Introduction

This advanced method uses a focused beam of light to precisely cut through metal, offering unparalleled accuracy and efficiency. As industries continue to seek faster and more reliable production methods, understanding the ins and outs of metal cutting laser machines becomes essential for anyone looking to stay competitive.

Understanding Laser Cutting Technology

At its core, laser cutting is a process that utilizes a high-powered beam of light to melt or vaporize material, creating intricate designs with exceptional precision. The technology has evolved significantly over the years, making it accessible for various applications in different sectors. Whether you're using a cutting machine laser for small-scale projects or large industrial tasks, the principle remains the same: harnessing light energy for superior results.

Advantages of Laser Cutting Aluminum

When it comes to aluminum specifically, there are numerous advantages that make laser cut aluminum highly desirable in various industries. One noteworthy benefit is the ability to achieve clean edges without burrs or rough finishes—something traditional methods struggle with. Additionally, metal cutting lasers minimize waste by making precise cuts that require less material overall, ultimately saving time and costs.

Applications of Laser Cut Aluminum

The versatility of laser cut aluminum allows it to be used across countless applications—from automotive components to intricate decorative pieces in architecture. Industries such as aerospace and electronics rely heavily on this technology due to its ability to create complex shapes quickly and accurately. Furthermore, custom designs and prototyping have never been easier thanks to metal cutting machines that can adapt rapidly without compromising quality.

What is Laser Cutting Aluminum?

Laser cutting aluminum is a sophisticated process that utilizes focused laser beams to slice through metal with precision and ease. This technique has revolutionized the way aluminum is processed, allowing for intricate designs and high-quality finishes that traditional methods struggle to achieve. Understanding the fundamentals of this technology is essential for anyone looking to harness its power in their projects.

Overview of Laser Cutting Process

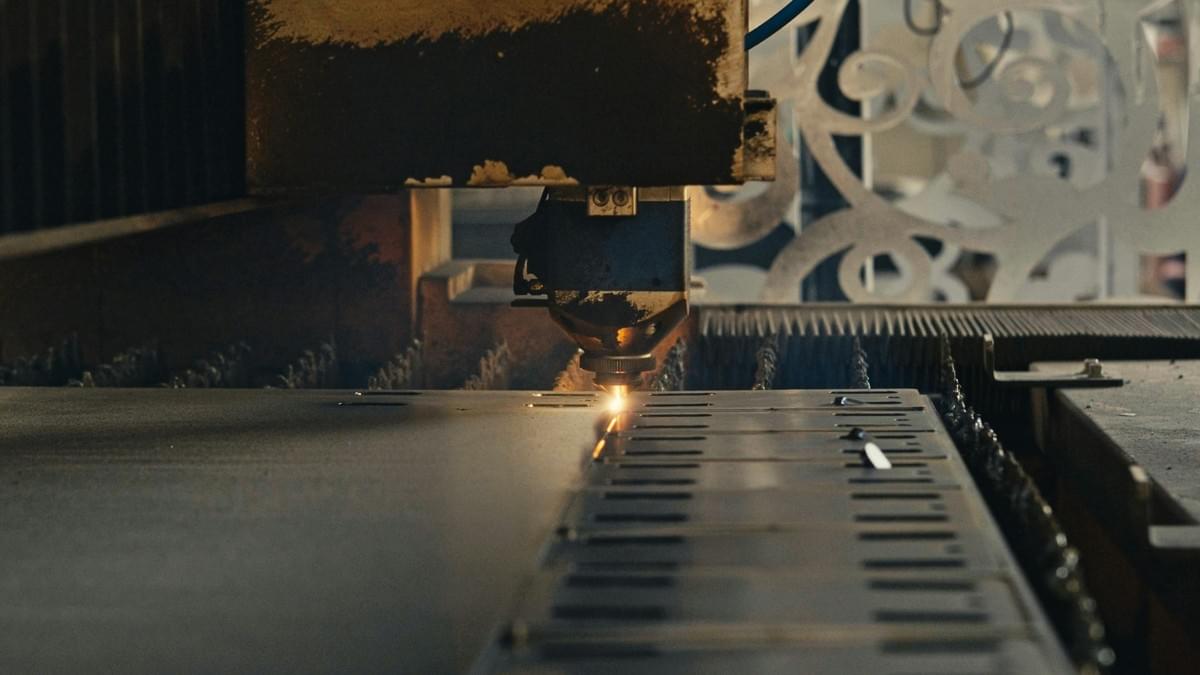

The laser cutting process begins with a highly concentrated beam of light generated by a metal cutting laser machine, which is directed onto the aluminum surface. This intense heat melts or vaporizes the material, allowing for clean cuts without excessive force or contact. As the cutting machine laser moves along predetermined paths, it creates intricate shapes and designs with impressive accuracy, making it ideal for both mass production and custom projects.

Types of Laser Cutting Machines

When it comes to selecting a metal cutting machine laser, there are several types available on the market, each designed for specific applications and materials. CO2 lasers are widely used for non-metal materials but can also handle thin sheets of aluminum effectively; however, fiber lasers have gained popularity due to their efficiency in cutting thicker metals like aluminum quickly and cleanly. The choice between these machines often depends on factors such as material thickness, desired speed, and budget constraints.

Key Components of Metal Cutting Laser

A typical metal cutting laser cutter consists of several key components that work together to ensure optimal performance during the cutting process. The main elements include the laser source (which generates the beam), focusing optics (that concentrates the beam onto a small area), and a motion control system (that guides the cutter along precise paths). Additionally, proper cooling systems are crucial to maintain operational efficiency and prolong the life of your cutting machine laser by preventing overheating during extended use.

The Advantages of Using a Laser Machine

When it comes to cutting metal, particularly aluminum, laser machines stand out for their remarkable capabilities. The precision and accuracy they offer are unparalleled, making them the go-to choice for industries requiring intricate designs and tight tolerances. Additionally, these cutting machines not only enhance productivity but also contribute to environmental sustainability by reducing waste.

Precision and Accuracy in Metal Cutting

Laser cut aluminum is known for its exceptional precision, which is crucial in industries where even the slightest deviation can lead to significant issues. The metal cutting laser machine utilizes focused beams of light that can be finely adjusted, allowing operators to achieve intricate designs with ease. This level of accuracy ensures that every piece meets exact specifications, resulting in high-quality products that require little to no post-processing.

Clean Edges and Minimal Waste

One of the standout features of a metal cutting laser cutter is its ability to produce clean edges on every cut. Unlike traditional methods that may leave rough edges or require additional finishing work, a cutting machine laser provides smooth surfaces straight from the machine. This not only enhances the aesthetic appeal of laser cut aluminum but also minimizes material waste—an essential factor in both cost management and environmental responsibility.

Speed and Efficiency Compared to Traditional Methods

In today's fast-paced manufacturing environment, speed matters more than ever; that's where a metal cutting machine laser truly shines. Laser machines can operate at impressive speeds without sacrificing quality or precision, significantly outperforming traditional cutting methods like saws or plasma cutters. This efficiency translates into quicker turnaround times for projects, enabling businesses to meet tight deadlines while maintaining high standards for their products.

Choosing the Right Metal Cutting Laser Cutter

Selecting the right metal cutting laser cutter can feel like searching for a needle in a haystack, especially with so many options available. The ideal machine should not only meet your specific needs but also align with your budget and production goals. To make an informed decision, it’s essential to consider factors such as power, cutting speed, and material compatibility.

Factors to Consider in Selection

When choosing a metal cutting machine laser, several key factors come into play. First off, assess the thickness of aluminum you plan to cut; different machines have varying capabilities regarding material thickness. Additionally, consider the precision required for your projects—some applications demand intricate designs that only high-end laser machines can deliver.

Another vital aspect is the type of laser technology used; CO2 lasers are excellent for non-metal materials but fiber lasers are typically preferred for cutting aluminum due to their efficiency and speed. Don’t overlook the operational costs either; energy consumption and maintenance expenses can add up over time. Finally, ensure that you choose a model that offers excellent customer support and training resources to help you get started with your new metal cutting laser cutter.

Kiant Machinery’s Offerings

Kiant Machinery stands out in the marketplace with its impressive range of metal cutting laser machines designed specifically for aluminum applications. Their models offer advanced features such as high-speed cutting capabilities and superior precision—perfect for those intricate designs we talked about earlier! Plus, Kiant provides customizable solutions tailored to meet unique project requirements.

What sets Kiant apart is their commitment to quality; each machine undergoes rigorous testing before it reaches your workshop floor. They also prioritize user-friendliness, ensuring that even those new to using a cutting machine laser can operate their equipment effectively with minimal training. With robust customer service and support teams ready to assist you at any time, investing in a Kiant machine means you're not just buying hardware; you're gaining a partner in innovation.

Comparing Different Models in the Market

In today’s crowded market of metal cutting machines, it's crucial to compare various models before making a purchase decision. Start by looking at specifications like wattage—higher wattage often translates into faster cutting speeds and thicker material capabilities when dealing with tasks involving laser cut aluminum. Also pay attention to features such as automation options or integrated software systems which can enhance productivity.

Another factor worth considering is user reviews; feedback from other users provides valuable insights into performance reliability and ease of use over time with different models of metal cutting laser cutters available on the market today. Lastly, don’t forget about warranty terms—having robust coverage gives you peace of mind knowing that if something goes awry down the line, you'll be covered without incurring hefty costs.

Common Applications for Laser Cut Aluminum

Laser cut aluminum has carved a niche across various industries due to its versatility and precision. The ability of a metal cutting laser machine to produce intricate designs and shapes makes it an invaluable asset in modern manufacturing. From automotive components to decorative elements, the applications are as diverse as they are innovative.

Industries Utilizing Laser Cutting

The automotive industry is one of the primary sectors leveraging the benefits of laser cut aluminum, where precision is paramount for components like brackets and chassis parts. Aerospace manufacturers also rely on metal cutting laser machines for lightweight yet durable parts that meet stringent safety standards. Beyond these, industries such as electronics, architecture, and furniture design are increasingly incorporating cutting machine lasers to enhance their product offerings.

Custom Designs and Prototyping

One of the standout features of using a metal cutting laser cutter is its ability to create custom designs with remarkable accuracy. Designers can prototype unique pieces quickly without incurring high costs or long lead times associated with traditional manufacturing methods. This flexibility allows businesses to experiment with new ideas while ensuring that their products stand out in a competitive market.

Structural Components and Fabrication

Laser cutting technology plays a crucial role in fabricating structural components for construction projects, where strength meets aesthetic appeal through laser cut aluminum panels and beams. The precision offered by a metal cutting machine laser ensures that these components fit together seamlessly, reducing waste and improving overall efficiency during assembly. Furthermore, the clean edges produced by the cutting laser metal process enhance both functionality and visual appeal in architectural applications.

Maintenance and Safety Tips for Laser Cutting

Proper maintenance and safety protocols are essential for ensuring that your metal cutting laser machine operates efficiently and safely. Neglecting these aspects can lead to costly repairs, downtime, or even accidents. By adhering to regular maintenance procedures and safety guidelines, operators can maximize the lifespan of their cutting machine laser while minimizing risks.

Regular Maintenance Procedures

To keep your metal cutting laser cutter in top shape, regular maintenance is crucial. This includes routine checks on the optics, ensuring they are clean and free from debris that could affect the quality of laser cut aluminum. Additionally, inspecting the mechanical components—like belts and bearings—for wear will help you avoid unexpected breakdowns during operation.

Another important aspect is maintaining the cooling system of your metal cutting machine laser. Overheating can severely impact performance; therefore, ensuring coolant levels are adequate and that there are no blockages in cooling lines is vital. Lastly, regularly updating software and firmware will ensure your laser cutting machine remains compatible with new materials or design software.

Safety Protocols When Operating Machines

Safety should always be a priority when operating any type of cutting laser metal equipment. First off, wearing appropriate personal protective equipment (PPE), such as safety goggles and gloves, is non-negotiable to protect against potential hazards like flying debris or intense light emitted by the laser machine. Operators should also familiarize themselves with emergency shut-off procedures in case something goes awry during operation.

It’s equally important to maintain a clutter-free workspace around your metal cutting laser cutter. This minimizes the risk of accidents caused by tripping or knocking over materials that could interfere with machinery operations. Furthermore, conducting regular safety drills will ensure all personnel know how to respond effectively in case of an emergency.

Troubleshooting Common Issues

Even the best-maintained metal cutting machines can experience issues from time to time; knowing how to troubleshoot common problems can save you a lot of headaches down the line. For instance, if you notice irregular cuts or excessive dross on your laser cut aluminum pieces, it may indicate a misalignment in optics or an issue with power settings on your cutting machine laser.

Another common problem could be inconsistent feed rates leading to uneven cuts; this often points toward mechanical issues such as worn gears or belt slippage within your metal cutting machine laser setup. If you encounter persistent errors despite troubleshooting efforts, consulting manufacturer guidelines or reaching out to technical support may be necessary for more complex problems.

Conclusion

In wrapping up our exploration of laser cutting technology, it's clear that this method is not just a passing trend but a cornerstone of modern manufacturing. The advancements in laser cutting machines have revolutionized how industries approach metal fabrication, particularly with materials like aluminum. As we look toward the future, the potential for innovation in laser cut aluminum applications seems limitless.

The Future of Laser Cutting Technology

The future of laser cutting technology is bright and filled with possibilities that could further enhance productivity and precision. With ongoing advancements in AI and automation, metal cutting laser machines are expected to become even more efficient, reducing downtime and increasing output. Additionally, as industries continue to push for sustainability, the ability of these cutting machines to minimize waste will play a crucial role in their adoption.

Benefits of Partnering with Kiant Machinery

Their extensive range of metal cutting laser cutters ensures that you find the perfect fit for your specific requirements, whether you're looking for speed or precision. Plus, their commitment to customer support means you're not just buying a machine; you're investing in a partnership that prioritizes your success.

Final Thoughts on Laser Cutting Aluminum

In conclusion, embracing laser cut aluminum technology can significantly enhance product quality and operational efficiency across various industries. The versatility offered by modern cutting machine lasers allows businesses to tackle everything from custom designs to large-scale production seamlessly. As you explore options in the market today, remember that investing in advanced metal cutting machines is an investment in your future growth and innovation.