Introduction

In the world of manufacturing and fabrication, understanding the intricacies of laser cutting costs is essential for making informed purchasing decisions. Whether you're a seasoned professional or a newcomer to the industry, grasping how various factors influence the price of a metal cutting machine laser can significantly impact your budget and operational efficiency. From equipment choices to market trends, every aspect plays a crucial role in determining the overall laser machine price.

Understanding Laser Cutting Costs

When considering a cutting machine laser, it's vital to recognize that its cost encompasses more than just the initial purchase price. Factors such as quality, size, and brand reputation contribute to what you’ll ultimately pay for a laser cutter price tag. Moreover, understanding these elements helps in evaluating long-term investments versus cheap laser cutter options that may compromise performance or durability.

Key Factors Influencing Prices

Several key factors influence the prices associated with laser cutting machines, including technology advancements and material compatibility. The type of laser source used—be it CO2 or fiber—can dramatically affect both performance and cost; thus, knowing which type suits your needs is crucial. Additionally, market demand often dictates pricing fluctuations; staying informed about these trends will help you navigate your options effectively.

The Importance of Equipment Choices

Choosing the right equipment is paramount when considering your investment in a metal cutting machine laser. Not only does it affect immediate costs like purchase price and setup expenses, but it also influences operational efficiency and maintenance needs down the line. Investing wisely in high-quality machines can lead to significant savings over time while ensuring superior performance compared to cheaper alternatives.

The Basics of Laser Cutting Technology

Laser cutting technology has come a long way since its inception, evolving from bulky, expensive machines to sleek, efficient tools that are accessible to a wider range of industries. Today’s laser cutting machines offer precision and speed that were once unimaginable, significantly reducing production times and costs. As more businesses recognize the potential of this technology, understanding the evolution of laser cutting machines becomes essential for anyone looking to invest in a laser cutter.

Evolution of Laser Cutting Machines

The journey of laser cutting machines began in the 1960s when the first industrial applications emerged using CO2 lasers. Fast forward to today, and we have a variety of advanced technologies such as fiber lasers and solid-state lasers that enhance performance while lowering laser cutting machine costs. This evolution has led to more compact designs with improved energy efficiency, making it easier for businesses to adopt metal cutting machine lasers without breaking the bank.

Types of Laser Machines and Their Uses

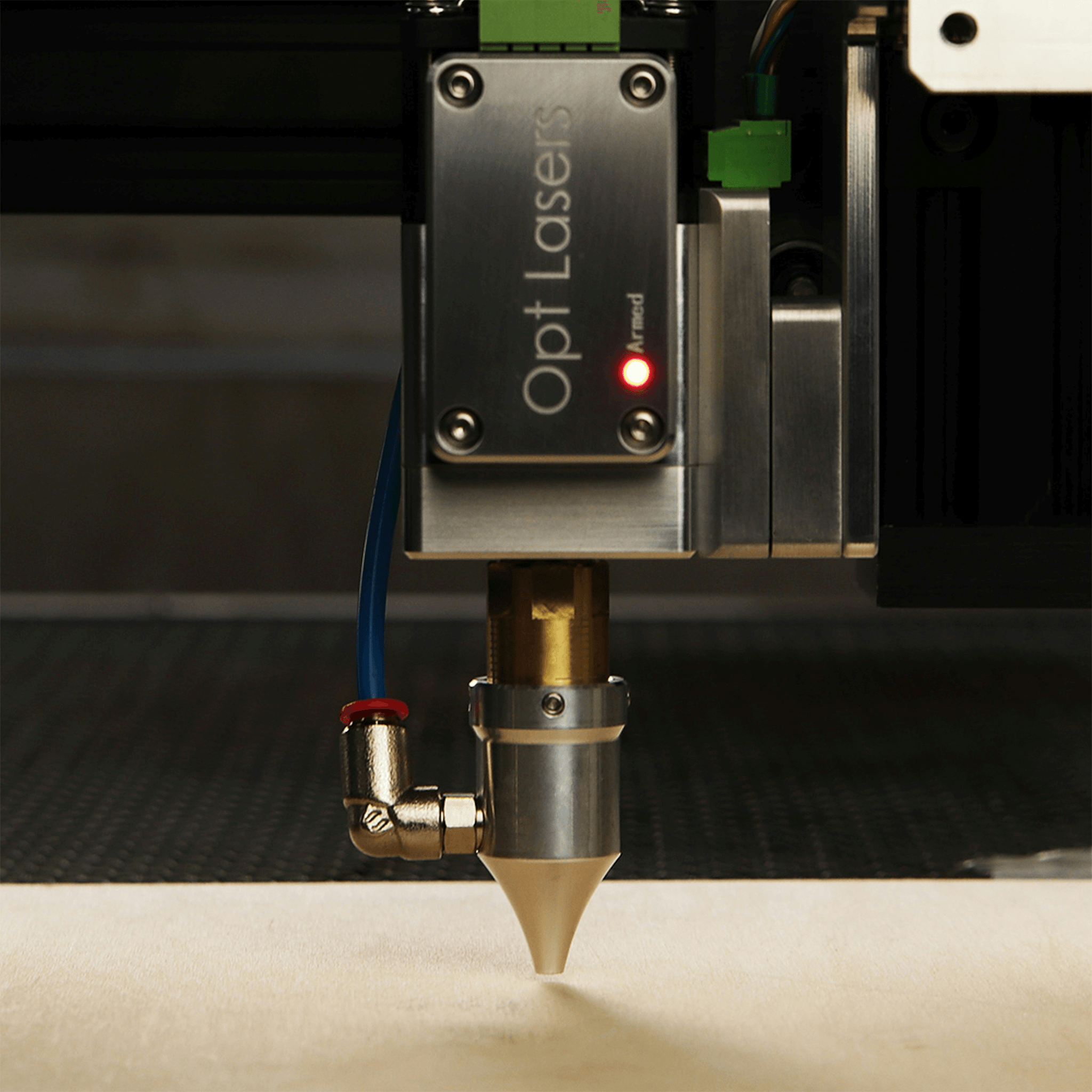

When it comes to types of laser machines, there’s no one-size-fits-all solution; each type serves specific purposes across various industries. CO2 lasers are popular for non-metal materials like wood and acrylic, while fiber lasers dominate metal cutting due to their efficiency and precision—making them ideal for those looking at a metal cutting machine laser investment. Understanding the different options available allows buyers to assess which cutting machine laser fits their unique needs best without overspending on unnecessary features.

Benefits of Using a Metal Cutting Machine Laser

Investing in a metal cutting machine laser offers numerous advantages that can significantly impact your bottom line. First off, these machines provide unparalleled accuracy and repeatability, ensuring high-quality cuts every time—something that's crucial in competitive markets where precision is key. Additionally, with advancements in technology driving down overall laser cutter prices, businesses can enjoy cost-effective solutions without sacrificing quality or performance; it's about getting the best bang for your buck!

Components that Affect Laser Cutting Machine Cost

When it comes to the laser cutting machine cost, several components play a significant role in determining the final price tag. Understanding these elements can help you make informed decisions when selecting a metal cutting machine laser that best suits your needs. Let's dive into the intricacies of what influences the cost of a cutting machine laser.

Laser Source Quality and Type

The quality and type of the laser source are paramount in defining a laser machine's efficiency and overall performance, which directly impacts its cost. High-quality lasers, such as fiber or CO2, offer different capabilities and applications; thus, their prices vary significantly. Investing in a superior laser source may elevate your initial expenses but can lead to long-term savings through improved precision and reduced operational downtime.

Moreover, cheap laser cutters often compromise on quality by using lower-grade lasers that may not withstand rigorous use or deliver consistent results. This inconsistency can result in higher costs down the line due to increased material waste and frequent repairs. Therefore, while assessing your budget for a metal cutting machine laser, consider how crucial the laser source's quality is to your production goals.

Machine Size and Cutting Area Considerations

The size of the machine and its cutting area are critical factors influencing both the initial purchase price and ongoing operational costs associated with any cutting machine laser. Larger machines capable of handling bigger sheets or thicker materials naturally come with a heftier price tag due to their advanced engineering and manufacturing requirements. However, if your projects demand versatility in material sizes, investing in a larger model could be more economical over time.

Additionally, keep in mind that larger machines may incur higher maintenance costs as well as increased energy consumption during operation—factors that can compound your overall investment in terms of laser cutting machine cost. On the flip side, opting for smaller models might save you money upfront but could limit your production capabilities or force you into frequent upgrades as demand grows. Balancing size with functionality is essential when considering all aspects of your new metal cutting machine laser.

Brand Reputation and Manufacturer Reliability

Brand reputation plays an integral role when evaluating potential options for a new laser cutter price; established manufacturers often command higher prices due to their proven reliability and customer support systems. Investing in equipment from reputable brands typically ensures better warranty terms, access to spare parts, and more robust service agreements—elements crucial for maintaining productivity levels over time without incurring unexpected costs.

Choosing lesser-known brands based solely on attractive pricing may seem tempting at first glance; however, this strategy could lead to unforeseen complications down the road regarding maintenance issues or lackluster performance from cheap laser cutters lacking adequate support infrastructure. Remember that every dollar saved upfront might translate into multiple dollars spent later on repairs or replacements if you don’t choose wisely! Prioritizing manufacturer reliability alongside competitive pricing will ultimately help you maximize value while minimizing risk related to your investment in a high-quality metal cutting machine laser.

Operational Costs Beyond Initial Purchase

The laser cutting industry is constantly evolving, influenced by various market trends that affect the overall laser cutting machine cost. Understanding these trends is crucial for businesses looking to invest in a metal cutting machine laser or any other type of cutting machine laser. As supply and demand fluctuate, so do the prices associated with these advanced machines.

Supply and Demand in the Laser Cutting Industry

The balance between supply and demand plays a significant role in determining the laser cutter price. When demand for high-quality metal cutting machine lasers surges—often due to increased manufacturing needs—prices tend to rise as suppliers scramble to keep up. Conversely, when new technologies emerge or if competitors flood the market with cheap laser cutters, prices can drop, giving buyers more options at lower costs.

Seasonal fluctuations also impact supply chains, affecting availability and consequently driving prices up or down based on urgency and necessity. Companies must stay informed about these trends to make timely purchases that align with their budget while ensuring they don’t compromise on quality. Ultimately, understanding this dynamic helps businesses strategize their investments wisely in order to maximize value while controlling costs.

Innovations Driving Laser Machine Price Changes

Innovation is at the heart of technological advancement, especially when it comes to laser machines. New features and improved capabilities can lead to significant shifts in laser machine price structures; for instance, advancements in speed or precision often justify higher costs for newer models. However, as technology becomes more widespread, older models may see a decrease in price as manufacturers aim to clear inventory.

Moreover, innovations like automation integration are becoming increasingly common in modern cutting machines, impacting both operational efficiency and costs associated with labor training for operators. Buyers should keep an eye on emerging technologies that can enhance production capabilities without breaking the bank on initial investments—after all, investing in a future-proof technology can save money long-term despite higher upfront expenses associated with advanced features.

The Role of Competitors in Pricing Strategies

In a competitive landscape like the laser cutting industry, companies constantly adjust their pricing strategies based on what others are doing. This competition drives innovation but also affects how brands position their products regarding cost; cheaper alternatives often emerge as brands seek to capture market share from established players offering premium products at higher prices.

For buyers seeking value without sacrificing quality, it’s essential to compare offerings across brands while keeping an eye out for promotions or bundled services that may reduce overall expenses related to purchasing a metal cutting machine laser or any other type of cutting machine laser. Ultimately, savvy consumers will benefit from understanding how competitor dynamics influence pricing strategies within this ever-evolving market landscape.

Finding Affordable Options Without Sacrificing Quality

When it comes to investing in a laser cutting machine, finding an affordable option that still delivers quality can feel like searching for a needle in a haystack. The market is flooded with choices, from cheap laser cutters to high-end machines, making it essential to navigate this landscape wisely. Understanding how to evaluate options based on your specific needs will help you strike the right balance between cost and performance.

Evaluating Cheap Laser Cutter Options

Not all cheap laser cutter options are created equal; some may seem budget-friendly but could end up costing you more in the long run due to poor performance or maintenance issues. Start by examining the specifications of these machines—look for details such as cutting speed, accuracy, and the types of materials they can handle effectively. Additionally, check user reviews and testimonials; real-world experiences can provide valuable insights into whether a low price tag translates into quality performance or just a false economy.

When evaluating cheaper models, consider their compatibility with your current projects and future needs. A metal cutting machine laser that appears inexpensive might lack features necessary for your operations or could have limited support from manufacturers. Ultimately, it's crucial to weigh the initial savings against potential operational costs over time—after all, investing wisely now can save you headaches later.

Comparing Prices Among Leading Brands

Price comparison among leading brands is crucial when determining which laser machine best fits your budget without compromising on quality. Many reputable manufacturers offer various models at different price points; take advantage of online resources and forums dedicated to laser cutting technology for insights on brand reliability and customer satisfaction ratings. Keep an eye out for seasonal sales or promotions—these opportunities can significantly reduce the overall laser cutter price while ensuring you're purchasing from trusted sources.

While comparing prices, don’t forget to factor in warranty options and after-sales service support offered by different brands. A slightly higher initial investment may be worthwhile if it comes with robust customer service or extended warranties that cover potential issues down the line. Remember that choosing a well-known brand often equates to better reliability and resale value—a key consideration if you plan on upgrading equipment in the future.

Investing in Future-Proof Technology

Investing in future-proof technology is essential when selecting a cutting machine laser that will remain relevant as industry demands evolve over time. Opting for machines equipped with advanced features such as automation capabilities or software integration ensures your investment pays off long-term by enhancing productivity and versatility across various applications. While these models may come with higher upfront costs, their ability to adapt to new technologies makes them worth considering against cheaper alternatives.

Furthermore, consider how easy it is to upgrade components on your chosen machine; modular designs allow you to enhance functionality without needing an entirely new setup down the line. This adaptability not only protects your initial investment but also positions your business favorably as market trends shift toward more sophisticated manufacturing processes. In short, spending wisely now on a capable metal cutting machine laser will yield dividends well into the future.

Conclusion

In the world of laser cutting, making a smart investment is crucial for maximizing value and ensuring a successful operation. Understanding the various components that contribute to laser cutting machine cost can help you make informed decisions. By focusing on quality, efficiency, and long-term performance, you can optimize your investment in a metal cutting machine laser.

Maximizing Value in Your Laser Cutting Investment

To maximize value in your laser cutting investment, it's essential to evaluate not just the initial price but also the operational costs associated with running a cutting machine laser. Consider factors like maintenance requirements and energy consumption—these can significantly impact overall expenses over time. By choosing a reliable brand known for durability and performance, you can ensure that your laser cutter price reflects its true worth.

The Balance Between Cost and Performance

Striking the right balance between cost and performance is key when selecting a laser machine for your business needs. While it may be tempting to opt for a cheap laser cutter, compromising on quality could lead to higher costs down the line due to frequent repairs or inefficiencies. Investing in a high-performance metal cutting machine laser may come with a higher upfront cost but will likely pay off through enhanced productivity and lower long-term operational expenses.

Choosing Kiant Machinery for Your Needs

When it comes to selecting equipment that meets both your budgetary constraints and quality expectations, Kiant Machinery stands out as an excellent choice. Their range of reliable machines offers competitive prices without sacrificing performance or durability—perfect for those mindful of their laser cutting machine cost. With Kiant Machinery, you're not just buying equipment; you're investing in future-proof technology that will keep your operations efficient and cost-effective for years to come.