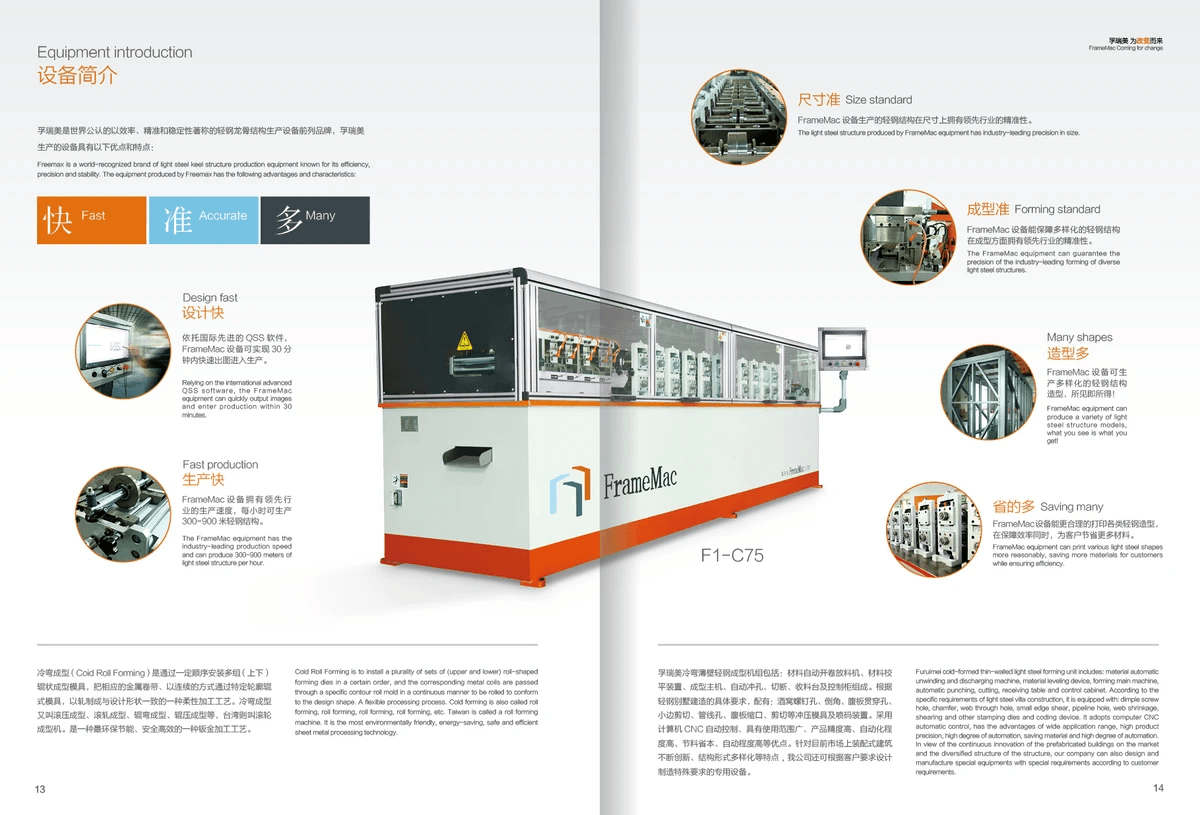

There are several types of LGS production machines tailored for different applications within construction. Some common types include roll-forming machines, which shape steel into desired profiles; shearing machines, which cut materials to precise lengths; and punching machines that create holes for fasteners and connections. Each type plays a vital role in ensuring that what does LGS stand for in construction translates into tangible results on-site.

Understanding these types helps contractors choose the right equipment based on their specific needs, whether it's for residential buildings or commercial projects utilizing what is LGS material. The versatility of these machines allows them to adapt to various designs and specifications, enhancing their utility across diverse construction scenarios.

Key Features and Innovations

LGS production machines come packed with features that elevate their performance beyond traditional methods. Innovations such as automated controls enable precise adjustments during production, reducing waste and increasing efficiency significantly. Additionally, modern safety features ensure operators can work without compromising safety standards—an important factor in any construction environment.

Another exciting development in this realm is the integration of software solutions that allow real-time monitoring and data analysis during production runs. This not only optimizes performance but also provides valuable insights into material usage—important when considering sustainability aspects of what is LGS material.

Leading Brands in LGS Machinery

When discussing leading brands in the realm of LGS machinery, a few names consistently rise to the top due to their innovation and reliability. Companies like Roll Forming Corporation, Purlin Mill Systems, and Kiant Machinery have established themselves as frontrunners by offering state-of-the-art lgs production machine solutions tailored for various project scales.

These brands are known not just for quality but also for excellent customer service and support throughout the lifecycle of their products—making them trusted partners in navigating what does lgs stand for in construction effectively. Their commitment to advancing technology ensures that builders have access to cutting-edge tools essential for mastering modern building techniques using light gauge steel.

What is LGS Material?

Light Gauge Steel (LGS) material is revolutionizing the construction industry, offering a modern alternative to traditional building materials. Understanding what LGS material is involves delving into its composition and properties, comparing it with other materials, and assessing its sustainability. As we explore these aspects, it becomes clear why LGS has gained traction in contemporary construction practices.

Composition and Properties

LGS material typically consists of thin steel sheets that are cold-formed into various shapes for structural applications. This innovative composition results in a lightweight yet strong framework that can support significant loads while maintaining structural integrity. The properties of LGS include excellent corrosion resistance, high strength-to-weight ratio, and ease of assembly, making it an ideal choice for modern buildings.

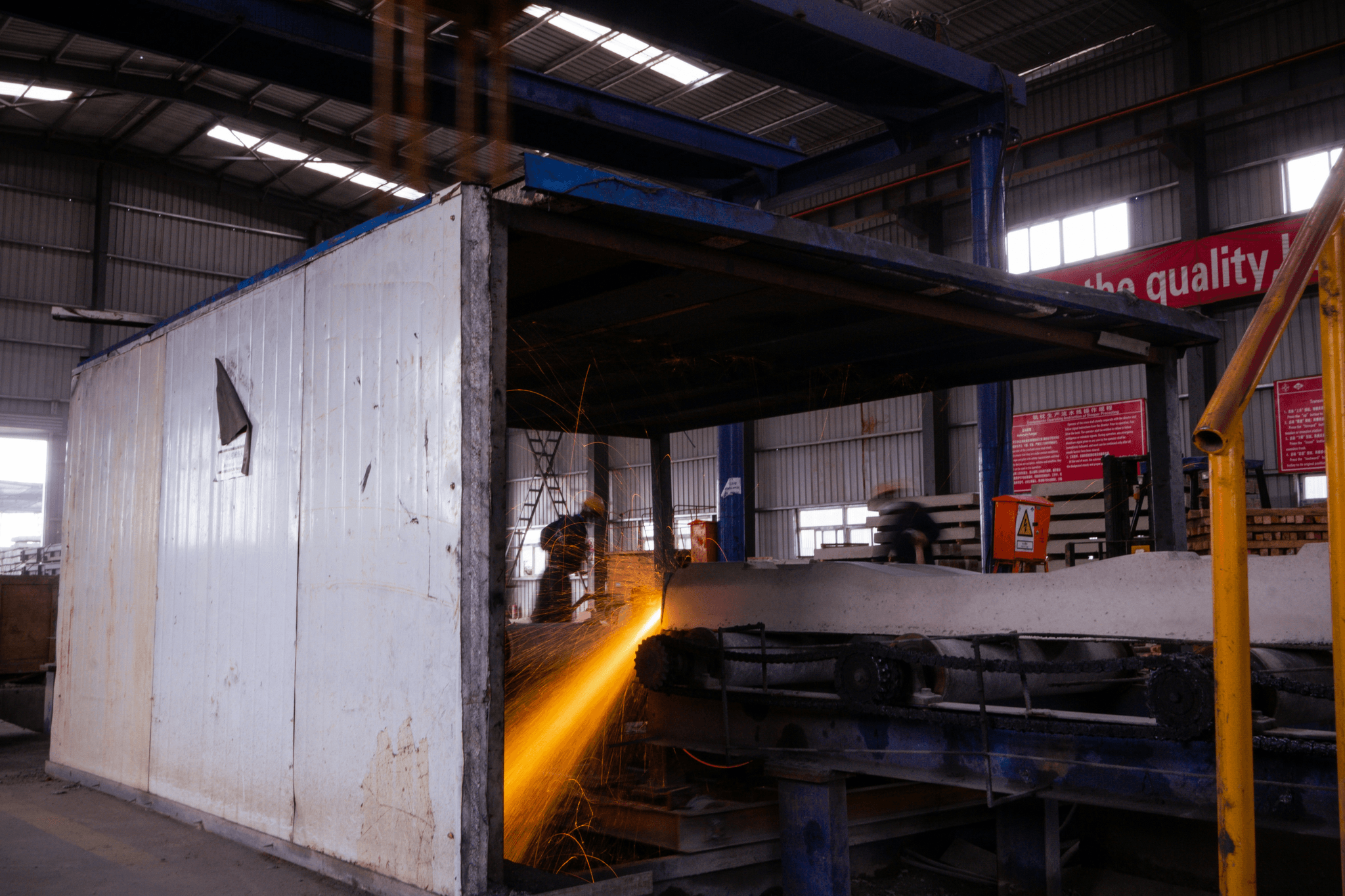

When discussing the production of this material, one cannot overlook the importance of the lgs production machine. These machines are designed to create precise components that fit seamlessly together during construction. With advancements in technology, these machines have enhanced efficiency and accuracy in producing LGS elements.

Comparison with Other Building Materials

When comparing LGS to traditional materials like wood or concrete, several advantages become apparent. For starters, LGS boasts superior durability against environmental factors such as pests and moisture—issues that often plague wood structures. Additionally, when considering weight and flexibility in design, what does LGS stand for in construction? It stands for efficiency without compromising strength.

Moreover, unlike concrete which can be heavy and cumbersome to work with, light gauge steel allows for quicker installation due to its manageable weight and pre-fabricated components from lgs production machines. This not only speeds up the building process but also reduces labor costs significantly compared to conventional methods. In short, when you weigh the pros and cons against other building materials, LGS often comes out on top.

Sustainability of LGS

Sustainability is a critical factor in today’s construction landscape; here again, light gauge steel shines bright like a beacon of hope! One major advantage is that LGS material is predominantly made from recycled steel—making it an environmentally friendly option right from its inception. Furthermore, the longevity of steel means structures built using this material require less frequent replacement or repair over time.

Another aspect worth mentioning is how efficient lgs production machines are at minimizing waste during manufacturing processes compared to traditional methods involving wood or concrete. This efficiency not only conserves resources but also contributes positively to overall project sustainability by reducing site waste during construction phases as well.

In conclusion, understanding what is LGS material reveals a wealth of benefits ranging from its robust composition to its sustainable attributes—solidifying its place as a preferred choice among builders today!

Kiant Machinery: Your Partner in LGS Solutions

When it comes to the world of Light Gauge Steel (LGS), Kiant Machinery stands out as a beacon of innovation and reliability. Specializing in LGS production machines, they offer cutting-edge solutions that cater to the evolving needs of modern construction. With a commitment to quality and performance, Kiant is your go-to partner for all things related to LGS building technology.

Overview of Kiant Machinery

Kiant Machinery has carved a niche for itself in the construction industry by focusing on what LGS stands for in construction: efficiency, strength, and sustainability. Their expertise lies not only in manufacturing advanced lgs production machines but also in understanding how these machines can transform building processes. With years of experience under their belt, they have become synonymous with high-quality machinery tailored for light gauge steel applications.

Equipment and Services Offered

At Kiant Machinery, you’ll find a comprehensive range of equipment designed specifically for LGS applications. From state-of-the-art lgs production machines that streamline fabrication processes to tools that enhance precision and reduce waste, their offerings are top-notch. Additionally, they provide extensive services including training and support to ensure that clients maximize the benefits of their LGS material investments.

Success Stories and Case Studies

The impact of Kiant Machinery’s products is evident through numerous success stories from satisfied clients who have embraced what is LGS building technology can achieve for their projects. For instance, one client reported a significant reduction in construction time after integrating Kiant's lgs production machine into their workflow—transforming how they managed resources and timelines. These real-world examples highlight not just the versatility but also the effectiveness of using advanced machinery when working with LGS materials.

Conclusion

In wrapping up our exploration of Light Gauge Steel (LGS) framing solutions, it’s clear that this innovative technology is shaping the future of construction. The versatility and efficiency of LGS production machines are paving the way for a new era in building techniques. As we look ahead, understanding what LGS building technology entails will be crucial for industry professionals and builders alike.

The Future of LGS Framing

The future of LGS framing is bright and brimming with potential. With advancements in technology, particularly in what is the production machine used for creating LGS components, we can expect faster construction times and reduced costs. Moreover, as awareness grows about the benefits of sustainable materials, what does LGS stand for in construction will increasingly become synonymous with eco-friendly practices.

Why Choose LGS for Your Next Project

Choosing Light Gauge Steel for your next project presents numerous advantages that traditional materials simply can't match. Not only does it offer superior strength-to-weight ratios, but it also provides excellent resistance to environmental factors like fire and pests—qualities often highlighted when discussing what is LGS material. By opting for LGS, you're not just investing in a building; you’re investing in durability and longevity.

Maximizing Efficiency with Kiant Machinery

Partnering with Kiant Machinery means unlocking unparalleled efficiency through their advanced lgs production machine offerings. Their equipment is designed to streamline processes while ensuring quality output—crucial elements when considering what is the production machine needed to elevate your construction projects. With proven success stories under their belt, Kiant Machinery stands ready to help you maximize every aspect of your building endeavors.