Introduction

In the ever-evolving world of construction, the significance of advanced machinery cannot be overstated. Among these machines, the steel deck cold bending machine stands out as a vital tool for achieving precision and efficiency in metal forming processes. Understanding how these machines operate is essential for anyone looking to optimize their projects and improve overall productivity.

Understanding Steel Deck Bending Machines

Steel deck bending machines, particularly cold bending models, are designed to shape steel sheets with remarkable accuracy. These machines utilize specialized rollers and dies to form steel into various profiles, perfect for applications like roofing and flooring systems. By grasping the mechanics behind a steel deck roll forming machine, manufacturers can harness its capabilities to create high-quality products that meet stringent industry standards.

Importance of Precision in Metal Forming

Precision is paramount in metal forming; even minor discrepancies can lead to significant issues down the line. A reliable steel roll forming machine ensures that each piece produced is identical and meets exact specifications, which is crucial for structural integrity in construction projects. The right tools can make all the difference between a flawless installation and costly rework due to inaccuracies.

Efficiency Gains in Construction

The integration of advanced machinery like steel roofing roll forming machines has revolutionized construction practices by enhancing efficiency and reducing labor costs. With automated features and user-friendly interfaces, these sheet making machines streamline production processes while minimizing waste. Investing in a quality forming machine not only boosts output but also contributes positively to your bottom line by optimizing resource use.

Overview of Steel Deck Cold Bending Machines

Steel deck cold bending machines are revolutionizing the way we approach metal forming in construction. By utilizing innovative technology, these machines offer precision and efficiency that traditional methods simply can't match. Understanding how cold bending works is essential to appreciating its advantages and applications in the industry.

How Cold Bending Works

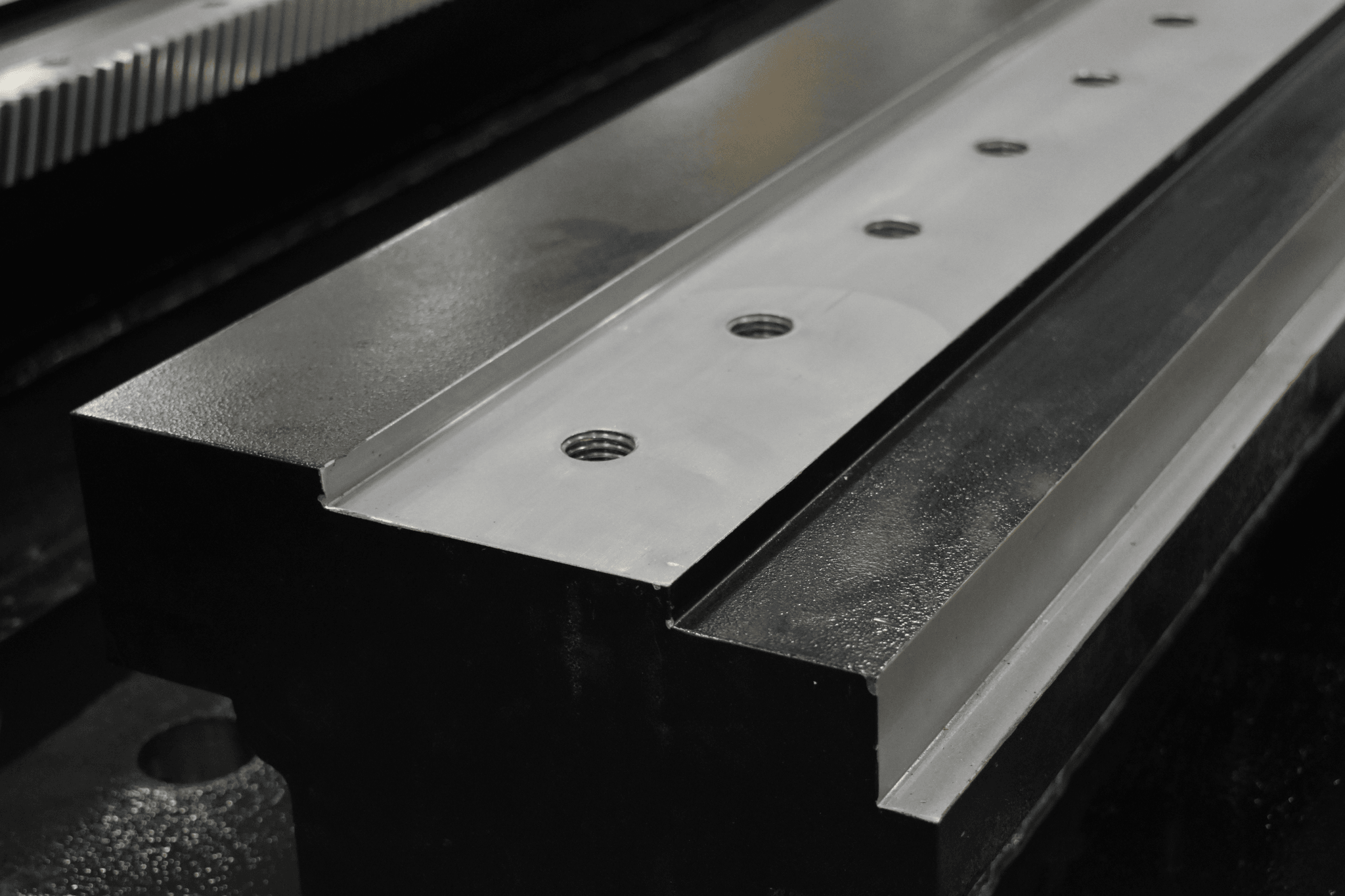

Cold bending involves shaping steel without applying heat, allowing for greater control over the material's properties. The process utilizes a steel deck cold bending machine that gradually forms the metal into desired shapes through a series of rollers and dies. This method not only preserves the integrity of the steel but also enhances its strength, making it ideal for various construction applications.

Advantages of Using Cold Bending

One significant advantage of using a steel roll forming machine for cold bending is its ability to produce complex shapes with high precision. This means less waste and lower costs, as materials are utilized more efficiently compared to traditional hot bending methods. Additionally, the forming machine price remains competitive due to reduced energy consumption and faster production times, making it an attractive option for contractors.

Applications in Construction and Architecture

Steel deck roll forming machines have numerous applications in both construction and architecture, providing solutions for roofing systems, wall panels, and structural components. Their versatility allows architects and builders to create intricate designs while maintaining structural integrity and durability. Whether it's for commercial buildings or residential projects, these machines play a crucial role in modern construction practices.

Key Features of Roll Forming Machines

Roll forming machines are the unsung heroes of modern construction, offering a blend of efficiency and precision that is hard to beat. These machines, particularly the steel deck cold bending machine, are designed to create complex shapes from metal sheets with remarkable accuracy. Understanding their key features can help you choose the right equipment for your projects and maximize your investment.

Customization Options for Different Projects

One standout feature of steel roll forming machines is their customization capabilities. Whether you’re looking at a steel roofing roll forming machine or a specialized steel deck roll forming machine, these machines can be tailored to meet specific project requirements. From adjusting the dimensions to accommodating various profiles, customization ensures that your sheet making machine produces exactly what you need for each unique application.

Furthermore, many manufacturers offer bespoke solutions that cater to niche markets within construction and architecture. This means that no matter how intricate your design needs may be, there’s likely a roll forming machine ready to tackle it head-on. The ability to customize not only enhances project outcomes but also opens up new avenues for creativity in design.

Automation and User-Friendly Interfaces

The modern roll forming machine comes equipped with automation features that significantly boost productivity while reducing labor costs. With intuitive user-friendly interfaces, operators can easily program settings and monitor production processes without needing extensive training or experience. This level of automation is particularly beneficial when using a steel deck cold bending machine since it minimizes human error and maximizes output efficiency.

Additionally, many advanced models incorporate smart technology that allows for real-time adjustments based on material behavior during the forming process. This adaptability ensures consistent quality across batches—an essential factor in maintaining standards in construction projects. Ultimately, investing in automated solutions not only streamlines operations but also enhances overall safety on job sites.

Comparison of Steel Roll Forming Machine Models

When considering a steel sheet making machine for your business, comparing different models is crucial to finding the best fit for your needs and budget constraints like roll forming machine price or forming machine price variations across brands. Each model comes with its own set of features tailored to specific applications—be it high-speed production capabilities or versatility in material types used.

For instance, some steel roofing roll forming machines excel at producing large volumes quickly but may sacrifice some precision compared to more specialized options like the steel deck roll forming machine designed specifically for intricate designs and details. Evaluating these differences will help you identify which model aligns best with both your operational goals and financial resources while ensuring you get maximum value from your investment.

Ultimately, understanding these key features will empower you as a buyer or operator in selecting machinery that not only meets today’s demands but also adapts seamlessly into future projects requiring innovative solutions.

Steel Deck Roll Forming Machine: A Deep Dive

When it comes to the construction industry, the steel deck roll forming machine stands as a cornerstone of efficiency and precision. These machines are engineered to transform flat steel sheets into structurally sound decks that support various architectural designs. Understanding the engineering behind these machines is crucial for anyone looking to invest in steel sheet making technology.

Engineering Behind Deck Forming

The engineering behind steel deck roll forming machines is a blend of advanced technology and mechanical expertise. These machines use a series of rollers to progressively shape flat steel into desired profiles, ensuring uniformity and strength throughout the production process. The precision involved in this engineering is vital; even minor deviations can lead to significant structural issues down the line.

Notably, the design of a steel deck cold bending machine focuses on optimizing material flow and reducing waste, which contributes to cost savings in large-scale projects. This meticulous approach ensures that every piece produced meets stringent quality standards while minimizing downtime during operation. The result is a highly efficient manufacturing process that keeps projects on schedule and within budget.

Innovations in Steel Deck Design

Innovations in steel deck design have revolutionized how construction projects are approached today. With advancements in technology, modern roll forming machines can create complex profiles that were previously unattainable with traditional methods. This flexibility allows architects and engineers to push boundaries, resulting in unique designs that enhance both aesthetics and functionality.

In addition, new materials and coatings have been introduced alongside these innovations, improving durability against environmental factors such as corrosion or extreme weather conditions. Steel roofing roll forming machines now incorporate these advancements seamlessly into their production processes, providing builders with high-quality materials for long-lasting structures. As a result, clients benefit from both enhanced performance and lower maintenance costs over time.

Cost-Effectiveness of Forming Solutions

When analyzing roll forming machine price versus its benefits, it's essential to consider long-term savings rather than just initial costs. Investing in a reliable steel deck roll forming machine can lead to significant reductions in labor costs due to increased automation and efficiency during production runs. Moreover, the durability of products made from these machines often translates into fewer repairs or replacements needed over time.

Factors influencing forming machine price include customization options, automation features, and overall capacity—each impacting your return on investment significantly. By selecting the right model for your needs—whether it's a compact sheet making machine or an expansive industrial unit—you ensure that you're not only meeting current demands but also positioning yourself for future growth opportunities within the industry. Ultimately, understanding these dynamics will help you make informed decisions about your equipment investments.

Investment Insights: Roll Forming Machine Price

When it comes to investing in machinery for steel production, understanding the roll forming machine price is essential. A steel deck cold bending machine can be a significant investment, but its benefits often outweigh the initial costs. By analyzing the costs versus benefits, businesses can make informed decisions that enhance productivity and profitability.

Analyzing Costs vs. Benefits

Investing in a steel deck roll forming machine means weighing upfront costs against long-term gains. While the roll forming machine price may seem daunting at first glance, consider the efficiency and precision it brings to metal forming processes. The ability to produce high-quality steel sheets consistently not only reduces waste but also minimizes labor costs over time.

Moreover, these machines often come equipped with advanced technology that enhances their functionality, such as automated systems and user-friendly interfaces. This means less downtime for training and more time dedicated to production. Ultimately, when evaluating a forming machine price, it's vital to factor in potential savings from reduced material waste and increased output.

Factors Influencing Machine Pricing

Several factors contribute to the pricing of steel roofing roll forming machines, making it crucial for buyers to do their homework before purchasing. The complexity of design plays a significant role; customizations tailored for specific projects typically drive up costs compared to standard models. Additionally, features such as automation capabilities and advanced engineering can significantly influence the overall price tag.

Another consideration is the brand reputation; established manufacturers often command higher prices due to reliability and service support offered post-purchase. Maintenance requirements also play a part; machines that are easier to service or require less frequent repairs might justify a higher initial investment when considering long-term operational expenses.

Finally, market demand can fluctuate pricing trends; keeping an eye on industry developments could help buyers snag deals on quality equipment like steel sheet making machines during off-peak times.

Budgeting for Your Steel Sheet Making Machine

Budgeting for your next steel sheet making machine requires careful planning and foresight into both immediate needs and future scalability options. Start by determining your production goals—how much output you anticipate will guide your choice between various models of steel roll forming machines available in today’s market.

Factor in not just the purchase price but also ongoing operational expenses such as electricity consumption, maintenance plans, and potential upgrades down the line—these all add up quickly! It’s wise to set aside additional funds for unexpected repairs or enhancements that may improve efficiency even further.

Lastly, consider financing options if upfront costs are prohibitive; many manufacturers offer payment plans or leasing arrangements that can ease financial pressure while allowing you access to cutting-edge technology like steel deck cold bending machines right away.

Essential Equipment for Sheet Making

In the realm of construction and manufacturing, having the right equipment is crucial for producing high-quality steel sheets. The variety of machines available can significantly influence both efficiency and output quality. Understanding the different types of steel sheet making machines is essential for any business looking to invest wisely.

Types of Steel Sheet Making Machines

When it comes to steel sheet making, there are several types of machines designed to meet specific needs. The steel deck cold bending machine is particularly popular for its ability to create precise bends without compromising the integrity of the material. On the other hand, steel roofing roll forming machines excel in producing continuous sheets that can be easily installed on various structures, showcasing versatility in applications.

In addition to these specialized machines, there are also general-purpose roll forming machines that can handle a range of tasks from simple bends to complex profiles. Each machine has unique features tailored for specific projects, ensuring that businesses can find a solution that fits their production requirements perfectly. Investing in a quality steel roll forming machine not only enhances productivity but also ensures consistent results across different jobs.

Maintenance and Longevity of Equipment

Maintaining your sheet making machine is vital for ensuring longevity and optimal performance over time. Regular inspections and servicing can prevent costly breakdowns and extend the life of your equipment significantly. For instance, a well-maintained steel deck roll forming machine will operate more efficiently, reducing downtime and increasing output.

Moreover, understanding how to care for your machinery extends beyond routine maintenance; it also involves using the right lubricants and cleaning agents suited for your specific equipment type. This attention to detail not only preserves functionality but also enhances safety during operation—an often overlooked aspect in industrial settings. Remember, investing in maintenance today means reaping benefits tomorrow when you avoid unexpected repairs or replacements.

Choosing the Right Model for Your Needs

Selecting the appropriate model among various sheet making machines requires careful consideration of your project's unique demands. Factors such as production volume, material type, and desired features should guide your decision-making process when evaluating options like a steel roofing roll forming machine or a more specialized model like a steel deck cold bending machine.

Additionally, it's essential to weigh roll forming machine prices against potential benefits; sometimes spending slightly more upfront can lead to significant savings through increased efficiency or lower operational costs over time. Engaging with suppliers who understand your needs can provide valuable insights into which models offer the best return on investment tailored specifically for you—ensuring you're equipped with machinery that aligns with both current projects and future growth plans.

Conclusion

In the rapidly evolving landscape of construction, advanced machinery plays a pivotal role in enhancing efficiency and precision. The integration of steel deck cold bending machines and steel roll forming machines has revolutionized how we approach metal forming, allowing for greater design flexibility and reduced labor costs. As we look to the future, embracing these technologies will undoubtedly transform construction practices and outcomes.

Transforming Construction with Advanced Machinery

The advent of the steel deck roll forming machine has significantly streamlined the process of creating structural components. With its ability to produce high-quality sheets quickly and accurately, this machinery reduces waste while maintaining precision—key factors in modern construction projects. The impact is clear: projects are completed faster, with less manual intervention, leading to overall cost savings.

Kiant Machinery: Your Partner in Efficiency

Kiant Machinery stands out as a leader in providing innovative solutions for steel sheet making machines and other related equipment. Their commitment to quality ensures that clients receive reliable machinery at competitive roll forming machine prices, enhancing productivity without breaking the bank. With a focus on customer satisfaction, Kiant Machinery supports businesses in navigating their investment decisions effectively.

Future Trends in Steel Deck Manufacturing

Looking ahead, we can expect continued advancements in technology related to steel roofing roll forming machines and other sheet making machines. Innovations such as automation and smart technology integration are set to redefine efficiency standards within the industry. As manufacturers adapt to these trends, we will likely see even more cost-effective solutions that prioritize sustainability alongside performance.