Introduction

In the ever-evolving landscape of construction, light gauge steel framing (LGS) has emerged as a game changer. This innovative approach utilizes cold-formed steel to create robust structures that are both lightweight and durable. As the demand for efficient building solutions grows, understanding the intricacies of LGS steel framing becomes essential for contractors and builders alike.

Understanding Light Gauge Steel Framing

Light gauge steel framing is a construction method that employs thin sheets of steel to create structural components. Unlike traditional materials such as wood or concrete, LGS offers superior strength-to-weight ratios, making it an ideal choice for modern buildings. With its versatility, LGS can be used in various applications, from residential homes to commercial complexes.

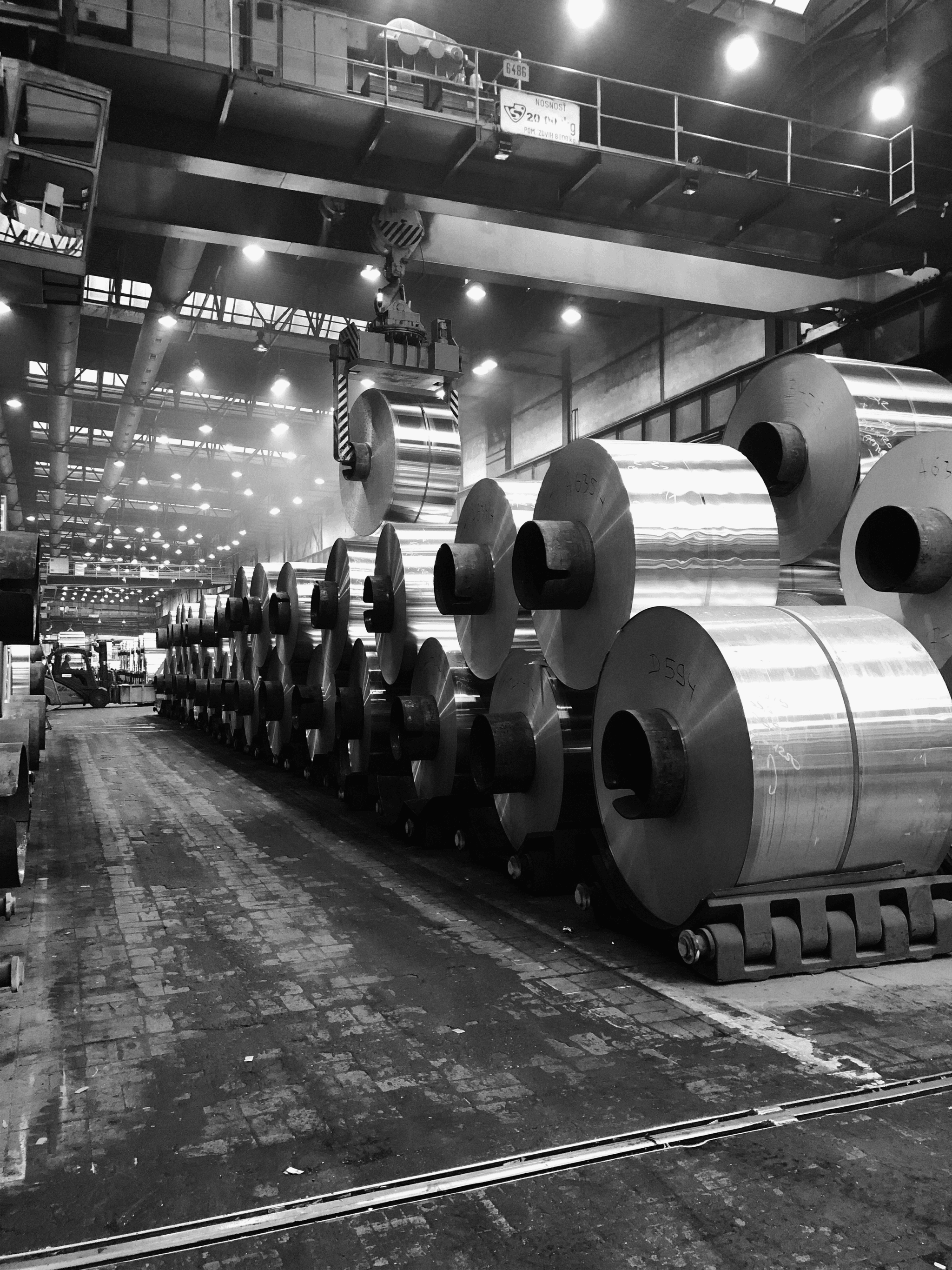

The Rise of Cold Formed Steel

Cold-formed steel has gained significant traction in recent years due to its numerous advantages over conventional materials. Its manufacturing process allows for precise dimensions and consistency, reducing waste and ensuring high-quality outcomes. As more builders recognize the benefits of cold-formed steel, it is becoming increasingly prevalent in the construction industry.

Benefits of Using Framing Machines

Framing machines play a pivotal role in enhancing the efficiency and precision of light gauge steel framing projects. These machines streamline the production process by automating tasks that would otherwise be labor-intensive and time-consuming. Additionally, with options like Framecad machine for sale at competitive framecad machine prices, contractors can invest in technology that pays off through improved productivity and reduced costs.

What is Light Gauge Steel Framing?

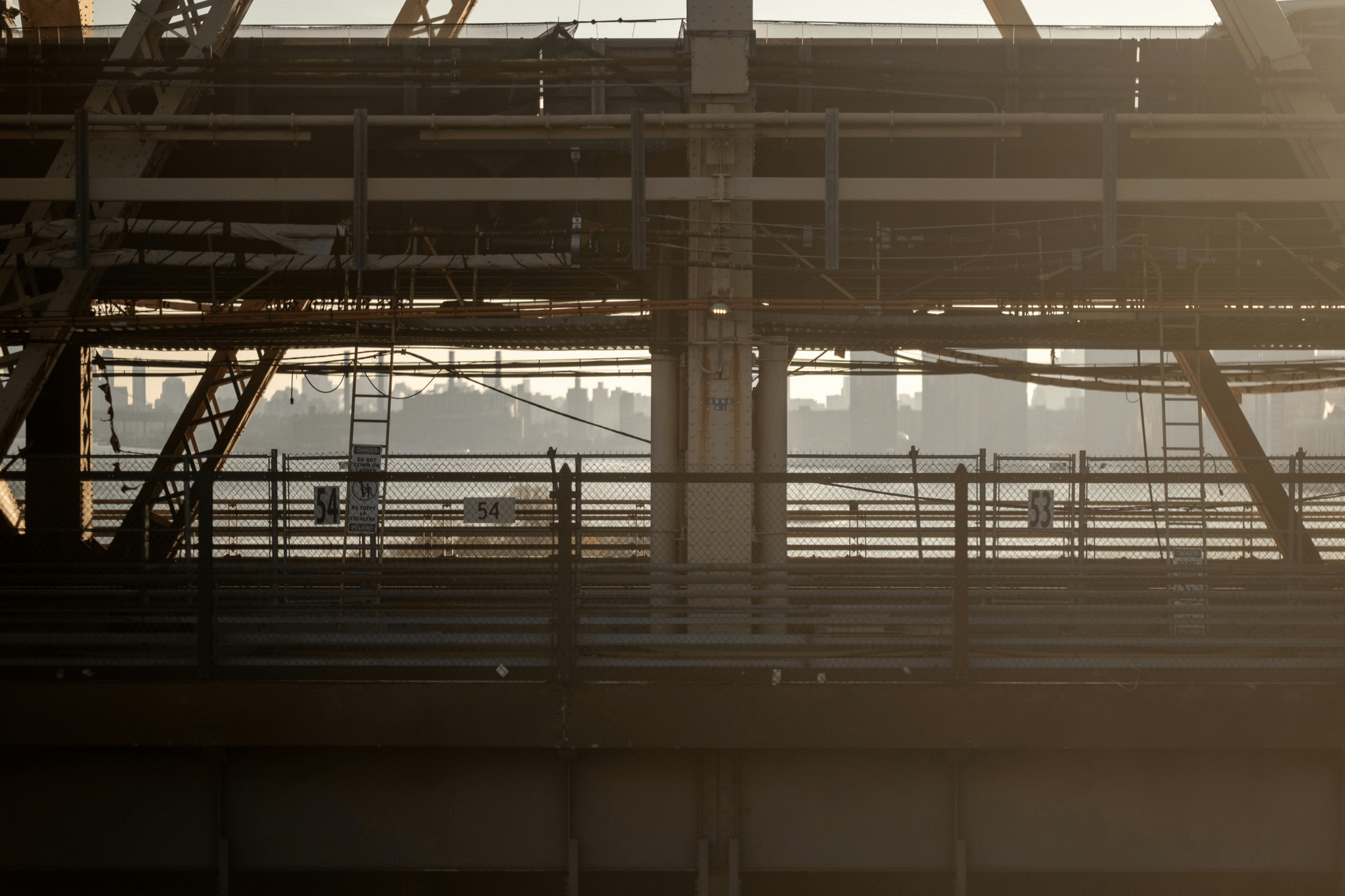

Light Gauge Steel Framing (LGSF) is an innovative construction method that utilizes thin sheets of steel to create a robust structural framework for buildings. This technique has gained popularity due to its versatility and efficiency, making it an ideal choice for various applications, from residential homes to commercial buildings. With the right framing machine, contractors can quickly produce high-quality steel components tailored to specific project needs.

Definition and Applications

LGSF refers to the use of cold-formed steel sections that are manufactured into various shapes and sizes. These sections are lightweight yet strong, making them suitable for a wide range of construction applications, including walls, roofs, and floor systems. The adaptability of LGSF allows it to be used in different environments, from urban high-rises to rural homes, showcasing its versatility in modern architecture.

Advantages over Traditional Materials

One of the standout benefits of LGSF is its resistance to common issues faced by traditional materials like wood or concrete—such as pests, rot, and warping. Additionally, using a steel frame roll forming machine streamlines the manufacturing process, ensuring precision and consistency in production. This efficiency leads not only to time savings on site but also reduces waste material significantly compared to conventional building methods.

Common Uses in Construction

LGSF is commonly employed in various construction projects due to its lightweight nature and structural integrity. You’ll find it used extensively in residential buildings where space optimization is crucial; it allows for larger open areas without compromising strength. Furthermore, commercial structures benefit from LGSF's quick assembly capabilities when using advanced tools like a framing machine designed specifically for steel framing projects.

The Role of Framing Machines

Framing machines play a pivotal role in the construction industry, especially when it comes to light gauge steel (LGS) framing. These machines automate the process of shaping and assembling steel components, making construction faster and more efficient. By utilizing advanced technology, framing machines ensure precision and consistency in building structures, which is essential for modern architectural demands.

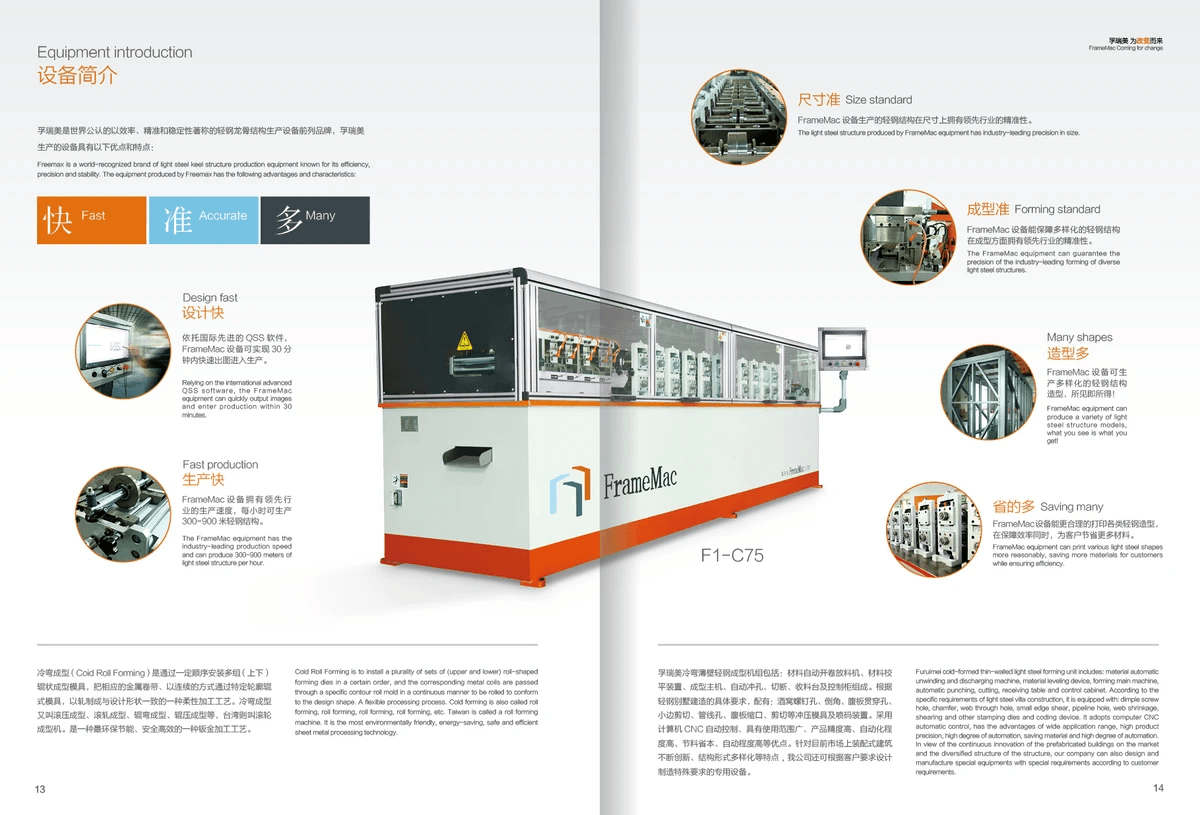

How Framing Machines Work

Framing machines operate by feeding steel coils into a series of rollers that shape the metal into desired profiles for LGS framing. The process typically involves cutting, bending, and forming the steel to create studs, tracks, and other structural elements required for construction projects. This automation not only speeds up production but also minimizes human error, leading to higher quality outcomes in every build.

The main advantage of using a framing machine lies in its ability to produce components on-site or off-site with remarkable efficiency. With features like computer numerical control (CNC), these machines can execute complex designs with ease while maintaining tight tolerances. This level of precision is crucial when considering framecad machine prices; investing in such technology can provide significant long-term savings through reduced labor costs and material waste.

Types of Steel Frame Roll Forming Machines

There are several types of steel frame roll forming machines available on the market today, each designed for specific applications within LGS framing. Some common types include standard roll formers that create basic profiles and specialized machines tailored for unique architectural designs or complex shapes. Understanding these options can help builders choose the right machine based on their project requirements.

One popular choice among contractors is the framecad machine for sale that combines versatility with efficiency; it can produce a wide range of profiles suitable for various construction needs. Additionally, some advanced models offer features like integrated software solutions that streamline design processes from conception to production. This flexibility allows builders to adapt quickly to changing project specifications without sacrificing quality or speed.

Key Features to Look For

When considering a steel frame roll forming machine for your business, several key features should be prioritized to ensure you make an informed investment decision. First and foremost is production speed; look for machines that can handle high output without compromising quality—this directly affects your bottom line regarding framecad machine cost versus productivity gains over time.

Another important feature is ease of operation; user-friendly interfaces and automated settings can significantly reduce training time for new operators while enhancing overall efficiency during production runs. Additionally, consider durability and maintenance requirements—machines built with high-quality materials will withstand wear and tear better than cheaper alternatives but may come at a higher initial price point.

Lastly, don’t forget about support services offered by manufacturers like Kiant Machinery; having access to reliable customer service ensures you’ll receive assistance when needed as well as potential upgrades or accessories down the line—all vital aspects when investing in a framing machine designed specifically for LGS steel framing projects.

Exploring Framecad Machines

When it comes to modern construction, few innovations have made as significant an impact as Framecad machines. These steel frame roll forming machines are designed specifically for light gauge steel (LGS) framing, streamlining the building process and enhancing efficiency. With their advanced technology, Framecad machines have become a go-to option for contractors looking to maximize productivity while maintaining high-quality standards.

Overview of Framecad Technology

Framecad technology is at the forefront of revolutionizing how LGS steel framing is produced and installed. These machines utilize a combination of precision engineering and automated processes to create components that fit together seamlessly on-site. The ease of use and adaptability of these framing machines make them suitable for various applications, from residential homes to large commercial buildings.

By employing advanced software and design capabilities, Framecad machines allow users to customize their projects easily, ensuring that every piece is tailored to specific needs. This level of precision not only reduces material waste but also accelerates construction timelines significantly. In an industry where time is money, embracing Framecad technology can provide a considerable competitive edge.

Framecad Machine Price and Cost Comparisons

When considering the investment in a framing machine, understanding the price range is crucial for making informed decisions. The cost of a Framecad machine can vary widely depending on features, capabilities, and whether it’s new or used; however, many find that the long-term savings justify the initial expense. On average, potential buyers should expect framecad machine prices to range from tens of thousands to over a hundred thousand dollars.

Comparing framecad machine costs against traditional framing methods reveals significant advantages in terms of labor savings and reduced material wastage. While upfront costs may seem daunting compared to conventional tools, the efficiency gained through automation often leads to quicker project completions and lower overall expenses in the long run. Therefore, investing in a steel frame roll forming machine like those offered by Framecad can be viewed as not just an expense but rather a strategic financial decision.

Exceptional Features of Framecad Machines

What sets Framecad machines apart from other options on the market are their exceptional features tailored for optimal performance in LGS steel framing projects. For starters, these machines boast user-friendly interfaces that simplify operation even for those who may not have extensive experience with heavy machinery. Additionally, they come equipped with advanced safety features designed to protect operators while ensuring compliance with industry regulations.

Another standout feature is their versatility; many models can produce various profiles and sizes without needing extensive reconfiguration or downtime between jobs—ideal for contractors handling multiple projects simultaneously! Moreover, some framecad machines offer integrated software solutions that facilitate design modifications on-the-fly while providing real-time feedback on production metrics—making them indispensable tools in today’s fast-paced construction landscape.

Kiant Machinery: A Leader in Innovation

When it comes to innovation in the world of light gauge steel framing, Kiant Machinery stands out as a prominent player. This company has carved a niche for itself by focusing on cutting-edge technology and exceptional service in the steel frame roll forming machine sector. With an unwavering commitment to quality and efficiency, Kiant Machinery is redefining how construction projects are approached.

Introduction to Kiant Machinery

Kiant Machinery has established itself as a trusted name in the manufacturing of high-performance framing machines designed specifically for LGS steel framing applications. Their expertise lies not only in providing advanced machinery but also in understanding the unique needs of their clients across various construction sectors. As a result, they have become synonymous with reliability and innovation, making them an ideal choice for anyone looking to invest in a steel frame roll forming machine.

Products Offered by Kiant Machinery

Kiant Machinery offers a diverse range of products tailored to meet the demands of modern construction projects. Their lineup includes various models of framing machines that cater to different project scales and requirements, ensuring that there's something suitable for everyone. Additionally, their Framecad machines are available at competitive price points, allowing clients to find options that fit within their budget while still delivering exceptional performance.

Among their offerings, you'll find specialized equipment designed for quick assembly and superior structural integrity—qualities essential for successful LGS steel framing projects. The Framecad machine cost is often balanced by its long-term efficiency and durability, making it an investment worth considering. With multiple options available for sale, customers can easily choose the right machinery that aligns with their specific needs.

Services Beyond the Sale

Kiant Machinery doesn’t just stop at selling top-notch framing machines; they also provide comprehensive support services that enhance customer satisfaction and project success. From initial consultations on selecting the right steel frame roll forming machine to ongoing technical support post-purchase, they ensure clients feel supported throughout their journey with them. Their commitment extends into training programs designed to help operators maximize the potential of their new machinery efficiently.

Moreover, Kiant's customer service team is always ready to assist with any inquiries regarding Framecad machine price comparisons or maintenance tips—ensuring you get the most out of your investment over time. This level of dedication sets them apart from competitors who may focus solely on sales without offering continued assistance after purchase. Choosing Kiant Machinery means partnering with an industry leader who values innovation and client success equally.

The Future of Cold Formed Steel

The future of cold formed steel (CFS) is looking brighter than ever, as advancements in technology and shifting market demands drive innovation. With the growing popularity of light gauge steel (LGS) framing, industry players are keen to capitalize on these trends by investing in state-of-the-art framing machines. As construction projects increasingly favor sustainable materials, cold formed steel is poised to take center stage.

Market Trends and Innovations

As the construction industry evolves, several market trends are shaping the landscape for cold formed steel and framing machines. The demand for efficiency has led to a surge in automated solutions like the steel frame roll forming machine, which streamlines production processes while maintaining high quality. Furthermore, innovations in design software and machine technology have enabled builders to create more complex structures with LGS framing, pushing the boundaries of what’s possible.

Moreover, competitive pricing for framecad machines has made them more accessible to a wider range of contractors and builders. With framecad machine prices becoming more reasonable, many businesses are now considering investing in their own equipment rather than outsourcing fabrication work. This shift not only enhances operational efficiency but also allows companies to respond swiftly to changing project requirements.

Environmental Impact Considerations

Environmental sustainability is at the forefront of modern construction practices, and cold formed steel offers significant advantages in this regard. Unlike traditional materials that may require extensive harvesting and processing, LGS framing is often made from recycled content and can be fully recycled at the end of its life cycle. This makes it an attractive option for environmentally-conscious builders looking to minimize their carbon footprint.

Furthermore, using a framing machine reduces waste during production since these machines can be precisely calibrated to cut materials accurately according to project specifications. By decreasing material waste on-site and ensuring that every piece is utilized efficiently, companies can contribute positively to sustainability goals while also benefitting from cost savings associated with reduced waste disposal fees.

Predictions for Industry Growth

Looking ahead, predictions indicate robust growth within the cold formed steel sector as more builders recognize its advantages over traditional materials. The increasing reliance on advanced technologies such as framecad machines will likely enhance productivity levels across various construction projects—resulting in faster build times without compromising quality or safety standards.

Additionally, as urbanization continues globally and demand for affordable housing rises sharply, CFS will play a crucial role due to its strength-to-weight ratio and structural integrity—making it ideal for high-density living spaces. As new players enter the market with innovative products like updated versions of the steel frame roll forming machine or specialized framecad machinery for sale, competition will further drive down costs while improving performance standards across the board.

Conclusion

In wrapping up our exploration of light gauge steel (LGS) framing and the machinery that supports it, it's clear that this innovative approach to construction is more than just a trend—it's a revolution. The benefits of using LGS steel framing, such as its durability and cost-efficiency, make it an attractive option for builders and developers alike. With advancements in technology like steel frame roll forming machines, the future looks bright for this industry.

Key Takeaways on Steel Framing

Light gauge steel framing has emerged as a reliable alternative to traditional building materials, offering strength without the weight. Its applications range from residential homes to commercial buildings, proving its versatility across various projects. Investing in quality framing machines can significantly enhance productivity and precision in construction processes.

Making Informed Choices in Framing Machines

When considering a framing machine for your projects, it's essential to evaluate not only the initial framecad machine price but also the long-term value it provides. Look for features that enhance efficiency and ease of use, ensuring that your investment pays off over time. Understanding the different types of steel frame roll forming machines available will help you choose one that best suits your specific needs.

Getting Started with Kiant Machinery

Kiant Machinery stands out as a leader in innovation within the LGS steel framing sector, offering a range of products tailored to meet diverse construction demands. Their commitment extends beyond just selling machinery; they provide comprehensive support services to ensure customer satisfaction and optimal performance of their equipment. By exploring Kiant's offerings, you can find competitive framecad machine costs that align with your budget while gaining access to cutting-edge technology.