Introduction

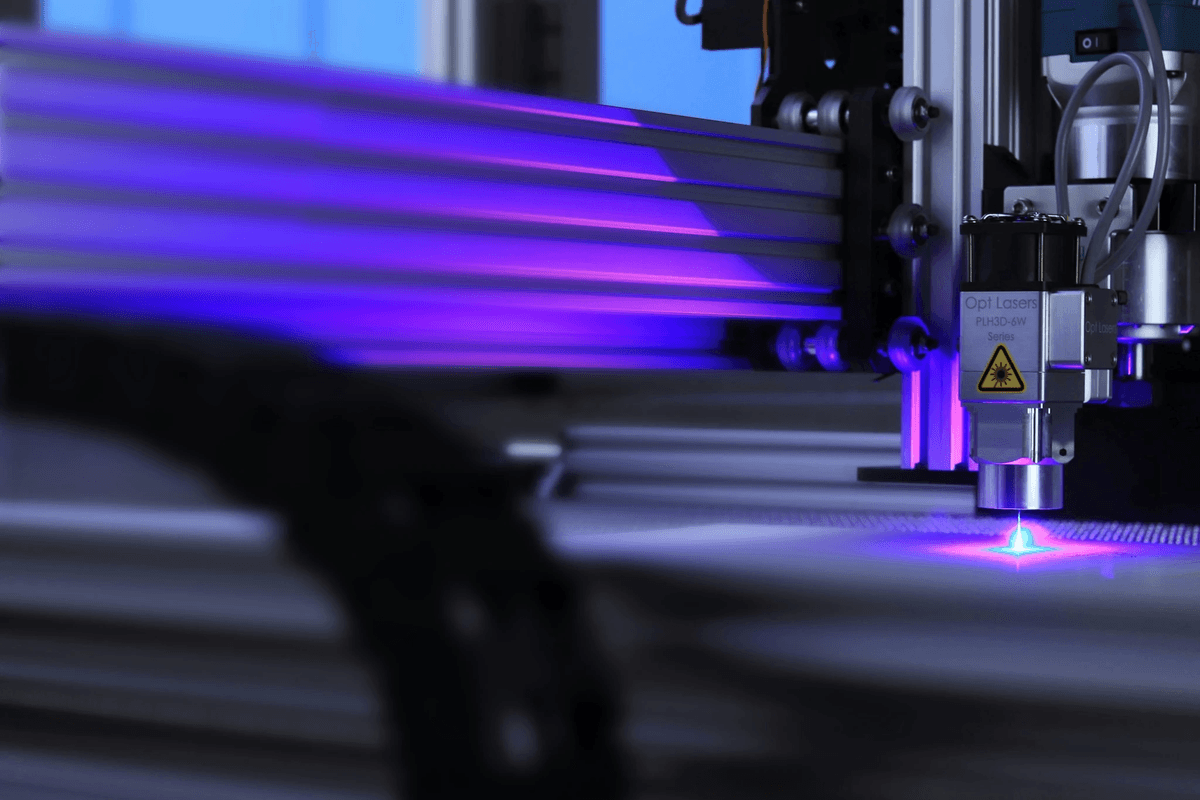

In the world of manufacturing and craftsmanship, laser cutter machines have emerged as game-changers, revolutionizing how materials are shaped and designed. These high-tech devices utilize focused beams of light to cut through various materials with remarkable precision. Whether it's a hobbyist creating intricate designs or a factory producing metal components, understanding the capabilities and features of a laser cutting machine for metal is essential.

Understanding Laser Cutter Machines

A laser cutter machine operates by directing a powerful laser beam onto the material being cut, effectively melting or vaporizing it along a predetermined path. This process not only ensures clean edges but also allows for complex shapes that traditional cutting methods struggle to achieve. With advancements in technology, today's metal cutting laser cutters can handle diverse materials, making them indispensable tools in workshops and production lines alike.

The Importance of Cutting Precision

A slight error in cutting can lead to wasted materials, increased costs, and delays in production timelines. Laser cutters excel at delivering unmatched accuracy; thus, investing in a reliable metal cutting machine laser can significantly enhance overall project outcomes.

Types of Laser Cutter Machines

There are several types of laser cutter machines available on the market today, each designed for specific applications and materials. CO2 lasers are popular for non-metal applications like wood and acrylics, while fiber lasers are preferred for their efficiency when working with metals—making them ideal choices for those seeking a dedicated laser cutter for metal projects. Additionally, some machines combine both technologies to offer versatility across various material types without sacrificing performance or precision.

Core Features of Laser Cutter Machines

Laser cutter machines have revolutionized the way materials are processed, offering unparalleled efficiency and versatility. Understanding the core features of these machines is essential for anyone looking to optimize their cutting tasks. From cutting speed and power to precision and material versatility, each aspect plays a crucial role in determining the effectiveness of a laser cutting machine for metal.

Cutting Speed and Power

The cutting speed and power of a laser cutter machine are fundamental characteristics that dictate its performance. High-powered lasers can slice through thick metals at impressive speeds, making them ideal for industrial applications where time is money. When considering a metal cutting laser cutter, it’s essential to evaluate both the wattage of the laser and its ability to maintain consistent speeds across various materials.

A powerful laser cutter for metal not only enhances productivity but also improves the quality of cuts made. Faster cutting speeds minimize heat exposure, reducing thermal distortion on sensitive materials. This results in cleaner edges and less post-processing work, making your workflow more efficient.

Precision and Accuracy

Laser cutting machines for metal achieve remarkable accuracy by focusing a high-energy beam on a specific point, allowing for tight tolerances that traditional methods struggle to match. This level of precision ensures that each cut meets exact specifications, which is crucial in sectors like aerospace or automotive manufacturing.

Moreover, advancements in technology have led to improved control systems within these machines, further enhancing their accuracy over time. With features such as computer numerical control (CNC), operators can execute complex patterns with ease while maintaining high levels of repeatability across multiple cuts. The result? A reliable metal cutting machine laser that consistently delivers exceptional results.

Versatility in Materials

One standout feature of modern laser cutters is their versatility in handling various materials beyond just metals. While they excel as a metal cutting machine laser, many models can also process wood, acrylics, fabrics, and composites seamlessly—making them invaluable assets across multiple industries. This adaptability allows businesses to expand their offerings without needing separate machines for different materials.

Additionally, different types of lasers (CO2 vs fiber) cater to specific material requirements; fiber lasers are particularly effective with reflective metals like copper or brass while CO2 lasers shine with non-metallic surfaces. This capability means you can invest in one robust laser cutter machine instead of juggling multiple devices tailored for specific jobs—saving both space and budget!

Advantages of Laser Cutter for Metal

These machines have transformed the way industries approach metal cutting, offering unparalleled efficiency and precision. With a metal cutting laser cutter, businesses can achieve results that were once thought impossible with traditional methods.

Efficient Metal Cutting Solutions

The efficiency of a laser cutting machine for metal is one of its standout features. Unlike conventional methods that may require multiple passes or extensive manual labor, a laser cutter machine can slice through various metals with remarkable speed and accuracy. This not only reduces production time but also allows for higher throughput, making it an ideal choice for businesses looking to maximize their output.

Moreover, the advanced technology behind these machines enables them to maintain consistent performance across different projects. Whether you're working with thin sheets or thicker plates, the metal cutting machine laser adapts seamlessly to the task at hand. As a result, companies can rely on these solutions to meet tight deadlines without sacrificing quality.

Minimal Material Waste

One of the most compelling reasons to invest in a laser cutter is its ability to minimize material waste significantly. Traditional cutting methods often result in excess scrap material due to imprecise cuts and larger kerf widths. In contrast, a metal cutting laser cutter produces narrow cuts that optimize material usage and reduce waste.

This efficiency not only saves money on raw materials but also contributes positively to environmental sustainability efforts within industries. By choosing a laser cutting machine for metal applications, businesses demonstrate their commitment to responsible manufacturing practices while improving their bottom line. The combination of precision and reduced waste makes these machines an intelligent investment for any operation focused on efficiency.

Intricate Design Capabilities

Intricate designs are where the true power of a laser cutter shines through! The flexibility offered by a laser cutting machine allows designers and engineers to create complex shapes and patterns that would be nearly impossible with other types of equipment. With precise control over beam focus and movement, this technology enables the creation of detailed engravings or cutouts in various metals without compromising structural integrity.

Additionally, this capability opens up new avenues for creativity in product design—think custom signage or artistic installations made from metals like stainless steel or aluminum! The versatility provided by modern metal cutting machines means that artists and manufacturers alike can push boundaries previously thought unattainable in their projects. Ultimately, investing in a high-quality laser cutter machine empowers users with endless possibilities in design innovation.

Comparing Metal Cutting Machines

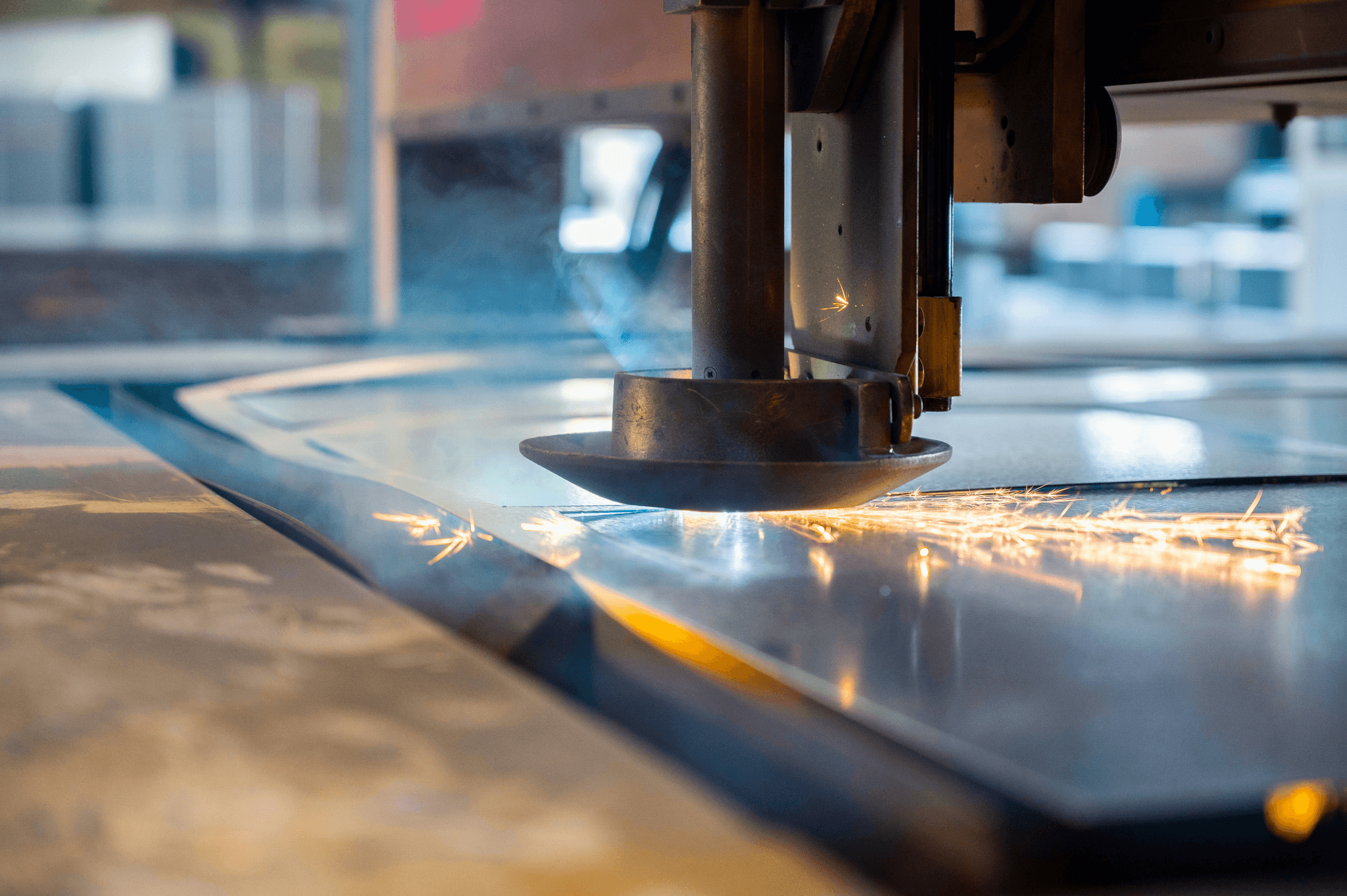

In the world of metal fabrication, choosing the right cutting technology is crucial. Two popular contenders are the laser cutter machine and plasma cutting machines, each with its own strengths and weaknesses. Understanding these differences can help you make an informed decision for your specific needs.

Laser vs. Plasma Cutting Machines

Utilizing focused beams of light, a metal cutting laser cutter delivers clean edges and intricate designs that plasma cutting simply can't match. While plasma cutting machines excel in speed for thicker materials, they often leave rougher edges that require additional finishing work—something that can slow down production timelines.

Laser cutting machines for metal also offer greater versatility in terms of material thickness and types. They can handle everything from thin sheets to thicker plates with remarkable accuracy, making them ideal for various applications in industries like automotive and aerospace. In contrast, plasma cutters are typically limited by their inability to achieve similar precision on thinner materials or delicate designs.

Ultimately, if you're looking for a solution that combines speed with exceptional detail, a laser cutter machine is your best bet. However, if you're working primarily with very thick metals and need quick cuts without much concern for edge quality, plasma might be worth considering.

Cost-Effectiveness of Laser Cutting

While the initial investment in a metal cutting machine laser may seem higher than other options like plasma cutters, it's essential to consider long-term savings when evaluating cost-effectiveness. The efficiency of a laser cutter allows it to operate at lower power levels while maintaining high-quality cuts; this translates into lower energy costs over time compared to its counterparts. Moreover, due to minimal material waste generated during the process—thanks to precise cuts—you'll find yourself saving money on raw materials as well.

Additionally, maintenance costs tend to be lower with laser cutting machines since they have fewer moving parts than traditional mechanical cutters or even plasma systems. This reliability means less downtime in your operations and ultimately contributes to better profit margins over time. Therefore, investing in a quality laser cutter can lead not just to immediate savings but also long-term financial benefits.

In summary, while upfront costs may appear daunting when choosing a laser cutter for metal applications, smart operators recognize that efficiency and reduced waste lead directly to cost savings down the line—making them an economically savvy choice overall.

Long-Term Durability

Durability is another significant factor when comparing metal cutting machines; here again, the advantages lean toward the laser cutter machine side of things. These advanced machines are engineered using robust components designed specifically for high-performance environments—ensuring they withstand rigorous daily use without compromising on quality or precision over time.

On top of this durability factor lies their ability to maintain consistent performance levels throughout their lifespan; unlike some plasma systems which may degrade faster due to wear-and-tear from high temperatures involved in operation processes—laser cutters remain reliable from day one until retirement! This longevity not only enhances productivity but also reduces replacement frequency—a win-win situation!

Investing in a durable laser cutting machine offers peace of mind knowing you'll have dependable equipment at your disposal for years ahead—a crucial consideration whether you're running a small workshop or managing large-scale industrial operations.

Selecting the Right Laser Cutting Machine

Choosing the right laser cutting machine can feel like finding a needle in a haystack, especially with so many options available. Whether you're looking for a laser cutter for metal or a versatile machine that can handle various materials, it's essential to assess your specific needs first. This decision will not only impact your workflow but also define the quality of your projects.

Assessing Your Specific Needs

Before diving into the world of metal cutting laser cutters, take a moment to evaluate what you truly need from your equipment. Are you primarily focusing on intricate designs, or do you require high-speed cuts for bulk production? Understanding these requirements will narrow down your choices and help you find the perfect laser cutting machine for metal that aligns with your operational goals.

Additionally, consider the types of materials you'll be working with—some machines excel at cutting thicker metals while others are better suited for lighter materials. If you're venturing into diverse applications, look for a versatile laser cutter that can adapt to various tasks without compromising on quality. Remember, selecting the right equipment is an investment in efficiency and productivity.

Brand Reliability: Kiant Machinery

When it comes to investing in a laser cutter machine, brand reliability should be at the forefront of your decision-making process. Kiant Machinery has built a solid reputation in the industry known for producing high-quality metal cutting machines that stand the test of time. Their commitment to innovation and customer satisfaction makes them an excellent choice for anyone seeking a dependable laser cutting solution.

Moreover, Kiant Machinery offers robust support and maintenance services, ensuring that users get maximum value from their investment over time. With numerous positive reviews from satisfied customers highlighting their experiences with Kiant products, it's clear this brand prioritizes quality and performance in every model they produce. Choosing a trusted brand like Kiant Machinery can provide peace of mind as you navigate through your metal cutting projects.

Key Specifications to Consider

When selecting a metal cutting machine laser, certain specifications should top your checklist to ensure optimal performance and results. Pay attention to factors such as wattage; higher wattage typically means faster cutting speeds and greater material thickness capabilities—which is crucial when working with tougher metals! Additionally, consider the bed size; larger beds allow for bigger projects without needing multiple setups.

Another important aspect is precision—look for features like advanced optics or motion control systems that enhance accuracy during cuts. Don't forget about software compatibility; many modern laser cutters come equipped with user-friendly interfaces or integration options that streamline design processes significantly. By keeping these key specifications in mind while searching for your ideal laser cutter machine, you'll be well-equipped to make an informed decision.

Maintenance Tips for Laser Cutting Machines

Maintaining your laser cutter machine is crucial for ensuring its longevity and optimal performance. Regular upkeep not only maximizes efficiency but also helps prevent costly repairs down the line. Here are some essential maintenance tips tailored specifically for your metal cutting laser cutter.

Routine Maintenance Practices

Routine maintenance practices are key to keeping your laser cutting machine in peak condition. Start by regularly cleaning the optics, as dust and debris can significantly affect the cutting quality of your metal cutting machine laser. Additionally, check the alignment and focus of the laser beam; a misaligned beam can lead to poor cuts and increased wear on components.

Another vital practice is to inspect and replace worn-out parts, such as lenses and mirrors, on a regular basis. These components play a critical role in directing the laser beam effectively, so maintaining them ensures precision in every cut made by your laser cutter for metal. Lastly, keep an eye on the cooling system; overheating can lead to serious damage, so ensure that it’s functioning properly at all times.

Troubleshooting Common Issues

Even with diligent maintenance, issues may arise with your metal cutting laser cutter from time to time. One common problem is inconsistent cutting depth or quality; this could be due to a dirty lens or misalignment of the optics. If you notice this happening, take a moment to clean all optical elements thoroughly before recalibrating your machine.

Another frequent issue is unexpected shutdowns during operation; these can often be traced back to overheating or electrical faults within the system. If you encounter this problem, check both cooling systems and electrical connections before proceeding with any further troubleshooting steps on your laser cutting machine for metal. Remember that addressing these issues promptly will save you time and money in repairs later on.

Professional Servicing Advice

While routine maintenance can be performed by most users of a laser cutter machine, there are times when professional servicing becomes necessary. It’s advisable to schedule annual inspections with certified technicians who specialize in metal cutting machines lasers; they possess the expertise needed to identify potential problems before they escalate into major issues.

During these professional evaluations, technicians will not only perform thorough inspections but also provide valuable insights into optimizing your equipment's performance based on current technological advancements in laser technology. Investing in professional servicing ensures that your investment remains productive over its lifespan while minimizing downtime due to unforeseen complications.

Conclusion

In the ever-evolving world of manufacturing and design, laser cutter machines have emerged as indispensable tools for achieving cutting precision and efficiency. By harnessing the power of a metal cutting laser cutter, businesses can enhance their production capabilities while minimizing waste. As we look to the future, investing in a quality laser cutting machine for metal will undoubtedly pay off through improved productivity and innovative designs.

Maximizing Efficiency with Laser Cutters

To truly maximize efficiency with a laser cutter, it’s essential to understand its core features and how they align with your specific needs. The speed and power of a metal cutting machine laser can drastically reduce production time while maintaining high-quality results. Additionally, leveraging the versatility of a laser cutter for metal allows users to tackle various materials without compromising on precision.

The Future of Laser Cutting Technology

The future of laser cutting technology promises exciting advancements that will further revolutionize the manufacturing landscape. Innovations such as improved software integration and enhanced automation capabilities will enable even greater precision in designs and cuts. With ongoing research into more energy-efficient lasers and eco-friendly materials, the next generation of laser cutters is set to redefine industry standards.

Investing in Quality Laser Cutting Solutions

When it comes to investing in a reliable laser cutter machine, quality should never be compromised. Opting for reputable brands like Kiant Machinery ensures that you receive not only superior performance but also long-term durability from your metal cutting laser cutter. Ultimately, making an informed decision about which laser cutting machine for metal suits your needs can lead to significant gains in operational efficiency and creative potential.