Introduction

In the ever-evolving world of construction, understanding the tools that shape our built environment is crucial. Light gauge steel machines play a pivotal role in the production of cold formed steel, which has become a staple in modern metal framing. These machines streamline the process of creating durable and versatile framing solutions for various applications, making them indispensable for builders and architects alike.

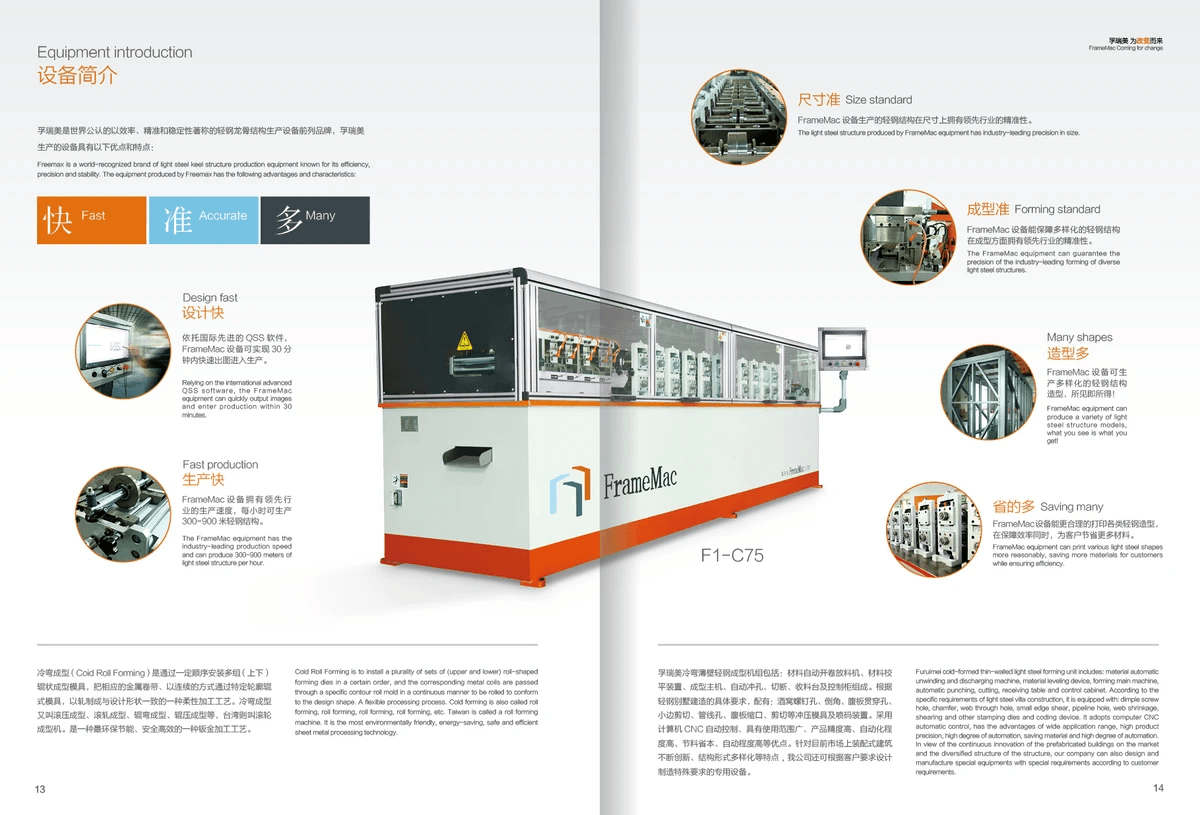

Understanding Light Gauge Steel Machines

Light gauge steel machines are specialized equipment designed to produce cold formed steel components efficiently and accurately. They work by shaping flat sheets of cold rolled metal into various profiles used in light gauge steel framing, essential for constructing both residential and commercial buildings. By automating the manufacturing process, these machines not only enhance productivity but also ensure precision in every piece produced.

Benefits of Using Cold Formed Steel

Cold formed steel offers numerous advantages that make it an attractive option for framing steel buildings. First and foremost, it provides a lightweight yet incredibly strong material that can withstand significant loads while reducing overall structural weight. Additionally, its cost-effectiveness in producing cold formed metal framing allows builders to maximize their budgets without compromising on quality or performance.

Overview of Kiant Machinery's Offerings

Kiant Machinery stands out as a leading provider of innovative solutions tailored to meet the needs of modern construction projects. Their range of cold formed steel machines includes advanced models that cater to various requirements within light gauge steel framing applications. With a commitment to quality and customer satisfaction, Kiant Machinery ensures that builders have access to reliable equipment designed for longevity and efficiency in their operations.

What is a Multi Profile Light Gauge Steel Machine

Multi profile light gauge steel machines are revolutionizing the way we approach metal framing in construction. These machines are designed to produce various profiles of cold formed steel, enabling builders to create strong and lightweight structures efficiently. Understanding their functionality is crucial for anyone involved in framing steel buildings.

Definition and Functionality

A multi profile light gauge steel machine is a specialized piece of equipment that fabricates cold formed steel into different shapes and sizes for construction purposes. This versatility allows manufacturers to produce custom sections that meet specific design requirements while maintaining structural integrity. By utilizing advanced technology, these machines streamline the production process, reducing labor costs and time on site.

The functionality of these machines extends beyond simple shaping; they can also integrate features like punching, cutting, and bending in one seamless operation. This all-in-one capability makes them invaluable for contractors looking to optimize their workflow when working with light gauge steel framing. With the ability to quickly switch profiles, these machines enhance productivity without sacrificing quality.

Differences Between Cold Formed and Cold Rolled Steel

When discussing cold formed steel versus cold rolled steel, it's essential to recognize their distinct manufacturing processes and applications in metal framing. Cold formed steel is made by bending or shaping flat sheets of metal at room temperature, resulting in a material that retains its strength while being lightweight and flexible for various designs. In contrast, cold rolled steel undergoes additional processing where it is rolled at lower temperatures after being heated; this gives it different properties suitable for other applications.

Cold formed metal framing generally offers enhanced structural performance due to its unique manufacturing process, making it ideal for building frameworks that require precision and durability. On the other hand, cold rolled steel tends to be used more commonly in applications where thickness or specific mechanical properties are necessary but may not provide the same level of flexibility as its cold-formed counterpart. Recognizing these differences helps builders choose the right material based on project requirements.

Importance in Metal Framing

The importance of multi profile light gauge steel machines in metal framing cannot be overstated; they are essential tools that empower builders with innovative solutions for modern construction challenges. As architects push the boundaries of design with increasingly complex structures, having access to versatile machinery allows contractors to keep pace while ensuring safety standards are met through reliable materials like cold formed steel.

Moreover, using these machines contributes significantly to sustainability efforts within the industry by minimizing waste during production processes compared to traditional methods involving heavier materials like wood or concrete. This eco-friendly aspect aligns well with contemporary construction practices focused on reducing environmental impact while maximizing efficiency—key components when constructing buildings today.

In summary, multi profile light gauge steel machines play a vital role in advancing techniques within metal framing by providing adaptability and performance benefits over conventional methods like using cold rolled metal or other materials less suited for modern architectural demands.

Advantages of Cold Formed Steel in Construction

Cold formed steel is revolutionizing the construction industry, particularly in metal framing applications. Its unique properties make it a highly sought-after material for both residential and commercial projects. Understanding the advantages of cold formed steel can help builders and architects make informed decisions when selecting materials for framing steel buildings.

Lightweight Yet Strong Material

One of the standout features of cold formed steel is its impressive strength-to-weight ratio. When compared to traditional building materials, cold rolled steel offers significant structural integrity without adding unnecessary weight to the overall design. This lightweight quality not only simplifies transportation and handling but also reduces stress on foundations, making light gauge steel framing an ideal choice for various construction projects.

Additionally, the strength derived from this type of steel allows for longer spans and more open spaces within buildings, enhancing architectural creativity. This means that designers can push boundaries without compromising safety or structural performance, creating innovative spaces that are both functional and aesthetically pleasing. The versatility of cold formed metal framing ensures it meets diverse needs across different sectors while maintaining durability.

Cost-Effectiveness in Framing Steel Buildings

The efficiency gained from using a cold formed steel machine translates into reduced labor costs during installation due to faster assembly times. Moreover, the longevity and low maintenance requirements associated with cold rolled metal contribute to savings over the lifespan of any building.

Investing in cold formed metal framing also minimizes waste during construction since precision manufacturing ensures accurate dimensions and fewer errors on-site. This aspect not only helps keep project budgets intact but also aligns with sustainability goals by reducing material waste in landfills. In a market where every penny counts, opting for light gauge steel framing can lead to significant financial benefits without sacrificing quality or performance.

Flexibility in Design and Application

The adaptability of cold formed steel makes it an excellent choice for various architectural styles and purposes—whether you’re constructing a sleek modern office or a cozy family home. Its ease of customization allows builders to create intricate designs that would be challenging with other materials like wood or concrete; this flexibility opens up endless possibilities for creative expression in construction projects.

Furthermore, light gauge steel framing accommodates changes during the design process without incurring excessive costs or delays—an essential feature when working on complex builds where modifications are common. As trends evolve or client needs shift, having a material that can adapt quickly is invaluable in today’s fast-paced construction environment. Embracing cold rolled steel not only enhances design potential but also streamlines workflows from concept to completion.

Applications of Light Gauge Steel Framing

Light gauge steel framing has emerged as a versatile solution in various construction sectors, thanks to its unique properties and the efficiency offered by cold formed steel machines. This innovative approach to metal framing allows for rapid assembly and strong structural integrity, making it an ideal choice for both residential and commercial projects. The adaptability of cold formed metal framing is transforming how we think about building design and construction methodologies.

Residential vs. Commercial Uses

When it comes to residential applications, light gauge steel framing is increasingly popular for homes that require durability without compromising on aesthetics. Builders appreciate the lightweight yet robust nature of cold rolled steel, which simplifies transportation and installation while maintaining structural strength. On the commercial side, cold formed steel machines are instrumental in constructing office buildings, warehouses, and retail spaces where flexibility in design is paramount.

In both sectors, the use of light gauge steel allows architects and builders to push boundaries in terms of design possibilities, leading to innovative structures that stand out in their environments. Whether it's a cozy family home or a sprawling commercial complex, cold formed metal framing offers solutions that meet diverse needs efficiently. The ability to customize designs with this type of metal framing ensures that projects can be tailored specifically to client requirements.

Impact on Modern Architecture

The influence of light gauge steel framing on modern architecture cannot be overstated; it has opened up new avenues for creativity while ensuring stability and safety in structures. Architects are now able to explore daring shapes and expansive spaces without the constraints typically associated with traditional building materials like wood or concrete. Cold rolled metal provides an aesthetic appeal alongside functionality—think sleek lines combined with robust frameworks.

Moreover, integrating cold formed steel into architectural designs allows for larger spans without additional support beams, creating vast open areas within buildings—perfect for contemporary layouts! This evolution not only enhances visual appeal but also optimizes usable space within both residential homes and commercial establishments alike. As modern architecture continues to evolve, the role of light gauge steel will undoubtedly grow even more prominent.

Sustainability and Environmental Benefits

Sustainability is at the forefront of today’s construction practices, making light gauge steel framing an attractive option due to its recyclability and minimal environmental impact compared to traditional materials like wood or concrete. Cold formed steel can be recycled repeatedly without losing strength or quality; this characteristic significantly reduces waste during production processes as well as at end-of-life stages for buildings constructed using this material.

Additionally, using cold rolled metal contributes to energy efficiency during construction since less energy is required for manufacturing compared to other building materials—this aligns perfectly with green building initiatives worldwide! Incorporating light gauge steel into projects not only supports sustainable practices but also promotes long-term savings through reduced maintenance costs over time due to its durability against elements such as pests or rot.

Choosing the Right Cold Formed Steel Machine

Selecting the right cold formed steel machine is crucial for any business involved in metal framing. The right equipment can enhance productivity, ensure precision, and ultimately lead to better quality in framing steel buildings. With so many options available, it's essential to consider various features that align with your specific needs.

Key Features to Consider

When evaluating cold formed steel machines, several key features should be at the forefront of your decision-making process. First and foremost is the machine's capacity; you need a system that can handle the gauge and width of cold rolled steel you plan to work with. Additionally, look for machines that offer versatility—those capable of producing different profiles can significantly boost your operational flexibility in light gauge steel framing projects.

Another important feature is automation level; machines that integrate advanced technology can streamline production processes and reduce human error. Efficiency is key, so consider machines with high-speed capabilities and those designed for easy setup and changeovers between projects. Finally, don't overlook after-sales support; a reliable manufacturer like Kiant Machinery provides ongoing assistance that ensures your cold formed metal framing operations run smoothly.

Comparing Manual vs. Automated Options

When it comes to choosing between manual and automated options for cold formed steel machines, understanding their pros and cons is vital for making an informed choice. Manual machines tend to be more affordable upfront but often require skilled labor for operation, which can slow down production times when demand increases. On the other hand, automated systems generally come with a higher initial investment but offer greater efficiency in producing large volumes of cold rolled metal components.

Automated options excel in precision and consistency—ideal attributes when working on complex light gauge steel framing projects where accuracy matters most. They also reduce labor costs over time as fewer operators are needed per shift compared to manual setups. Ultimately, the choice depends on your budget constraints and production goals; weigh these factors carefully before making a commitment.

Solutions from Kiant Machinery

Kiant Machinery stands out as a leading provider of innovative solutions tailored specifically for businesses focused on cold formed metal framing applications. Their range of cold formed steel machines includes both manual and automated options designed to meet diverse operational needs without compromising quality or performance standards in metal framing projects.

One notable offering is their multi-profile light gauge steel machine, which combines versatility with high efficiency—perfect for companies looking to maximize productivity while minimizing waste during manufacturing processes involving cold rolled steel materials. Furthermore, Kiant Machinery emphasizes customer satisfaction by providing comprehensive training programs alongside robust after-sales support—ensuring you get the most out of your investment in their equipment.

In summary, choosing the right cold formed steel machine involves careful consideration of features like capacity, automation level, and manufacturer support—factors all expertly addressed by Kiant Machinery’s extensive product lineup tailored specifically for today's competitive market demands.

Maintenance and Support for Cold Rolled Steel Equipment

When it comes to cold rolled steel equipment, regular maintenance is not just a suggestion—it's a necessity. Keeping your cold formed steel machine in top shape ensures that your metal framing projects run smoothly and efficiently. Neglecting maintenance can lead to costly downtime and repairs, which is something no one wants when framing steel buildings.

Importance of Regular Maintenance

Regular maintenance of cold rolled metal equipment is vital for ensuring optimal performance and longevity. A well-maintained cold formed steel machine minimizes the risk of unexpected breakdowns, allowing you to focus on what truly matters: delivering high-quality light gauge steel framing solutions. Moreover, routine checks can help identify potential issues before they escalate into major problems, saving both time and money in the long run.

Kiant Machinery's After-Sales Support

Kiant Machinery understands that purchasing a cold formed steel machine is just the beginning of your journey in metal framing. Their after-sales support is designed to provide you with peace of mind, offering assistance whenever you need it most. Whether it's troubleshooting issues or providing replacement parts for your cold rolled steel equipment, Kiant Machinery stands behind their products with unwavering commitment.

Training for Efficient Operations

To maximize the efficiency of your cold formed metal framing operations, proper training is essential. Kiant Machinery offers comprehensive training programs tailored specifically for users of their light gauge steel machines. With expert guidance on operating techniques and best practices, you'll be equipped to get the most out of your cold rolled metal equipment while ensuring safety and compliance in all your projects.

Conclusion

In the ever-evolving landscape of construction, cold formed metal framing is poised to play a pivotal role in shaping the future of building design and efficiency. The advantages offered by cold formed steel machines are undeniable, from their lightweight properties to their robust strength, making them an ideal choice for both residential and commercial projects. As we look ahead, it is clear that the demand for innovative metal framing solutions will only grow, setting the stage for exciting advancements in construction technology.

The Future of Cold Formed Metal Framing

The future of cold formed metal framing is bright, with increasing recognition of its benefits over traditional materials like cold rolled steel. Architects and builders are increasingly turning to light gauge steel framing due to its flexibility and adaptability to various design requirements. With sustainability becoming a cornerstone of modern architecture, cold formed steel's recyclability positions it as a frontrunner in eco-friendly building materials.

Maximizing Efficiency with Advanced Machinery

To maximize efficiency in constructing framing steel buildings, investing in advanced machinery is essential. Cold formed steel machines equipped with cutting-edge technology streamline production processes and reduce waste, ultimately enhancing profitability. Automated systems not only improve speed but also ensure precision in fabrication, allowing builders to focus on creativity rather than labor-intensive tasks.

Partnering with Kiant Machinery for Success

Their extensive range of reliable cold formed steel machines provides tailored solutions that meet diverse project needs while maintaining high standards of quality and performance. With exceptional after-sales support and training programs available, Kiant Machinery ensures that you are well-equipped to succeed in your endeavors within the world of metal framing.