Introduction

In the world of precision engineering and manufacturing, the choice of laser cutting manufacturers can significantly impact your production outcomes. Selecting the right provider not only influences the quality of your products but also affects operational efficiency and cost-effectiveness. With a plethora of options available, understanding your specific cutting needs becomes essential to ensure that you invest wisely in a metal cutting machine laser that meets your requirements.

Why Choosing Laser Cutting Manufacturers Matters

Choosing the right laser cutting manufacturers is crucial for ensuring high-quality results and reliability in production processes. The manufacturer you select will determine the technology used, which directly impacts precision and speed—two vital factors in any successful project. Whether you're looking for a fiber laser cutter or a versatile laser and engraving machine, understanding what each manufacturer offers can make or break your production line.

Understanding Your Cutting Needs

Before diving into the selection process, it's important to assess your unique cutting needs to find a suitable metal laser cutter or fiber laser cutting machine. Consider factors such as material types, thicknesses, and desired finish quality; these elements will dictate which technology aligns best with your objectives. By clearly defining these needs upfront, you can streamline your search for reputable laser cutting manufacturers who specialize in solutions tailored to those specifications.

Different Types of Laser Cutting Machines

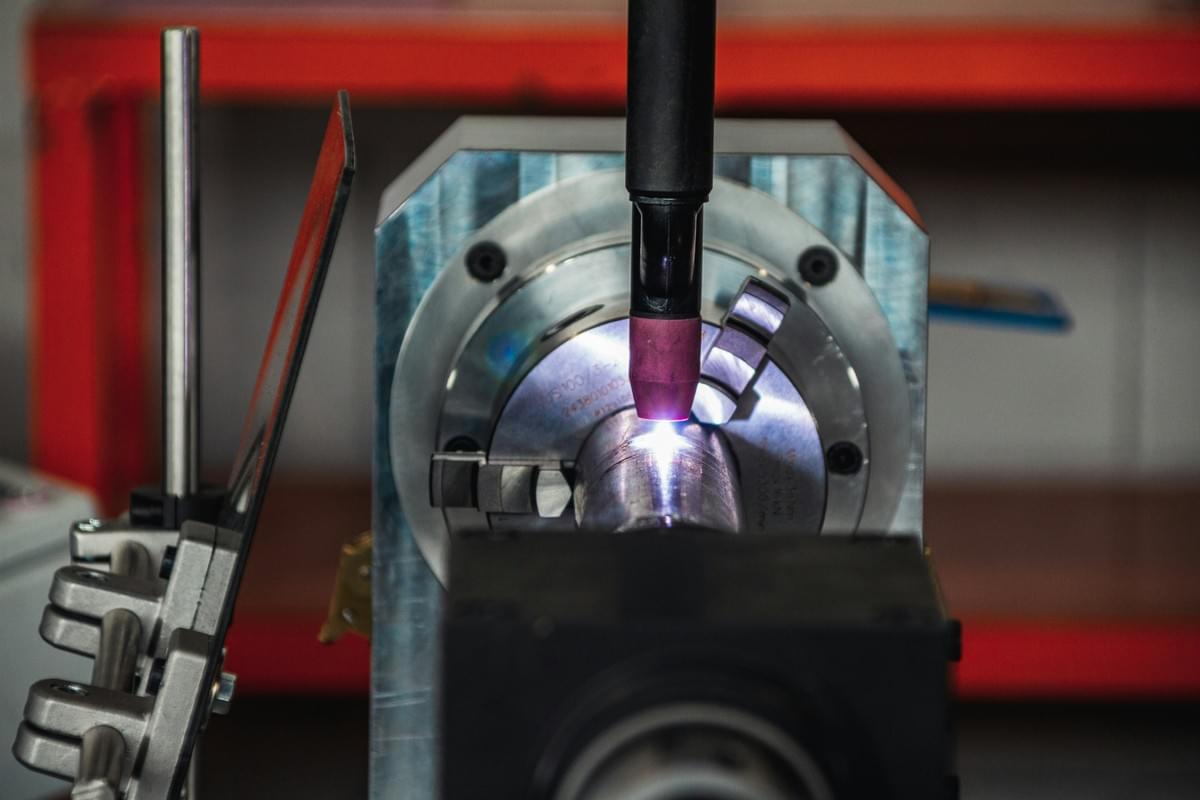

Laser cutting machines come in various forms, each designed to cater to specific applications and materials. For instance, fiber lasers are known for their efficiency with metals while CO2 lasers excel with non-metal materials like wood or acrylics. Familiarizing yourself with these different types allows you to make an informed decision when selecting from leading laser cutting manufacturers that offer machines suitable for your projects.

Assessing Manufacturer Reputation

Researching Industry Experience

The first step in assessing a manufacturer's reputation is to look into their industry experience. Manufacturers that have been around for several years typically have honed their skills and technologies, such as fiber laser cutting machines or metal laser cutters, to meet evolving market demands. A wealth of experience often translates into better craftsmanship and innovation, making it essential to choose those who have established themselves as leaders among laser cutting manufacturers.

Moreover, consider how diverse their experience is; a manufacturer that has worked across various sectors may offer more versatile solutions tailored to your specific needs. For instance, if you're interested in both laser and engraving machines, an experienced manufacturer is likely to provide comprehensive support across different applications. Ultimately, understanding their background will help you gauge whether they can meet your expectations.

Checking Customer Reviews and Testimonials

Customer reviews and testimonials act like gold nuggets when evaluating potential laser cutting manufacturers. They provide firsthand insights from other users about the performance of products like fiber lasers or metal cutting machines lasers they've purchased. A slew of positive reviews can indicate not just product quality but also customer satisfaction regarding service and support.

However, don't just focus on the glowing reviews; take note of any recurring issues mentioned by customers as well. This balanced view will help you avoid pitfalls associated with less reliable manufacturers while steering you toward those who truly excel in delivering high-quality equipment like fiber laser cutters or advanced metal laser cutters. Engaging with online forums or social media can also give you a broader perspective on customer experiences.

Industry Certifications and Awards

Another layer to assess when evaluating manufacturer reputation is looking at industry certifications and awards they may have received over the years. Certifications often indicate adherence to high standards in manufacturing processes—something crucial for producing reliable machinery like fiber lasers or metal cutting machines lasers that stand up to rigorous use over time.

Awards from reputable industry organizations serve as external validation of a manufacturer's capabilities and commitment to excellence within the field of laser cutting technologies. If you're considering investing in equipment from specific manufacturers, check if they’ve been recognized for innovation or quality assurance—this could be an indicator that you’re dealing with one of the top players among laser cutting manufacturers.

In conclusion, thoroughly researching industry experience, checking customer feedback, and verifying certifications can significantly aid your decision-making process when selecting a manufacturer for your next project involving precision tools such as fiber lasers or engraving machines.

Evaluating Product Quality

When it comes to selecting laser cutting manufacturers, evaluating product quality is essential to ensure you get the best value for your investment. High-quality machines not only enhance production efficiency but also reduce operational costs in the long run. In this section, we’ll delve into comparing various laser cutting technologies, identifying key features of reliable machines, and emphasizing the importance of precision and consistency.

Comparing Laser Cutting Technologies

The landscape of laser cutting technologies is diverse, with options ranging from CO2 lasers to fiber lasers. Each type has its unique advantages; for instance, fiber laser cutters are renowned for their efficiency in cutting metal materials with exceptional speed and accuracy. On the other hand, a metal cutting machine laser may be more suitable for thicker materials due to its powerful beam capabilities. Understanding these differences will help you choose the right technology that aligns with your specific needs.

Features of a Reliable Metal Laser Cutter

When assessing different models from various laser cutting manufacturers, certain features stand out as indicators of reliability in a metal laser cutter. Look for machines equipped with advanced cooling systems to prevent overheating during prolonged use and ensure longevity. Additionally, features such as automated focusing systems can significantly enhance usability and reduce setup time—making your operations smoother than ever before.

Importance of Precision and Consistency

In the world of manufacturing, precision and consistency are non-negotiable qualities that can make or break your production line's success. A high-quality fiber laser cutting machine should deliver consistent results across multiple runs without compromising on detail or accuracy—this is crucial when dealing with intricate designs or tight tolerances in metal fabrication projects. By prioritizing these aspects when evaluating potential suppliers, you set yourself up for long-term success in your manufacturing endeavors.

Support and After-Sales Service

When investing in a metal cutting machine laser, the support and after-sales service provided by laser cutting manufacturers can make or break your experience. A reliable manufacturer understands that the journey doesn’t end with the sale; it’s just the beginning. The level of support you receive can significantly impact your operational efficiency and overall satisfaction with your fiber laser cutter or engraving machine.

Training Opportunities for Operators

One of the most critical aspects of support is training opportunities for operators. Laser cutting manufacturers often offer comprehensive training programs to ensure that your team is well-equipped to handle the intricacies of a metal laser cutter or fiber laser cutting machine. This investment in education not only boosts productivity but also enhances safety, reducing the likelihood of costly mistakes that could arise from improper handling.

Moreover, these training sessions can cover everything from basic operation techniques to advanced troubleshooting methods, ensuring that operators feel confident and capable. A well-trained operator can maximize the capabilities of your metal cutting machine laser, leading to better outcomes and increased efficiency in production processes. Always inquire about available training programs when selecting a manufacturer.

Availability of Spare Parts and Maintenance

Another essential factor to consider is the availability of spare parts and maintenance services offered by laser cutting manufacturers. Regular maintenance is crucial for keeping your fiber laser cutter operating at peak performance, and having easy access to replacement parts can minimize downtime during repairs. Manufacturers who prioritize after-sales service typically stock essential components or have quick shipping options in place.

Additionally, some manufacturers provide maintenance contracts that include scheduled check-ups and servicing, which can be invaluable for long-term operational success. By ensuring you have access to timely repairs and quality parts, you’ll prolong the lifespan of your equipment while maintaining consistent production quality with minimal interruptions.

Customer Service Response Times

Lastly, customer service response times are paramount when evaluating potential manufacturers for your engraving machine or fiber laser cutting machine needs. The ability to reach knowledgeable representatives quickly can save you time and frustration during critical moments when issues arise with your equipment. Ideally, look for companies known for their prompt responses—after all, delays in communication could lead to extended downtimes affecting productivity.

A responsive customer service team should be accessible through multiple channels—whether via phone calls, emails, or live chat—to ensure you receive timely assistance whenever necessary. When researching different manufacturers, don’t hesitate to ask about their average response times; this will give you insight into how they prioritize customer care post-purchase.

Customization Options

When it comes to selecting laser cutting manufacturers, the ability to customize solutions is a game changer. A one-size-fits-all approach rarely works in the world of precision manufacturing, especially when dealing with intricate designs and diverse materials. By choosing a manufacturer that offers tailored solutions, you ensure that your specific cutting needs are met with high efficiency and effectiveness.

Tailoring Solutions to Your Needs

Laser cutting manufacturers often provide customizable options that cater specifically to your operational requirements. Whether you need a metal laser cutter for intricate designs or a fiber laser cutter for faster processing speeds, customization allows you to select features that align perfectly with your production goals. This adaptability not only enhances productivity but also optimizes the overall performance of your metal cutting machine laser.

Examples of Successful Custom Projects

Consider the success stories from various industries where laser and engraving machines have been customized for unique applications. For instance, one manufacturer collaborated with an automotive company to develop a specialized fiber laser cutting machine that could handle complex shapes while maintaining tight tolerances. Such successful custom projects demonstrate how flexible manufacturing can lead to innovative solutions and competitive advantages in the market.

Importance of Flexibility in Manufacturing

Flexibility in manufacturing is crucial for staying ahead in today’s fast-paced business environment. Laser cutting manufacturers who prioritize customization can quickly adapt their processes based on evolving market demands or customer specifications, ensuring timely delivery and satisfaction. This flexibility not only fosters long-term partnerships but also positions companies as leaders in their respective fields, ready to tackle any challenge that comes their way.

Cost Considerations

When it comes to investing in a laser cutting machine, understanding the cost is more than just looking at the price tag. The total cost of ownership (TCO) encompasses not only the initial purchase price of your selected metal cutting machine laser but also ongoing operational costs, maintenance, and potential downtime. By analyzing TCO, you can make a more informed decision about which laser cutting manufacturers offer the best value for your specific needs.

Analyzing Total Cost of Ownership

The total cost of ownership involves evaluating all expenses associated with operating a fiber laser cutter over its lifespan. This includes energy consumption, maintenance costs, and any necessary training for operators to ensure optimal performance from your metal laser cutter. Additionally, consider how often you'll need to replace parts or invest in upgrades; these factors can significantly affect your long-term budget.

Moreover, when assessing TCO, think about the efficiency and speed of the machine. A high-quality fiber laser cutting machine might come with a higher upfront cost but could save you money over time through faster production rates and lower operational costs. In contrast, cheaper options may lead to increased expenses due to frequent repairs or inefficiencies that slow down production.

Comparing Quotes from Different Manufacturers

Once you've established an understanding of TCO, it's time to compare quotes from various laser cutting manufacturers. Don't settle for the first quote you receive; instead, gather multiple estimates that detail not only the price but also what features are included in each package. Ensure you're comparing apples to apples—look for similar specifications such as power output and cutting speed among different models like a metal cutting machine laser or fiber laser cutter.

While initial pricing is important, be wary of hidden costs that may arise later on—these could include shipping fees or additional charges for installation and training on your new equipment like a laser and engraving machine. By scrutinizing each quote carefully, you can identify which manufacturer offers genuine value without sacrificing quality or service.

Finally, keep in mind that some manufacturers may offer discounts for bulk purchases or long-term contracts. If you're planning on scaling up operations in the future or need multiple machines for different applications, negotiating these terms could lead to significant savings down the line.

Financing Options and ROI

Investing in advanced technologies like a fiber laser cutter often requires substantial capital upfront; however, many manufacturers provide financing options designed to ease this burden. Explore various payment plans such as leasing versus purchasing outright—each has its pros and cons depending on your business model and cash flow situation. A well-structured financing plan can help you manage expenses while still acquiring top-notch equipment from reputable laser cutting manufacturers.

Additionally, it's essential to calculate potential return on investment (ROI) when considering financing options for your metal laser cutter purchase. Assess how quickly you expect to recoup your investment based on increased productivity or reduced material waste generated by using advanced technology like a metal cutting machine laser compared to older methods. This analysis will empower you with insights into whether investing now will pay off significantly later.

In conclusion, being mindful of cost considerations ensures that you're making an informed decision when selecting among various suppliers and types of machinery available today—from traditional models to innovative fiber lasers designed specifically for precision work.

Conclusion

In the world of manufacturing, choosing the right laser cutting manufacturers can make all the difference in your operational efficiency and product quality. A thorough assessment of your cutting needs, combined with an understanding of the various technologies available, will pave the way for informed decision-making. By prioritizing reputation, product quality, and after-sales support, you position your business for success in a competitive landscape.

Key Takeaways for Choosing Manufacturers

When selecting laser cutting manufacturers, it’s essential to consider their industry experience and customer feedback to gauge reliability. Pay special attention to the types of machines they offer—whether it's a fiber laser cutter or a metal cutting machine laser—as each has unique benefits tailored to specific applications. Lastly, don’t overlook the importance of after-sales service; training opportunities and responsive customer support are vital for maximizing your investment in equipment like a metal laser cutter.

The Role of Innovative Technology

Advances such as fiber laser cutting machines have revolutionized precision and speed, enabling businesses to achieve higher productivity levels without compromising on quality. Staying abreast of these technological advancements allows you to make strategic choices that enhance operational capabilities while keeping costs manageable.

Final Thoughts on Long-Term Partnerships

Building long-term partnerships with reliable laser cutting manufacturers can yield substantial benefits over time. These relationships foster collaboration that leads to customized solutions tailored specifically for your business needs—whether through specialized projects or ongoing technical support. Ultimately, investing time in selecting a manufacturer who aligns with your vision will pay dividends in both efficiency and innovation as you navigate future challenges.