Introduction

In the realm of modern construction, the steel frame roll forming machine stands as a pivotal innovation, transforming raw materials into precisely engineered components. This technology is not just about bending steel; it’s about efficiency, versatility, and meeting the diverse needs of today’s building projects. As industries increasingly lean towards cold formed steel machines and light gauge steel roll forming machines, understanding these tools becomes essential for manufacturers aiming to stay competitive.

Understanding Steel Frame Roll Forming

Steel frame roll forming is a process that involves shaping metal sheets into desired profiles through a series of rollers and dies. This technique enables manufacturers to produce high-quality components with exceptional consistency and precision, making it ideal for various applications in construction and manufacturing. With the rise of sustainable building practices, cold formed steel machines have gained popularity due to their lightweight yet robust nature, offering an eco-friendly alternative to traditional materials.

The Importance of Machine Features

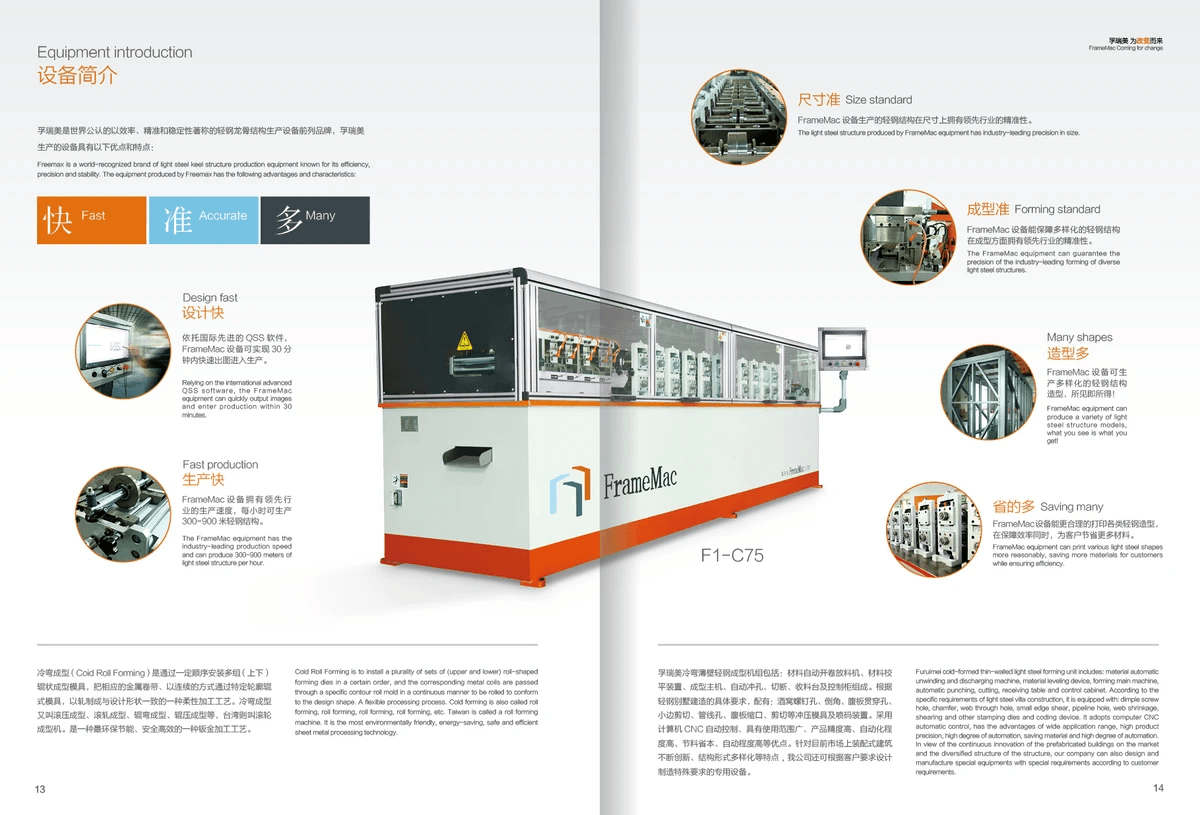

When investing in a steel frame roll forming machine, the features it offers can significantly impact production efficiency and output quality. Key attributes such as advanced control systems, durable rollers, and energy-efficient drive mechanisms are crucial for optimizing performance while minimizing operational costs. For instance, those considering a FrameCAD machine for sale should evaluate its specifications carefully to ensure it aligns with their production goals and budget constraints.

Exploring Machine Options

The market offers a variety of options when it comes to selecting the right machinery for your needs; from light gauge steel roll forming machines to more specialized models like those from FrameCAD. Each option presents unique advantages tailored to specific applications within the construction sector. By exploring these choices thoroughly—factoring in aspects like frameCAD machine cost—manufacturers can make informed decisions that enhance their production capabilities while meeting project demands efficiently.

Key Components of a Steel Frame Roll Forming Machine

When diving into the world of steel frame roll forming machines, it's crucial to understand the key components that make these machines tick. Each part plays a vital role in ensuring that the machine operates efficiently and produces high-quality products. From rollers and dies to control systems, let's take a closer look at what makes a steel frame roll forming machine so effective.

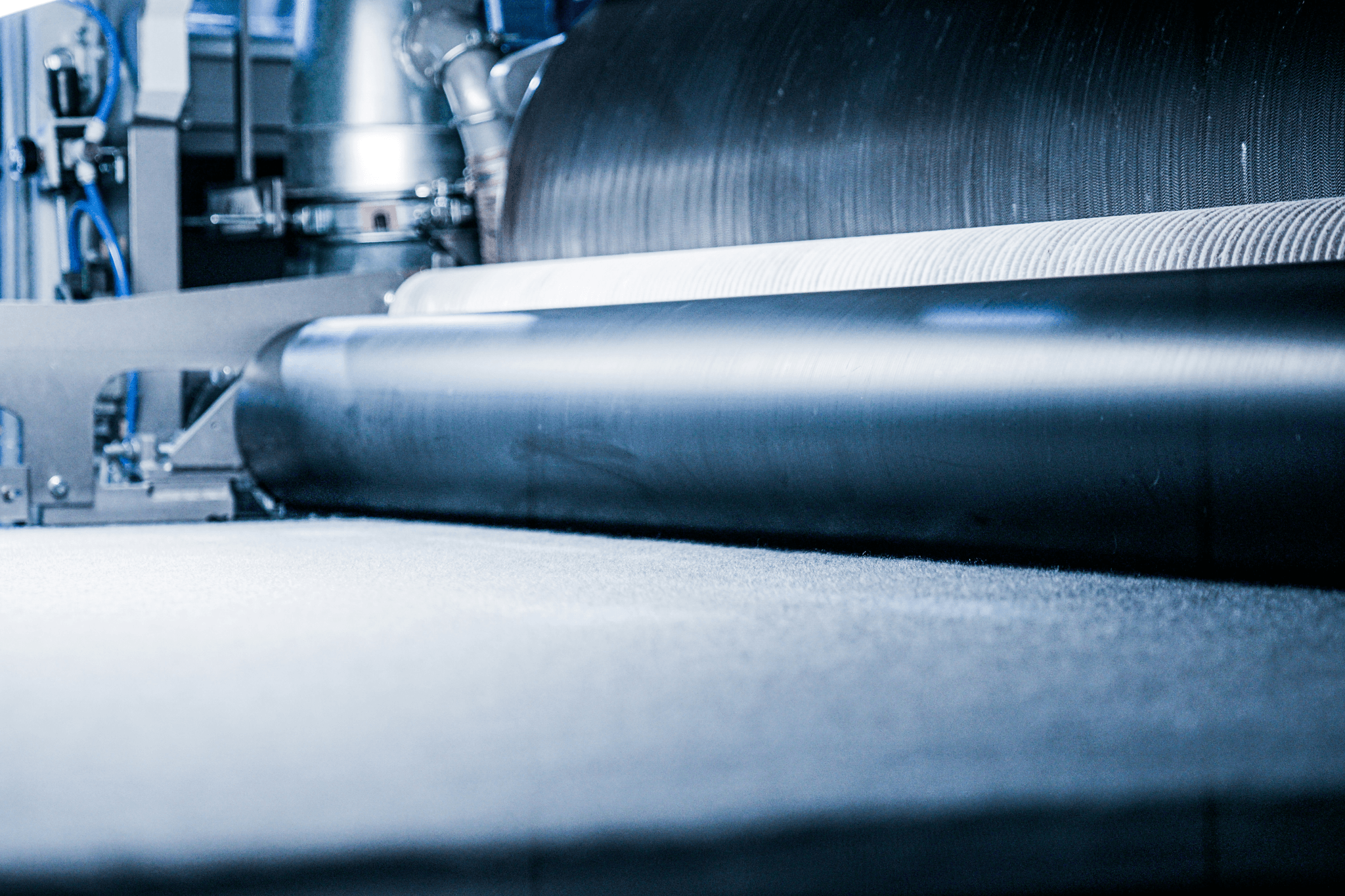

Rollers and Dies

At the heart of any cold formed steel machine are its rollers and dies, which shape the raw material into the desired profiles. These components are meticulously engineered to ensure precision and consistency in every piece produced. The quality of rollers can significantly impact production speed and output, making it essential for manufacturers to consider options like those found in FrameCAD machines for sale.

The design of the rollers must accommodate various thicknesses and widths of light gauge steel, allowing for versatility in applications. A well-constructed die not only shapes but also supports material during processing, reducing waste and increasing efficiency. Therefore, investing in high-quality rollers and dies is paramount when evaluating framecad machine costs.

Drive Mechanisms

The drive mechanism is another critical component that determines how power is transmitted within a steel frame roll forming machine. This system can include electric motors or hydraulic drives that provide the necessary force to move materials through the rollers effectively. A robust drive mechanism ensures smooth operation while maintaining consistent production speeds—key factors for any manufacturer looking to optimize their cold formed steel machine's performance.

Moreover, different drive mechanisms can affect energy consumption, making it vital for manufacturers to choose wisely based on their operational needs. An efficient drive system not only enhances productivity but also contributes positively to overall cost considerations associated with acquiring a FrameCAD machine or similar equipment. Thus, understanding your options here can lead you toward better investment decisions.

Control Systems

In today's tech-savvy world, control systems have become indispensable in modern light gauge steel roll forming machines. These systems manage everything from speed settings to product dimensions with remarkable accuracy, ensuring that every run meets stringent quality standards. Advanced control systems often come equipped with user-friendly interfaces that allow operators to monitor production metrics easily.

Additionally, sophisticated software solutions enable real-time adjustments during operation—maximizing efficiency while minimizing downtime due to errors or misalignments. By integrating these technologies into their processes, manufacturers can significantly improve precision and tolerance levels across their product range without sacrificing speed or output quality. As such, investing in top-notch control systems is essential for anyone considering a steel frame roll forming machine.

Efficiency and Performance Metrics

In the competitive world of manufacturing, efficiency and performance metrics play a crucial role in determining the success of a steel frame roll forming machine. These metrics not only influence production capabilities but also impact overall operational costs. By analyzing production speed, energy consumption, and precision, manufacturers can make informed decisions to enhance their processes.

Production Speed and Output

When it comes to production speed, the steel frame roll forming machine is designed for high throughput without compromising quality. Manufacturers often seek machines that can produce a significant output per hour while maintaining consistent results—this is where the FrameCAD machine shines. With its advanced technology, the FrameCAD machine for sale offers impressive speeds that cater to both small-scale projects and large industrial demands.

A faster production rate means more products can be manufactured in less time, leading to increased profitability. However, it’s essential to balance speed with quality; otherwise, you risk producing subpar items that could hurt your reputation. Investing in a light gauge steel roll forming machine that optimizes both speed and output ensures your operations remain competitive in today’s market.

Energy Consumption

Energy consumption is another vital metric manufacturers must consider when evaluating their equipment options. A cold formed steel machine should not only be efficient in terms of output but also consume energy wisely to keep operational costs low. The right machinery will integrate energy-saving features without sacrificing performance—making it an environmentally friendly choice as well.

For instance, many modern steel frame roll forming machines utilize advanced drive mechanisms that reduce power usage during operation. This results in lower electricity bills while maintaining high productivity levels. When comparing options like the FrameCAD machine cost against other technologies, it's crucial to factor in long-term energy savings alongside initial investment costs.

Precision and Tolerance

Precision and tolerance are non-negotiable aspects of any manufacturing process involving metal fabrication; they directly affect product quality and customer satisfaction. The best steel frame roll forming machines are engineered to deliver tight tolerances consistently across various applications—ensuring every piece meets strict specifications required by clients or industry standards.

Investing in high-precision machinery like a light gauge steel roll forming machine allows manufacturers to produce components that fit together seamlessly without additional adjustments or rework needed later on. This level of accuracy can significantly reduce waste materials and enhance overall efficiency throughout your operations—a win-win situation!

In summary, focusing on efficiency metrics such as production speed, energy consumption, and precision helps manufacturers choose the right equipment for their needs while maximizing returns on investments made into machines like those offered by FrameCAD.

Versatility in Applications

The versatility of steel frame roll forming machines is one of their most compelling features, enabling a broad spectrum of applications across various industries. From construction to manufacturing, these machines can adapt to different needs, making them essential tools for modern production environments. Whether using a cold formed steel machine or a light gauge steel roll forming machine, manufacturers can achieve efficient and precise results tailored to specific projects.

Cold Formed Steel Machine Uses

Cold formed steel machines are primarily utilized in the construction sector, where they create robust structural components with remarkable strength-to-weight ratios. These machines enable the production of framing systems that support walls, roofs, and floors while minimizing material waste and maximizing efficiency. Additionally, cold formed steel is increasingly favored for its resistance to environmental factors like corrosion and fire, making it an ideal choice for various building applications.

Light Gauge Steel Roll Forming Machine Benefits

Light gauge steel roll forming machines offer an array of benefits that make them indispensable in both residential and commercial construction projects. These machines produce lightweight yet durable components that are easy to handle and install while maintaining structural integrity over time. Furthermore, the framecad machine cost associated with light gauge systems often proves more economical than traditional materials like wood or concrete due to reduced labor costs and faster installation times.

Customization Options

One of the standout features of modern steel frame roll forming machines is their ability to be customized according to specific project requirements. Manufacturers can adjust parameters such as thickness, profile shape, and length to create unique components suited for diverse applications. The availability of a framecad machine for sale also allows businesses to invest in technology that aligns perfectly with their operational needs while ensuring they remain competitive in an ever-evolving market.

Cost Considerations for Manufacturers

When it comes to investing in a steel frame roll forming machine, manufacturers must navigate a landscape filled with various costs and financial implications. The price of machinery like the FrameCAD machine can vary significantly based on features, capabilities, and market demand. Understanding these cost considerations is essential for making informed purchasing decisions that align with business goals.

FrameCAD Machine Cost Analysis

The FrameCAD machine cost is often a focal point for manufacturers looking to enhance their production capabilities. These machines are designed for efficiency and durability, but they come at a premium price compared to some alternatives on the market. However, when evaluating the total cost of ownership—including maintenance and operational efficiency—the initial investment in a high-quality cold formed steel machine can yield substantial long-term benefits.

Additionally, manufacturers should consider the scalability offered by the FrameCAD machine for sale; its ability to adapt to various production needs can make it a wise investment despite higher upfront costs. While cheaper options may seem appealing initially, they might lack the reliability and performance metrics necessary to meet modern standards in light gauge steel roll forming applications. Ultimately, assessing the value provided by FrameCAD machines versus their costs will help manufacturers make strategic choices that support sustainable growth.

Comparison of Costs with Other Technologies

When comparing costs associated with steel frame roll forming machines against other technologies, several factors come into play that can influence overall expenditure. For instance, traditional methods may have lower initial equipment costs but could incur higher labor expenses due to inefficiencies in production processes. On the other hand, investing in advanced machinery like light gauge steel roll forming machines often leads to reduced labor costs over time due to automation and streamlined operations.

Moreover, while some alternatives may require less capital upfront, they might not offer the same level of precision or speed as modern cold formed steel machines like those from FrameCAD. This disparity can result in increased waste and rework costs that diminish any perceived savings from cheaper equipment options. Therefore, it's crucial for manufacturers to look beyond sticker prices and consider how different technologies impact their bottom line over time.

Investment vs. Return on Investment

Understanding investment versus return on investment (ROI) is vital when considering a steel frame roll forming machine purchase. The ROI from advanced machinery such as light gauge steel roll forming machines typically includes factors like increased production capacity, improved quality control, and reduced material waste—all leading to greater profitability over time. Manufacturers who strategically invest in efficient technologies will likely see significant returns through enhanced productivity levels.

To measure ROI effectively, businesses should analyze not only direct financial gains but also intangible benefits such as improved employee satisfaction due to less strenuous work environments created by automated systems like those found in cold formed steel machines from reputable brands like FrameCAD. Additionally, considering long-term maintenance costs associated with different types of machinery will provide further clarity regarding overall value propositions when evaluating investments.

In conclusion, weighing all these cost considerations ensures that manufacturers choose wisely when investing in a new steel frame roll forming machine—setting themselves up for success now and into the future.

Choosing the Right Manufacturer

Selecting the right manufacturer for your steel frame roll forming machine can significantly impact your production efficiency and overall satisfaction. With so many options available, it’s essential to consider factors like reputation, product quality, and customer support. A well-chosen manufacturer not only provides a reliable machine but also ensures you have the necessary support throughout its lifecycle.

Why Choose Kiant Machinery

Kiant Machinery stands out in the crowded market of steel frame roll forming machines due to its commitment to innovation and quality. Their machines are designed with advanced technology that enhances performance and durability, making them a top choice for manufacturers seeking reliability in cold formed steel machines. Additionally, their FrameCAD machine for sale offers competitive features that cater specifically to the needs of modern construction projects.

When investing in a light gauge steel roll forming machine, it’s crucial to choose a manufacturer known for its excellent craftsmanship and customer service. Kiant Machinery has built a solid reputation over the years by consistently delivering high-quality products at reasonable prices, including favorable FrameCAD machine cost options that suit various budgets. With their focus on user-friendly designs and effective solutions, you can trust that you're making a wise investment.

Evaluating Support and Service

When purchasing a steel frame roll forming machine, evaluating the manufacturer's support and service is vital for long-term success. Look for companies like Kiant Machinery that offer comprehensive training programs for operators as well as ongoing technical support after installation. This ensures that your team can maximize efficiency while minimizing downtime due to operational issues.

Moreover, responsive customer service is crucial when dealing with machinery malfunctions or inquiries about your cold formed steel machine's performance capabilities. A good manufacturer will provide timely assistance and resources to help you troubleshoot any problems effectively—keeping your production line running smoothly. Always check online reviews or testimonials from other users about their experiences with post-purchase support before making your decision.

Understanding Warranty and Maintenance

Understanding warranty terms is essential when investing in a light gauge steel roll forming machine; this protects you against unforeseen defects or failures in machinery components. Kiant Machinery typically offers robust warranties on their products, which demonstrates confidence in their manufacturing process and materials used in their machines. Be sure to read the fine print regarding what’s covered under warranty—some companies may have limitations that could affect your operations down the line.

Maintenance is another critical factor; regular servicing can extend the lifespan of your cold formed steel machines significantly while ensuring optimal performance levels are maintained throughout their use. Manufacturers who provide maintenance packages or guidance on routine checks make it easier for businesses to keep their equipment running at peak efficiency without unexpected costs piling up later on. Investing time into understanding these aspects will ultimately lead you toward smarter purchasing decisions regarding any frameCAD machine cost considerations.

Conclusion

As we wrap up our exploration of steel frame roll forming machines, it’s clear that understanding their essential features is crucial for maximizing efficiency and performance. These modern machines, such as the light gauge steel roll forming machine, come equipped with advanced technology that enhances production capabilities while ensuring precision. Manufacturers need to prioritize these features to remain competitive and meet evolving industry demands.

Essential Features for Modern Machines

When considering a steel frame roll forming machine, several key features should be at the forefront of your decision-making process. Look for robust rollers and dies that can handle various materials and thicknesses, which is particularly important for cold formed steel machines. Additionally, an efficient drive mechanism paired with an intuitive control system can significantly enhance operational efficiency and reduce downtime.

Making Informed Purchase Decisions

Navigating the market for a FrameCAD machine requires careful consideration of cost versus value. While the initial framecad machine cost might seem daunting, evaluating long-term benefits such as energy savings and increased output will help justify the investment. Always compare options like the framecad machine for sale against other technologies to ensure you're making a well-informed decision that aligns with your production goals.

Future of Steel Frame Roll Forming Technology

The future of steel frame roll forming technology looks promising as advancements in automation and smart manufacturing continue to emerge. Innovations will likely lead to even more versatile applications for light gauge steel roll forming machines, making them indispensable in construction projects worldwide. As manufacturers embrace these technologies, they will not only enhance efficiency but also contribute to sustainability efforts within the industry.