Introduction

In the realm of modern manufacturing, the tube laser cutting machine stands out as a revolutionary tool that has transformed how we approach metal fabrication. This advanced piece of equipment utilizes laser technology to deliver unparalleled precision and efficiency, making it an essential asset for industries ranging from automotive to aerospace. With its ability to cut through various materials with ease, the machine metal cutter has become synonymous with innovation in metal processing.

Overview of Tube Laser Technology

Tube laser technology employs high-powered lasers to slice through tubular materials with extreme accuracy, resulting in clean cuts and intricate designs. Unlike traditional cutting methods that may leave rough edges or require additional finishing work, laser cutting ensures a smooth finish right off the machine. This technology not only enhances productivity but also minimizes waste, making it a sustainable choice for manufacturers looking to optimize their operations.

Benefits of Using a Tube Laser Cutting Machine

The benefits of using a tube laser cutting machine are numerous and compelling. First and foremost, these machines offer unmatched precision; even complex geometries can be achieved without compromising on quality. Additionally, they provide versatility in handling various types of metals—whether it's steel, aluminum, or brass—making them ideal for diverse applications across different sectors.

Key Features of a Laser Cutting Machine

A quality laser cutting machine is equipped with several key features that enhance its functionality and user experience. High-speed cutting capabilities allow for rapid production runs without sacrificing accuracy, while advanced software integration simplifies design modifications and programming tasks. Moreover, features such as automated loading systems and real-time monitoring contribute to increased efficiency in the manufacturing process.

What is a Tube Laser Cutting Machine?

A tube laser cutting machine is a specialized device designed for precision cutting of tubular materials using advanced laser technology. This metal machine cutter employs high-powered lasers to achieve intricate designs and shapes with minimal waste, making it an essential tool in modern manufacturing. With its ability to cut through various metals, the tube laser cutting machine has revolutionized the way industries approach metal fabrication.

Definition and Functionality

At its core, a tube laser cutting machine combines advanced optics and computer-controlled movements to deliver precise cuts on cylindrical or rectangular tubes. Unlike traditional methods, this machine metal cutter uses focused laser beams that melt or vaporize the material along the desired path. The result? Clean edges and reduced need for secondary finishing processes, allowing manufacturers to save time and resources.

The functionality of a laser cutting machine extends beyond mere cutting; it can also engrave or mark surfaces with exceptional detail. This versatility makes it an invaluable asset in industries ranging from automotive to furniture design. By utilizing CNC (Computer Numerical Control) technology, operators can program complex designs that would be nearly impossible to achieve with conventional tools.

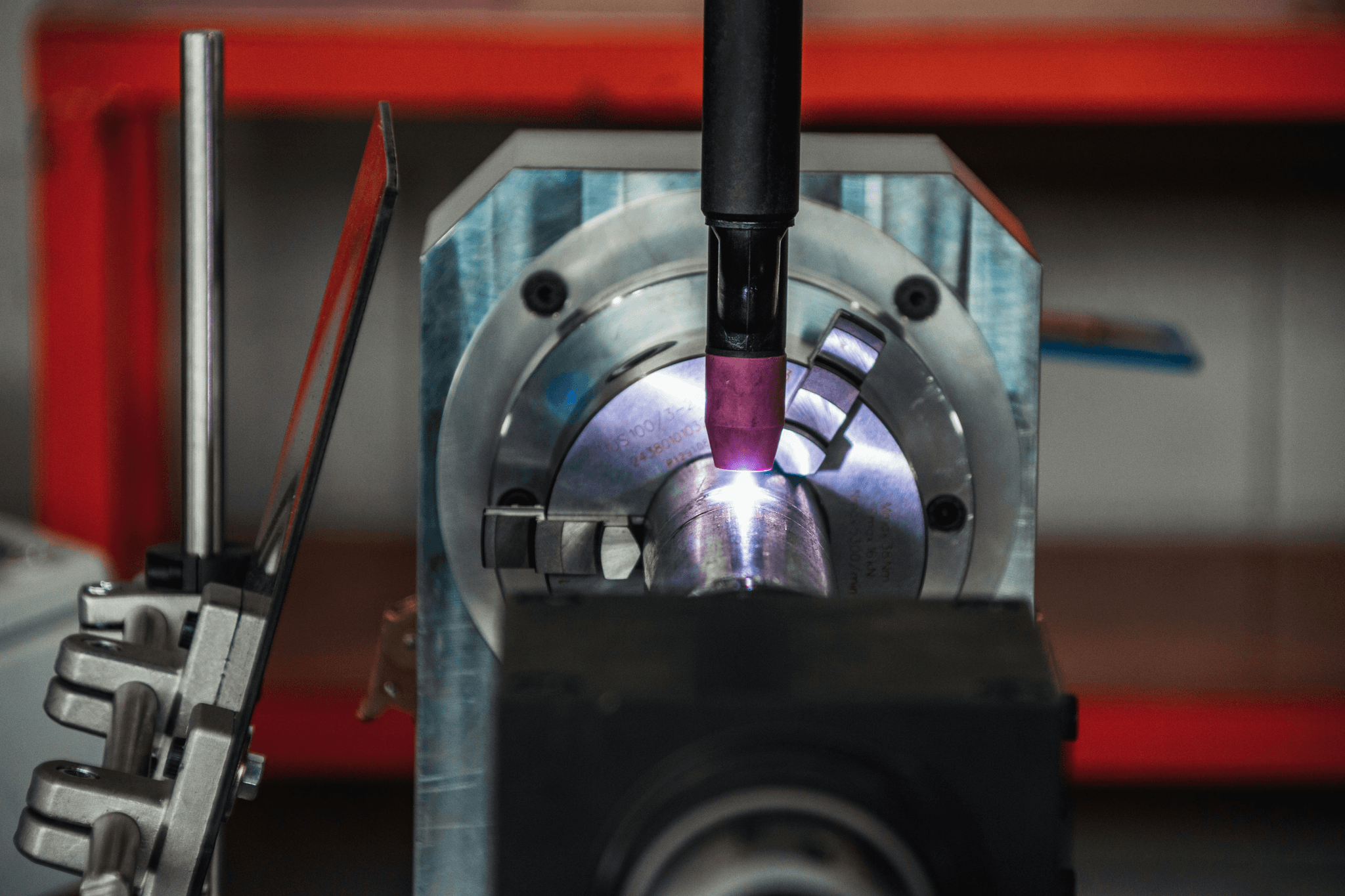

How It Works: The Technology Behind It

The technology behind a tube laser cutting machine involves several key components working harmoniously together. First, a high-powered CO2 or fiber laser generates intense light energy that is focused through lenses onto the material surface at high speeds. This concentrated energy heats the metal until it reaches its melting point, allowing for clean cuts without excessive force.

In addition to the laser source, sophisticated software controls the motion of the cutting head along predetermined paths based on CAD designs. As the cutting machine moves, assist gases like oxygen or nitrogen may be employed to further enhance cut quality by blowing away molten material and preventing oxidation. The combination of these elements ensures that each cut is executed with remarkable precision.

Comparison with Traditional Metal Cutting Methods

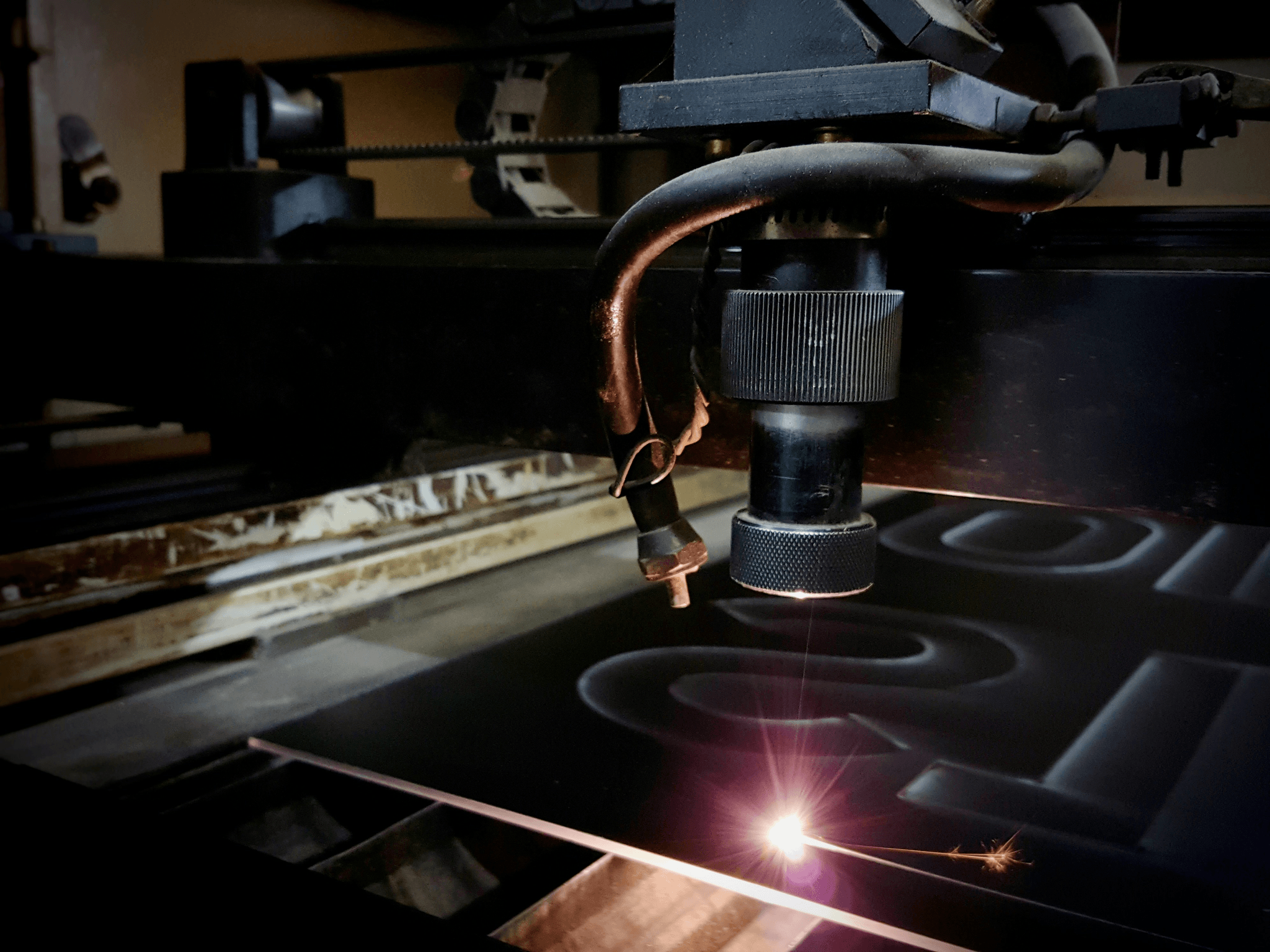

When comparing tube laser cutting machines with traditional metal cutting methods such as saws or plasma cutters, it's clear why many manufacturers are making the switch. Traditional methods often produce rough edges requiring extensive finishing work—something that can significantly increase production time and costs. In contrast, a metal cutting machine laser provides smooth cuts right off the bat.

Moreover, traditional methods typically struggle with complex geometries and intricate designs due to their reliance on physical blades or bits that can wear down quickly over time. A cutting machine laser overcomes these limitations by utilizing beams of light that remain consistent in performance without wear-related degradation. This not only enhances efficiency but also expands creative possibilities for designers looking to push boundaries in their projects.

Advantages of Laser Cutting in Metal Manufacturing

When it comes to the world of metal manufacturing, laser cutting technology stands out as a game changer. The tube laser cutting machine has revolutionized how industries approach metal cutting, offering unmatched precision and efficiency. Let's dive into the key advantages that make laser cutting a preferred choice for many manufacturers.

Precision and Accuracy in Cuts

One of the standout features of a laser cutting machine is its unparalleled precision. Unlike traditional methods, which can produce jagged edges or require extensive finishing work, a machine metal cutter powered by lasers delivers clean, sharp cuts every time. This accuracy minimizes material waste and ensures that components fit together perfectly, which is vital in industries where tolerances are tight.

The technology behind laser cutting allows for intricate designs that would be nearly impossible with conventional metal cutting methods. Whether you’re working with simple shapes or complex geometries, the tube laser cutting machine can handle it all without compromising on quality. This level of precision not only enhances product quality but also boosts production efficiency by reducing rework and scrap rates.

Versatility in Material Types

Another significant advantage of using a metal cutting machine laser is its versatility across various materials. From stainless steel to aluminum and even plastics, the capabilities of a laser cutting machine are broad enough to accommodate diverse manufacturing needs. This flexibility allows businesses to expand their offerings without investing in multiple machines for different materials.

Moreover, the ability to cut through various thicknesses adds another layer of versatility that traditional methods simply cannot match. With advancements in laser machinery technology, manufacturers can now achieve excellent results with thicker materials while still maintaining high-quality cuts on thinner sheets. This adaptability makes the tube laser cutting machine an invaluable asset for companies looking to diversify their production lines.

Speed and Efficiency in Production

In today’s fast-paced manufacturing environment, speed is essential—and this is where a cutting machine laser truly shines. The rapid processing capabilities of a tube laser cutting machine mean that projects can be completed much faster than with traditional methods like plasma or mechanical cutters. This increased speed translates directly into higher throughput and improved delivery times for customers.

Furthermore, the automation involved in modern laser systems reduces labor costs and human error significantly while increasing operational efficiency. Operators can focus on other tasks instead of monitoring lengthy manual processes since most functions are programmable and require minimal supervision once set up correctly. As such, businesses leveraging these advanced technologies find themselves more competitive than ever before.

Applications of Tube Laser Cutting Machines

Tube laser cutting machines have revolutionized various industries, offering unparalleled precision and efficiency. From automotive to aerospace, these machines are integral in shaping the future of metal manufacturing. Their versatility allows for a wide range of applications, making them a staple in modern production lines.

Industries That Benefit Most

Several industries reap significant benefits from the use of tube laser cutting machines. The automotive sector, for instance, relies on precise cuts for components like exhaust systems and chassis parts, ensuring safety and performance. Similarly, the construction industry utilizes these metal cutting machine lasers for fabricating structural elements that require exact specifications to meet regulatory standards.

Another industry that thrives on laser cutting technology is the aerospace sector, where lightweight and strong components are critical. Here, precision is not just preferred; it’s essential for ensuring safety at high altitudes and speeds. Additionally, furniture manufacturing has seen a surge in creativity thanks to the flexibility offered by machine metal cutters that can handle intricate designs with ease.

Specific Use Cases in Manufacturing

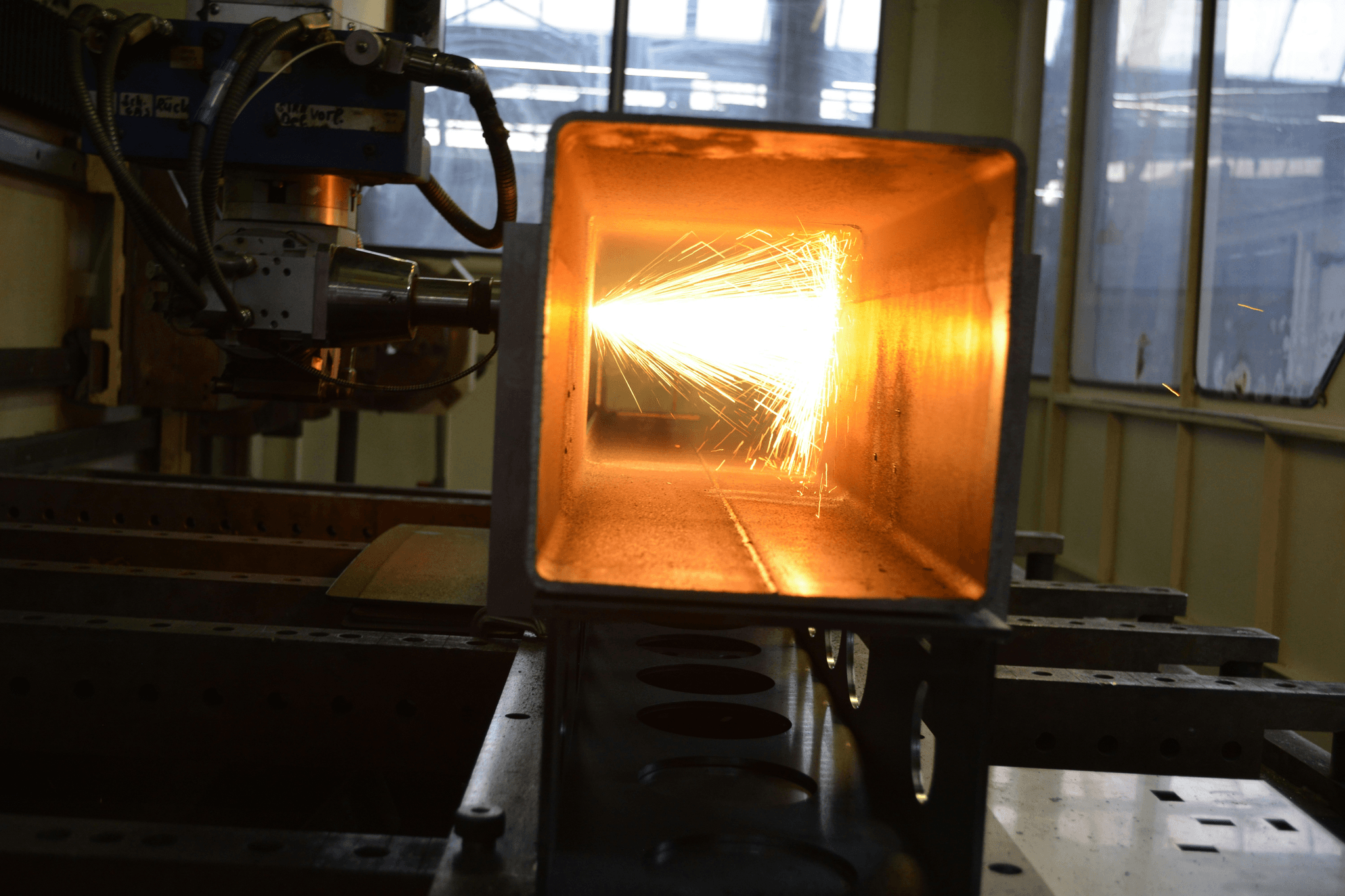

In manufacturing settings, tube laser cutting machines serve a multitude of specific purposes that enhance productivity. For example, they are commonly used to create complex geometries in tubing for HVAC systems or medical devices where accuracy is paramount. The ability to cut multiple tubes simultaneously increases throughput while maintaining high-quality standards.

Moreover, businesses involved in creating signage find immense value in laser cutting technology as it allows for detailed designs that stand out visually without sacrificing durability. Customization has become easier than ever; companies can produce unique pieces tailored specifically to client needs with minimal lead time using advanced laser machinery. This adaptability makes tube laser cutting machines indispensable across various manufacturing processes.

Innovations Driven by Laser Technology

The advent of tube laser cutting technology has sparked numerous innovations within the metalworking field. One notable advancement is the integration of automation with machine metal cutters which enhances operational efficiency while reducing human error significantly. Automated loading and unloading systems allow manufacturers to run their operations continuously without interruptions.

Additionally, software advancements accompanying these lasers enable real-time monitoring and adjustments during the cutting process—ensuring optimal performance at all times while minimizing waste material generated during production runs. The ongoing development of fiber lasers further pushes boundaries by providing greater energy efficiency and faster processing speeds compared to traditional CO2 lasers.

As industries continue embracing these innovations driven by laser technology, we can expect even more groundbreaking applications that redefine what’s possible in metal fabrication and design.

Selecting the Right Laser Cutting Machine

Choosing the right laser cutting machine can feel like searching for a needle in a haystack, especially with the multitude of options available. A tube laser cutting machine is an investment that can significantly enhance your metal manufacturing capabilities, so understanding what to look for is crucial. Factors such as size, power, and intended applications will guide you in making an informed decision that meets your specific needs.

Factors to Consider: Size and Power

When selecting a tube laser cutting machine, size and power are paramount considerations. The size of the machine should align with your workspace and the dimensions of the materials you'll be cutting; larger machines offer more versatility but require more floor space. Power is equally important: higher wattage means faster cutting speeds and better performance on thicker materials, making it essential for efficient production in any metal cutting operation.

Additionally, consider whether you need a fiber or CO2 laser; fiber lasers tend to be more efficient for metals due to their wavelength properties. The type of metal you'll be working with also influences your choice—different machines excel at cutting various materials like stainless steel or aluminum. Ultimately, striking a balance between size and power will ensure you have a capable machine metal cutter that fits seamlessly into your manufacturing process.

Leading Brands in Laser Machinery

The market is brimming with reputable brands specializing in laser machinery, each offering unique features tailored to different industries. Some leading names include Trumpf, Bystronic, and Mazak; these companies have established themselves as pioneers in innovative laser technology while providing robust support systems for their customers. Investing in a well-known brand often translates to reliability and enhanced performance from your metal cutting machine laser.

Another noteworthy mention is Amada, which has made significant strides in developing user-friendly interfaces alongside powerful machinery designed specifically for tube laser applications. These brands not only produce high-quality equipment but also provide extensive training resources to help users get the most out of their machines. When choosing among these top-tier manufacturers, consider factors such as customer service reputation and warranty offerings—they can make all the difference when you're operating a complex piece of equipment like a laser cutting machine.

Kiant Machinery's Role in the Market

Kiant Machinery has carved out its niche within the competitive landscape of laser machinery by focusing on quality and affordability without compromising performance. Known for their advanced tube laser cutting machines, Kiant offers solutions that cater specifically to small- to medium-sized enterprises looking to enhance their production capabilities without breaking the bank. Their commitment to innovation ensures that customers receive state-of-the-art features tailored for precision metal work.

Moreover, Kiant Machinery provides excellent customer support—from installation assistance to regular maintenance tips—ensuring that users get maximum uptime from their machines while minimizing operational headaches associated with troubleshooting common issues. With an emphasis on training programs designed around best practices for operating their equipment effectively, they empower businesses to fully leverage their metal machine cutters' capabilities over time. As industries continue evolving toward automation and efficiency, Kiant's role becomes increasingly vital as they help shape the future landscape of metal fabrication through advanced technology solutions.

Maintenance and Support for Laser Machines

When it comes to keeping your tube laser cutting machine in top shape, maintenance is key. Regular upkeep not only extends the life of your laser cutting machine but also ensures optimal performance during metal cutting tasks. By following a few simple care tips, you can avoid costly repairs and downtime.

Routine Care Tips for Longevity

To achieve longevity from your metal cutting machine laser, make routine inspections a habit. Check for any debris buildup around the cutting area and ensure that all components are clean and free of obstructions. Additionally, regularly lubricating moving parts will keep your machine metal cutter running smoothly and reduce wear over time.

Another essential tip is to monitor the alignment of your laser beam; even minor misalignments can lead to poor cuts and increased material waste. Keep an eye on the cooling system as well, as overheating can significantly impact the efficiency of your tube laser cutting machine. Lastly, always refer to the manufacturer’s guidelines for specific maintenance schedules tailored to your particular model.

Troubleshooting Common Issues

Even with diligent care, issues may arise with your laser cutting machinery from time to time. One common problem is inconsistent cut quality; this could be due to worn-out optics or improper settings on the machine metal cutter. If you notice irregularities in your cuts, check these components first before seeking professional help.

Another frequent issue involves software glitches that can affect the performance of a cutting machine laser. Ensure that all software updates are applied promptly and consider rebooting the system if errors occur frequently during operation. If problems persist despite troubleshooting efforts, contacting technical support from leading brands may save you time and trouble.

The Importance of Professional Training

While basic maintenance can be handled by operators, professional training is crucial for maximizing the effectiveness of any tube laser cutting machine. Trained personnel understand not only how to operate machinery safely but also how to troubleshoot more complex issues that may arise during operation or setup phases. Investing in training ensures that everyone using the metal machinery is familiar with best practices.

Moreover, professional training provides insights into advanced techniques that enhance productivity and efficiency in metal manufacturing processes using lasers. This knowledge ultimately leads to better cut quality and reduced material waste—benefits every manufacturer seeks! So don’t overlook this aspect; it’s an investment in both safety and operational excellence.

Conclusion

In the ever-evolving landscape of manufacturing, tube laser cutting technology stands as a beacon of innovation and efficiency. The advancements in laser machinery not only enhance precision but also redefine the possibilities of metal fabrication. As we look to the future, it's clear that these machines will continue to play a crucial role in shaping industries worldwide.

Future Trends in Tube Laser Technology

The future of tube laser cutting machines is poised for exciting developments, including increased automation and integration with AI systems. These enhancements promise to streamline operations further, allowing for real-time adjustments and improved accuracy in metal cutting processes. Additionally, innovations like fiber laser technology are expected to revolutionize how we approach material types and thicknesses, making the machine metal cutter more versatile than ever.

Cost-Effectiveness of Laser Cutting Solutions

When it comes to evaluating the cost-effectiveness of laser cutting solutions, one must consider both initial investment and long-term savings. While a high-quality laser cutting machine may require a significant upfront expenditure, its efficiency leads to reduced waste and lower operational costs over time. Furthermore, the speed at which a metal machine cutter operates means quicker turnaround times—translating into enhanced productivity that can significantly boost your bottom line.

How Kiant Machinery Enhances Metal Cutting Efficiency

Kiant Machinery has positioned itself as a leader in providing advanced tube laser cutting machines tailored for various manufacturing needs. Their commitment to quality ensures that each machine metal cutter is designed for optimal performance while maintaining ease of use and reliability. By offering comprehensive support and maintenance services alongside their innovative products, Kiant Machinery enhances overall metal cutting efficiency—making them an invaluable partner in any modern workshop.