Introduction

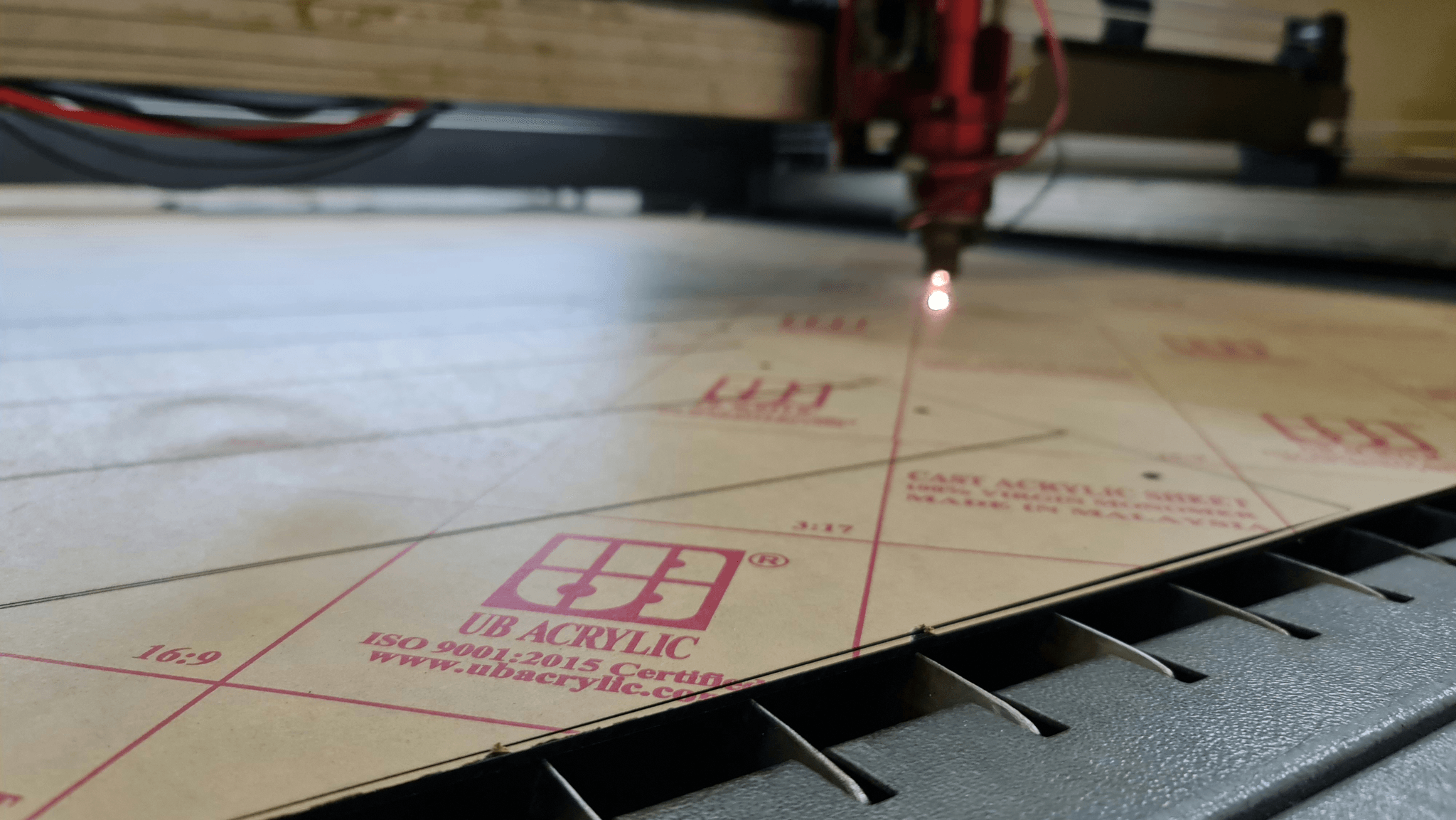

In today's fast-paced manufacturing landscape, the use of a laser cut machine has revolutionized the way we approach precision cutting and engraving. With advancements in technology, these machines offer unparalleled benefits that enhance productivity and quality across various industries. Whether you're looking to create intricate designs or streamline your production process, understanding the advantages of laser machinery is essential.

Discover the Benefits of Laser Cutting

Laser cutting is not just about making clean cuts; it's about efficiency and versatility. A laser cutter can handle a wide range of materials, from wood to metal, allowing businesses to explore new creative avenues without changing equipment. Additionally, the precision offered by a laser etching machine minimizes waste and maximizes output, making it a smart investment for any operation.

Key Features of Laser Cut Machines

When considering a cutting machine laser, it's vital to recognize its key features that set it apart from traditional methods. High-speed operation, automated settings, and customizable options are just a few characteristics that enhance usability and performance. Furthermore, modern laser and engraving machines often come equipped with user-friendly interfaces that make them accessible even for those new to this technology.

Understanding Laser Machinery Types

The world of laser machinery is diverse, encompassing various types tailored for specific applications. From industrial-grade systems designed for heavy-duty tasks to compact models suitable for small workshops, there's a solution for every need. By familiarizing yourself with these different types of machines—such as those focused on precise engraving or high-volume cutting—you can make informed decisions that align with your business goals.

Precision and Accuracy

A laser cut machine can achieve levels of accuracy that traditional cutting methods simply cannot match. This precision not only enhances the aesthetic quality of the finished product but also ensures that parts fit together perfectly, reducing waste and rework.

Importance of Precision in Laser Cutting

Precision in laser cutting is crucial for a variety of applications, from intricate designs to industrial components. The ability to create exact shapes and sizes means that manufacturers can produce high-quality products with minimal error margins. For industries like aerospace or automotive, where every millimeter counts, a laser cutter becomes indispensable.

Moreover, precise cuts lead to better material utilization, which translates into cost savings for businesses. When using a cutting machine laser, the accuracy minimizes scrap material and maximizes efficiency throughout the production process. Ultimately, investing in a reliable laser etching machine pays off by ensuring consistent results and maintaining high standards.

How Laser Cut Machines Achieve Accuracy

Laser cut machines utilize advanced technology to achieve their remarkable precision. These machines employ focused beams of light that are finely tuned to cut through various materials with extreme accuracy. The combination of computer numerical control (CNC) technology and sophisticated optics allows for detailed designs that would be difficult or impossible with traditional methods.

Additionally, many modern laser and engraving machines come equipped with features such as autofocus systems and real-time monitoring capabilities. These innovations ensure that the beam remains centered on the material throughout the cutting process, greatly enhancing overall accuracy. With such advancements in laser machinery, users can expect consistent results regardless of project complexity.

Comparing Laser Cutters to Traditional Methods

When comparing a laser cutter to traditional cutting methods like saws or blades, it's clear who comes out on top in terms of precision. Traditional tools often rely on manual adjustments and physical contact with materials, which can lead to human error and inconsistencies over time. In contrast, a machine laser engraving system operates autonomously based on pre-programmed specifications.

Moreover, while traditional methods may require multiple passes or adjustments for complex shapes or intricate designs, a cutting machine laser can handle these tasks in one go without compromising quality or speed. This not only saves time but also reduces labor costs associated with manual setups and corrections. As industries evolve toward automation and precision engineering, it's evident that relying on advanced technologies like laser cutters is key for staying competitive.

Speed and Efficiency

In the fast-paced world of manufacturing, speed and efficiency are paramount. The laser cut machine stands out as a champion in this arena, delivering rapid results without compromising quality. With advancements in technology, a laser cutter can execute intricate designs at lightning speed, streamlining production processes across various industries.

Fast Operation of Laser Machines

One of the most impressive features of laser machinery is its ability to operate at remarkable speeds. Unlike traditional cutting methods that may require multiple passes or slow setups, a cutting machine laser can slice through materials with precision in a single pass. This not only accelerates production but also reduces the wear and tear on tools, ensuring longevity for your equipment.

Optimizing Production Time with a Laser Cutter

To truly harness the potential of a laser cutter, it's essential to optimize production workflows effectively. By integrating software designed for laser and engraving machines, operators can schedule jobs efficiently and minimize downtime between tasks. Additionally, utilizing features like automatic material feeding allows for uninterrupted operation—maximizing output while keeping labor costs in check.

Case Studies of High-Speed Laser Cutting

Several companies have successfully showcased the benefits of high-speed laser cutting through innovative applications. For instance, one manufacturer utilized a laser etching machine to produce intricate signage at record speeds, reducing their average turnaround time by 50%. Another case involved an automotive parts supplier that implemented machine laser engraving techniques to enhance their production line efficiency—resulting in significant cost savings while maintaining superior quality standards.

Versatility in Materials

When it comes to versatility, laser cut machines are the Swiss Army knives of the manufacturing world. These machines can handle a wide array of materials, making them indispensable for various industries. Whether you’re working with wood, acrylic, metal, or textiles, a laser cutter can deliver precise cuts and intricate designs that might otherwise be impossible.

Materials Compatible with Laser Cut Machines

Laser cut machines are compatible with an impressive range of materials. From soft woods like pine and plywood to hard metals such as aluminum and stainless steel, the adaptability of cutting machine lasers is remarkable. Additionally, they can effortlessly work with plastics and fabrics, opening doors to creative possibilities in fashion design and product prototyping.

The ability to process various materials means that businesses can diversify their offerings without investing in multiple types of equipment. This versatility not only saves time but also reduces costs associated with material handling and production processes. As a result, many manufacturers are turning to laser machinery for its unmatched flexibility.

The Role of a Laser Etching Machine

A laser etching machine plays a pivotal role in adding detailed markings or designs onto surfaces without cutting through the material entirely. Unlike traditional engraving methods that may require physical tools or chemicals, machine laser engraving uses focused light beams for precision work on various substrates. This method is not only cleaner but also allows for intricate designs that stand out beautifully.

Laser etching is particularly popular for creating personalized items such as trophies or custom signage since it offers high accuracy while minimizing waste material. Moreover, the speed at which these machines operate ensures that businesses can meet tight deadlines without sacrificing quality. The combination of efficiency and creativity makes laser etching machines an essential tool in today’s manufacturing landscape.

Unique Applications in Different Industries

The unique applications of laser cut machines span across numerous industries—from automotive to fashion design—each benefiting from their capabilities in distinct ways. In the automotive sector, precision cuts allow for lightweight components that enhance fuel efficiency while maintaining structural integrity. Meanwhile, fashion designers use laser cutters to create intricate patterns on fabrics that add flair without compromising durability.

In addition to these applications, industries like architecture benefit from accurate models created using cutting machine lasers; they help visualize projects before construction begins. Furthermore, electronics companies utilize laser engraving techniques for branding purposes on circuit boards and casings—showcasing another layer of versatility found within this technology. With endless possibilities across various sectors, it's clear why investing in advanced laser machinery is becoming increasingly popular.

User-Friendly Interfaces

In the world of laser cutting, user-friendly interfaces can make a significant difference in productivity and creativity. A laser cut machine equipped with intuitive controls allows operators to focus on their craft rather than getting bogged down by complicated settings. This ease of use not only enhances workflow but also minimizes errors, ensuring that each project is executed flawlessly.

Importance of Easy-to-Use Controls

When operating a cutting machine laser, simplicity is key. Easy-to-use controls enable both seasoned professionals and newcomers to navigate the intricacies of laser technology without feeling overwhelmed. With straightforward interfaces, users can quickly adjust settings for different materials or designs, making the process more efficient and enjoyable.

Exploring Software for Laser and Engraving Machines

The software that accompanies a laser etching machine plays a crucial role in its functionality. Modern laser and engraving machines often come with sophisticated software that simplifies design input and project management. From vector graphics to 3D modeling capabilities, these tools empower users to unleash their creativity while ensuring precision in every cut.

Support and Training from Kiant Machinery

Kiant Machinery understands that investing in a laser cutter involves more than just purchasing equipment; it’s about ongoing support and education as well. Their dedicated team offers training sessions tailored to your specific needs, ensuring you get the most out of your cutting machine laser experience. With comprehensive support at your fingertips, you can confidently tackle any project while mastering the art of machine laser engraving.

Maintenance and Durability

When it comes to maintaining a laser cut machine, regular upkeep is essential for optimal performance. These machines are precision tools that require attention to detail, ensuring they operate smoothly and efficiently. By investing time in maintenance, you can prolong the life of your laser machinery and maintain high-quality output.

Keeping Your Cutting Machine Laser in Top Shape

To keep your cutting machine laser functioning at its best, start with a routine inspection schedule. Regularly check for any signs of wear or damage on components such as lenses, mirrors, and belts; these parts are crucial for the accuracy of your laser cutter. Additionally, ensure that the machine is clean from dust and debris to avoid any interference during operation.

Another vital aspect of maintenance involves calibrating your laser etching machine periodically. Calibration helps maintain precision and accuracy in cuts while preventing potential costly errors down the line. Don’t forget to follow manufacturer guidelines for lubrication and adjustments, as this will contribute significantly to the longevity of your equipment.

Long-Term Care Tips for Laser Machinery

Long-term care for your laser machinery goes beyond just regular cleaning; it involves creating an environment conducive to optimal performance. Make sure that your workspace is free from extreme temperatures or humidity levels that could affect the machine's components over time. Investing in quality air filtration systems can also help reduce contaminants that may harm sensitive parts of a cutting machine laser.

Furthermore, consider scheduling professional servicing at least once a year to catch any hidden issues before they escalate into major problems. This service often includes thorough inspections and adjustments that are best left to trained technicians who understand the intricacies of laser technology. Remember: proactive care today means fewer headaches tomorrow!

Benefits of Reliable Machines from Kiant Machinery

When you invest in reliable machines from Kiant Machinery, you're not just buying a piece of equipment; you're gaining peace of mind knowing you've chosen quality products designed for durability. Their cutting machines are built with robust materials that stand up against wear and tear while maintaining consistent performance over time—an essential factor when considering long-term investments in production capabilities.

Moreover, Kiant Machinery provides excellent customer support which includes training sessions on proper maintenance techniques tailored specifically for their products like laser engraving machines or other types within their range. This support ensures you fully understand how to keep your equipment running smoothly without unnecessary downtime or frustration.

In summary, maintaining a high-performing laser cut machine requires commitment but pays off significantly by enhancing productivity and extending equipment lifespan—a win-win scenario!

Conclusion

In the ever-evolving world of manufacturing and design, laser cutting stands out as a transformative technology. By harnessing the precision and speed of a laser cut machine, businesses can significantly enhance their production capabilities while ensuring high-quality results. The versatility offered by laser machinery allows for creative applications across various industries, making it an invaluable asset in modern production environments.

Enhancing Production with Laser Cutting

Laser cutting technology streamlines the production process, enabling manufacturers to achieve intricate designs with remarkable efficiency. The ability of a laser cutter to operate at high speeds without compromising accuracy means that businesses can meet tight deadlines while maintaining quality standards. This enhancement in productivity not only leads to cost savings but also allows companies to explore new opportunities and expand their market reach.

Investing in Quality Laser Machinery

When it comes to investing in a laser cut machine or a laser etching machine, quality should always take precedence over cost. High-quality machines ensure longevity and reliability, reducing downtime and maintenance costs in the long run. Companies like Kiant Machinery offer robust options that combine performance with user-friendly features, making them an excellent choice for those looking to elevate their operations.

Future Trends in Laser Technology

The future of laser technology is bright, with innovations continuously pushing the boundaries of what's possible with cutting machine lasers and engraving capabilities. As industries adopt more automated solutions, we can expect advancements that integrate artificial intelligence for even greater precision and efficiency in laser machinery operations. Keeping an eye on these trends will help businesses stay ahead of the curve and make informed investments that align with future demands.