Introduction

In the world of metal fabrication, cold bending has emerged as a game-changing technique, especially when it comes to working with steel. This innovative process allows manufacturers to create complex shapes and designs without the need for excessive heat, resulting in enhanced strength and durability. Understanding cold bending is essential for anyone involved in the production of stainless steel pipes, which play a crucial role in various industries.

Understanding Cold Bending in Steel

Cold bending refers to the process of shaping metal at room temperature, which preserves its inherent properties while allowing for intricate designs. Unlike traditional bending methods that often rely on heat to soften materials, cold bending maintains the structural integrity and strength of steel, making it an attractive option for many applications. The result is a more efficient production process that yields high-quality components with reduced risk of deformation or weakness.

The Importance of Stainless Steel Pipes

Stainless steel pipes are indispensable across numerous sectors including construction, automotive, and food processing due to their corrosion resistance and longevity. Their ability to withstand harsh environments makes them ideal for applications ranging from plumbing systems to structural frameworks. As demand grows for these versatile materials, understanding how cold bending can enhance their manufacturing becomes increasingly vital.

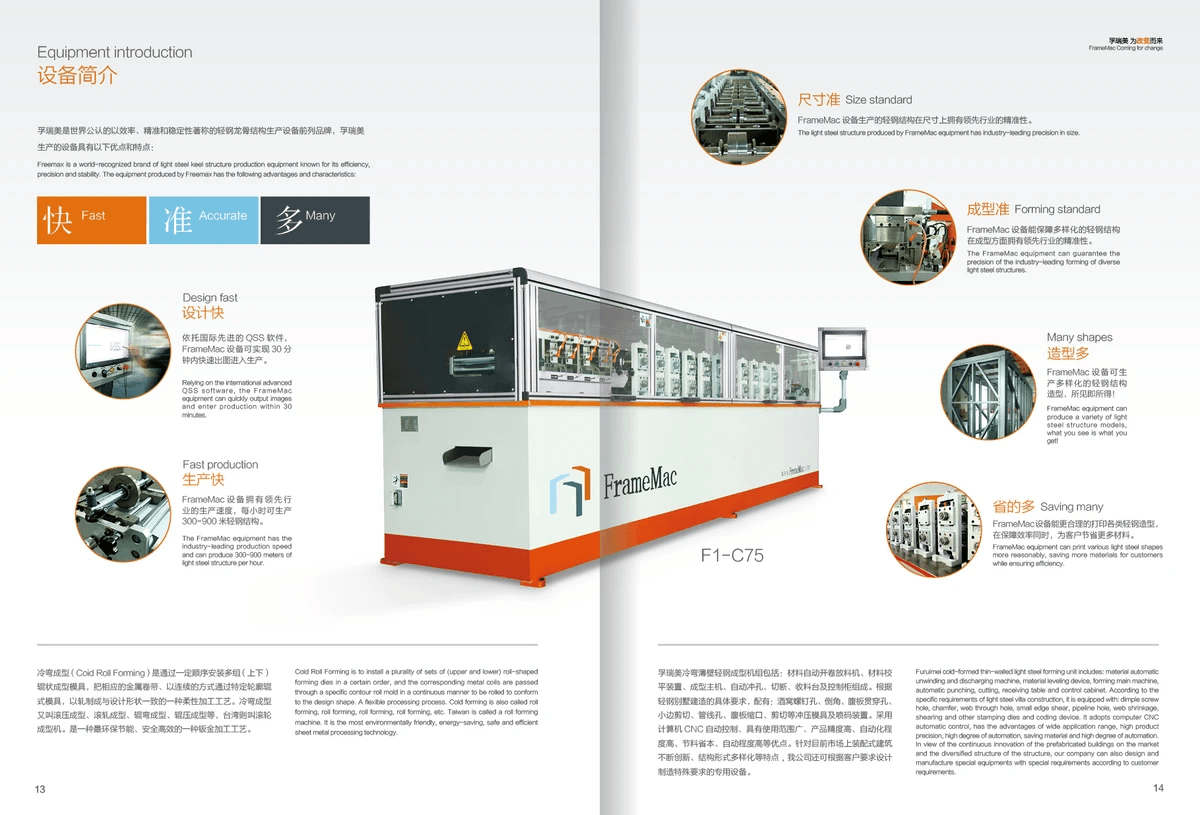

Overview of Cold Formed Steel Machine Options

When it comes to executing cold bending effectively, choosing the right machinery is key. There are various Cold Formed Steel Machine Options available that cater specifically to different types of projects and materials. From compact machines suitable for small workshops to large-scale industrial equipment designed for high-volume production, selecting the appropriate tools can significantly impact efficiency and output quality.

What is Cold Bending?

Cold bending is a manufacturing process that involves reshaping metal, particularly steel, at room temperature without the application of heat. This technique allows for the creation of curved or angled shapes while maintaining the integrity and strength of the material. Key characteristics of cold bending include its ability to produce precise bends, minimal material waste, and a finished product that often requires little to no additional machining.

Definition and Key Characteristics

Cold bending refers to the process where steel pipes or sheets are bent without any heating involved. The primary characteristic of this method is that it retains the original properties of the metal, which results in enhanced strength and durability compared to hot bending techniques. Additionally, cold bending can be performed quickly and efficiently using specialized machinery known as Cold Formed Steel Machine Options, making it a preferred choice in many manufacturing applications.

Differences from Traditional Bending

Traditional bending typically involves heating the metal to make it more malleable before shaping it into desired forms. In contrast, cold bending does not rely on heat; instead, it utilizes mechanical force applied at ambient temperatures. This fundamental difference results in various advantages for cold bending: it produces tighter radii without compromising material integrity and reduces energy costs associated with heating processes.

Common Applications in Manufacturing

Cold bending is widely used across various industries due to its versatility and efficiency. Common applications include creating frames for buildings, automotive components like exhaust systems, and intricate designs for furniture or architectural elements. The precision offered by cold formed steel machine options makes this technique ideal for producing high-quality parts that meet strict specifications while minimizing waste during production.

The Process of Cold Bending Stainless Steel Pipes

Cold bending stainless steel pipes involves a series of precise steps that ensure the material maintains its integrity while achieving the desired shape. Unlike traditional methods that may require heating, cold bending relies on the inherent strength and flexibility of stainless steel at room temperature. This technique is not only efficient but also enhances the performance characteristics of the material, making it ideal for various applications.

Steps Involved in Cold Bending

The cold bending process begins with careful preparation, where stainless steel pipes are measured and marked for accurate cuts and bends. Following this, the pipes are placed into a cold bending machine, which applies pressure to create the desired curvature without compromising structural integrity. After bending, quality checks are essential to ensure that dimensions align with specifications and that no defects have occurred during production.

In practice, operators must be vigilant about maintaining consistent pressure throughout the process to avoid kinks or distortions in the pipe. Each bend requires meticulous attention to detail since even slight deviations can lead to significant issues down the line. Thus, understanding each step is crucial for achieving optimal results in cold bending.

Techniques and Tools Required

Cold bending stainless steel pipes necessitates specialized tools designed specifically for manipulating metal without heat application. Commonly used tools include hydraulic benders, mandrels, and dies tailored to fit various pipe sizes and shapes seamlessly. These tools work together within cold formed steel machine options to produce precise bends consistently.

Operators often utilize computer numerical control (CNC) technology for enhanced accuracy during complex bends or when working with intricate designs. This advanced machinery allows for repeatable precision across multiple pieces while minimizing human error—an essential factor when dealing with high-quality materials like stainless steel. Ultimately, investing in reliable techniques and tools ensures efficiency and excellence in production.

Role of Temperature in the Bending Process

While cold bending primarily operates at room temperature, it's crucial to understand how temperature affects material properties during this process. Stainless steel exhibits unique characteristics under different thermal conditions; thus maintaining an optimal environment can influence outcomes significantly. If temperatures rise unexpectedly due to friction or machinery operation, they may alter material behavior during bends.

Moreover, manufacturers must consider ambient temperature when planning production runs since extreme conditions could impact tool performance or metal flexibility adversely. Proper cooling systems integrated into cold formed steel machine options can help mitigate these risks by ensuring consistent operational temperatures throughout production cycles. Therefore, understanding temperature's role is vital not just for achieving successful bends but also for prolonging equipment lifespan.

Advantages of Cold Bending for Stainless Steel

Cold bending has become a game-changer in the world of stainless steel fabrication, offering a plethora of advantages that enhance the overall quality and efficiency of production. By utilizing advanced techniques and Cold Formed Steel Machine Options, manufacturers can achieve superior results that traditional methods simply cannot match. Let’s dive into some key benefits that make cold bending a preferred choice for many in the industry.

Improved Strength and Durability

One of the standout advantages of cold bending is its ability to improve the strength and durability of stainless steel pipes. The process works by inducing work hardening in the material, which increases its tensile strength without compromising flexibility. As a result, products made through cold bending can withstand greater stress and are less prone to deformation over time, making them ideal for demanding applications.

Moreover, when using high-quality Cold Formed Steel Machine Options during the bending process, manufacturers can ensure precise control over dimensions and angles. This precision further contributes to the structural integrity of the final product. In an industry where durability is paramount, this enhanced strength makes cold-bent stainless steel pipes highly sought after.

Cost-Effectiveness in Production

Cost-effectiveness is another compelling reason why manufacturers are turning to cold bending techniques. The process typically requires less energy compared to traditional heating methods, leading to lower operational costs overall. Additionally, using efficient Cold Formed Steel Machine Options minimizes waste material during production—saving both time and money.

With reduced labor costs due to faster processing times, companies can streamline their operations significantly while maintaining high-quality standards. This combination of efficiency and savings allows businesses to remain competitive in today’s market while still delivering top-notch products that meet customer demands for affordability without sacrificing quality.

Enhanced Design Flexibility

Cold bending also opens up a world of design possibilities that traditional methods often restrict. With advanced machinery specifically designed for cold bending applications—such as various Cold Formed Steel Machine Options—manufacturers can create intricate shapes and curves with ease. This flexibility allows designers to innovate freely without being limited by conventional fabrication constraints.

Furthermore, since cold-bent components retain their structural properties better than those subjected to heat treatments, they lend themselves well to complex designs that require both aesthetics and functionality. The end result? Unique stainless steel products that not only perform exceptionally but also stand out visually—perfect for industries ranging from architecture to automotive engineering.

Popular Cold Formed Steel Machine Options

When it comes to cold bending, the right machinery can make all the difference in achieving precision and efficiency. The market is brimming with options, each offering unique features tailored to specific manufacturing needs. Understanding these cold formed steel machine options is essential for anyone looking to invest wisely in their production capabilities.

Overview of Leading Machinery Brands

The landscape of cold bending machinery is populated by several leading brands known for their reliability and innovative technology. Companies like Baileigh Industrial, JMT, and KAAST have established themselves as frontrunners in providing high-quality machines designed specifically for cold bending applications. Each brand brings its own flavor to the table—whether it’s advanced digital controls or robust construction—ensuring that manufacturers can find a machine that suits their specific requirements.

Features of Top Cold Bending Machines

Top-tier cold bending machines come equipped with a variety of features aimed at enhancing performance and user experience. Many models boast adjustable bending radii, allowing operators to create complex shapes with ease and precision. Additionally, advanced safety systems are often integrated into these machines, ensuring that operators can work confidently while minimizing risks associated with cold bending processes.

Kiant Machinery's Innovative Offerings

Kiant Machinery has carved out a niche in the world of cold formed steel machine options by focusing on innovation and user-friendliness. Their machines often feature cutting-edge technology such as programmable controls that allow for rapid setup changes between different projects, significantly reducing downtime in production lines. Furthermore, Kiant's commitment to quality ensures that their equipment not only meets industry standards but also delivers exceptional durability under rigorous use.

Best Practices for Cold Bending Stainless Steel

Cold bending stainless steel can be a precise and rewarding process when done correctly. To ensure the best results, it's essential to follow certain practices that enhance efficiency and product quality. By adhering to these best practices, you can maximize the benefits of cold bending while minimizing potential issues.

Tips for Achieving Optimal Results

Achieving optimal results in cold bending requires careful planning and execution. First, always choose the right type of stainless steel for your project; different grades have varying properties that affect bendability and strength. Additionally, use a well-calibrated Cold Formed Steel Machine to ensure accurate bends—precision is key in maintaining tolerances.

Another important tip is to perform regular tests on sample pieces before proceeding with full production runs. This allows you to fine-tune your machine settings and techniques based on real-time feedback from the material’s behavior during bending. Lastly, consider using lubrication during the process; this can significantly reduce friction and improve the overall quality of your bends.

Safety Considerations During the Process

Safety should always be a top priority when engaging in cold bending operations. Start by ensuring that all operators are trained in using the machinery properly; this includes understanding emergency procedures and equipment handling protocols. Wearing appropriate personal protective equipment (PPE) such as gloves, goggles, and steel-toed boots is also vital to safeguard against injuries.

It's crucial to keep work areas clean and organized to prevent accidents related to slips or falls while operating heavy machinery like Cold Formed Steel Machines. Regularly inspect equipment for wear or damage—any malfunction could lead not only to poor results but also pose safety hazards during operation. Lastly, maintain clear communication among team members; this helps coordinate efforts effectively, especially when handling large pieces of stainless steel.

Maintenance of Bending Equipment

Proper maintenance of your cold bending equipment is essential for consistent performance over time. Establish a routine inspection schedule where you check critical components such as hydraulic systems, blades, and alignment mechanisms on your Cold Formed Steel Machines regularly. Keeping everything in top condition will help avoid unexpected breakdowns that could disrupt production schedules.

Additionally, make it a habit to clean machines after each use; this prevents build-up from lubricants or metal shavings that could interfere with future operations or lead to corrosion over time. Don’t forget about software updates if your machinery has digital controls—keeping software current can enhance functionality and safety features significantly.

Finally, document all maintenance activities meticulously so you can track performance trends over time; this data will prove invaluable when troubleshooting issues or planning future upgrades on your bending machines.

Conclusion

In wrapping up our exploration of cold bending, it’s clear that this technique isn't just a passing trend; it's a pivotal process that shapes the future of manufacturing, especially in the realm of stainless steel pipes. As industries evolve and demand for innovative solutions grows, cold bending techniques will likely continue to improve, integrating advanced technologies and methodologies. This evolution promises not only enhanced efficiency but also greater sustainability in production practices.

The Future of Cold Bending Techniques

The future of cold bending techniques looks promising as advancements in technology pave the way for more precise and efficient processes. With the integration of automation and smart machinery, manufacturers can expect to achieve higher levels of accuracy and consistency in their products. Furthermore, ongoing research into materials science may lead to new alloys or treatments that enhance the performance characteristics of stainless steel during cold bending, making it an even more attractive option for various applications.

Maximizing Efficiency with Proper Machinery

To truly harness the benefits of cold bending, investing in top-notch Cold Formed Steel Machine Options is crucial. These machines are designed to optimize every aspect of the bending process—from setup time to execution—ensuring that manufacturers can produce high-quality components without unnecessary delays or waste. By selecting machinery equipped with advanced features like programmable controls and real-time monitoring systems, companies can significantly boost their operational efficiency while maintaining stringent quality standards.

Key Takeaways on Stainless Steel Bending Processes

In summary, understanding the nuances of cold bending is essential for anyone involved in manufacturing stainless steel products. Key takeaways include recognizing its advantages—such as improved strength and design flexibility—and ensuring proper maintenance and safety practices are followed during operation. Ultimately, embracing effective cold bending techniques alongside reliable Cold Formed Steel Machine Options will empower businesses to meet market demands while optimizing production costs.