Introduction

In today's fast-paced manufacturing landscape, the world of laser cutting is transforming how industries approach precision and efficiency. From intricate designs to robust industrial applications, laser cutting technology has become a staple in various sectors. In this exploration, we will delve into the fascinating realm of high precision laser machines, particularly focusing on their role in pipe cutting and other innovative applications.

Explore the World of Laser Cutting

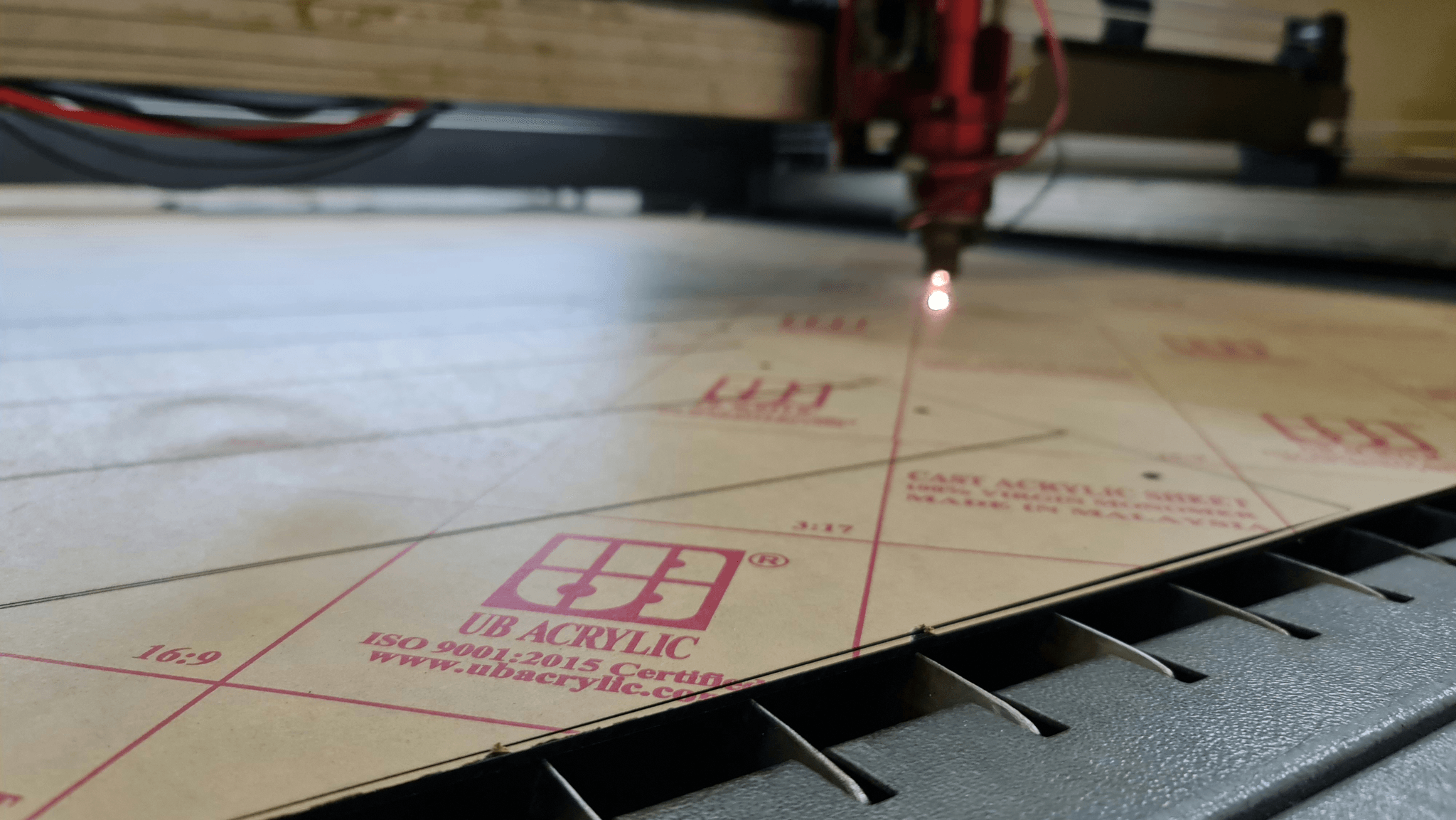

Laser cutting has revolutionized the way materials are processed, offering unparalleled accuracy and versatility. Whether it's a laser paper cutting machine for artistic projects or an industrial laser machine for heavy-duty tasks, this technology caters to a diverse range of needs. As we venture deeper into this world, we will uncover how different types of lasers—like CO2 laser cutting machines—are utilized across various industries.

The Technology Behind Laser Pipe Cutting

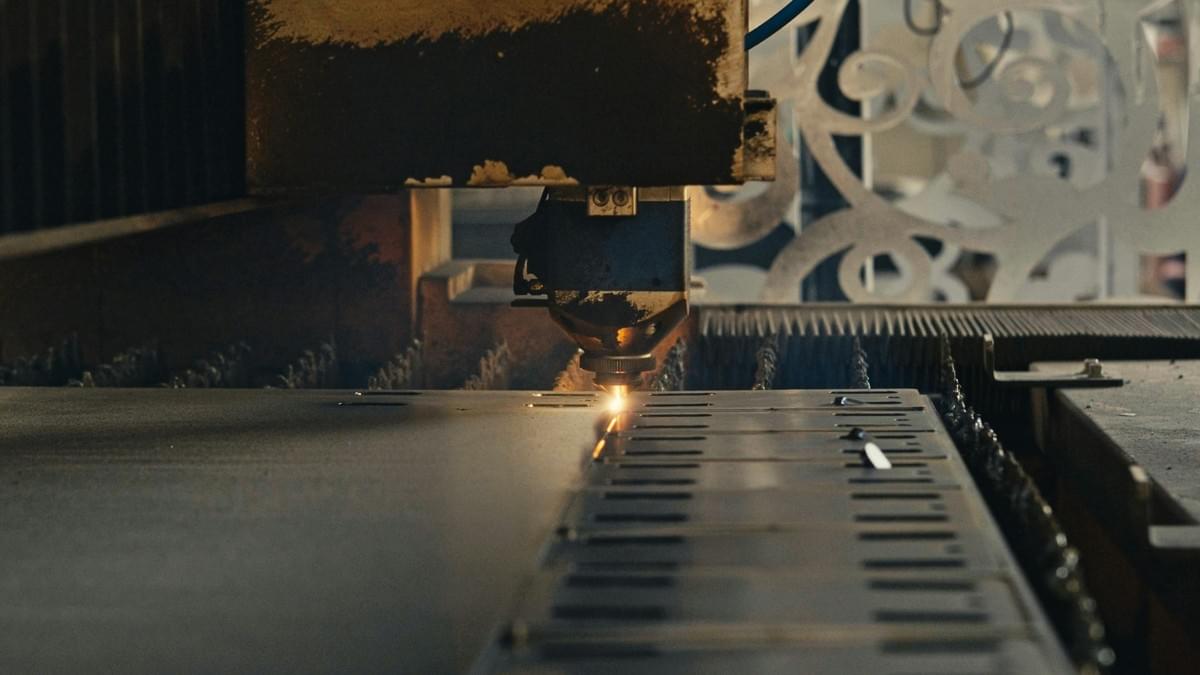

Understanding how do lasers cut is crucial for appreciating their impact on modern manufacturing processes. Laser pipe cutting employs focused beams of light to slice through materials with exceptional precision, making it ideal for complex shapes and designs. This method not only enhances productivity but also reduces waste compared to traditional cutting techniques.

Benefits of High Precision Laser Machines

The advantages offered by high precision laser machines extend far beyond mere functionality; they embody speed, efficiency, and cost-effectiveness over time. By minimizing errors and maximizing output quality, these machines stand out when compared to alternatives like CNC routers in the CNC router vs laser cutter debate. As industries continue to evolve, investing in technologies like desktop laser cutting machines becomes increasingly vital for staying competitive.

High Precision Laser Pipe Cutting Technology

In the realm of manufacturing and fabrication, high precision laser pipe cutting technology stands out as a game-changer. This technology utilizes focused laser beams to slice through materials with unmatched accuracy, making it ideal for various industrial applications. Understanding how lasers cut is crucial for recognizing their advantages over traditional methods like CNC routing.

Understanding How Lasers Cut

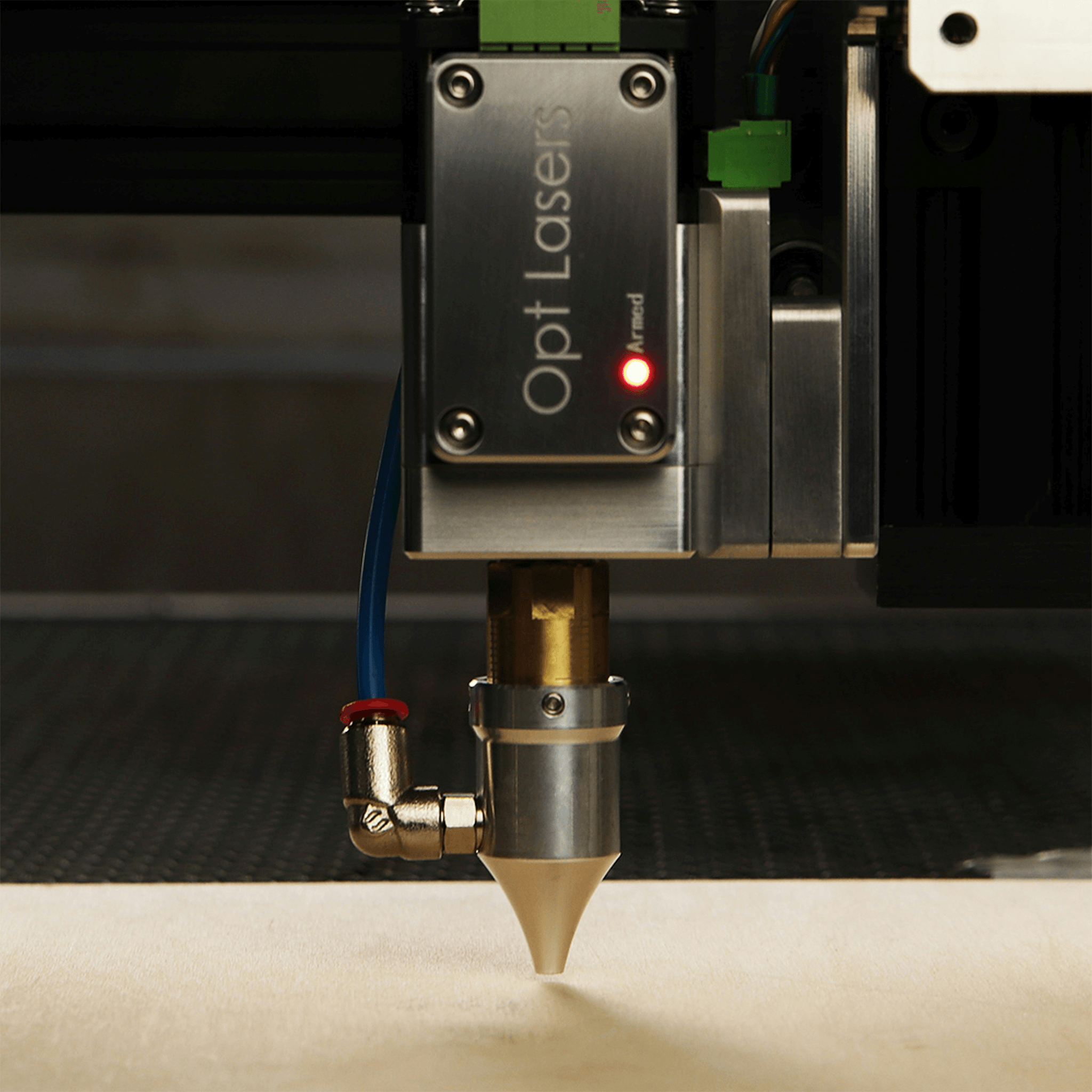

So, how do lasers cut? Essentially, they emit a concentrated beam of light that generates heat capable of melting or vaporizing materials upon contact. The precision of this method allows for intricate designs and fine details that would be challenging to achieve with other tools, such as a CNC router vs laser cutter scenario where the latter often prevails in terms of accuracy. Moreover, high precision laser machines can operate on various materials, including metals, plastics, and even fabrics—making them incredibly versatile.

The Role of CO2 Laser Cutting Machines

Among the different types of industrial laser machines available today, CO2 laser cutting machines are particularly noteworthy. These machines utilize carbon dioxide gas to produce a powerful beam that excels in cutting thick materials with exceptional speed and precision. Whether you're using a desktop laser cutting machine for small projects or an industrial model for large-scale production, CO2 lasers provide consistent results that meet stringent quality standards across various industries.

Applications in Various Industries

The applications of high precision laser pipe cutting technology span multiple sectors—from automotive to aerospace and beyond. In manufacturing environments where accuracy is paramount, these machines facilitate the creation of complex components that require tight tolerances. Additionally, leading laser cutting manufacturers are continually innovating to expand the capabilities of these systems; whether it's enhancing software or improving machine design, the future looks bright for industries relying on advanced laser technologies.

Comparing CNC Router vs Laser Cutter

Key Differences in Functionality

CNC routers are primarily designed for cutting and shaping materials like wood, plastic, and softer metals using a rotating bit. In contrast, laser cutters utilize focused beams of light to slice through materials with incredible precision—think of how do lasers cut through metal or even paper! While CNC routers excel at carving and milling tasks, laser machines shine in intricate designs and delicate projects such as those handled by a laser paper cutting machine.

One crucial difference lies in the types of materials each machine can handle effectively; CNC routers are more versatile when it comes to thicker materials like hardwoods, while CO2 laser cutting machines are ideal for thinner substrates like acrylic or paper. Additionally, the speed at which each machine operates varies; lasers typically provide faster cuts with cleaner edges compared to their router counterparts. Ultimately, your choice may hinge on whether you prioritize versatility or precision in your projects.

Advantages of Each Technology

The advantages of industrial laser machines are hard to overlook—they offer unmatched precision and accuracy that is vital for detailed work. When considering a desktop laser cutting machine versus a CNC router, the former allows for intricate designs that might be challenging or impossible with traditional routing methods. Moreover, industrial lasers tend to require less post-processing due to their clean cuts.

On the flip side, CNC routers have their own set of perks; they can handle larger workpieces without breaking a sweat and offer greater flexibility when working with various material thicknesses. Whether you're crafting furniture from solid wood or creating prototypes from plastics, a CNC router can adapt well to different demands. This makes them particularly advantageous for businesses focused on large-scale production runs where versatility is key.

Choosing the Right Machine for Your Needs

Selecting between a CNC router vs laser cutter ultimately depends on your specific needs and project requirements. If you’re working primarily with thinner materials or require high detail—say you’re running a small business that specializes in personalized gifts—a laser paper cutting machine might be your best bet. Conversely, if you're involved in woodworking or need robust shaping capabilities across various material types, investing in a reliable CNC router could serve you better.

Consider also future scalability; if your projects may evolve into more complex designs requiring higher precision over time, opting for an industrial CO2 laser cutting machine could be wise investment long-term strategy. Another factor is budget: while both technologies come at varying price points depending on brand and capabilities offered by leading laser cutting manufacturers like Kiant Machinery, understanding what you need now versus what you may require later will guide your decision-making process effectively.

The Advantages of Industrial Laser Machines

Industrial laser machines have revolutionized the manufacturing landscape, offering unparalleled benefits that traditional cutting methods simply cannot match. With their ability to deliver high precision and accuracy, these machines are essential for industries that demand perfection in every cut. Whether it’s a laser paper cutting machine or a CO2 laser cutting machine, the technology behind these devices ensures that they consistently meet stringent quality standards.

Enhanced Precision and Accuracy

When we ask ourselves, how do lasers cut? the answer lies in their remarkable ability to focus energy on a tiny point. This concentrated energy allows industrial laser machines to carve out intricate designs with pinpoint accuracy, which is particularly beneficial for sectors like aerospace and automotive manufacturing. Compared to traditional methods or even CNC routers, the precision achieved by laser cutters minimizes waste and maximizes material utilization.

Moreover, the enhanced accuracy of industrial laser machines means fewer errors during production runs. This reduction in error rates translates into less rework and scrap material, making processes more efficient overall. In applications where detail matters—like creating prototypes or custom parts—having a reliable laser paper cutting machine can make all the difference.

Speed and Efficiency in Production

Speed is another significant advantage of industrial laser machines over other technologies such as CNC routers. These machines can operate at high speeds without sacrificing quality, allowing businesses to ramp up production without compromising on precision or accuracy. The efficiency gained from using CO2 laser cutting machines means that projects can be completed faster than ever before.

Additionally, because these machines can handle complex cuts in one pass—unlike some CNC router setups that may require multiple passes—the overall time spent on each project is significantly reduced. Industries looking to improve their turnaround times will find that investing in an industrial laser machine pays off quickly due to increased productivity levels.

Cost-Effectiveness Over Time

While the initial investment for an industrial laser machine may seem steep compared to other options like desktop laser cutting machines or CNC routers, it’s essential to consider long-term savings as well. The durability and low maintenance requirements of these systems often lead to lower operational costs over time, making them a wise choice for businesses aiming for sustainability in their production processes.

Furthermore, because industrial lasers operate with such high efficiency and minimal waste generation, companies can see significant reductions in material costs as well—especially when working with expensive materials like metals or composites. In essence, while you might weigh your options between CNC router vs laser cutter technologies initially, opting for an advanced industrial solution could yield substantial financial benefits down the line.

Desktop Laser Cutting Machines for Small Projects

In the world of crafting and small-scale manufacturing, desktop laser cutting machines have revolutionized how enthusiasts and entrepreneurs work. These compact yet powerful devices allow users to engage in intricate designs, making them perfect for hobbyists and small businesses alike. With the ability to cut through various materials, including wood, acrylic, and even paper, these machines bring professional-grade capabilities right into your workshop.

Ideal for Hobbyists and Small Businesses

For hobbyists, a laser paper cutting machine opens up a realm of creative possibilities. Whether you're designing custom invitations or crafting unique gifts, having access to a desktop laser cutter means you can achieve precision that hand tools simply can't match. Similarly, small businesses benefit greatly; they can produce high-quality products quickly without investing in costly industrial laser machines that take up significant space.

Small businesses often find themselves at a crossroads when deciding between a CNC router vs laser cutter for their needs. While both technologies have their merits, desktop models offer unmatched accessibility and versatility at an affordable price point. This makes them an ideal choice for those just starting out or looking to expand their production capabilities without breaking the bank.

Versatility of Desktop Models

Desktop laser cutting machines are incredibly versatile; they can handle everything from delicate paper projects to robust materials like wood and acrylic with ease. This adaptability allows users to explore various applications—from crafting jewelry to producing signage—making them invaluable tools in any creative workspace. Furthermore, many models come equipped with software that simplifies the design process, allowing even beginners to navigate the complexities of how do lasers cut through different substrates.

The compact size of these machines doesn’t compromise their functionality; they often feature advanced CO2 laser cutting technology that provides exceptional results across diverse materials. This means you can easily switch between tasks without needing separate equipment for each material type. The ability to tackle multiple projects efficiently is what sets these desktop models apart from traditional methods or larger industrial alternatives.

Popular Brands and Models

When it comes to choosing a desktop laser cutting machine, several brands stand out in terms of reliability and performance within the market of laser cutting manufacturers. For instance, Glowforge has gained popularity due to its user-friendly interface and impressive capabilities tailored for both hobbyists and professionals alike. Another noteworthy mention is Epilog Laser; known for its robust CO2 laser cutting machines that deliver excellent precision while maintaining ease of use.

Other brands worth considering include Dremel's DigiLab series which offers great entry-level options ideal for educational purposes or small businesses looking to dip their toes into the world of laser cutting technology without overwhelming complexity. Each brand provides unique features catering specifically to different user needs while ensuring quality output every time you press “start.”

Investing in one of these popular desktop models could be your ticket into an exciting world where creativity meets technology—perfectly blending art with science!

Leading Laser Cutting Manufacturers

In the competitive landscape of laser cutting technology, several manufacturers stand out for their innovative approaches and high-quality machinery. From industrial laser machines to desktop laser cutting machines, these companies cater to a wide range of applications and industries. Understanding who the key players are can help you make informed decisions when investing in laser technology.

Overview of Top Industry Players

The market for laser cutting manufacturers is diverse, featuring both established giants and emerging innovators. Companies like Trumpf and Bystronic have long been recognized for their advanced CO2 laser cutting machines that deliver exceptional precision and speed. Meanwhile, newer entrants are making waves with compact models designed specifically for hobbyists, bridging the gap between industrial capabilities and personal projects.

These manufacturers not only focus on producing powerful industrial laser machines but also emphasize user-friendly designs that enhance versatility across various applications. For example, some brands offer integrated systems that combine CNC router vs laser cutter functionalities, allowing users to switch between technologies seamlessly. As the demand for high precision continues to rise, these leading players are constantly evolving their offerings to meet industry needs.

Spotlight on Kiant Machinery

Kiant Machinery has carved a niche as a prominent player in the realm of high precision laser cutting technology. Known for its robust line of industrial laser machines, Kiant combines reliability with innovation to provide solutions tailored for both large-scale production and smaller projects alike. Their flagship models include advanced CO2 laser cutting machines that excel in delivering intricate cuts with minimal waste.

What sets Kiant apart is its commitment to customer satisfaction through continuous improvement and support services. They also offer desktop laser cutting machines that are perfect for small businesses or hobbyists looking to explore creative possibilities without compromising on quality or performance. With a focus on user experience, Kiant ensures that its products remain accessible while maintaining professional-grade capabilities.

Innovations from Major Brands

Innovation is at the heart of the success enjoyed by leading laser cutting manufacturers today. Many companies are investing heavily in research and development to enhance their offerings continually; this includes advancements in how do lasers cut materials more efficiently and accurately than ever before. New technologies such as fiber lasers have emerged alongside traditional CO2 options, providing users with greater flexibility depending on their specific needs.

Additionally, brands are exploring automation features that streamline operations within industrial settings—reducing manual labor while increasing throughput significantly. The integration of smart technology into desktop laser cutting machines has also made it easier than ever for users to create complex designs without needing extensive technical knowledge or experience in CNC router vs laser cutter operations. These innovations not only improve productivity but also open up new avenues for creativity across various sectors.

Conclusion

In the rapidly evolving world of manufacturing, investing in high precision laser technology is no longer just an option; it's a necessity. Businesses looking to stay competitive must embrace advancements like the laser paper cutting machine and industrial laser machines, which offer unparalleled accuracy and efficiency. By integrating these technologies, companies can reduce waste, improve product quality, and ultimately enhance their bottom line.

Investing in High Precision Laser Technology

High precision laser technology represents a significant leap forward in modern manufacturing processes. With tools like the CO2 laser cutting machine, industries can achieve intricate designs and clean cuts that traditional methods simply can't match. As businesses invest in these advanced solutions, they are not only improving their production capabilities but also paving the way for innovative applications across various sectors.

Future Trends in Laser Cutting

Looking ahead, the future trends in laser cutting promise even greater advancements that will revolutionize how we approach design and manufacturing. The integration of artificial intelligence with CNC router vs laser cutter technologies is set to optimize operations further by enhancing decision-making processes and automating tasks. Moreover, as desktop laser cutting machines become more accessible to hobbyists and small businesses, we can expect a surge of creativity that will redefine product development across industries.

Maximizing Efficiency with Kiant Machinery

Kiant Machinery stands out among leading laser cutting manufacturers by consistently delivering reliable equipment designed for both industrial applications and smaller projects alike. Their commitment to innovation ensures that users can maximize efficiency while enjoying the benefits of high precision technology in their operations. By choosing Kiant Machinery's products—whether it’s a robust industrial laser machine or a versatile desktop model—businesses are well-equipped to thrive in today’s competitive landscape.