Introduction

In the world of precision manufacturing, the **no drawing laser cutting machine** stands out as a game-changer. This innovative technology eliminates the need for complex drawings, allowing users to cut materials with unmatched accuracy and efficiency. As industries evolve, understanding the unique advantages of this cutting-edge **laser cutter** technology becomes essential for businesses looking to stay competitive.

Understanding No Drawing Laser Cutting Machines

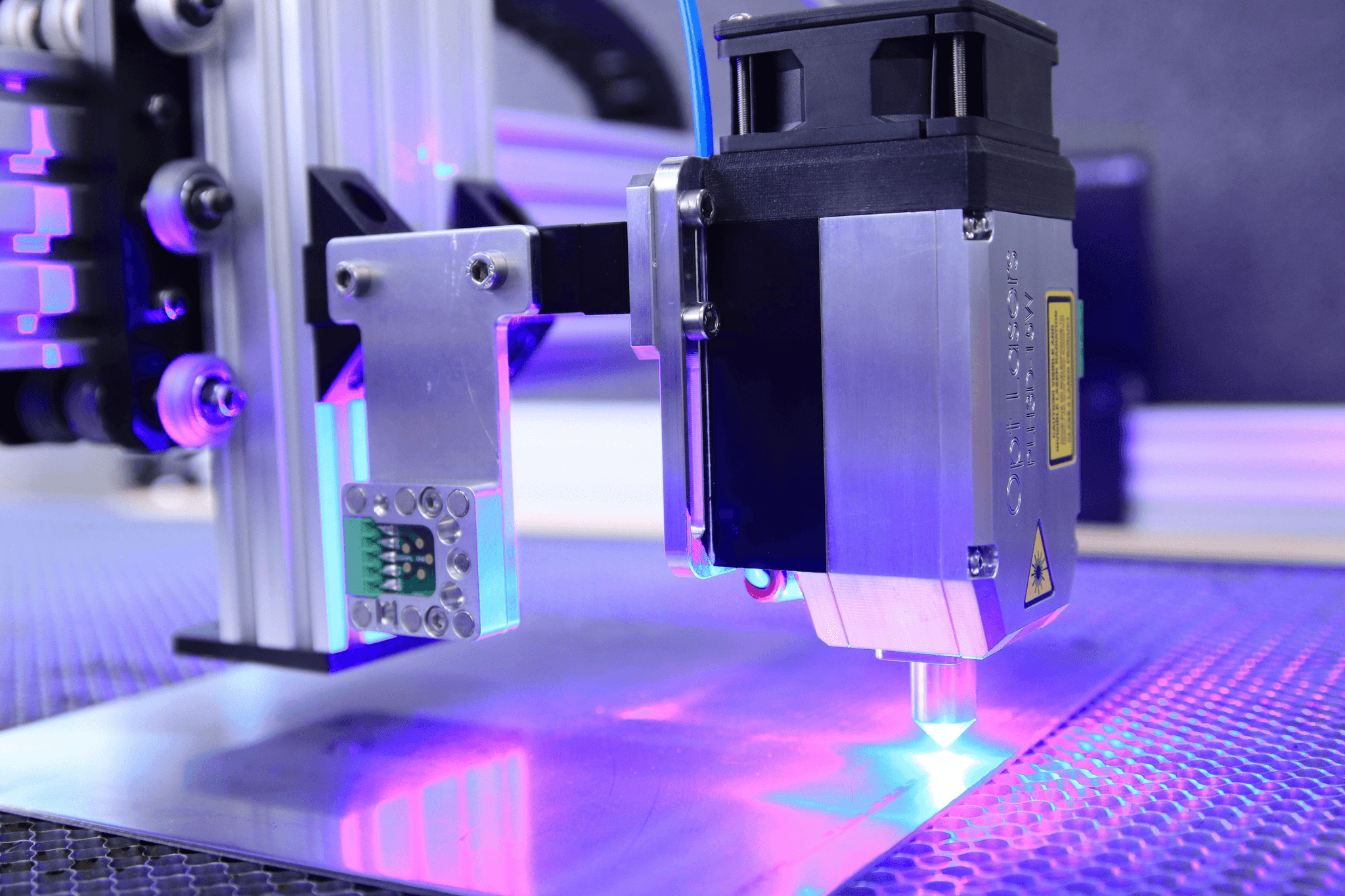

A **no drawing laser cutting machine** is designed to streamline the cutting process by directly interpreting digital designs without requiring manual drawings. This functionality not only accelerates production times but also reduces human error, making it an ideal choice for various applications across different sectors. By harnessing advanced software and high-powered lasers, these machines can produce intricate shapes and patterns with ease.

Advantages of Using Laser Cutting Technology

The benefits of using a **laser cutter** are numerous and compelling. First and foremost, laser cutting technology offers remarkable precision that traditional methods simply cannot match; this means cleaner edges and less material waste. Additionally, **cutting machine lasers** can work with a wide range of materials—from metals to plastics—making them incredibly versatile tools in any workshop or factory.

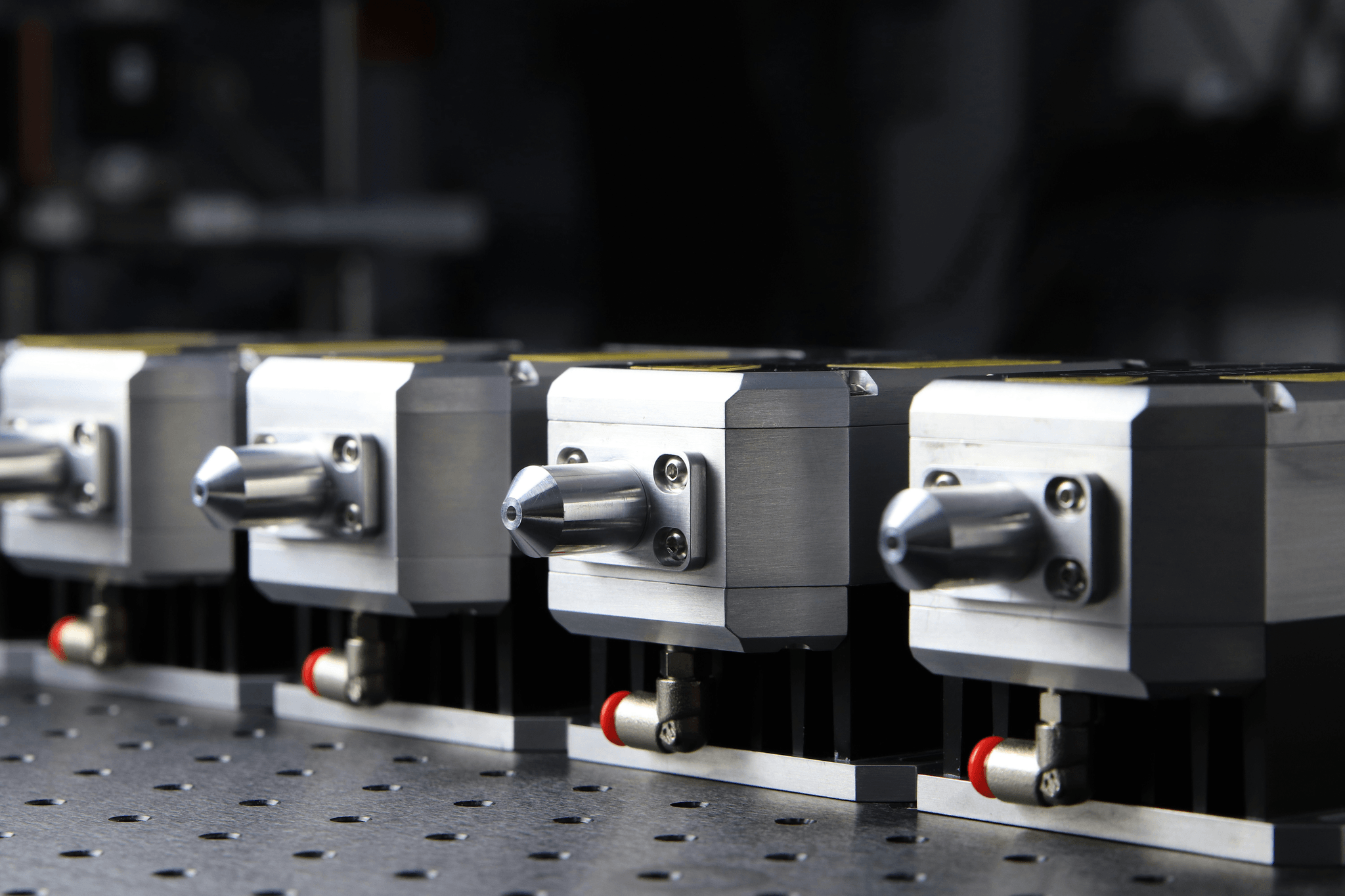

Key Components of a Laser Cutter

Understanding the key components of a **laser cutter machine** is crucial for maximizing its potential. At its core, a laser machine consists of several vital elements: the laser source (often fiber-based), optics to focus the beam, and a motion system that guides the material being cut. Each component plays an integral role in ensuring that your **fiber laser cutting machine** operates smoothly and delivers high-quality results every time.

What is a No Drawing Laser Cutting Machine

When it comes to precision and efficiency, the no drawing laser cutting machine stands out in the world of laser machinery. Unlike traditional cutting methods that rely on manual drawings or templates, this advanced technology allows users to directly input designs into the software, streamlining the entire process. This innovation not only saves time but also enhances accuracy, making it an essential tool for various industries.

Definition and Functionality

A no drawing laser cutting machine is designed to automate the laser cutting process without requiring preliminary drawings or sketches. Instead, users can upload digital files directly into the system, which then translates these designs into precise cuts executed by a powerful fiber laser cutting machine. The functionality of these machines is rooted in their ability to handle complex shapes and intricate designs with remarkable speed and precision.

This means that whether you're working on metal, wood, or acrylic materials, a laser cutter machine can deliver clean edges and detailed patterns effortlessly. By eliminating the need for manual templates, businesses can increase productivity while reducing material waste—an appealing prospect in today’s cost-conscious market.

Differences from Traditional Laser Cutters

The primary difference between no drawing laser cutters and traditional models lies in their operational approach. Traditional laser cutters often require physical drawings or templates that must be painstakingly created before any cutting can begin. In contrast, no drawing machines operate entirely through digital input, allowing for greater flexibility and rapid adjustments.

Moreover, traditional machines may struggle with intricate designs due to their reliance on manual setups; however, no drawing systems thrive in this area by utilizing sophisticated software algorithms that enhance design capabilities. This leads to improved turnaround times for projects across various applications—from prototyping to mass production—making them indispensable tools in modern manufacturing environments.

Applications Across Industries

No drawing laser cutting machines have found applications across a multitude of industries due to their versatility and efficiency. In manufacturing settings, they are commonly used for creating components ranging from automotive parts to electronic enclosures with unmatched precision. Additionally, sectors such as fashion design benefit from these machines when producing intricate patterns on fabrics or leather goods.

Small businesses also leverage this technology for creative projects like custom signage or personalized gifts—demonstrating how accessible this advanced equipment has become even outside industrial contexts. With increasing demand for customization and rapid production times across various fields, it's clear that the future of fabrication will heavily rely on innovative solutions like no drawing laser cutting machinery.

Selecting the Right Laser Cutter Machine

Choosing the right laser cutter machine can feel like navigating a maze of specifications and options. With advancements in technology, particularly with no drawing laser cutting machines, the market is flooded with choices that cater to various needs and budgets. Understanding what to look for will help you make an informed decision that meets your operational requirements.

Factors to Consider

When selecting a laser cutter, several factors come into play. First, assess the materials you'll be working with; different laser machinery excels at cutting specific materials like metal, wood, or acrylic. Additionally, consider the thickness of these materials, as it will determine the power needed from your cutting machine laser.

Another crucial factor is the size and workspace available for your laser cutter machine. If you're operating in a compact area, a desktop model might be ideal; however, larger operations may require industrial-grade fiber laser cutting machines for efficiency. Finally, don’t overlook software compatibility; ensuring that your chosen machine integrates smoothly with design software is vital for seamless operation.

Comparing Fiber Laser Cutting Machines

Fiber laser cutting machines have gained popularity due to their efficiency and precision over traditional CO2 lasers. They are particularly effective when working on metals and provide faster cutting speeds while consuming less energy—a win-win situation! However, it's essential to compare features such as wattage and bed size across different brands to find the best fit for your projects.

Another point of comparison is maintenance requirements; fiber lasers typically require less upkeep than their CO2 counterparts which can save you time and money in the long run. Additionally, consider customer support services offered by manufacturers; having reliable assistance can be invaluable when troubleshooting issues or seeking upgrades down the line. Ultimately, weigh these aspects against your specific needs to ensure you choose a fiber laser cutting machine that aligns perfectly with your business goals.

Top Brands in the Market

When it comes to investing in a no drawing laser cutting machine or any type of laser machinery, brand reputation matters significantly. Some top contenders include Epilog Laser known for its user-friendly interface and robust customer support systems; Trotec Laser which offers versatile solutions for both small businesses and large-scale operations; and Trumpf renowned for its high-performance fiber lasers designed specifically for industrial applications.

Each brand brings something unique to the table—whether it's innovative technology or exceptional service—so take time to research each one thoroughly before making a purchase decision. Customer reviews can also provide valuable insights into real-world performance and reliability of these machines over time. By choosing a reputable brand that aligns with your needs, you're investing not just in equipment but also in peace of mind as you embark on your laser-cutting journey.

Setting Up Your Laser Cutting Machine

Setting up a no drawing laser cutting machine can seem daunting, but with the right guidance, it becomes a straightforward process. This section will provide essential tips for installation, highlight safety precautions to ensure a secure working environment, and offer advice on configuring your software for optimal performance. By following these steps, you can maximize the efficiency of your laser cutter machine from the get-go.

Essential Installation Tips

When installing your cutting machine laser, start by selecting a well-ventilated area that allows for ample space around the machine. Ensure that the surface is level and sturdy enough to support the weight of your laser machinery while providing easy access to power outlets and ventilation systems. After positioning your fiber laser cutting machine correctly, double-check all connections and follow the manufacturer’s guidelines for assembly to avoid any mishaps.

Cable management is another critical aspect of installation; keep cables organized and away from moving parts to prevent accidents during operation. Additionally, verify that all components are securely attached before powering on your laser cutter machine for the first time. Taking these essential installation steps will set you up for success as you embark on your cutting adventures.

Safety Precautions to Follow

Safety should always be a top priority when operating any type of laser machinery, including no drawing laser cutting machines. First and foremost, ensure that you are wearing appropriate personal protective equipment (PPE), such as safety goggles specifically designed for laser use, gloves, and long sleeves to protect against potential hazards from sparks or debris.

Moreover, keep flammable materials away from the workspace; lasers generate heat that could ignite nearby items if not handled properly. Familiarize yourself with emergency shut-off procedures in case anything goes awry during operation; this knowledge can save both equipment and lives in critical situations.

Configuring Software for Optimal Performance

Configuring software is crucial in ensuring that your laser cutter operates smoothly and efficiently; after all, it’s what transforms your design ideas into reality! Start by installing any necessary drivers specific to your no drawing laser cutting machine model before connecting it to your computer or network system. Next, adjust settings such as power levels and speed according to material specifications in order to achieve clean cuts without compromising quality.

Don’t forget about regularly updating software; manufacturers often release updates that improve functionality or fix bugs which can enhance overall performance of your cutting machine laser over time. Finally, consider utilizing design software compatible with fiber laser cutting machines—this integration allows seamless communication between design creation and execution stages while maximizing productivity!

Mastering the Operation of a Laser Machine

Operating a laser machine, particularly a no drawing laser cutting machine, can seem daunting at first. However, with the right knowledge and practice, you'll soon be cutting through materials like butter. This section will guide you through the essential steps to master your laser cutter and ensure optimal performance.

Step-by-Step Operating Guide

To start using your laser cutter machine effectively, follow these steps: First, ensure that your workspace is clean and free from any flammable materials since safety is paramount when working with cutting machinery. Next, power on the laser machine and configure your software settings; this typically involves selecting the material type and thickness to ensure precise cuts.

Once you've set up your parameters in the software, it's time to load your design file into the system. For no drawing laser cutting machines, this usually means uploading a vector file that contains all necessary cut paths. After double-checking everything from material placement to focus settings on the fiber laser cutting machine, hit that start button and watch as it transforms raw material into intricate designs!

Troubleshooting Common Issues

Even with high-quality laser machinery like fiber laser cutting machines, issues can arise during operation. One common problem is inconsistent cuts; if you notice this happening, check for proper alignment of both the material and lens focus. Dust or debris on the lens can also cause issues—clean it regularly for optimal performance.

Another frequent issue might be unexpected shut-downs or errors during operation—this could indicate overheating or power supply problems in your cutting machine laser. Always ensure that ventilation is adequate around your equipment to prevent overheating and refer to user manuals for specific error codes if they appear on-screen.

Lastly, if you're experiencing excessive smoke or burning marks on materials being cut by your no drawing laser cutting machine, it may be time to adjust speed settings or focus depth in your software configuration. These adjustments can help refine results and enhance overall efficiency.

Maintenance Tips for Longevity

To keep your laser cutter running smoothly over time requires regular maintenance; think of it as giving some TLC to your beloved piece of equipment! Start by routinely cleaning lenses and mirrors using appropriate cleaning solutions designed specifically for optical components—this ensures clarity during operation.

Additionally, inspect belts and rails regularly for wear; replacing worn parts promptly prevents larger issues down the line with precision in cuts from becoming compromised in future projects involving a cutting machine laser. Keeping an eye on coolant levels (if applicable) is also crucial since overheating can lead not only to performance dips but also damage internal components of fiber lasers over extended periods.

Finally, don't forget about software updates! Manufacturers often release patches that improve functionality or fix bugs within their systems—keeping yours updated ensures compatibility with new design files while maximizing efficiency across all tasks performed by your no drawing laser cutting machine.

Real-World Applications of Laser Machinery

Laser machinery has transformed various industries with its precision and versatility. From manufacturing to creative projects, the no drawing laser cutting machine has found its place as an indispensable tool. Let's explore how this technology is revolutionizing applications across different sectors.

Innovative Uses in Manufacturing

In manufacturing, the no drawing laser cutting machine is a game-changer, allowing for intricate designs that traditional methods simply can't achieve. These machines can cut through materials like metal, wood, and acrylic with remarkable speed and accuracy, making them ideal for mass production. Companies are increasingly turning to fiber laser cutting machines for their efficiency and ability to create complex shapes without the need for extensive tooling.

The adaptability of laser cutter machines means they can be used in various contexts—from automotive parts fabrication to electronics assembly. For instance, manufacturers can create custom components with minimal waste due to the precise nature of laser cutting technology. This not only enhances productivity but also contributes significantly to sustainability efforts within the industry.

Moreover, integrating a cutting machine laser into automated production lines streamlines operations even further. As industries continue to innovate and seek efficiency gains, it's clear that the role of laser machinery will only expand in scope and importance.

Creative Projects for Small Businesses

For small businesses looking to stand out in a competitive market, a laser cutter offers endless possibilities for creativity and customization. Entrepreneurs are leveraging no drawing laser cutting machines to produce unique items such as personalized gifts, bespoke signage, and intricate home décor pieces that captivate customers' attention. The ability to quickly prototype designs allows small business owners to experiment without significant upfront investment.

Additionally, these machines enable artisans to bring their visions to life with precision that was previously unattainable using traditional methods like hand-cutting or engraving. Whether crafting jewelry or creating custom packaging solutions, small businesses are finding innovative ways to utilize their laser cutter machines effectively. This not only enhances product offerings but also boosts brand identity through distinctive designs.

As more small business owners discover the potential of fiber laser cutting machines for creative projects, we can expect an influx of unique products hitting the market—each one showcasing the power of modern technology combined with artistic vision.

Case Studies of Success with Kiant Machinery

Kiant Machinery has been at the forefront of showcasing how effective a no drawing laser cutting machine can be across various applications. One notable case involved a furniture manufacturer that implemented a fiber laser cutting machine into its production line; they reported a 30% increase in output while maintaining superior quality standards thanks to reduced material waste during cuts.

Another success story comes from an artisan who utilized Kiant’s advanced technology for creating custom wedding invitations—a niche market where personalization is key. By employing a high-precision laser cutter machine, this entrepreneur could offer clients beautifully crafted invitations that were both intricate and unique—setting her apart from competitors who relied on standard printing methods.

These case studies highlight not just how versatile these machines are but also how investing in quality equipment like those from Kiant Machinery pays off in terms of efficiency and customer satisfaction across diverse sectors.

Conclusion

In conclusion, the world of laser cutting technology is evolving rapidly, and understanding how to maximize the potential of a no drawing laser cutting machine is essential for any business looking to enhance productivity. By integrating advanced laser cutter machinery into your operations, you can streamline processes, reduce waste, and achieve precision cuts that were previously unimaginable. Embracing these innovations not only boosts efficiency but also opens doors to creative applications across various industries.

Maximizing Efficiency with Laser Cutters

To truly harness the power of a laser cutter machine, it's vital to optimize its operation and workflow. Implementing best practices for using a cutting machine laser can significantly enhance production rates while ensuring high-quality outcomes. Regular training for operators on the latest techniques and software updates will further ensure that your fiber laser cutting machine performs at its peak efficiency.

Investing in Quality Laser Machinery

When it comes to investing in a laser machine, quality should never be compromised. The right no drawing laser cutting machine can be a game-changer for your business, offering durability and advanced features that cheaper alternatives simply can't match. By prioritizing reputable brands known for their reliable products and support services, you are setting your operation up for long-term success.

Future Trends in Laser Cutting Technology

The future of laser cutting technology promises exciting advancements that will redefine what’s possible with machinery like the fiber laser cutting machine. Innovations such as AI integration for smarter operation and enhanced automation capabilities are on the horizon, making these machines even more user-friendly and efficient. Staying informed about these trends will help businesses remain competitive in an ever-evolving market landscape.