Introduction

In the ever-evolving world of construction, cold formed steel machinery has emerged as a game-changer, revolutionizing how we approach metal home construction and steel frame building projects. The versatility and strength of cold formed steel make it an ideal choice for modern metal framing solutions, providing builders with reliable materials that stand the test of time. As we delve deeper into the benefits of metal frame buildings and the importance of selecting the right equipment, it's clear that understanding this technology is crucial for anyone involved in steel building construction.

Understanding Cold Formed Steel Machinery

Cold formed steel machines are specialized tools designed to shape and manipulate steel into various forms suited for construction applications. These machines utilize advanced techniques to create precise components that contribute to the overall integrity of metal framing systems. By grasping how these machines operate, builders can appreciate their impact on efficiency and quality in steel framing projects.

Benefits of Metal Frame Building

Metal frame buildings offer numerous advantages over traditional construction methods, including enhanced durability, reduced maintenance costs, and improved energy efficiency. The lightweight nature of cold formed steel allows for quicker assembly times while maintaining structural integrity, making it an attractive option for both residential and commercial projects alike. Additionally, utilizing a cold formed steel machine can lead to significant savings in terms of labor costs and material waste during the construction process.

Choosing the Right Equipment

Selecting the appropriate cold formed steel machine is essential for optimizing your metal home construction endeavors. Factors such as project size, budget constraints, and desired features should all influence your decision-making process when investing in equipment for steel building construction. By carefully evaluating your options and considering long-term support needs, you can ensure that your chosen machinery will meet your requirements effectively throughout its lifespan.

What is Cold Formed Steel?

Cold formed steel is a versatile material that has gained popularity in the construction industry for its strength, durability, and lightweight properties. This type of steel is manufactured at room temperature, which helps maintain its structural integrity while allowing for intricate designs. Its use in metal home construction and steel frame buildings has revolutionized the way we approach modern architecture.

Definition and Characteristics

Cold formed steel refers to steel products that are shaped or formed at ambient temperatures through processes like roll forming or bending. One of its defining characteristics is its high strength-to-weight ratio, making it an excellent choice for metal framing applications. Additionally, cold formed steel exhibits excellent resistance to corrosion and fire, enhancing the longevity and safety of structures built with this material.

How It's Made

The manufacturing process of cold formed steel involves several steps that begin with flat sheets or strips of raw steel. These sheets are then passed through a series of rollers in a cold forming machine to create specific shapes such as C-channels or Z-sections used in metal framing. This efficient process not only minimizes waste but also allows for precise dimensions essential for quality steel building construction.

Applications in Construction

Cold formed steel finds extensive applications across various sectors, particularly in residential and commercial buildings where metal frame construction is preferred. Its lightweight nature facilitates easier handling during installation while providing robust structural support essential for any building project. From multi-story office complexes to single-family homes, cold formed steel machines enable builders to achieve cost-effective solutions without compromising on quality or design flexibility.

Types of Cold Formed Steel Machines

When it comes to metal home construction and steel building construction, the right equipment can make all the difference. Cold formed steel machines are essential for creating the precise components needed for effective metal framing and steel framing projects. Understanding the various types of machines available will help you choose the best tools to optimize your steel frame building process.

Roll Forming Machines

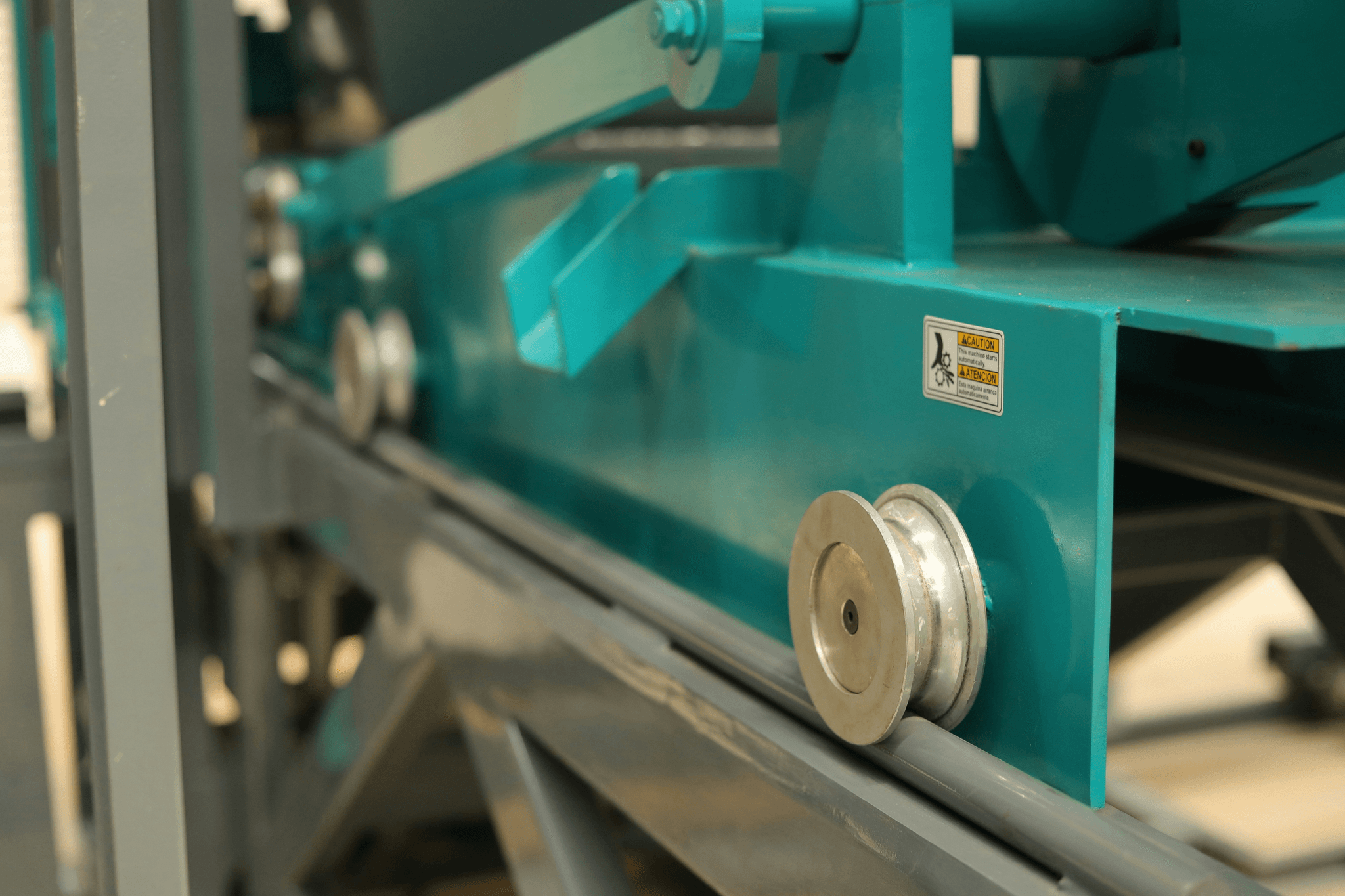

Roll forming machines are a staple in cold formed steel manufacturing, designed to create continuous lengths of metal profiles with consistent cross-sections. These machines work by feeding flat sheets of cold formed steel through a series of rollers that gradually shape them into desired profiles, perfect for metal frame building applications. With their ability to produce high volumes efficiently, roll forming machines significantly reduce labor costs while ensuring accuracy in every piece produced.

In the context of steel building construction, these machines excel at producing components like studs and tracks used in wall systems. The versatility of roll forming allows manufacturers to customize profiles according to specific project requirements, making them invaluable in various metal home construction scenarios. By investing in a quality roll forming machine, businesses can enhance their production capabilities and streamline their operations while reducing overall steel building costs.

Punching and Shearing Machines

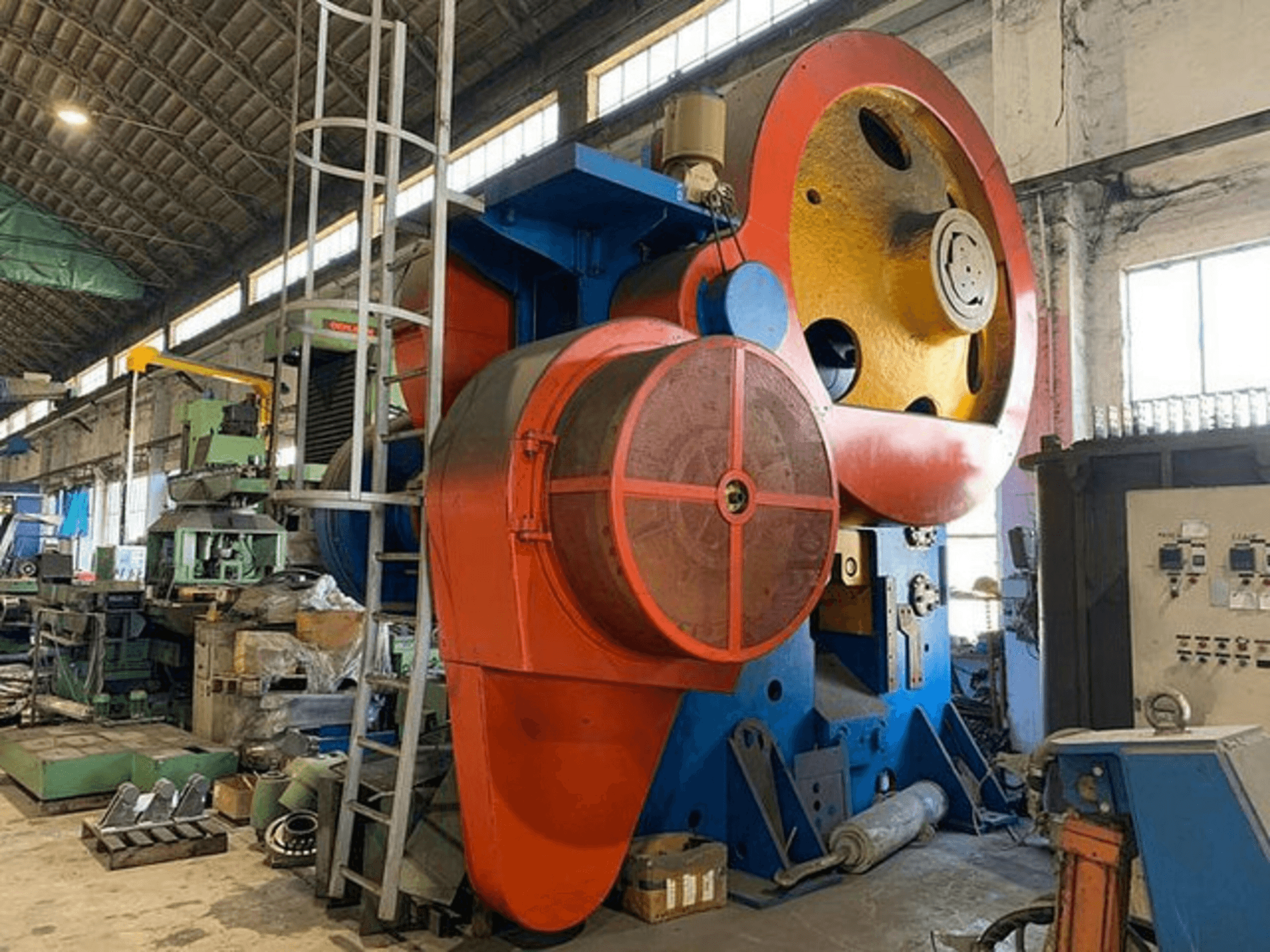

Punching and shearing machines play a crucial role in shaping cold formed steel by creating holes or cutting materials into specific lengths or shapes. These machines utilize powerful hydraulic or mechanical systems to punch holes through metal sheets or shear them with precision—ideal for preparing materials for assembly in any metal framing project. Their efficiency not only speeds up production but also minimizes waste, which is critical when managing costs in steel frame building.

In addition to standard punching and shearing tasks, some advanced models offer automated features that enhance productivity further by integrating with other machinery like roll formers or laser cutters. This integration allows for seamless transitions between processes during manufacturing, resulting in faster turnaround times on projects involving complex designs or large-scale applications. For anyone involved in metal home construction or general construction using cold formed steel machine technology, these tools are indispensable.

Laser Cutting Technology

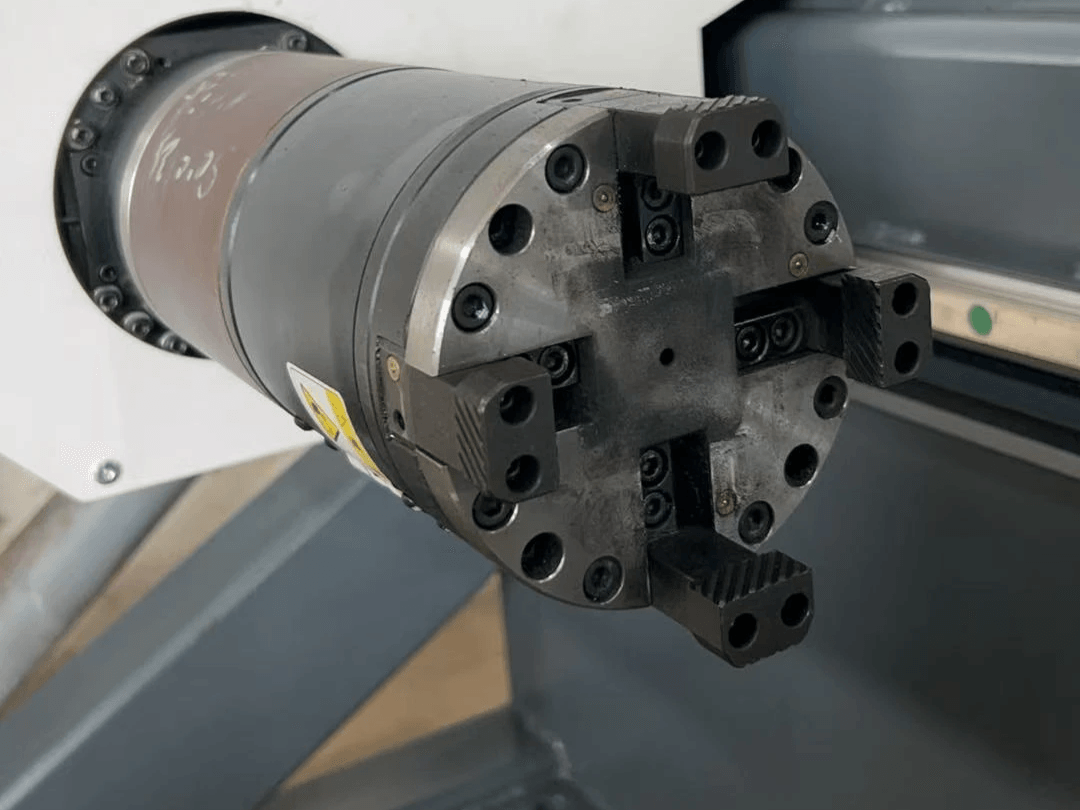

Laser cutting technology represents one of the most advanced methods available for processing cold formed steel today. Utilizing high-powered lasers focused on thin sheets of metal allows for intricate cuts with remarkable precision—perfectly suited for detailed components used in both residential and commercial structures within the realm of metal framing. This method enhances design flexibility since it accommodates complex geometries that traditional cutting techniques may struggle with.

Moreover, laser cutting reduces material waste significantly compared to conventional methods while maintaining high-speed operation—an essential factor when considering overall project timelines and costs associated with steel building construction projects. As such, incorporating laser cutting technology into your workflow can lead not only to improved accuracy but also cost savings over time as less material is wasted during production processes related to your cold formed steel machine needs.

Leading Brands in Cold Formed Steel Equipment

When it comes to cold formed steel equipment, the market is teeming with brands that promise efficiency and quality. Selecting the right manufacturer can significantly impact your metal home construction project, ensuring you have the best tools for steel framing and building. In this section, we’ll dive into Kiant Machinery, other notable players in the industry, and how their features stack up against one another.

Kiant Machinery Overview

Kiant Machinery has carved out a niche for itself in the realm of cold formed steel machines, offering a diverse range of equipment tailored for metal framing needs. Their innovative designs focus on enhancing productivity while maintaining exceptional quality standards. With a reputation for durability and cutting-edge technology, Kiant Machinery is often the go-to choice for those engaged in steel building construction.

Kiant’s product lineup includes advanced roll forming machines that streamline production processes and reduce waste, making them ideal for large-scale projects. Their commitment to customer satisfaction ensures that clients receive ongoing support and maintenance services tailored to their specific requirements. This level of service reinforces Kiant's position as a leader in the cold formed steel machine market.

Other Key Players in the Market

While Kiant Machinery stands out, several other brands also contribute significantly to the cold formed steel equipment landscape. Notable competitors include Purlin Mill Systems, which specializes in high-speed roll forming solutions designed specifically for metal frame building applications. Their machines are renowned for precision and efficiency, catering to both small-scale builders and large enterprises alike.

Another key player is HGG Robotics; they focus on laser cutting technology that enhances precision during fabrication processes essential to steel framing projects. Their innovations not only improve accuracy but also contribute to lower overall costs associated with steel building construction by minimizing material wastage. These companies collectively enrich the options available for those interested in investing in cold formed steel machinery.

Comparing Features and Performance

When evaluating different manufacturers of cold formed steel machines, it's crucial to consider various factors such as performance capabilities, ease of use, and after-sales support—each can greatly influence your project's success. For instance, while Kiant Machinery excels with its robust roll forming systems known for their versatility across multiple applications within metal home construction, HGG Robotics' laser cutting technology offers unmatched precision that might be essential depending on your specific needs.

Additionally, budget considerations play a significant role when comparing these brands; some may offer premium features at a higher cost while others provide more basic models at competitive prices without sacrificing quality or performance. It’s wise to conduct thorough research on each brand's offerings before making an investment decision that aligns with both your project goals and financial constraints related to steel building cost.

In conclusion, understanding what each brand brings to the table will empower you as you navigate through your options in selecting machinery critical for effective metal framing practices.

Innovations in Cold Formed Steel Technology

In the ever-evolving landscape of construction, innovations in cold formed steel technology are paving the way for more efficient and sustainable building practices. These advancements not only enhance the capabilities of cold formed steel machines but also significantly improve the quality and efficiency of metal home construction. As we delve into these innovations, it becomes clear that they play a vital role in shaping the future of metal framing and steel building construction.

Advanced Automation Solutions

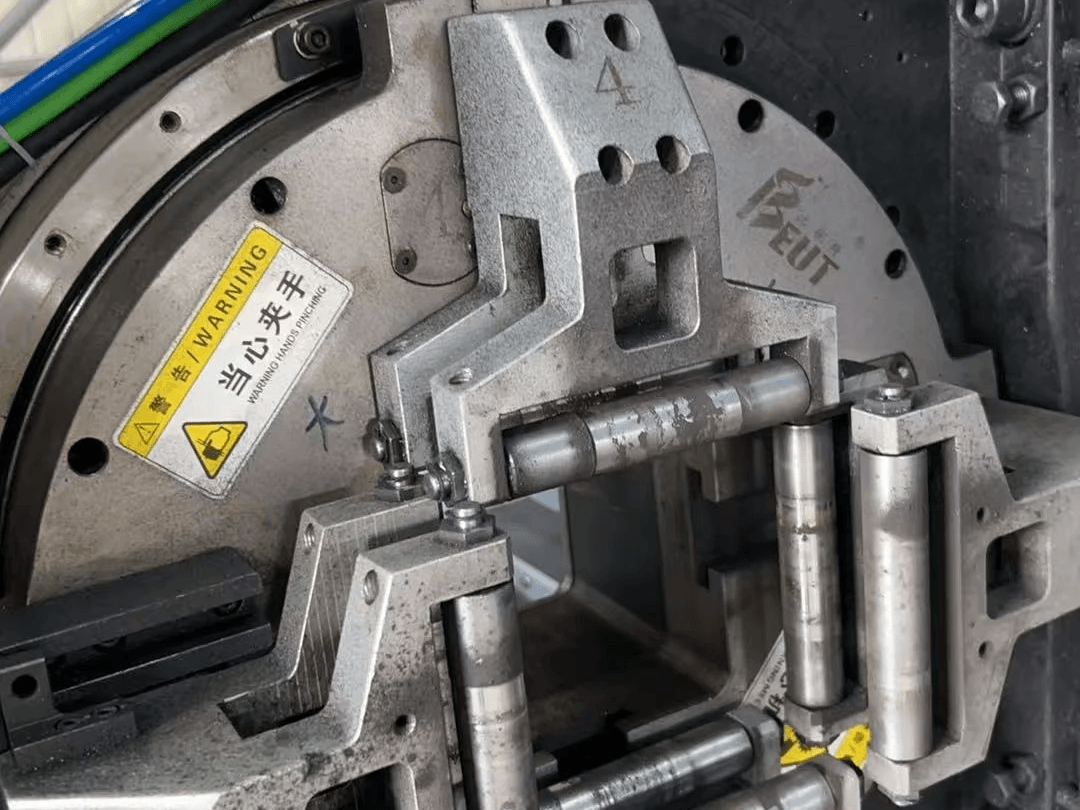

One of the most exciting developments in cold formed steel technology is the rise of advanced automation solutions. These automated systems streamline production processes, allowing for faster and more precise manufacturing of components used in metal frame buildings. With features like computer numerical control (CNC) and robotics, cold formed steel machines can operate with minimal human intervention, reducing labor costs while increasing output quality.

Moreover, automation enhances flexibility in production runs. Whether you're constructing a small residential project or a large commercial steel frame building, these machines can quickly adapt to different specifications without extensive retooling. This adaptability not only saves time but also minimizes waste—a crucial factor in today's eco-conscious market.

Eco-Friendly Manufacturing Processes

Sustainability is at the forefront of modern construction practices, and eco-friendly manufacturing processes are transforming how we approach metal framing. Cold formed steel machines are increasingly being designed to minimize energy consumption during production while maximizing material efficiency. Techniques such as using recycled materials and reducing emissions during fabrication contribute to greener steel building construction.

Additionally, innovative methods like water-based coatings instead of solvent-based ones further reduce environmental impact without compromising on durability or aesthetic appeal. As builders prioritize eco-friendly options, integrating these sustainable practices into metal frame building becomes essential for meeting both regulatory requirements and consumer expectations.

Impact on Steel Building Cost Efficiency

The innovations discussed above have a profound impact on cost efficiency within the realm of steel building construction. By utilizing advanced automation solutions, manufacturers can significantly reduce labor costs while maintaining high-quality standards across all projects involving cold formed steel machines. This translates to lower overall expenses for contractors and developers alike.

Furthermore, eco-friendly manufacturing processes not only help save costs related to energy use but also open doors for potential tax incentives aimed at promoting sustainability in construction practices. Ultimately, these advancements lead to more competitive pricing for clients seeking affordable yet durable options for their metal home constructions—making investing in a metal frame building an increasingly attractive choice.

Tips for Selecting the Right Machine

Choosing the right cold formed steel machine is crucial for any metal home construction project. A well-selected machine can enhance efficiency, reduce costs, and improve the quality of your steel framing. Here are some essential tips to guide you through the selection process.

Assessing Your Project Needs

Before investing in a cold formed steel machine, it's vital to evaluate your specific project needs. Consider the scale of your steel building construction; larger projects may require more advanced machines with higher production capacities. Additionally, think about the types of metal frame building designs you plan to implement—different machines offer varying capabilities for customization and precision.

Understanding your project requirements will also help you determine which features are non-negotiable for your operations. If you're focusing on intricate designs or unique specifications, investing in advanced technology like laser cutting may be worthwhile. Ultimately, aligning your equipment choice with your project goals ensures that you get the most out of your investment in steel framing machinery.

Budget Considerations for Steel Framing

Budgeting is a critical aspect when selecting a cold formed steel machine for metal home construction projects. While it's tempting to go for lower-priced options, remember that quality and durability often come at a cost; cheap machines may lead to higher long-term expenses due to maintenance or inefficiencies during production. Therefore, set a realistic budget that accounts not just for the initial purchase but also for ongoing operational costs.

Consider potential savings in labor and material waste when evaluating different machines' price points; investing in a high-quality machine can lead to significant reductions in overall steel building costs over time. Also, keep an eye out for financing options or leasing agreements that can make high-end machines more accessible without breaking the bank upfront. In short, balancing performance with budget constraints is key to making an informed decision about your metal framing equipment.

Long-Term Support and Maintenance

When selecting a cold formed steel machine, don't overlook the importance of long-term support and maintenance services offered by manufacturers or suppliers. Reliable support can save you from costly downtime caused by equipment malfunctions or technical issues during crucial phases of metal frame building projects. Look into warranty terms and customer service responsiveness as indicators of how much support you'll receive after making a purchase.

Regular maintenance is essential in ensuring that your machine operates efficiently throughout its lifespan; ask potential suppliers about their maintenance programs and whether they provide training on proper upkeep practices. Investing time in understanding these aspects will pay off by prolonging the life of your equipment while ensuring consistent performance in steel building construction tasks. Ultimately, choosing a vendor who prioritizes customer care can make all the difference as you navigate through various challenges associated with metal framing projects.

Conclusion

In wrapping up our exploration of cold formed steel machinery and its role in modern construction, it's clear that the advantages of metal frame building are numerous and compelling. From durability to design flexibility, metal framing has revolutionized the way we think about building structures. As you consider your next project, remember that investing in the right equipment can significantly optimize your metal home construction efforts.

Optimizing Your Metal Home Construction

To truly optimize your metal home construction, understanding the capabilities of various cold formed steel machines is essential. These machines can streamline processes such as cutting, punching, and forming steel into precise shapes necessary for effective steel framing. By selecting advanced technology tailored to your specific needs, you can enhance efficiency while reducing overall steel building costs.

Future Trends in Steel Frame Building

The future of steel frame building is bright with innovations on the horizon that promise to improve both performance and sustainability. Advancements in automation and eco-friendly manufacturing processes are set to redefine how we approach metal framing projects. As these trends emerge, they will not only enhance structural integrity but also contribute to lower costs in steel building construction.

Making Informed Decisions for Your Projects

When it comes to making informed decisions for your projects involving cold formed steel machinery, thorough research is key. Assessing project needs alongside budget considerations will help you choose the right equipment for effective metal frame building solutions. Long-term support and maintenance should also be factored into your decision-making process to ensure continued success in all future endeavors.