Introduction

In the world of manufacturing and fabrication, the debate between CNC machines and laser cutters is a hot topic. Both technologies have carved out their niches, offering unique advantages for various applications. Whether you're diving into CNC milling or considering an industrial laser cutting machine, understanding these tools is crucial for making informed decisions.

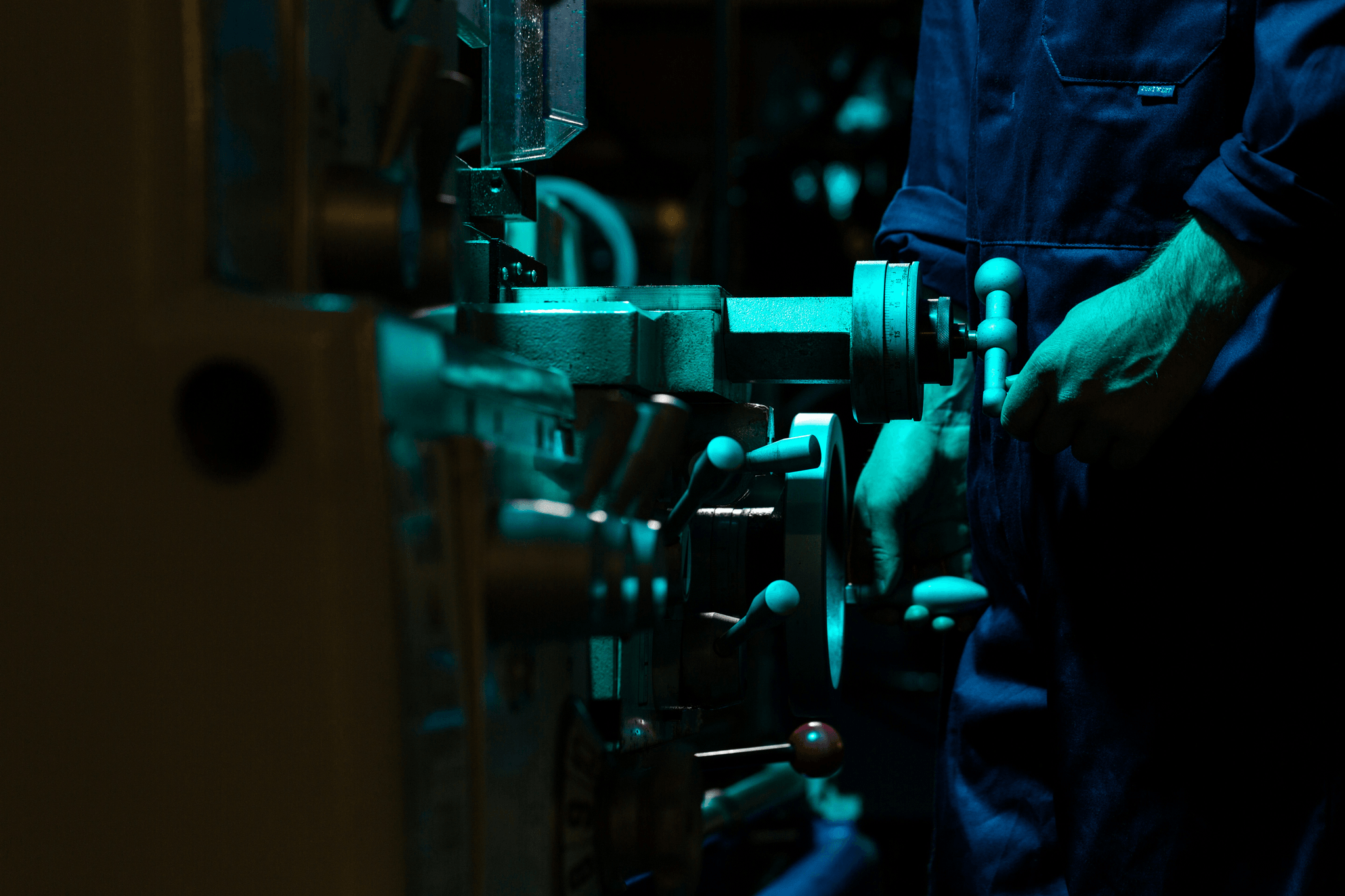

Overview of CNC Machines

CNC machines, or Computer Numerical Control machines, have revolutionized the way we approach machining tasks. They automate processes like milling, drilling, and turning with impressive precision and repeatability. The versatility of CNC machines allows them to work with a variety of materials—especially metals—making them essential in industries ranging from aerospace to automotive.

Introduction to Laser Cutters

On the other side of the spectrum lies laser cutting technology, which utilizes focused beams of light to slice through materials with remarkable accuracy. Industrial laser cutters are designed for high-speed operations and can handle various materials beyond just metals; think plastics, wood, and even textiles! The appeal of metal laser cutting machines lies in their ability to produce intricate designs that would be challenging for traditional methods.

Choosing Between Technologies

Each method has its strengths; while CNC milling excels at producing robust parts with tight tolerances, laser cutting shines in delivering fine details at high speeds. Ultimately, understanding your specific needs will guide you toward the right choice between these two powerful technologies.

Understanding CNC Machines

In the world of fabrication and manufacturing, CNC machines have carved out a significant niche. These computer-controlled devices automate the machining process, allowing for precision and repeatability that manual methods simply can't match. Whether you're crafting intricate designs or large components, understanding CNC technology is crucial for making informed choices about your production needs.

What is CNC Milling?

CNC milling is a subtractive manufacturing process where material is removed from a workpiece using rotating cutting tools controlled by a computer program. This technique allows for high precision in creating complex shapes and features, making it particularly popular in industries requiring detailed metalwork. Unlike laser cutting, which uses focused light to cut through materials, CNC milling relies on physical tools to achieve its results.

Types of CNC Machines

There are several types of CNC machines tailored to various applications, including vertical and horizontal milling machines, lathes, routers, and plasma cutters. Each type serves different purposes; for instance, a metal laser cutting machine excels at slicing through thin sheets of metal with high accuracy while traditional lathes are better suited for cylindrical objects. Understanding the differences between these machines helps businesses choose the right tool based on their specific needs—especially when weighing the cnc machine vs laser cutter debate.

Key Advantages of CNC Machines

CNC machines offer numerous advantages that make them essential in modern manufacturing environments. They provide exceptional precision and repeatability; once programmed correctly, they can produce identical parts with minimal variation over time—something that’s harder to achieve with manual methods or even industrial laser cutters in certain scenarios. Additionally, CNC milling can work with a wide range of materials beyond metals, from plastics to wood composites, giving manufacturers flexibility that enhances their production capabilities.

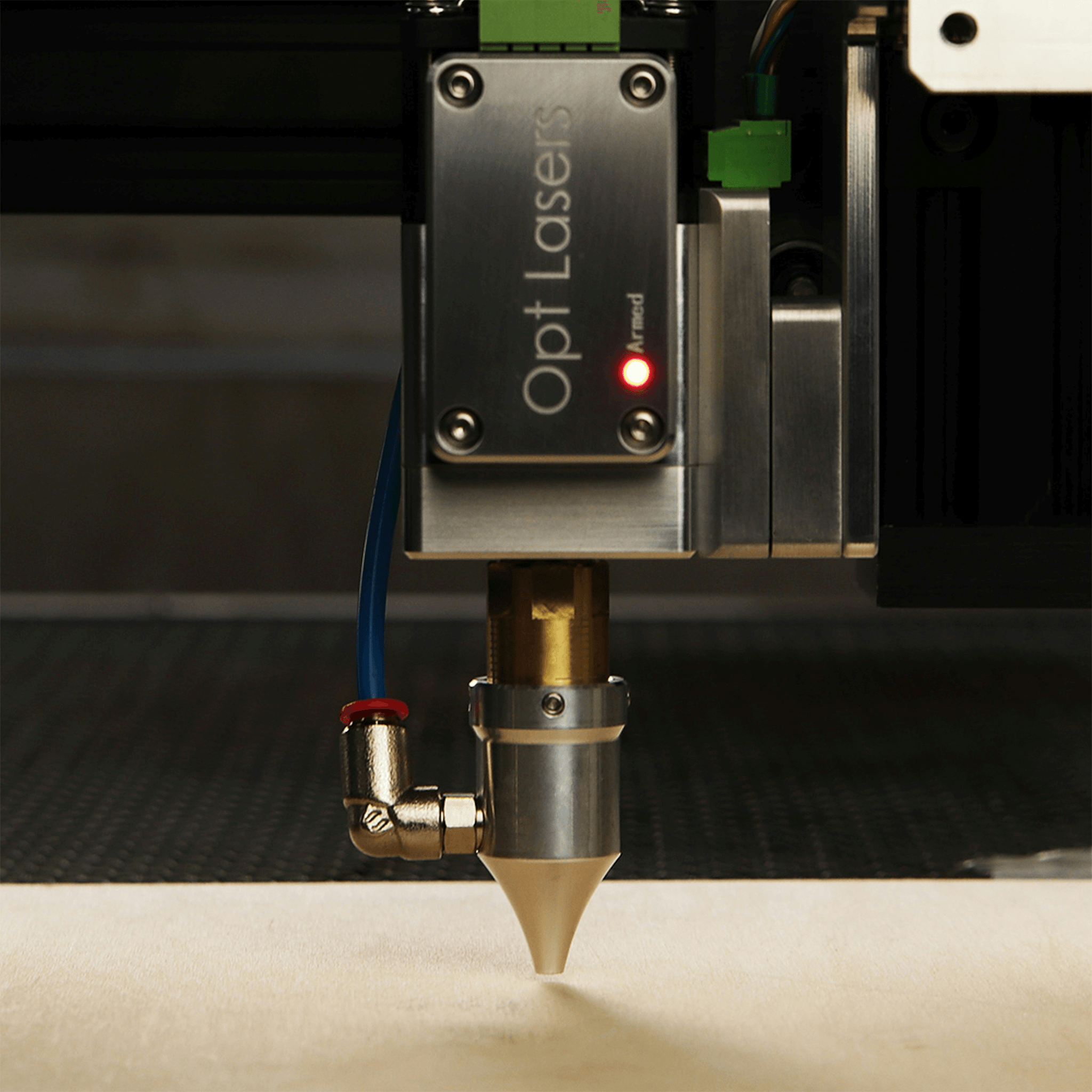

Exploring Laser Cutters

Laser cutting technology has revolutionized the manufacturing landscape, offering precision and versatility that traditional methods often struggle to match. This section dives into the mechanics of laser cutting, the various types of machines available, and the benefits they bring to industrial applications. By understanding these aspects, you can better appreciate how a metal laser cutting machine stacks up against a CNC machine vs laser cutter scenario.

How Laser Cutting Works

At its core, laser cutting employs focused beams of light to slice through materials with remarkable accuracy. The process begins when a high-powered laser generates a concentrated beam that is directed onto the material's surface, heating it to the point of melting or vaporization. This method allows for intricate designs and clean edges that are hard to achieve with traditional CNC milling techniques.

The beauty of laser cutting lies in its ability to handle various materials, from metals to plastics and beyond. As the beam moves across the surface, it can be programmed for complex shapes and patterns—an advantage that sets it apart from standard metal cutting machines. Whether you're crafting delicate components or robust parts, an industrial laser cutter can deliver results that are consistently precise.

Types of Laser Cutting Machines

There are several types of laser cutting machines tailored for different applications and materials. CO2 lasers are commonly used for non-metallic materials like wood and acrylic due to their efficiency in those areas. On the other hand, fiber lasers shine when it comes to metal processing; they offer superior speed and energy efficiency compared to their CO2 counterparts.

Another popular option is the solid-state laser cutter, which combines elements from both CO2 and fiber technologies for enhanced versatility across multiple materials. Each type of machine has its strengths—while some excel at fine detail work on thin sheets, others tackle thicker metals with ease using powerful beams from metal laser cutting machines designed specifically for heavy-duty tasks. Understanding these distinctions helps businesses choose between a CNC machine vs laser cutter based on their specific needs.

Benefits of Industrial Laser Cutters

Industrial laser cutters offer numerous advantages that make them indispensable in modern manufacturing processes. One significant benefit is their unparalleled precision; they can achieve tolerances within microns—something that's crucial when working on intricate projects where every detail matters more than ever compared to traditional methods like CNC milling.

Additionally, these machines provide flexibility in design capabilities; whether you're creating prototypes or large-scale production runs, an industrial laser cutting machine can adapt quickly without requiring extensive retooling or setup changes—saving both time and money in production cycles. Lastly, safety features integrated into modern lasers minimize risks associated with high-speed operations while maximizing productivity—a win-win scenario for any workshop environment.

CNC Machine vs Laser Cutter: Precision and Detail

When diving into the world of precision machining, the debate of CNC machine vs laser cutter often arises. Both technologies boast impressive accuracy, but they achieve it through different means. While CNC milling excels in creating intricate shapes and contours, laser cutting machines offer remarkable finesse in slicing through materials with precision.

Precision Levels in CNC vs Laser

Precision is a hallmark of both CNC machines and laser cutters, yet their approaches vary significantly. CNC milling operates with a mechanical process that involves rotating cutting tools to shape materials, allowing for tight tolerances and repeatable results. In contrast, a metal laser cutting machine uses focused beams of light to melt or vaporize material, achieving high levels of accuracy that can be particularly beneficial for detailed designs.

The choice between these two methods often hinges on the specific requirements of a project. For applications demanding complex three-dimensional shapes or features with varying depths, CNC milling might take the edge due to its versatile tooling capabilities. However, when it comes to flat cuts or intricate patterns on sheet materials, an industrial laser cutter can deliver unparalleled precision without compromising speed.

Detail Achieved in CNC Milling

CNC milling is renowned for its ability to produce fine details and complex geometries that are difficult to replicate with other methods. The process allows operators to manipulate multiple axes simultaneously, enabling the creation of parts with elaborate features such as pockets, grooves, and contours. This capability makes it a preferred choice for industries requiring high detail levels in components like molds or prototypes.

Moreover, the quality of finish achieved through CNC machining is often superior due to its ability to control feed rates and tool paths meticulously. This results in smoother surfaces and more refined edges compared to those produced by some laser cutting processes. Thus, when considering projects where detail matters most—like aerospace components or medical devices—CNC milling stands out as an excellent option.

Comparing Laser Cutting Accuracy

When discussing accuracy in the context of industrial applications, comparing laser cutting accuracy against traditional methods reveals interesting insights. Laser cutting machines utilize focused beams that can achieve kerf widths as small as 0.1 mm; this level of precision makes them ideal for tasks where minimal material wastage is crucial—think intricate signage or delicate art pieces made from various materials.

However, while metal laser cutting machines excel at producing precise cuts quickly across large sheets, they may struggle with thicker materials compared to their CNC counterparts which can handle robust metal sections effectively without sacrificing detail integrity. Ultimately, while both technologies offer impressive accuracy within their domains—CNC machines shine in three-dimensional shaping while industrial laser cutters dominate flat surface detailing—the best choice depends on your specific project needs.

Material Compatibility: CNC and Laser

Each method has its strengths and weaknesses, especially when working with various materials. Understanding how each machine interacts with different substrates can help you make an informed decision.

Metals Suitable for CNC Machines

CNC milling is particularly adept at handling a variety of metals, making it a go-to choice for many manufacturers. Common metals suitable for CNC machines include aluminum, brass, steel, and titanium. These materials can withstand the precision cutting and shaping processes of CNC technology, allowing for intricate designs and robust end products.

While CNC machines excel in metalworking, they are also versatile enough to handle plastics and composites effectively. This means that if your project requires diverse material usage, a metal cutting machine laser may not be as flexible as traditional CNC milling options. Ultimately, understanding the specific properties of the metals you plan to work with will guide your choice between these technologies.

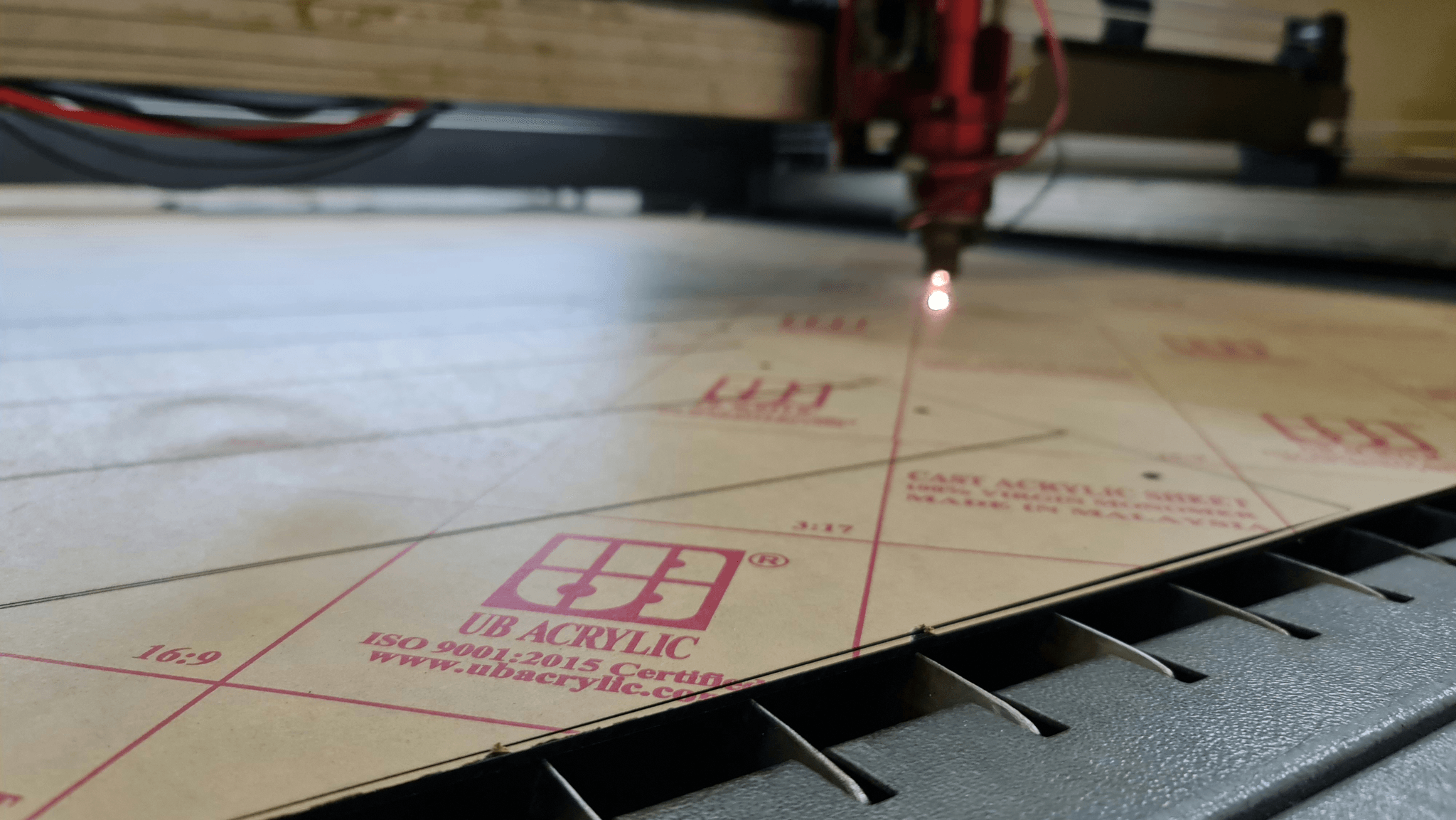

Laser Cutting for Various Materials

Laser cutting technology shines when it comes to versatility across multiple materials beyond just metals. An industrial laser cutter can efficiently cut through plastics, wood, glass, fabric, and even some composites with impressive precision. This adaptability makes laser cutting machines an excellent choice for projects that require intricate designs or detailed patterns on varied substrates.

Metal laser cutting machines are particularly popular due to their ability to create clean cuts without significant heat-affected zones (HAZ), preserving the integrity of the material being worked on. However, it's essential to consider that while lasers can handle many materials well, certain thicker or denser materials might present challenges compared to traditional methods like CNC milling. Thus, evaluating your specific material requirements will help clarify which option—CNC or laser—is more appropriate.

Strengths and Weaknesses of Each Method

In comparing the strengths and weaknesses of both methods—CNC machine vs laser cutter—it's clear that each has its unique advantages tailored to specific applications. For instance, CNC milling excels at producing high-tolerance parts from tough metals where durability is paramount; however, it may lack the finesse required for delicate designs found in softer materials like fabric or paper.

On the flip side, industrial laser cutting machines offer unparalleled speed and precision when working with thin materials or complex geometries but may struggle with thicker metals compared to traditional metal cutting machines like those used in CNC operations. Additionally, while initial costs may vary significantly between these technologies based on capabilities and features offered by each machine type—long-term maintenance expenses should also be factored into your decision-making process.

Ultimately, understanding these strengths and weaknesses ensures you choose a method aligned with your project needs while maximizing efficiency and quality in production.

Cost Considerations

Initial Investment in CNC Machines

Investing in a CNC machine can be quite the financial commitment, especially for high-quality models designed for precise operations like cnc milling. Depending on the size, capabilities, and brand, prices can range from several thousand to tens of thousands of dollars. While this initial investment might seem steep, it’s essential to consider the long-term benefits and potential return on investment when evaluating your options.

Costs Associated with Laser Cutting

On the other hand, costs associated with laser cutting vary based on the type of laser cutting machine you choose—whether it's an industrial laser cutter or a more compact model for smaller projects. While entry-level machines may have lower price tags, industrial laser cutting machines often come with advanced features that justify their higher costs. Additionally, expenses such as consumables (e.g., lenses and gases) should also be factored into your overall budget when considering metal laser cutting machines.

Long-term Maintenance Expenses

Long-term maintenance expenses are another critical aspect when comparing cnc machine vs laser cutter options. CNC machines typically require regular upkeep and calibration to maintain precision during cnc milling processes; this can translate into additional costs over time. Conversely, while industrial laser cutters may have fewer mechanical components needing maintenance, they still require periodic servicing and replacement parts that can add up in the long run.

Conclusion

In the world of precision manufacturing, the debate between CNC machines and laser cutters is as hot as a freshly cut metal edge. Both technologies offer unique advantages tailored to specific applications, making it crucial for businesses to understand their needs before making a decision. Whether you're leaning towards the robust capabilities of CNC milling or the finesse of an industrial laser cutter, knowing your options can significantly impact production efficiency and product quality.

Ideal Applications for CNC Machines

CNC machines shine in scenarios requiring complex shapes and intricate designs, especially in industries like aerospace, automotive, and custom fabrication. The precision of a CNC milling machine allows for high tolerances and repeatability, which is essential when crafting components that must fit together perfectly. Additionally, these machines excel at working with metals such as aluminum and steel, making them ideal for heavy-duty applications where durability is key.

Best Uses for Laser Cutters

On the other hand, laser cutting technology offers remarkable versatility across various materials including wood, plastic, and fabric—making it a favorite among artisans and manufacturers alike. Industrial laser cutters are particularly well-suited for projects requiring fine detail or intricate patterns that would be challenging to achieve with traditional methods. Moreover, metal laser cutting machines provide exceptional speed without sacrificing accuracy, allowing businesses to meet tight deadlines while maintaining high-quality standards.

Making the Right Choice for Your Needs

Choosing between a CNC machine vs laser cutter ultimately boils down to your specific production requirements and material types involved in your projects. If you need precise machining of tough metals with complex geometries, investing in a metal cutting machine laser may be your best bet. Conversely, if your focus is on diverse materials or artistic designs that require rapid prototyping capabilities without compromising quality—an industrial laser cutting machine could be the perfect solution.