Introduction

In the ever-evolving world of manufacturing, selecting the best laser cutting machine suppliers can make all the difference in your production efficiency and quality. Whether you're in automotive, aerospace, or any other industry that relies on precision metalwork, understanding the nuances of laser cutting is crucial. The right supplier not only provides you with advanced equipment but also ensures you have ongoing support to maximize your investment.

Discover the Best Laser Cutting Suppliers

Finding reputable laser cutting machine suppliers requires a keen eye for quality and innovation. With a plethora of options available, it's essential to sift through various offerings to discover those that stand out for their reliability and technological advancements. The best suppliers will offer a range of products including industrial laser cutters and specialized metal cutting machines tailored to meet diverse needs.

Why Choosing the Right Supplier Matters

A dependable partner not only provides high-quality equipment but also offers essential after-sales support and maintenance services that keep your operations running smoothly. Moreover, selecting a supplier with industry credentials ensures you receive machinery that meets safety standards and performance expectations.

Key Features to Look For in Suppliers

When evaluating potential metal cutter machine suppliers, certain key features should be at the forefront of your decision-making process. Look for companies that boast robust customer support systems, comprehensive warranties, and positive customer reviews highlighting their reliability in service delivery. Additionally, consider suppliers who offer customization options for their industrial laser cutting machines to better suit your specific production requirements.

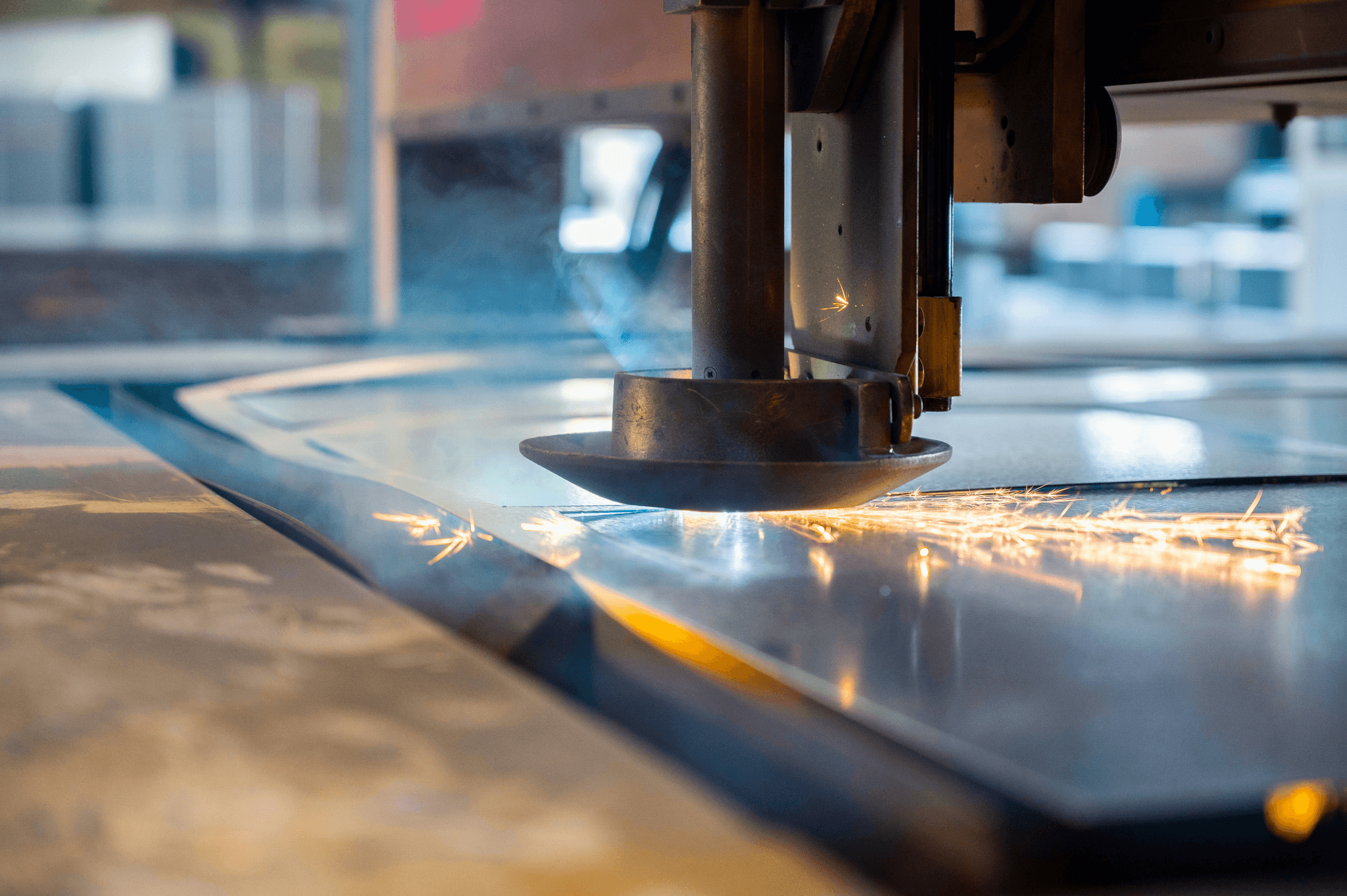

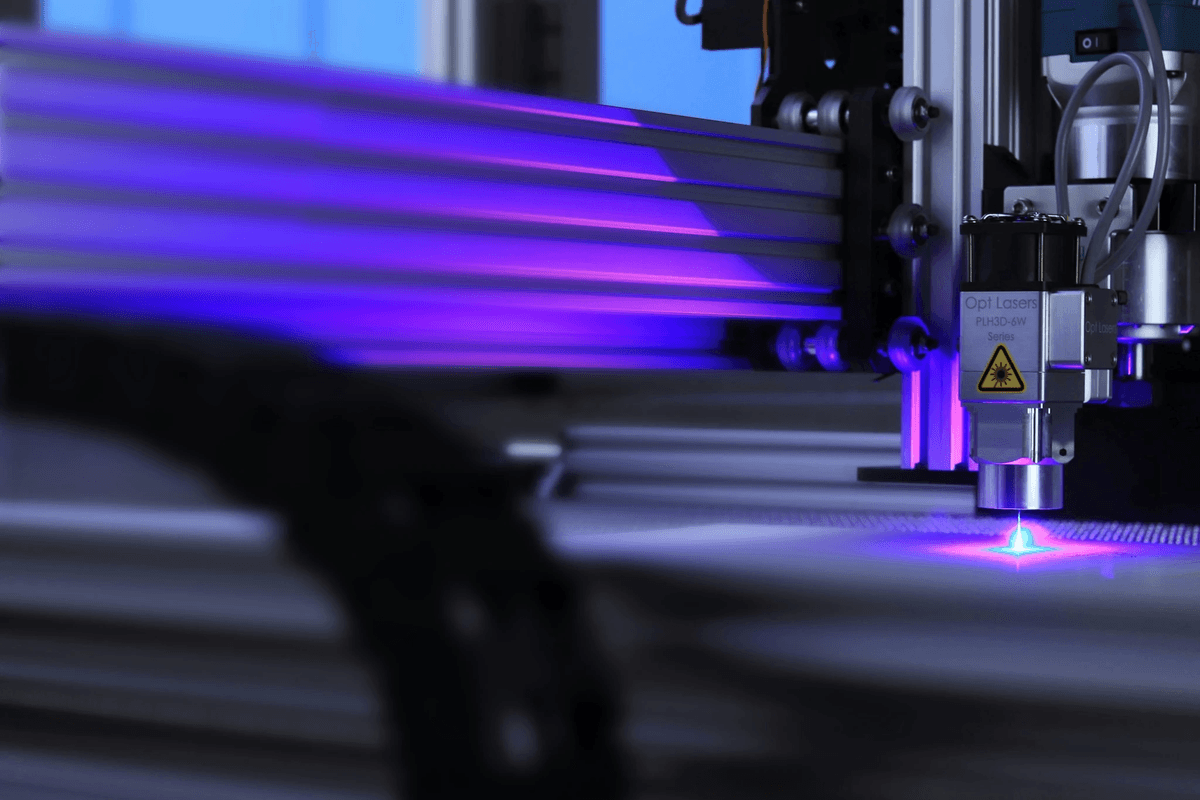

Overview of Laser Cutting Technology

Laser cutting technology has revolutionized the manufacturing landscape, offering precision and efficiency that traditional methods simply can’t compete with. At its core, laser cutting utilizes focused light beams to slice through materials with unparalleled accuracy. This technique is particularly beneficial for metal fabrication, where the need for clean cuts and intricate designs is paramount.

Understanding Laser Cutting Techniques

Laser cutting techniques can vary widely depending on the type of laser used and the material being cut. Common methods include CO2 lasers, fiber lasers, and solid-state lasers, each having unique advantages suited to different applications. For instance, industrial laser cutters often employ fiber lasers for metal due to their efficiency in cutting through thick materials with minimal waste.

The process itself involves directing a high-powered beam onto the surface of the material, which melts or vaporizes it away. This allows for complex shapes and fine details that would be difficult to achieve with conventional cutting methods. Understanding these techniques helps businesses select the right metal laser cutting machine tailored to their specific needs.

Advantages of Metal Laser Cutting

One key advantage of metal laser cutting is its precision; even intricate designs can be executed flawlessly without compromising quality. Additionally, metal cutting laser cutters provide a clean edge finish that often eliminates the need for secondary processing, saving both time and money in production cycles. Furthermore, these machines are highly efficient; they minimize material waste while maximizing productivity.

Another benefit is versatility—metal cutting machines can handle various metals like steel, aluminum, and brass without significant adjustments or downtime between jobs. This adaptability makes them invaluable assets within many industries from automotive to aerospace manufacturing. With advancements in technology continuously improving these machines’ capabilities, investing in a top-tier industrial laser cutting machine pays off significantly over time.

Applications in Various Industries

The applications of laser cutting span numerous industries due to its versatility and effectiveness in handling various materials and thicknesses. In aerospace engineering, precise cuts are essential for components that must meet stringent safety standards; thus, many rely on trusted laser cutting machine suppliers for reliable equipment solutions. Similarly, automotive manufacturers use metal cutter machines extensively for everything from chassis parts to decorative trim elements.

In addition to traditional sectors like manufacturing and construction, newer fields such as fashion design have also begun incorporating industrial laser cutters into their processes—creating unique fabric patterns with precision unheard of before! Other areas benefiting from this technology include electronics (for circuit boards) and signage (for custom designs). The adaptability of metal cutting machine lasers ensures they remain at the forefront of innovation across diverse applications.

Top Laser Cutting Machine Suppliers

A top-tier supplier can significantly enhance your production capabilities, ensuring precision and efficiency in metal laser cutting. In this section, we’ll explore three of the most reputable suppliers in the industry: Trumpf, Bystronic, and Kiant Machinery.

Trumpf: Leading the Laser Cutting Game

Trumpf has established itself as a titan among laser cutting machine suppliers, renowned for its advanced technology and robust industrial laser cutting machines. Their commitment to innovation means that their metal cutting laser cutter systems are not just tools; they are game-changers that enhance productivity while maintaining high-quality standards. With an extensive range of products tailored for various applications, Trumpf continues to set benchmarks in the world of metal cutting.

What sets Trumpf apart is their focus on automation and connectivity within their metal cutter machines. They offer solutions that integrate seamlessly into existing workflows, providing users with enhanced flexibility and control over their operations. Moreover, their customer support is exceptional—ensuring that users have access to assistance whenever needed.

Bystronic: Innovative Solutions for Metal Cutting

Bystronic is another heavyweight in the realm of laser cutting machine suppliers, celebrated for its innovative approaches to metal processing. Their industrial laser cutters are designed with versatility in mind, making them suitable for a wide array of industries—from automotive to aerospace. Bystronic's commitment to research and development keeps them at the forefront of technology advancements in metal laser cutting.

One notable feature of Bystronic’s offerings is their user-friendly interfaces and automation options that streamline operations without sacrificing quality or precision. Customers have praised Bystronic’s ability to customize solutions based on specific needs—whether it's a standard model or a bespoke design tailored for unique requirements. This adaptability makes them a preferred choice among manufacturers looking for reliable metal cutting machines.

Kiant Machinery: Excellence in Tube Cutting and More

Kiant Machinery may not have the same name recognition as Trumpf or Bystronic but stands out as an up-and-coming player among specialized laser cutting machine suppliers. They excel particularly in tube cutting applications where precision is paramount; their metal cutting machine lasers deliver outstanding results consistently across various materials and thicknesses.

Their focus on niche markets allows Kiant Machinery to offer tailored solutions that larger companies might overlook—providing customers with exactly what they need without unnecessary extras. Additionally, Kiant places great emphasis on customer satisfaction through robust after-sales services which ensure smooth operation post-purchase—a key factor when selecting any industrial laser cutter supplier.

Specializations of Laser Cutting Suppliers

Different suppliers specialize in various types of laser cutting technology, catering to unique industrial needs and applications. Understanding these specializations can help you make an informed choice when selecting from the myriad of laser cutting machine suppliers available.

Industrial Laser Cutting Machines Explained

Industrial laser cutting machines are designed for high-volume production and precision work, making them a staple in manufacturing environments. These machines utilize advanced technology to deliver clean cuts on a variety of materials, including metals and plastics. The efficiency and speed offered by industrial laser cutters often translate into significant cost savings for businesses that require consistent quality and rapid turnaround times.

The versatility of industrial laser cutting machines means they can handle everything from intricate designs to large-scale projects without compromising accuracy. Many suppliers provide tailored solutions that fit specific production needs, ensuring that clients get the most out of their metal cutter machine investments. By opting for specialized industrial models, companies can enhance productivity while maintaining high standards in their manufacturing processes.

Metal Cutting Laser Cutters: When Precision Matters

Metal cutting laser cutters excel in delivering high-quality cuts with minimal material wastage thanks to their focused beam technology. This level of precision not only enhances product quality but also reduces the need for secondary operations such as grinding or finishing.

Laser cutting provides a clean edge that often requires no further processing, which is a significant advantage over traditional methods like sawing or shearing. When selecting from various metal cutting machine laser options, it's crucial to consider factors such as beam quality and power settings—these will determine how effectively the cutter performs on different materials and thicknesses. Ultimately, choosing a reliable supplier who specializes in precision metal cutting can lead to better outcomes for your projects.

Different Types of Metal Cutting Machines

The landscape of metal cutting machines is diverse, with several types designed for specific applications within the industry. From CO2 lasers ideal for non-metal materials to fiber lasers that excel at slicing through tough metals like stainless steel and aluminum—each type has its own strengths and weaknesses based on material compatibility and thickness requirements. Understanding these differences will guide you toward selecting the right equipment from reputable laser cutting machine suppliers.

Another important aspect is whether you need a flatbed or tube/pipe cutter; each serves distinct purposes depending on your project needs. Flatbed cutters are perfect for sheet metals while tube cutters specialize in hollow profiles, showcasing how specialization among suppliers can meet varied demands efficiently. By identifying your specific requirements ahead of time, you'll be better positioned to choose the most suitable metal cutter machine for your operations.

Evaluating Supplier Reliability

Customer Support and After-Sales Services

Customer support is a cornerstone of any successful partnership with laser cutting machine suppliers. You want assurance that when you invest in a metal laser cutting machine, help is just a call away if something goes awry. Look for suppliers that offer comprehensive after-sales services, including technical support, maintenance packages, and training programs for your staff to ensure smooth operations with your industrial laser cutter.

Moreover, consider the availability and responsiveness of customer service teams. A reliable supplier will have dedicated personnel ready to assist you promptly—whether it’s troubleshooting an issue with your metal cutting machine laser or answering questions about upgrades and replacements for your metal cutter machine. This level of support can save you time and money in the long run.

Checking Industry Credentials and Certifications

Before committing to any supplier, it's wise to check their industry credentials and certifications related to laser cutting technology. Reputable metal cutting laser cutter manufacturers often hold certifications from recognized organizations that validate their quality standards and adherence to safety regulations. These credentials not only reflect their commitment to excellence but also provide peace of mind that you're working with a legitimate provider.

Additionally, look for awards or recognitions in the field of industrial laser cutting machines; these accolades highlight a supplier's innovative solutions and industry leadership. Suppliers who actively participate in industry associations are usually more engaged with current trends and technologies—making them better equipped to meet your needs as they evolve over time.

Importance of Customer Reviews and Testimonials

Customer reviews are like gold nuggets when evaluating potential suppliers for your metal cutting needs. They provide real-world insights into the experiences other businesses have had with particular laser cutting machine suppliers—offering clues about product performance and service quality that marketing materials simply can't convey. A plethora of positive testimonials can indicate reliability while negative feedback should raise red flags about potential issues down the line.

Don’t just skim through reviews on the supplier’s website; take time to explore independent review platforms or forums where customers share their firsthand experiences regarding specific industrial laser cutters or metal cutter machines they’ve purchased. Engaging directly with existing users can also yield valuable information about ongoing support from suppliers after purchase—a crucial aspect when investing in expensive equipment like an industrial laser cutting machine.

Cost Considerations When Choosing Suppliers

When it comes to investing in a metal cutting laser cutter, cost considerations play a pivotal role in the decision-making process. Understanding not just the sticker price but also the long-term financial implications is essential for any business looking to enhance its production capabilities. A well-planned budget can help you navigate through the myriad of laser cutting machine suppliers and find the best fit for your needs.

Budgeting for a Metal Cutting Laser Cutter

Budgeting effectively for a metal cutting laser cutter involves more than just considering the initial purchase price. It's crucial to account for installation costs, training expenses, and ongoing maintenance fees that can add up over time. By carefully assessing your financial situation and aligning it with your production goals, you can select a metal cutter machine that fits both your operational needs and budget constraints.

Additionally, different industrial laser cutting machines have varying price points based on their specifications and capabilities. For example, an entry-level industrial laser cutter may be affordable upfront but could lack features necessary for high-volume production runs. Therefore, take the time to compare options from various laser cutting machine suppliers while keeping future scalability in mind.

Understanding Total Cost of Ownership

The total cost of ownership (TCO) is an essential metric when evaluating different metal cutting machines laser options available in the market today. TCO encompasses all costs associated with acquiring, operating, and maintaining your equipment over its lifespan—not just the purchase price alone. This includes energy consumption, parts replacement, labor costs associated with operation and maintenance, as well as potential downtime losses.

For instance, while some industrial laser cutting machines may be cheaper initially, they might consume more energy or require frequent repairs down the line—resulting in higher overall costs. It's wise to inquire about energy efficiency ratings from various laser cutting machine suppliers to ensure you're making an informed decision based on long-term savings rather than short-term gains alone.

Hidden Costs to Watch Out For

When choosing among various metal cutting laser cutter options, hidden costs can sneak up on you if you're not vigilant during your evaluation process. Common hidden expenses include shipping fees that can significantly inflate initial quotes or unexpected taxes that come into play once you've made a selection from specific suppliers. Moreover, some manufacturers may offer enticing low prices but skimp on customer support or after-sales services—leading to potential headaches later on.

Another aspect often overlooked is software compatibility; certain industrial laser cutting machines may require proprietary software that comes at an additional cost or necessitates ongoing subscription fees for updates and support services. Therefore, it’s critical to thoroughly read through contracts and ask questions about any additional charges before finalizing any agreement with laser cutting machine suppliers.

Conclusion

In the realm of laser cutting, selecting the right supplier can significantly impact your operations and product quality. Whether you’re considering a metal laser cutting machine or an industrial laser cutter, understanding the landscape of laser cutting machine suppliers is crucial. With a plethora of options available, it's essential to narrow down your choices based on specialization and reliability.

Summary of Trusted Laser Cutting Suppliers

As we've explored throughout this guide, trusted laser cutting machine suppliers like Trumpf, Bystronic, and Kiant Machinery offer innovative solutions tailored to various needs. Each supplier brings unique advantages to the table—be it advanced technology in metal cutting or specialized expertise in tube cutting. By aligning your requirements with these established names in the industry, you can ensure that your investment in a metal cutting machine laser yields optimal results.

Importance of Supplier Specialization

Supplier specialization plays a pivotal role when it comes to choosing a metal cutter machine that meets specific operational demands. Different industries have varying requirements for precision and performance; thus, working with suppliers who excel in niche areas—such as industrial laser cutting machines—can lead to better outcomes. Understanding these specializations will not only enhance productivity but also help tailor solutions for your unique applications.

Final Tips for Choosing the Right Laser Cutting Partner

When selecting from among various laser cutting machine suppliers, consider factors like customer support and after-sales services that can make or break your experience. Always check industry credentials and customer reviews; they offer invaluable insights into reliability and service quality. Lastly, don’t forget about budgeting; understanding both the total cost of ownership and potential hidden costs will ensure you make an informed decision that aligns with your business goals.