Introduction

In the ever-evolving world of construction and manufacturing, Framecad machines play a pivotal role in modernizing how we approach building structures. These ingenious cold formed steel machines streamline the process of creating durable and lightweight steel frames, which are essential for various construction projects. As industries move towards more efficient solutions, understanding the significance of these machines can empower businesses to make informed decisions.

Discover the Role of Framecad Machines

By automating and optimizing the production of steel frames, these machines significantly reduce labor costs while increasing precision and speed. Whether you're looking for a light gauge steel roll forming machine or a comprehensive solution for larger projects, Framecad offers a range of options tailored to meet diverse needs.

Understanding Cold Formed Steel Technology

Cold formed steel technology is revolutionizing how we think about structural integrity and design flexibility in construction. This method involves shaping steel into desired profiles at room temperature, which not only enhances its strength but also reduces material waste—making it an eco-friendly choice. With sheet metal roll forming machines for sale that utilize this technology, businesses can achieve high-quality outputs while minimizing their environmental footprint.

Why Choose a Trustworthy Supplier

Selecting a reliable supplier is crucial when investing in framecad machine cost and ensuring long-term operational success. A trustworthy supplier will not only provide top-notch equipment but also offer essential after-sales support and training options that enhance your investment's value. By choosing wisely among suppliers offering framecad machine for sale, you set your business up for success with equipment that stands the test of time.

Overview of Framecad Machines

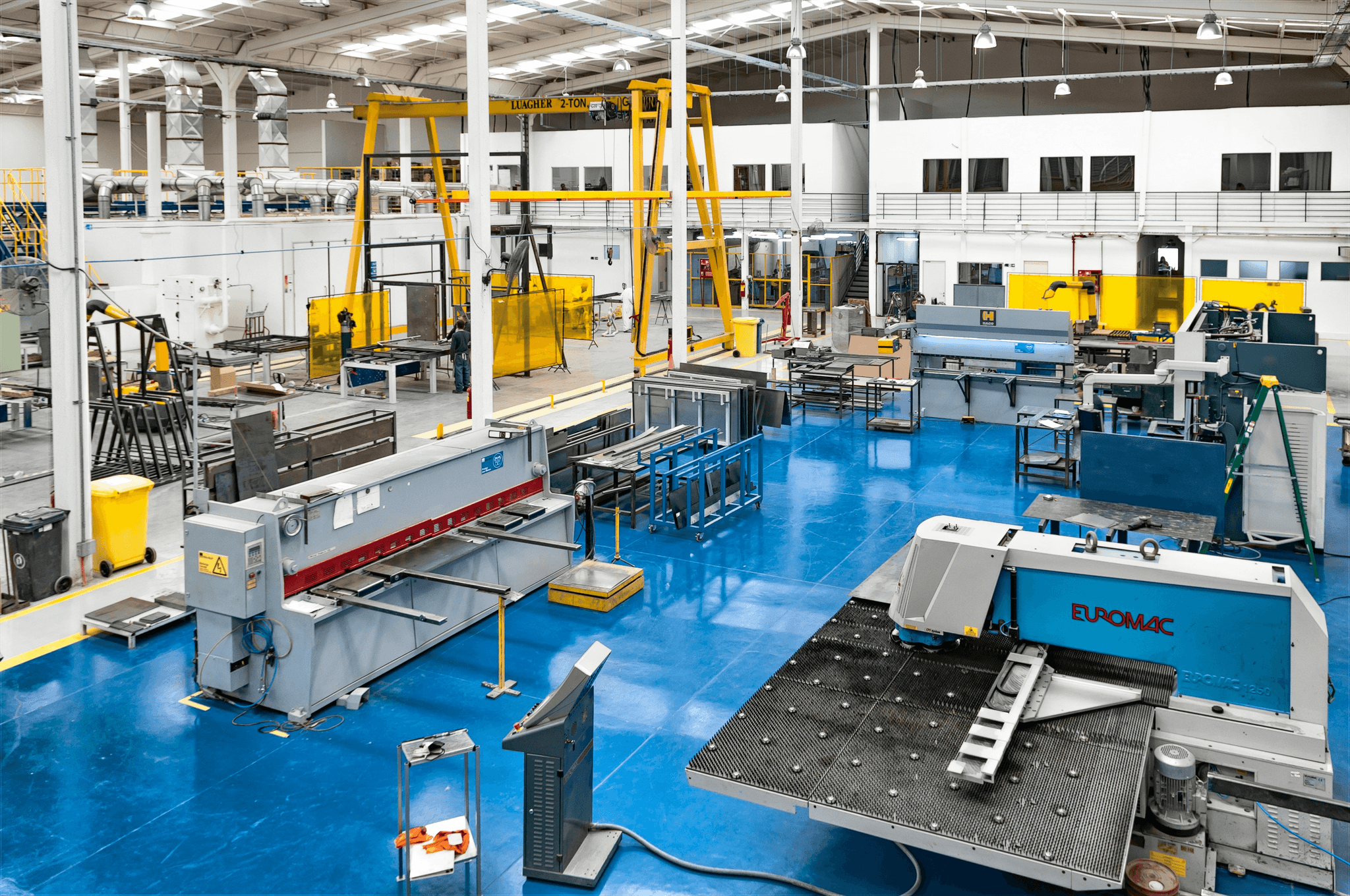

These innovative machines streamline the process of creating steel frames, making them a popular choice among builders and contractors. Understanding what a Framecad machine is and the benefits it offers can significantly impact your project’s efficiency and cost-effectiveness.

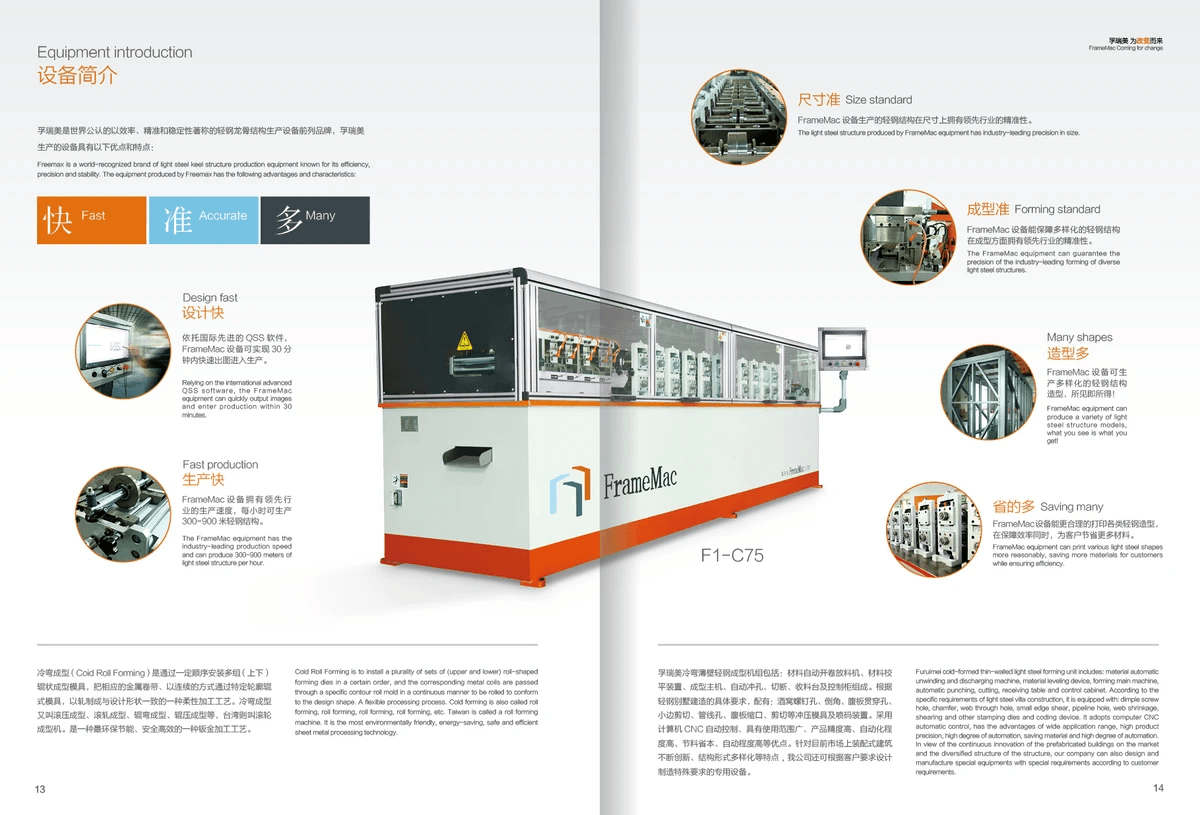

What is a Framecad Machine

A Framecad machine is a specialized piece of equipment designed for the production of cold formed steel components used in construction. These machines utilize advanced technology to roll-form steel sheets into precise shapes that serve as the backbone for various structures, from residential homes to commercial buildings. With options like light gauge steel roll forming machines available in the market, you can find a Framecad machine that perfectly fits your project needs.

Benefits of Using Steel Frame Machines

Using steel frame machines offers numerous advantages over traditional building methods. First and foremost, they enhance structural integrity and durability due to the strength of cold formed steel compared to other materials like wood or concrete. Additionally, these machines allow for faster construction timelines since they can produce components quickly and efficiently, reducing labor costs associated with manual fabrication.

Moreover, investing in sheet metal roll forming machines for sale can lead to significant savings over time due to their ability to minimize waste during production. The precision offered by these machines ensures that every piece fits together seamlessly on-site, which translates into fewer delays and rework scenarios during construction projects. Ultimately, opting for a steel frame roll forming machine not only boosts productivity but also enhances overall project quality.

The Importance of Cold Formed Steel Machines

Cold formed steel machines are crucial in today’s fast-paced construction environment where speed and efficiency are paramount. They enable builders to create lightweight yet robust structures that meet stringent safety standards while being cost-effective at the same time. As more industries recognize the benefits of cold formed steel technology, having access to reliable Framecad machinery becomes increasingly vital.

Furthermore, investing in a high-quality framecad machine for sale ensures you have access to cutting-edge technology that keeps your operations competitive in an evolving market landscape. These machines facilitate customization options tailored specifically for your projects—whether you're looking at residential developments or commercial spaces—making them indispensable tools in modern construction practices. In summary, understanding the role and benefits of cold formed steel machines will empower you as you make informed decisions about your building projects.

Leading Suppliers of Framecad Machines

The market is filled with options, but not all suppliers offer the same level of quality and support. In this section, we’ll highlight some leading suppliers of Framecad machines that are worth considering.

Kiant Machinery: Your Trusted Partner

Kiant Machinery has established itself as a reliable name in the realm of frame building technology. Specializing in steel frame roll forming machines, they provide equipment that not only meets industry standards but also enhances productivity. With their commitment to quality and customer service, Kiant Machinery stands out as a trusted partner for businesses looking for framecad machines for sale.

What sets Kiant apart is their extensive after-sales support and training programs tailored specifically for users of cold formed steel machines. This ensures that customers are not left high and dry after the purchase; instead, they receive ongoing assistance to maximize their investment. If you’re searching for sheet metal roll forming machines for sale that come with dependable support, look no further than Kiant Machinery.

Global Leaders in Framecad Technology

In addition to local suppliers like Kiant Machinery, there are several global leaders in Framecad technology that have made significant strides in innovation and efficiency. Companies such as FRAMECAD Limited have revolutionized the industry by offering cutting-edge light gauge steel roll forming machines designed for various applications ranging from residential buildings to large-scale commercial projects. Their commitment to research and development ensures that their products remain at the forefront of technology.

These global players often provide a wider range of options when it comes to framecad machine cost, allowing businesses of all sizes to find a solution that fits their budget without compromising on quality or performance. With numerous models available, it's essential to compare features such as production speed, material compatibility, and automation capabilities before making a decision on which supplier suits your needs best.

Comparing Framecad Machine Options

When exploring your options for framecad machines for sale, it's crucial to take stock of what each supplier offers beyond just price tags or brand names. Consider factors like machine specifications—what kind of materials can they handle? For instance, if you're focused on light gauge steel construction projects, ensure that your chosen supplier provides specialized light gauge steel roll forming machine models.

Additionally, understanding the warranty terms and customer reviews can give you insight into long-term reliability and performance satisfaction among existing users of these cold formed steel machines. By comparing these aspects across different suppliers—whether local like Kiant or global leaders—you'll be better equipped to make an informed decision about which sheet metal roll forming machines will be an asset to your operations.

Framecad Machine Cost and Investment

Investing in Framecad machines is a significant decision for any construction business. Understanding the costs associated with cold formed steel machines, including the initial purchase price and ongoing maintenance, is crucial for making an informed investment. Additionally, evaluating the return on investment (ROI) can help you determine if a steel frame roll forming machine is worth the expense.

Understanding Framecad Machine Costs

When considering framecad machine cost, it's essential to factor in various elements beyond just the sticker price. The cost of sheet metal roll forming machines for sale can vary widely based on features, capabilities, and brand reputation. Moreover, ongoing expenses such as maintenance, repairs, and operational costs must be included in your financial planning to get a true picture of ownership.

Another aspect to consider is the potential savings generated by using a light gauge steel roll forming machine compared to traditional building methods. These machines often lead to reduced labor costs and faster project completion times due to their efficiency and precision. Therefore, while the upfront investment might seem steep, understanding these hidden benefits can provide a clearer view of overall costs.

Evaluating the ROI of Framecad Machines

Evaluating the ROI of framecad machines involves assessing both tangible and intangible benefits that come from using cold formed steel technology. A well-chosen steel frame roll forming machine can drastically reduce production times and increase output quality—factors that directly impact profitability. To calculate ROI accurately, businesses should analyze factors like increased efficiency, lower waste levels, and enhanced product durability.

Moreover, consider how quickly you can recoup your initial investment through savings generated by improved processes or increased sales volume thanks to superior products made with advanced equipment like sheet metal roll forming machines for sale. When evaluating potential suppliers for your framecad machine for sale needs, look at their track record in helping clients achieve favorable returns on their investments as well.

In addition to financial metrics, remember that customer satisfaction plays a significant role in long-term success; satisfied clients are more likely to return or refer new business opportunities your way. Thus investing wisely in cold formed steel machines not only affects your bottom line but also enhances your brand reputation within the industry.

Budgeting for Steel Frame Roll Forming Machines

Budgeting effectively for steel frame roll forming machines requires careful planning and foresight into both immediate needs and future growth opportunities. Start by establishing a clear budget range based on thorough market research regarding framecad machine cost variations across different suppliers and models available today. This will help you identify which features are essential versus those that may be considered luxuries depending on your specific projects.

When budgeting for equipment like light gauge steel roll forming machines or other options available in today's market landscape—don't forget about ancillary costs such as installation fees or training programs offered by manufacturers post-purchase! It's crucial not only to set aside funds for purchasing but also allocate resources towards ensuring successful integration into daily operations through proper training initiatives provided by knowledgeable suppliers.

Finally—and perhaps most importantly—always leave some wiggle room within your budget! Prices fluctuate based on demand trends within this ever-evolving industry; having additional funds available allows flexibility when unexpected expenses arise during implementation phases or when upgrades become necessary down the line.

Types of Roll Forming Machines

When it comes to roll forming machines, the landscape is quite diverse. Each type serves a unique purpose and is tailored to specific materials and applications. Understanding the various types of roll forming machines can help you make an informed decision when selecting a cold formed steel machine or a sheet metal roll forming machine for sale.

Features of Light Gauge Steel Roll Forming Machines

Light gauge steel roll forming machines are designed specifically for handling thin sheets of cold formed steel, making them ideal for lightweight construction projects. These machines boast features such as high-speed operation, precision cutting, and easy setup, which enhance productivity while maintaining accuracy in every cut. With their ability to produce intricate profiles, light gauge steel roll forming machines are essential for creating components used in residential and commercial buildings.

Investing in a light gauge steel roll forming machine means you'll benefit from reduced material waste and increased efficiency during production runs. The compact design allows these machines to fit into smaller spaces without sacrificing performance, making them perfect for workshops with limited room. Plus, they often come equipped with advanced technology that allows operators to adjust settings quickly based on project requirements.

When searching for a framecad machine cost that fits your budget, consider the long-term savings associated with using light gauge steel instead of heavier alternatives. These machines not only lower your operational costs but also contribute to more sustainable building practices by utilizing recyclable materials. Ultimately, choosing a light gauge steel roll forming machine can lead to significant benefits both financially and environmentally.

How Sheet Metal Roll Forming Machines Work

Sheet metal roll forming machines operate through a continuous bending process where flat strips of metal are fed through consecutive rollers that shape them into desired profiles. This method ensures uniformity and precision in every piece produced while minimizing material waste—a crucial factor when considering options like framecad machine for sale or other cold formed steel machinery available on the market.

The process begins with loading sheet metal onto the feed table before it enters the roller system where it gets progressively shaped into its final form through carefully designed die sets. As these machines work at high speeds, they can produce large quantities of components quickly without compromising quality—ideal for businesses looking to scale up their operations efficiently.

Understanding how sheet metal roll forming machines work is vital when evaluating your investment options in this sector; knowing what goes into producing different profiles helps you assess potential returns on investment (ROI). For those considering purchasing such equipment, familiarizing yourself with their operational mechanics will enable you to choose the best fit according to your specific needs—whether that's maximizing output or enhancing versatility across various projects.

Customization Options for Your Machines

One of the standout features of modern roll forming technology is the extensive customization options available for your machinery needs. Whether you're investing in a steel frame roll forming machine or exploring alternatives like sheet metal solutions, many suppliers offer tailored setups that meet unique production requirements—ensuring you're never stuck with one-size-fits-all solutions.

Customization can range from adjusting roller configurations to accommodate different gauges of cold formed steel materials to incorporating specialized tooling that produces bespoke profiles suited specifically for niche applications within construction or manufacturing sectors. This flexibility allows businesses not only greater adaptability but also enhances their competitive edge by providing distinctive products that stand out in crowded markets.

When considering framecad machine costs against potential customization benefits, it's important to weigh how these modifications can impact overall efficiency and output quality over time—ultimately leading toward increased profitability down the line! Investing wisely today could pave the way toward tomorrow’s success stories built on innovative design capabilities powered by state-of-the-art machinery tailored just right for your business needs.

After-Sales Support and Training

When investing in a cold formed steel machine, after-sales support and training are pivotal to ensuring that you maximize your investment. A reliable supplier not only provides top-notch equipment but also stands by their customers with ongoing assistance. This can include everything from troubleshooting issues to offering spare parts, which are essential for maintaining the efficiency of your steel frame roll forming machine.

The Importance of Reliable After-Sales Service

Reliable after-sales service is crucial when dealing with complex machinery like sheet metal roll forming machines for sale. If something goes awry, having a dependable support system can mean the difference between a minor setback and a major production halt. Quality after-sales service ensures that your light gauge steel roll forming machine operates smoothly, allowing you to focus on what really matters: delivering high-quality products on time.

Training Options Offered by Suppliers

Training options offered by suppliers can significantly enhance your team's ability to operate cold formed steel machines effectively. Many reputable suppliers provide comprehensive training programs tailored to different skill levels, ensuring that everyone from novice operators to seasoned professionals can benefit. By investing in training for your team, you not only boost productivity but also reduce the risk of costly mistakes that could arise from improper use of the framecad machine for sale.

Ensuring Long-Term Success with Your Equipment

Ensuring long-term success with your equipment involves more than just initial training; it requires ongoing education and access to resources as technology evolves. Suppliers who offer continuous learning opportunities will help you stay ahead in a competitive market while maximizing the return on investment associated with framecad machine cost. Regular maintenance checks and updates will keep your steel frame roll forming machine running at peak performance, ultimately leading to greater profitability over time.

Conclusion

In summary, Framecad machines play a pivotal role in modern construction by utilizing advanced cold formed steel technology. These machines not only enhance efficiency but also offer a range of benefits, such as durability and cost-effectiveness. As the demand for steel frame roll forming machines continues to grow, understanding their capabilities and features is essential for making informed decisions.

Key Takeaways on Framecad Machines

Framecad machines are designed to revolutionize the way we think about construction materials, particularly cold formed steel machines that promise strength and flexibility. By investing in these innovative tools, users can capitalize on the numerous advantages they offer, from reducing labor costs to speeding up project timelines. It's crucial to consider various options available in the market when searching for a framecad machine for sale that best fits your needs.

The Future of Cold Formed Steel Technology

The future of cold formed steel technology looks bright as innovations continue to emerge within the industry. With advancements in automation and customization options for light gauge steel roll forming machines, manufacturers can expect even higher efficiency levels and product quality. As green building practices gain traction globally, cold formed steel machines will likely play an essential role in sustainable construction efforts.

Making an Informed Purchase Decision

When considering a purchase of sheet metal roll forming machines for sale, it's vital to evaluate not only the framecad machine cost but also the long-term value it brings to your operations. Researching suppliers thoroughly will help you find trustworthy partners who provide excellent after-sales support and training options tailored to your needs. Ultimately, making an informed decision will ensure that you invest wisely in equipment that enhances productivity while meeting industry standards.