Introduction

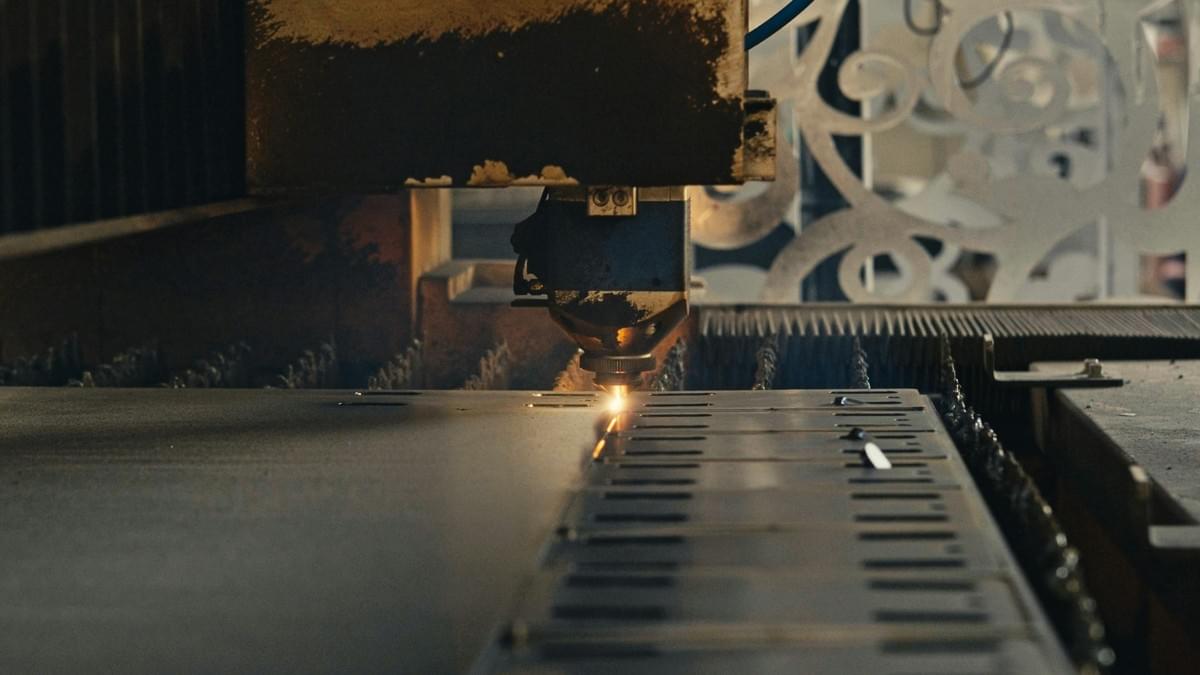

In the world of manufacturing, precision and efficiency are paramount, making the selection of laser cutting machine manufacturers a critical decision for businesses. With an array of options available, from fiber lasers to industrial laser cutters, it’s essential to navigate this landscape thoughtfully. The right industrial laser cutting machine can significantly enhance production capabilities and streamline operations.

Discovering Top Laser Cutting Brands

When exploring the best in metal cutting machine lasers, several brands stand out due to their commitment to innovation and quality. Companies like Trumpf and Bystronic have earned reputations as leaders in the field, offering advanced technologies that cater to diverse industrial needs. These top-tier laser cutting machine manufacturers provide solutions that not only meet but exceed expectations in precision and performance.

Importance of Choosing the Right Manufacturer

Choosing the right manufacturer for your industrial laser machines is crucial; it can mean the difference between success and costly setbacks. A reputable manufacturer ensures you receive a reliable cutting machine laser that meets your specific requirements while also providing ongoing support and maintenance. Investing time in selecting a trusted brand can lead to long-term partnerships that enhance operational efficiency.

Overview of Laser Cutting Machine Options

The market offers a variety of options when it comes to industrial laser cutting machines, each designed for different applications and materials. From high-speed fiber lasers capable of handling thick metals to versatile systems that adapt to various substrates, understanding these choices is vital for any business owner. By familiarizing yourself with these technologies, you can make informed decisions that align with your production goals.

Leading Laser Cutting Machine Manufacturers

In the world of laser cutting, selecting the right manufacturer can make all the difference. The leading laser cutting machine manufacturers have established themselves through innovation, reliability, and tailored solutions that cater to various industries. From industrial laser cutters to advanced fiber lasers, these brands offer a range of options designed to enhance production efficiency and precision.

Trumpf: Innovation at Its Core

Trumpf stands out among laser cutting machine manufacturers for its relentless pursuit of innovation. Known for their high-performance industrial laser cutting machines, they consistently push the envelope with state-of-the-art technology that enhances precision and speed. Their fiber laser systems are particularly noteworthy; these machines offer remarkable energy efficiency and reduced operational costs while maintaining top-notch performance.

The versatility of Trumpf's metal cutting machine lasers allows users to tackle a wide range of materials, from steel to aluminum, making them ideal for diverse applications in manufacturing. Additionally, their commitment to research and development ensures that customers benefit from the latest advancements in laser technology. With a strong reputation built on quality and service, Trumpf remains a go-to choice for those looking to invest in an industrial laser cutter.

Bystronic: Tailored Solutions for Various Industries

Bystronic has carved out its niche as one of the leading players among laser cutting machine manufacturers by offering tailored solutions that meet specific industry needs. Their approach focuses on providing customized machinery designed to optimize workflow in sectors ranging from automotive to aerospace. Bystronic’s industrial laser cutting machines are equipped with intelligent software that enhances operational efficiency and accuracy.

One standout feature is their ability to handle multiple materials effortlessly—whether it’s sheet metal or complex profiles—thanks to their innovative cutting machine lasers. Bystronic also places a strong emphasis on customer service; they work closely with clients throughout the entire process from selection through installation and beyond. This dedication ensures that users receive not just equipment but also ongoing support as they navigate their production challenges.

Amada: Reliable Machinery with Cutting-Edge Technology

Amada is synonymous with reliability in the realm of industrial laser machines, offering robust machinery equipped with cutting-edge technology tailored for high-volume production environments. Known for their durable construction and ease of use, Amada’s metal cutting machine lasers provide consistent results even under demanding conditions. Their product lineup includes both CO2 lasers and fiber lasers, giving customers flexibility based on specific application requirements.

What sets Amada apart is their commitment to integrating advanced automation into their systems; this significantly boosts productivity while minimizing human error during operation. Users can expect long-term cost savings due to lower maintenance needs and enhanced energy efficiency inherent in Amada's designs. With a solid reputation built over decades in the industry, choosing Amada means investing in quality machinery backed by extensive expertise.

Benefits of Investing in Quality Machinery

Investing in a high-quality laser cutting machine can significantly impact your production capabilities and overall business success. The right industrial laser cutter not only enhances the quality of your products but also optimizes operational efficiency. With numerous laser cutting machine manufacturers available, selecting the best equipment can lead to substantial advantages in precision, efficiency, and cost-effectiveness.

Enhanced Precision and Accuracy

One of the standout benefits of using a top-tier industrial laser cutting machine is the enhanced precision it offers. Advanced technology found in machines from leading laser cutting machine manufacturers ensures that cuts are executed with remarkable accuracy, reducing material wastage and minimizing errors. Whether you're working with metal or other materials, a fiber laser provides consistent results that meet stringent industry standards.

Improved Production Efficiency

Quality machinery translates directly into improved production efficiency, allowing businesses to meet tight deadlines without sacrificing quality. An industrial laser cutter designed for speed and reliability can streamline operations, enabling faster turnaround times for projects. This efficiency not only boosts productivity but also enhances customer satisfaction as orders are fulfilled promptly.

Long-Term Cost Savings

When considering the initial investment costs associated with purchasing an industrial laser cutting machine, it's essential to look at the long-term financial benefits as well. Quality machines often require less maintenance and have lower operational costs due to their energy-efficient designs and robust build quality. Over time, these savings on repairs and energy usage can significantly offset the initial laser machine price, making it a wise investment for any manufacturing operation.

Key Features to Look for in a Laser Cutting Machine

When diving into the world of laser cutting machines, it's crucial to understand the key features that distinguish top-tier models from the rest. Whether you're exploring options from renowned laser cutting machine manufacturers or considering an industrial laser cutter for your operations, these features will guide your decision-making process. A well-chosen cutting machine laser can make all the difference in efficiency and output quality.

Power and Speed: Finding the Right Balance

Power and speed are two critical aspects that define the performance of any industrial laser cutting machine. A higher wattage fiber laser typically translates to faster cutting speeds, allowing for quicker job completion without sacrificing precision. However, it's essential to strike a balance; too much power can lead to excessive heat input and material warping, while too little may result in slow processing times—nobody wants to wait around when metal cutting machine lasers are involved!

In addition, different materials require varying levels of power and speed settings; thus, a versatile industrial laser cutter should offer adjustable parameters tailored for specific tasks. This flexibility not only enhances production efficiency but also ensures high-quality results across diverse applications. Ultimately, investing in a machine with optimal power and speed capabilities will pay off in both productivity and finished product excellence.

Versatility: Handling Different Materials

The ability to handle various materials is another vital feature when evaluating potential industrial laser machines. A top-notch cutting machine laser should be capable of processing metals like steel, aluminum, copper, as well as non-metals such as plastics or wood with ease. This versatility allows businesses to diversify their offerings without needing multiple machines—saving both space and costs.

Moreover, some advanced models come equipped with adaptive technology that automatically adjusts settings based on material type and thickness. This feature not only simplifies operation but also minimizes human error during setup—a win-win for busy operators! When selecting among leading laser cutting machine manufacturers, prioritize those that offer multi-material capabilities for maximum operational flexibility.

User-Friendly Interfaces for Operators

A user-friendly interface is essential when it comes to operating an industrial laser cutting machine efficiently. The best machines on the market feature intuitive controls that enable operators of all skill levels to navigate easily through complex tasks without extensive training sessions or manuals by their side. Touchscreen displays with visual prompts can significantly enhance usability while reducing downtime caused by operator confusion.

Additionally, software integration plays a significant role in streamlining operations; look for systems compatible with popular design software so you can seamlessly transition from design phase to execution phase without hiccups along the way! After all, no one wants their workflow interrupted because they’re struggling with outdated interfaces—especially when there’s money on the line! By focusing on user-friendly designs from reputable manufacturers, you’ll ensure your team can hit the ground running.

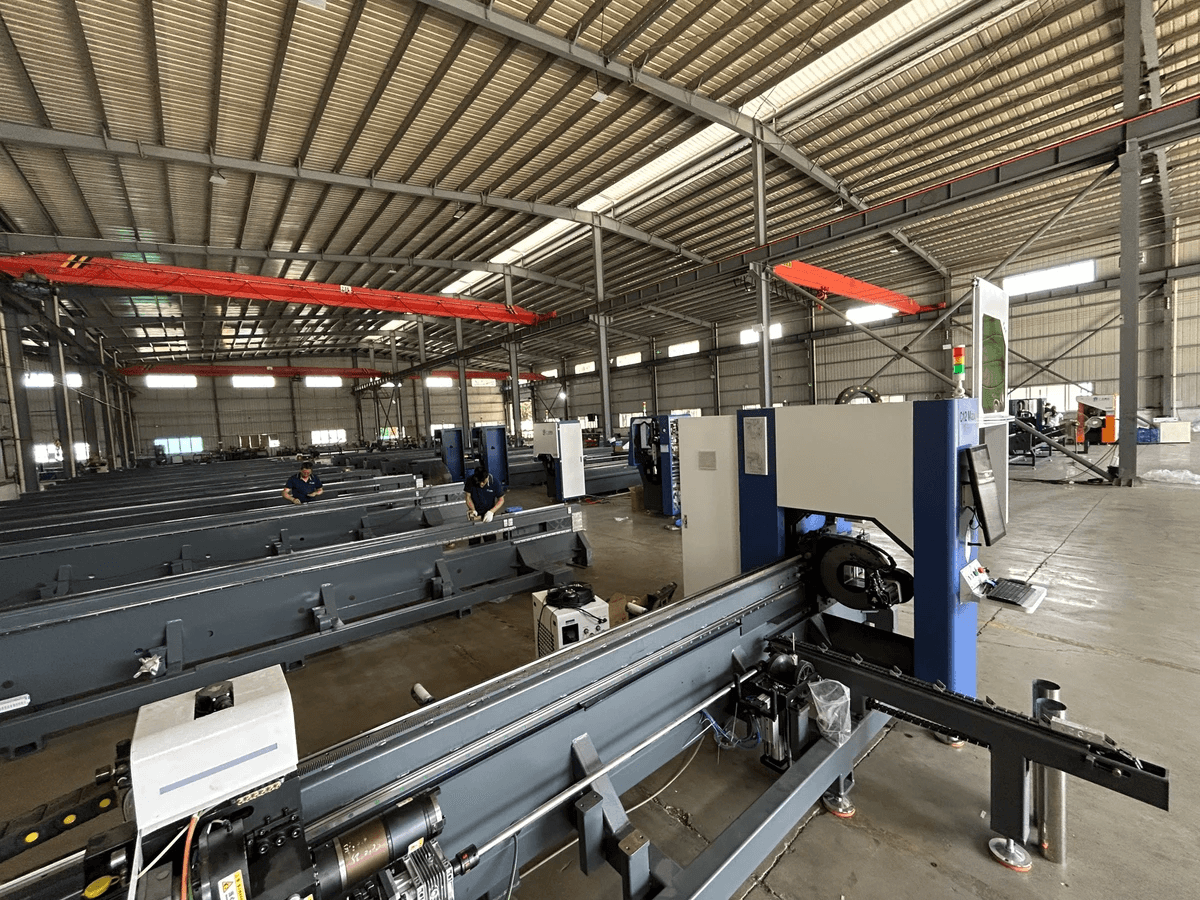

Exploring Kiant Machinery

When it comes to the world of laser cutting machine manufacturers, Kiant Machinery stands out with its innovative approach and commitment to excellence. Known for their advanced technology, particularly in metal cutting machine laser applications, they have made a significant impact on various industries. Their industrial laser cutting machines are designed to meet the demands of modern manufacturing, ensuring precision and efficiency.

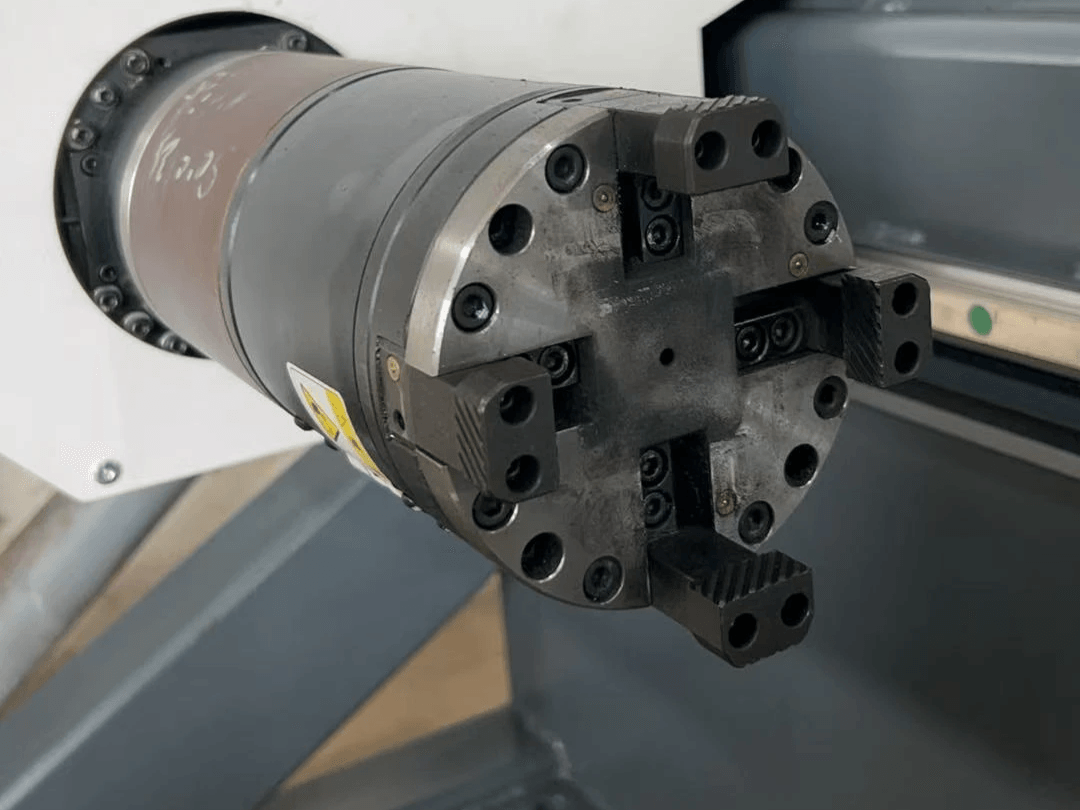

Advanced Laser Tube Cutting Equipment

Kiant Machinery specializes in advanced laser tube cutting equipment that pushes the boundaries of what an industrial laser cutter can achieve. Their fiber laser technology offers exceptional speed and accuracy, making it ideal for a range of applications from automotive components to intricate architectural designs. With a focus on versatility, these cutting machines can handle various materials, including steel and aluminum, making them a favorite among manufacturers seeking reliable solutions.

Commitment to Customer Support

One of the standout features of Kiant Machinery is their unwavering commitment to customer support. They understand that investing in an industrial laser cutting machine is a significant decision for any business, and they strive to provide comprehensive assistance throughout the purchasing process and beyond. From initial consultations on laser machine price options to ongoing maintenance and training for operators, Kiant ensures that clients have all the resources they need for success.

Real-World Applications and Success Stories

Kiant Machinery’s products have been put through their paces in numerous real-world applications across various sectors. For instance, companies utilizing their metal cutting machine lasers have reported substantial improvements in production efficiency while maintaining high-quality standards. Success stories abound where businesses have transformed their operations with Kiant's industrial laser machines, showcasing how effective these technologies can be when properly integrated into existing workflows.

Comparing Global Laser Cutting Players

In the competitive world of laser cutting machine manufacturers, two giants stand out: Trumpf and Bystronic. Each brand brings its own set of strengths and innovations to the table, making them popular choices for businesses seeking reliable industrial laser cutting machines. By examining their offerings, features, and customer support, we can gain insight into which might be the best fit for specific applications.

Comparing Trumpf and Bystronic

Trumpf is renowned for its innovative approach to industrial laser cutters, consistently pushing the boundaries of technology with advanced fiber laser systems that offer exceptional speed and precision. Their machines are often equipped with smart features that enhance workflow efficiency, making them suitable for high-volume production environments. On the other hand, Bystronic focuses on providing tailored solutions that cater to various industries, ensuring that their cutting machine lasers are versatile enough to handle different materials and thicknesses without compromising quality.

While both brands deliver high-quality industrial laser cutting machines, Trumpf tends to be favored for its robust engineering and extensive service network worldwide. Conversely, Bystronic shines in customization options—offering clients a chance to adapt machinery based on specific requirements. Ultimately, choosing between these two leading manufacturers will depend on individual business needs regarding production volume, material types, and budget constraints.

Amada vs. Kiant Machinery: Pros and Cons

Amada has long been a trusted name in the realm of metal cutting machine lasers due to its reputation for reliability and advanced technology integration within its products. Their industrial laser machines often feature user-friendly interfaces that simplify operation while maintaining precision in cuts across various materials. However, some may find Amada's pricing structure on the higher side when compared to other manufacturers like Kiant Machinery.

Kiant Machinery offers an appealing alternative with a focus on affordability without sacrificing quality in their offerings of advanced laser tube cutting equipment. They have garnered praise for their commitment to customer support and providing real-world applications tailored specifically for smaller businesses or startups looking to enter the market with a cost-effective solution. Nonetheless, potential buyers should consider whether Kiant's machinery can match Amada's established track record in terms of durability and performance over time.

When weighing these options—Amada’s reliability versus Kiant’s affordability—businesses must evaluate their unique operational needs alongside long-term goals related to investment returns from purchasing an industrial laser cutting machine.

Regional Leaders in Laser Cutting Technology

Beyond global players like Trumpf or Bystronic lies a diverse array of regional leaders making waves in the laser cutting industry as well. Companies specializing in localized solutions often provide tailored services that cater specifically to regional markets while maintaining competitive pricing against larger counterparts like Amada or Kiant Machinery. These regional players frequently focus on niche applications where specialized knowledge can lead them ahead by offering customized machinery designed around local demands.

For instance, some Asian manufacturers have emerged as strong contenders by producing cost-effective fiber lasers aimed at small-to-medium enterprises looking for budget-friendly options without sacrificing essential features found in more expensive models from established brands. This trend has led many businesses worldwide to explore alternatives beyond traditional powerhouses—opening doors toward innovation through collaboration between local suppliers and global advancements.

In conclusion, understanding how different laser cutting machine manufacturers stack up against each other allows companies not only to make informed decisions but also empowers them with insights into emerging technologies shaping future developments within this dynamic field.

Conclusion

In the ever-evolving world of manufacturing, making informed decisions on machinery is crucial for success. With a plethora of laser cutting machine manufacturers available, understanding their unique offerings can help businesses select the right equipment to meet their needs. Whether you’re in the market for an industrial laser cutter or exploring fiber laser options, knowledge is power.

Making Informed Decisions on Machinery

Choosing the right industrial laser cutting machine can significantly impact your production quality and efficiency. By evaluating various metal cutting machine laser options and comparing features among leading manufacturers, businesses can find machinery that aligns with their operational goals. Additionally, considering factors such as user-friendliness and maintenance costs will lead to smarter investments in industrial laser machines.

The Future of Laser Cutting Technology

The landscape of laser cutting technology is continuously advancing with innovations like fiber lasers and enhanced automation capabilities. As manufacturers strive for greater precision and speed, the future promises even more sophisticated solutions tailored to specific industries. Keeping an eye on emerging trends will ensure that businesses remain competitive while maximizing the benefits of their cutting machine lasers.

Final Thoughts on Choosing the Best Manufacturers

Ultimately, selecting from top-tier laser cutting machine manufacturers requires careful consideration of your business’s unique needs and budget constraints, including evaluating the laser machine price against performance capabilities. It’s not just about acquiring a piece of equipment; it’s about investing in a tool that enhances productivity and quality over time. By weighing all these factors thoughtfully, companies can confidently choose a partner that supports their long-term success in an increasingly competitive marketplace.