Introduction

Roll forming machines have emerged as essential tools in this arena, particularly the sheet roll forming machine, which specializes in producing rolled sheet metal roofing and various other profiles. Understanding how these machines operate and their significance in the wholesale market can provide valuable insights for contractors and manufacturers alike.

Understanding Roll Forming Machines

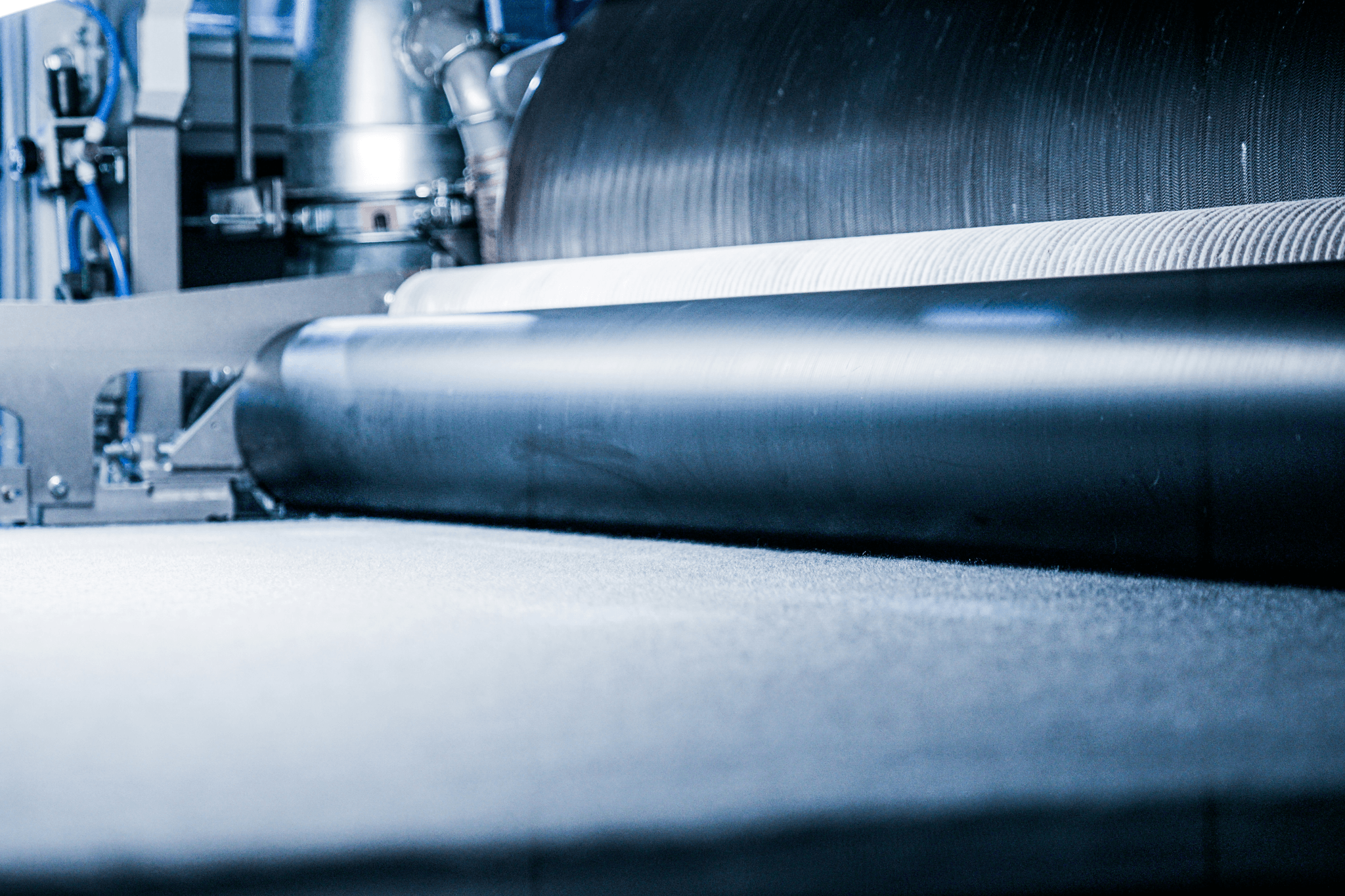

Roll forming machines are sophisticated devices designed to convert flat metal sheets into specific shapes through a continuous bending process. The sheet roll forming machine utilizes a series of rollers to shape metal into desired profiles, making it ideal for producing components like roofing panels and structural elements. These machines not only enhance production speed but also ensure high levels of accuracy, which is crucial for maintaining quality standards in construction projects.

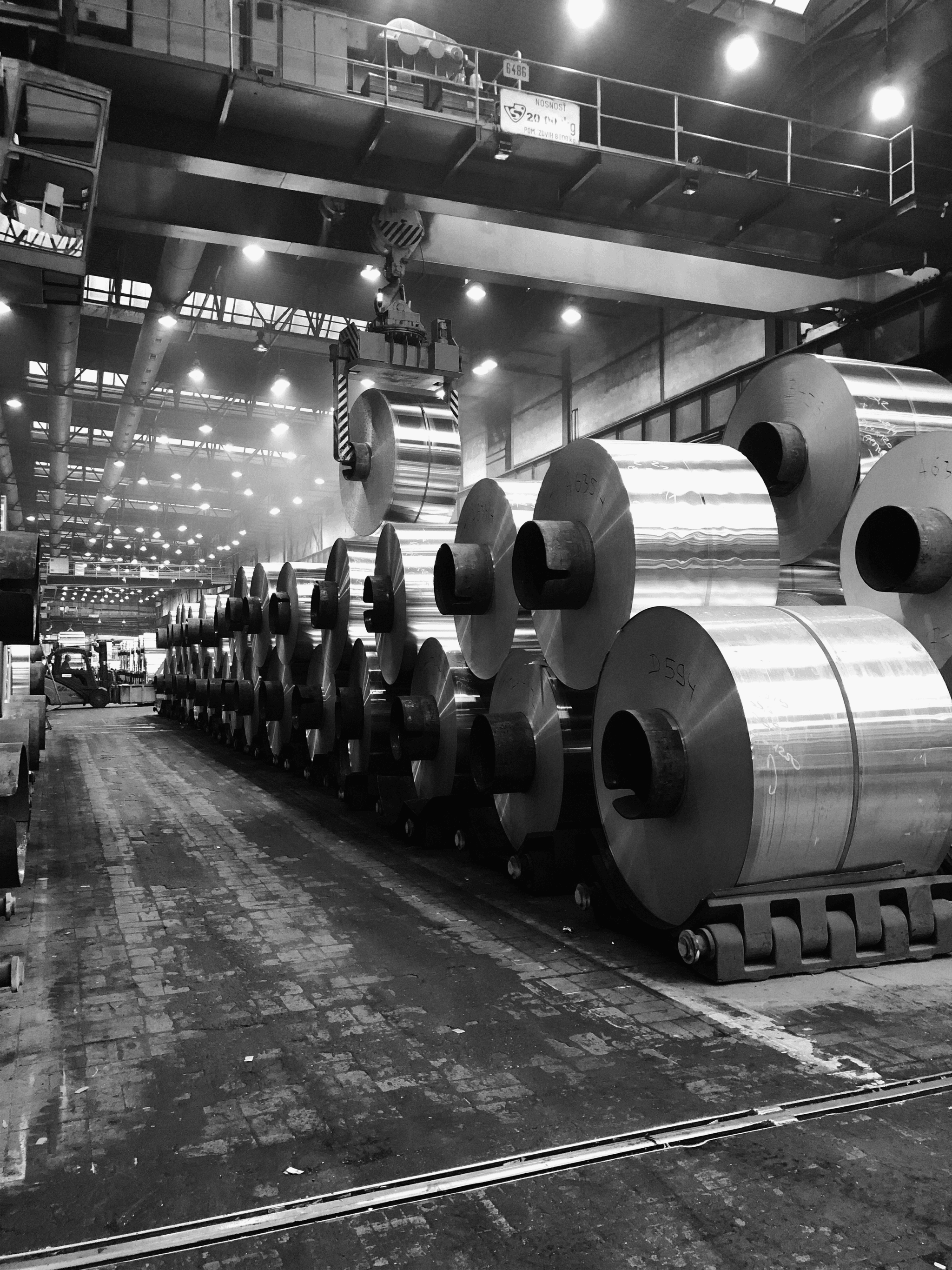

The Importance of Metal in Construction

Metal has long been a cornerstone material in construction due to its strength, durability, and versatility. Rolled metal roofing made from high-quality steel or aluminum provides superior protection against environmental elements while offering aesthetic appeal. As more builders recognize the advantages of using metal over traditional materials, demand for efficient manufacturing solutions like the metal roof forming machine continues to rise.

Overview of the Wholesale Market

The wholesale market for construction materials is thriving as businesses seek reliable suppliers who can provide quality products at competitive prices. This shift has led to an increased interest in roofing machines that can produce rolled sheet metal roofing efficiently and cost-effectively. Understanding roll forming machine prices and evaluating options such as the metal roof machine price is essential for businesses looking to optimize their operations while meeting customer demands.

What is a Sheet Roll Forming Machine?

This innovative equipment transforms flat sheets of metal into various profiles through a continuous bending process, creating everything from roofing panels to structural components. Its efficiency and versatility make it an essential tool in industries focused on rolled metal roofing and other applications.

Definition and Functionality

A sheet roll forming machine is designed to convert flat metal sheets into specific shapes by passing them through a series of rollers. Each roller gradually bends the metal until it reaches the desired profile, ensuring precision and consistency throughout production. This process not only enhances productivity but also allows for complex designs that might be difficult or impossible to achieve with traditional methods.

Advantages of Using These Machines

One of the standout advantages of using a sheet roll forming machine is its ability to produce high-quality products at an impressive speed. The automation involved minimizes human error, resulting in uniformity across all pieces produced, which is crucial for applications like rolled sheet metal roofing where precision matters immensely. Additionally, these machines are often more cost-effective in the long run due to reduced labor costs and material waste.

Common Applications in Industries

Sheet roll forming machines find their niche across various industries due to their adaptability and efficiency. They are particularly prevalent in construction for creating roofing materials, siding panels, and other structural components essential for buildings. Beyond construction, these machines also play a significant role in manufacturing HVAC systems and automotive parts, showcasing their versatility in meeting diverse industrial needs.

Exploring Rolled Metal Roofing Options

When it comes to roofing solutions, rolled metal roofing has become a popular choice among contractors and builders. The versatility of this material, combined with the efficiency of a sheet roll forming machine, makes it an ideal option for various construction projects. Understanding the benefits and options available can help you make informed decisions for your roofing needs.

Benefits of Rolled Sheet Metal Roofing

Rolled sheet metal roofing offers numerous advantages that make it stand out from traditional materials. For starters, its lightweight nature reduces structural load, making installation easier and more cost-effective. Additionally, rolled metal roofing boasts exceptional durability and resistance to harsh weather conditions, ensuring longevity and reduced maintenance costs over time.

Another significant benefit is its energy efficiency; many rolled metal options come with reflective coatings that help minimize heat absorption. This not only lowers energy bills but also enhances indoor comfort during extreme temperatures. Finally, the aesthetic appeal of rolled sheet metal roofing can elevate the overall look of any structure while providing versatile design options.

Comparison of Roofing Materials

When comparing roofing materials, it's essential to consider factors such as cost, durability, and maintenance requirements. Traditional asphalt shingles may be cheaper upfront but often require frequent repairs or replacements compared to rolled metal roofing systems created using a reliable roofing machine. On the other hand, concrete tiles are durable but can be heavy and costly to install.

Rolled sheet metal roofs provide an excellent balance between affordability and performance; they are lightweight yet robust enough to withstand severe weather conditions without extensive upkeep. Moreover, advancements in manufacturing technology have made these materials available in various styles and finishes that rival other options on the market today. Ultimately, choosing the right material depends on your specific needs and budget constraints.

How to Choose the Right Roofing Machine

Selecting the right roofing machine is crucial for ensuring high-quality production of rolled sheet metal roofing products. Start by evaluating your production requirements—consider factors like volume output and desired specifications for finished products before purchasing a metal roof forming machine for sale. A well-suited machine will enhance efficiency while meeting industry standards.

Next, pay attention to key features such as ease of operation, maintenance requirements, and compatibility with different types of materials used in roof forming processes. Additionally, understanding roll forming machine prices will help you find a balance between quality equipment and budget constraints without compromising performance or reliability in your production line.

Lastly, don’t forget about supplier reputation; investing in machines from reputable manufacturers ensures ongoing support services that can keep your operations running smoothly over time. By carefully considering these factors when selecting a roof forming machine, you'll set yourself up for success in producing high-quality rolled sheet metal products that meet market demands.

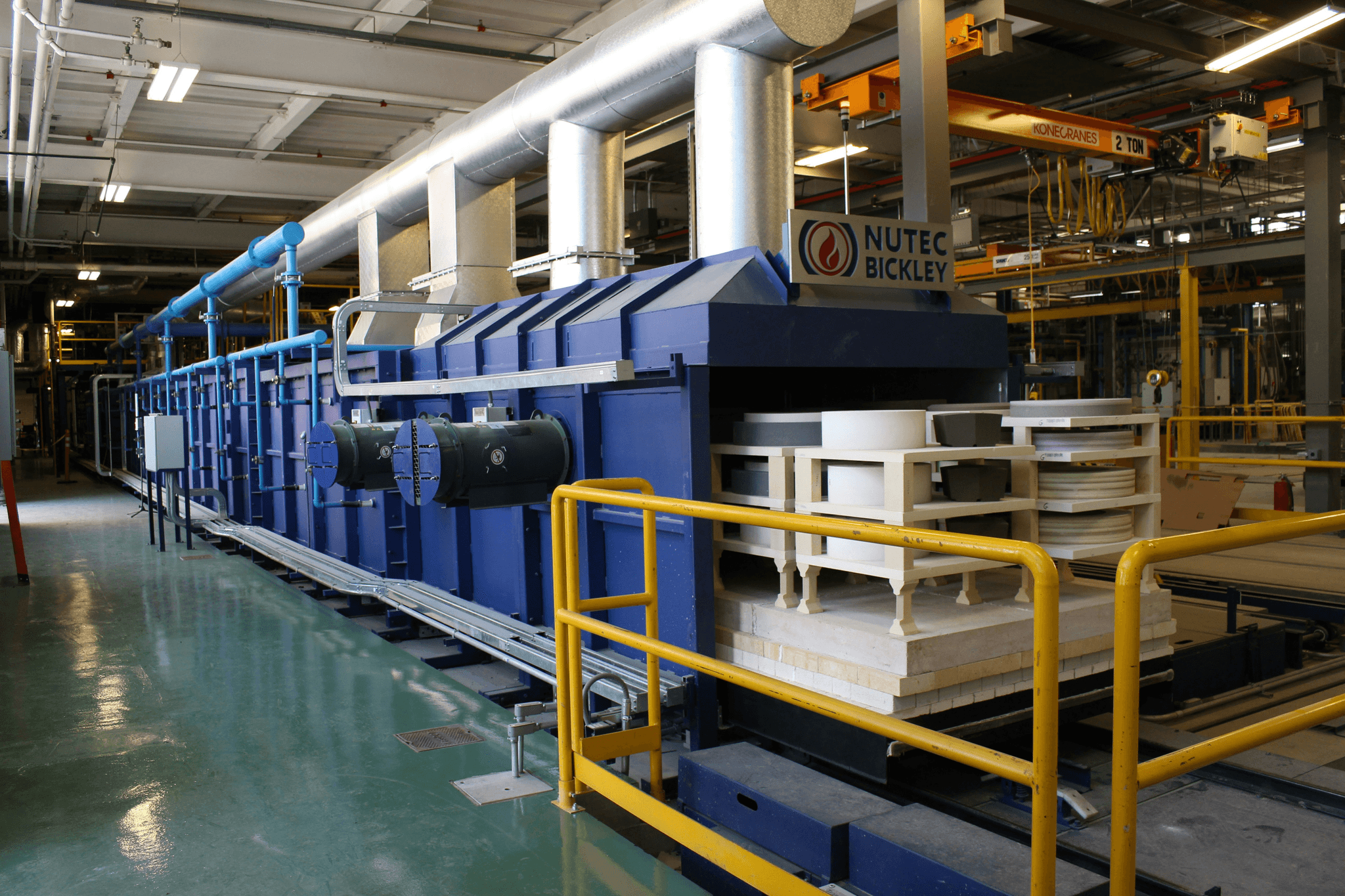

The Role of Roofing Machines in Manufacturing

In the world of construction and manufacturing, roofing machines play a pivotal role in producing high-quality rolled metal roofing materials. These machines streamline the process of shaping and forming metal sheets into various roofing profiles, ensuring efficiency and consistency. With a range of options available, understanding the different types of roofing machines can help manufacturers choose the right equipment for their specific needs.

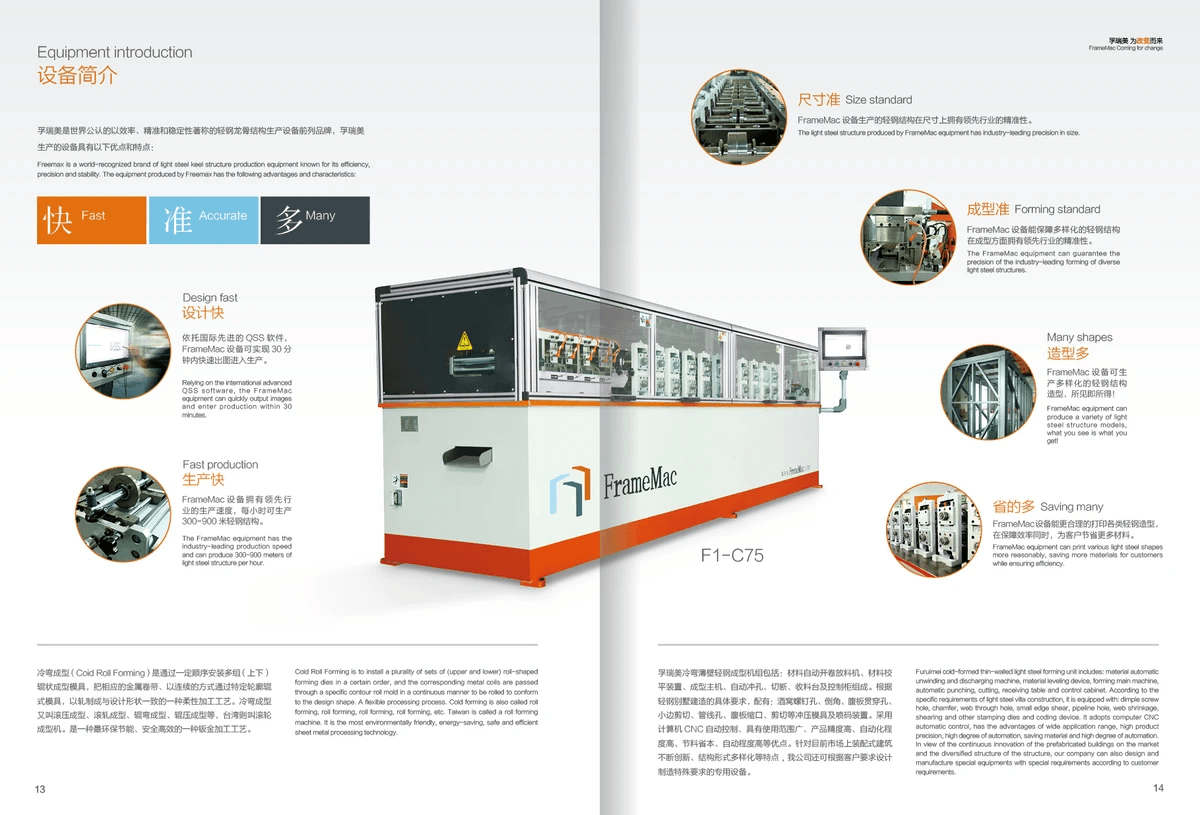

Overview of Different Types of Roofing Machines

Roofing machines come in various forms, each designed to cater to specific requirements in the production process. The most common type is the sheet roll forming machine, which continuously shapes metal sheets into desired profiles as they pass through rollers. Other types include standing seam machines and corrugated panel machines, each offering unique benefits for different applications in rolled sheet metal roofing.

Additionally, some advanced models incorporate features like automatic cutting and stacking systems to enhance productivity further. Manufacturers can opt for portable versions that allow on-site roof forming or stationary models for larger-scale operations. Understanding these variations is crucial when selecting a metal roof forming machine for sale that aligns with your business goals.

Key Features to Look For

When investing in a roofing machine, several key features should be considered to ensure optimal performance and longevity. First and foremost, look for a robust construction that can withstand continuous operation while delivering high-quality results consistently. Additionally, adjustable rollers are essential for accommodating different sheet thicknesses and profiles used in rolled metal roofing.

Another important feature is automation capabilities; modern roll forming machines often come equipped with digital controls that enhance precision during production runs. Efficiency also plays a significant role; consider energy consumption rates as well as maintenance requirements to avoid unexpected costs down the line. By focusing on these key features, manufacturers can make an informed decision when evaluating metal roof machine price options.

Cost Considerations: Roll Forming Machine Price

The price of roll forming machines can vary widely based on their features, capabilities, and brand reputation within the industry. While it may be tempting to go for lower-priced options initially, investing in quality equipment often pays off over time through increased efficiency and reduced maintenance costs associated with cheaper alternatives. Therefore, understanding your budget alongside long-term operational goals is essential when assessing potential investments.

Moreover, it's wise to factor in additional costs such as shipping fees or installation charges when calculating total expenditure on a new sheet roll forming machine or any other roofing machine model you may consider purchasing. Exploring financing options may also provide flexibility if upfront costs seem daunting but could lead to significant savings down the road with enhanced productivity levels from superior machinery investments.

In conclusion, choosing the right roofing machine involves careful consideration of various factors including type selection based on operational needs along with critical features that ensure durability and efficiency at competitive prices within today's market landscape.

What to Consider When Buying Metal Roof Forming Machines

When venturing into the world of metal roof forming machines, it's crucial to keep a few key considerations in mind. The right sheet roll forming machine can make all the difference in efficiency and output quality for your roofing projects. As you explore options, understanding specifications, pricing, and supplier reputation will guide you toward making a smart investment.

Key Specifications and Features

First up are the essential specifications and features that define a quality metal roof forming machine. Look for machines that offer versatility in producing various profiles of rolled sheet metal roofing, as this can enhance your project capabilities. Additionally, pay attention to features such as speed settings, automation levels, and ease of operation; these factors can significantly impact your production efficiency.

Another important aspect is the material thickness the roofing machine can handle; this directly influences the durability of your final product. Don't forget about safety features—machines equipped with emergency stops and protective guards ensure a safer working environment for operators. Ultimately, selecting a machine that combines robust construction with advanced technology will lead to better performance in roof forming tasks.

Understanding Metal Roof Machine Price

Now let’s talk dollars and cents—understanding metal roof machine price is vital when making your purchase decision. Prices vary based on specifications like capacity, automation level, and brand reputation; thus research is essential to find what fits within your budget without compromising on quality. While it may be tempting to go for cheaper models initially, remember that investing in a reliable sheet roll forming machine often pays off in long-term savings through reduced maintenance costs.

Consider not only the upfront cost but also potential operational expenses such as energy consumption and spare parts availability over time. Many manufacturers provide financing options or leasing arrangements which can make acquiring high-quality rolled metal roofing machines more feasible for businesses of all sizes. Take time to compare prices across different suppliers while keeping an eye on additional costs like shipping or installation services.

Evaluating Supplier Reputation

Last but certainly not least is evaluating supplier reputation before sealing any deals on a metal roof forming machine for sale! A reputable supplier should have positive customer reviews showcasing their commitment to service and product quality—after all, you want peace of mind with your investment! Don’t hesitate to ask potential suppliers about their after-sales support; reliable service ensures that any issues with machinery can be resolved quickly without disrupting operations.

Additionally, consider how long they’ve been in business; established companies often have more experience dealing with various customer needs and challenges related to roof forming equipment. Networking within industry circles or attending trade shows can also provide insights into which suppliers are trusted by fellow professionals in the field of rolled sheet metal roofing manufacturing. By taking these steps, you'll position yourself well for success as you invest in new machinery!

Kiant Machinery: Leading the Way in Roll Forming

Kiant Machinery has established itself as a pioneering force in the roll forming industry, particularly when it comes to sheet roll forming machines. With years of experience and a commitment to innovation, they provide cutting-edge solutions for manufacturers seeking efficiency and quality in metal roof forming. Their expertise is evident in every product, ensuring that clients receive not only machines but also comprehensive support throughout their operations.

Company Overview and Expertise

Kiant Machinery specializes in designing and manufacturing advanced roofing machines tailored for producing rolled sheet metal roofing. Their team consists of skilled engineers and industry veterans who understand the complexities of metal roof manufacturing. This wealth of knowledge allows them to create robust, reliable, and efficient metal roof forming machines for sale that meet diverse customer needs.

With a focus on quality and performance, Kiant Machinery has become synonymous with excellence in the roll forming market. They continuously invest in research and development to stay ahead of industry trends, ensuring their products remain at the forefront of technology. This dedication not only enhances their reputation but also solidifies their position as leaders in roofing machine solutions.

Innovative Solutions for Roof Forming

Kiant Machinery offers a range of innovative solutions specifically designed for roof forming applications, including advanced sheet roll forming machines that can handle various materials with ease. Their machines are equipped with state-of-the-art technology that maximizes production efficiency while minimizing waste—an essential factor for businesses aiming to improve profitability. Additionally, these roofing machines are customizable, allowing clients to tailor specifications according to unique project requirements.

One standout feature is their ability to produce different profiles of rolled metal roofing efficiently without compromising quality or speed. This flexibility empowers manufacturers to cater to diverse market demands while maintaining operational effectiveness. Furthermore, Kiant’s commitment to sustainability ensures that their machinery operates with energy efficiency in mind—an attractive proposition for environmentally conscious businesses.

Customer Success Stories and Testimonials

Kiant Machinery boasts numerous success stories from satisfied customers who have transformed their production capabilities through the use of their metal roof forming machines. Many clients have reported significant increases in output after upgrading to Kiant's advanced sheet roll forming machine models, which has directly contributed to improved profitability and reduced lead times on projects.

Testimonials highlight how Kiant's exceptional customer service played a crucial role during implementation phases; they provide thorough training sessions that empower users with confidence when operating new equipment. Clients frequently commend the durability and reliability of Kiant's products—essential attributes when investing in machinery like rolled sheet metal roofing systems.

In summary, choosing Kiant Machinery means partnering with an industry leader dedicated to providing top-notch solutions that drive success across various sectors within construction and manufacturing industries.

Conclusion

In the fast-paced world of construction, maximizing efficiency is crucial for staying ahead of the competition. Roll forming machines, particularly sheet roll forming machines, play a pivotal role in streamlining production processes and enhancing productivity. By automating the roof forming process, manufacturers can achieve consistent quality while reducing labor costs and lead times.

Maximizing Efficiency with Roll Forming Machines

The use of advanced sheet roll forming machines allows for precise shaping of rolled metal roofing materials, ensuring that every piece meets stringent specifications. This not only minimizes waste but also accelerates the manufacturing timeline, enabling quicker project turnarounds. As a result, companies leveraging these roofing machines can respond faster to market demands and customer needs.

Investing in Quality for Long-Term Success

When considering metal roof machine price, it's essential to weigh the initial investment against long-term benefits. High-quality roll forming machines may come at a premium but often lead to lower operational costs and enhanced durability over time. Investing in superior equipment ensures that your business remains competitive and capable of delivering high-quality rolled sheet metal roofing products.

Future Trends in Metal Roof Manufacturing

Looking ahead, the landscape of metal roof manufacturing is set to evolve with advancements in technology and materials science. Innovations such as automated systems and smart technology integration will further enhance the capabilities of metal roof forming machines for sale. Additionally, sustainability trends will drive demand for energy-efficient roofing solutions made from recycled materials, positioning businesses that adopt these practices as leaders in an ever-changing market.