Introduction

In the ever-evolving landscape of manufacturing, flatbed laser technology has emerged as a game-changer, redefining how industries approach precision cutting. This innovative method leverages industrial laser cutting machines to deliver unparalleled accuracy and efficiency, making it an essential tool for many businesses today. With its ability to cut through various materials effortlessly, the cutting machine laser has become synonymous with modern production techniques.

Understanding Flatbed Laser Technology

Flatbed laser technology operates on a simple yet powerful principle: using focused laser beams to cut or engrave materials with extreme precision. Unlike traditional methods that rely on mechanical blades or tools, industrial laser cutters utilize high-powered lasers that can be finely adjusted for different tasks and materials. This flexibility not only enhances productivity but also opens up new avenues for creativity in design and manufacturing.

Advantages of High Precision Cutting

One of the standout benefits of using a flatbed laser is its capability for high precision cutting, which ensures clean edges and intricate details that are often unattainable with other methods. The accuracy provided by these industrial laser cutting machines minimizes waste and reduces the need for extensive post-processing work, saving both time and resources. Furthermore, this level of precision allows businesses to meet stringent quality standards while maintaining competitive pricing.

Applications Across Different Materials

The versatility of flatbed lasers extends across a wide range of materials, making them invaluable in various industries—from automotive to fashion. Industrial laser cutters can efficiently process metals like steel and aluminum as well as non-metals such as wood, acrylic, and even fabric without compromising quality. As manufacturers increasingly seek solutions that accommodate composite materials and complex designs, the demand for advanced cutting machine lasers continues to rise.

What is a Flatbed Laser Cutter?

When it comes to precision and versatility in the manufacturing world, the flatbed laser cutter reigns supreme. This industrial laser cutting machine is designed to handle a wide array of materials while delivering impeccable results. Whether you're cutting metals, plastics, or fabrics, this cutting machine laser can do it all with speed and accuracy.

Definition and Functionality

A flatbed laser cutter is an advanced piece of machinery that utilizes high-powered lasers to cut through various materials. Unlike traditional cutting methods that may produce rough edges or require extensive finishing work, this industrial laser cutter provides clean cuts and intricate designs right from the start. Its functionality lies in its ability to be programmed for different shapes and sizes, making it an invaluable tool for industries ranging from automotive to fashion.

How It Works: The Cutting Process

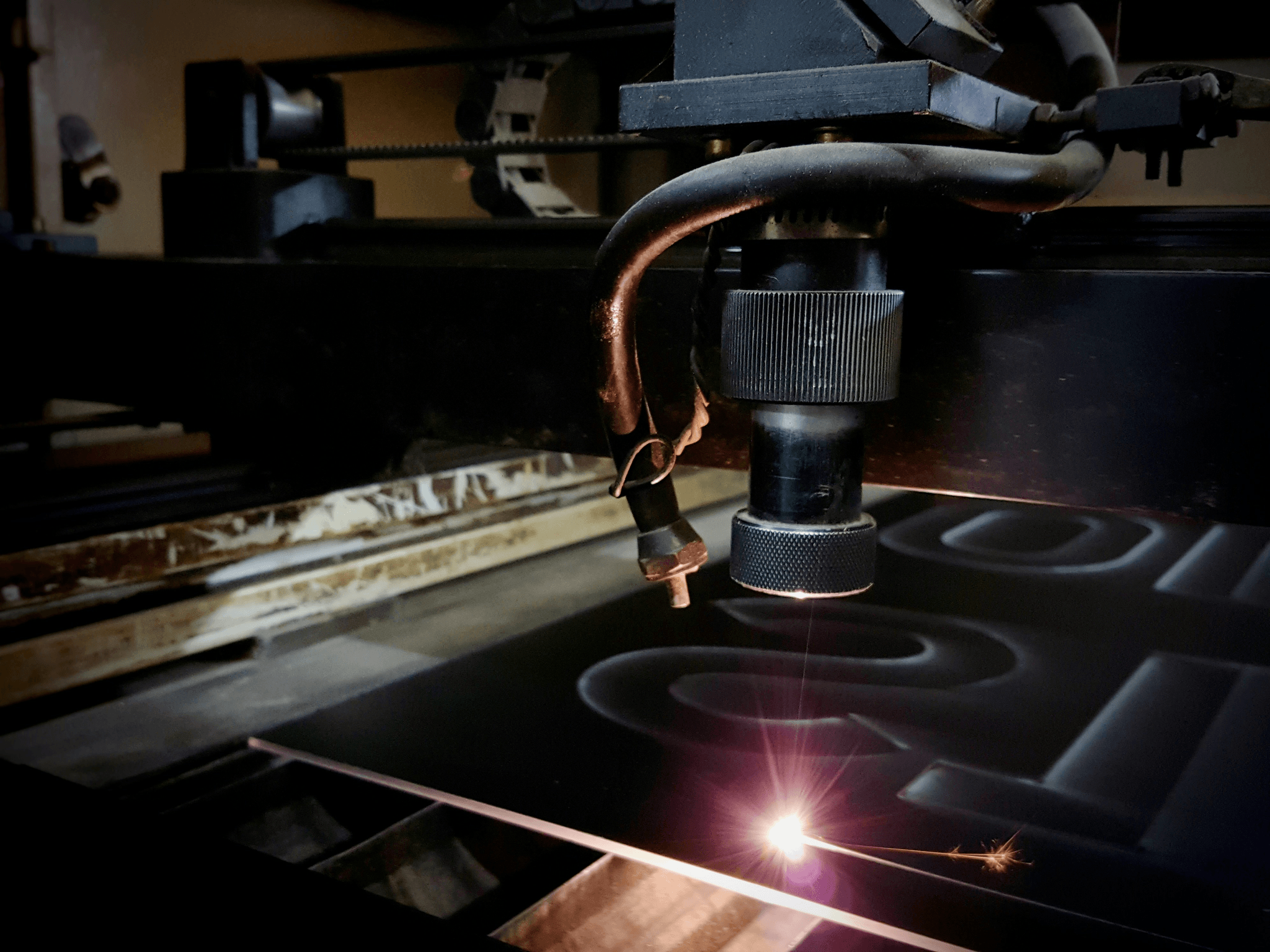

The cutting process of a flatbed laser involves several fascinating steps that combine technology and artistry. First, the material is placed on a flat bed where the large laser cutter's computer-controlled system reads a design file. The cutting machine then directs a concentrated beam of light onto the material's surface, melting or vaporizing it along predetermined paths—resulting in precise cuts without physical contact.

Key Components of Industrial Laser Cutters

Industrial laser cutters consist of several critical components that work together seamlessly for optimal performance. At their core is the laser source, which generates the intense beam needed for cutting; common sources include CO2 or fiber lasers depending on material compatibility. Additionally, these machines feature motion systems—like gantries or robots—that facilitate movement across the bed and ensure accuracy during operation; other vital parts include optics for beam focusing and cooling systems to maintain temperature control during lengthy projects.

Material Compatibility with Cutting Machine Laser

When it comes to flatbed laser technology, understanding material compatibility is crucial for maximizing the potential of your industrial laser cutting machine. Different materials respond uniquely to the precision and power of a cutting machine laser, affecting the quality and efficiency of the cuts produced. This section will explore various material categories, including metals, non-metals, and composite materials, highlighting their unique characteristics and challenges when using a large laser cutter.

Metals: Steel, Aluminum, and More

Metals are among the most common materials processed by industrial laser cutters due to their durability and versatility. Steel and aluminum are particularly popular choices; they can be cut with impressive accuracy using a flatbed laser due to their relatively low melting points compared to other metals. However, it’s essential to adjust settings like speed and power depending on the thickness of the metal sheet being cut—this ensures that your cutting machine achieves clean edges without excessive heat distortion.

Moreover, each type of metal presents its own set of challenges; for instance, stainless steel requires a different focus than carbon steel when using a cutting machine laser. The key is understanding how each metal reacts during the cutting process so that you can optimize your industrial laser cutter's performance accordingly. With proper calibration and technique, even complex designs can be executed flawlessly on metals ranging from brass to titanium.

Non-Metals: Wood, Acrylic, and Fabric

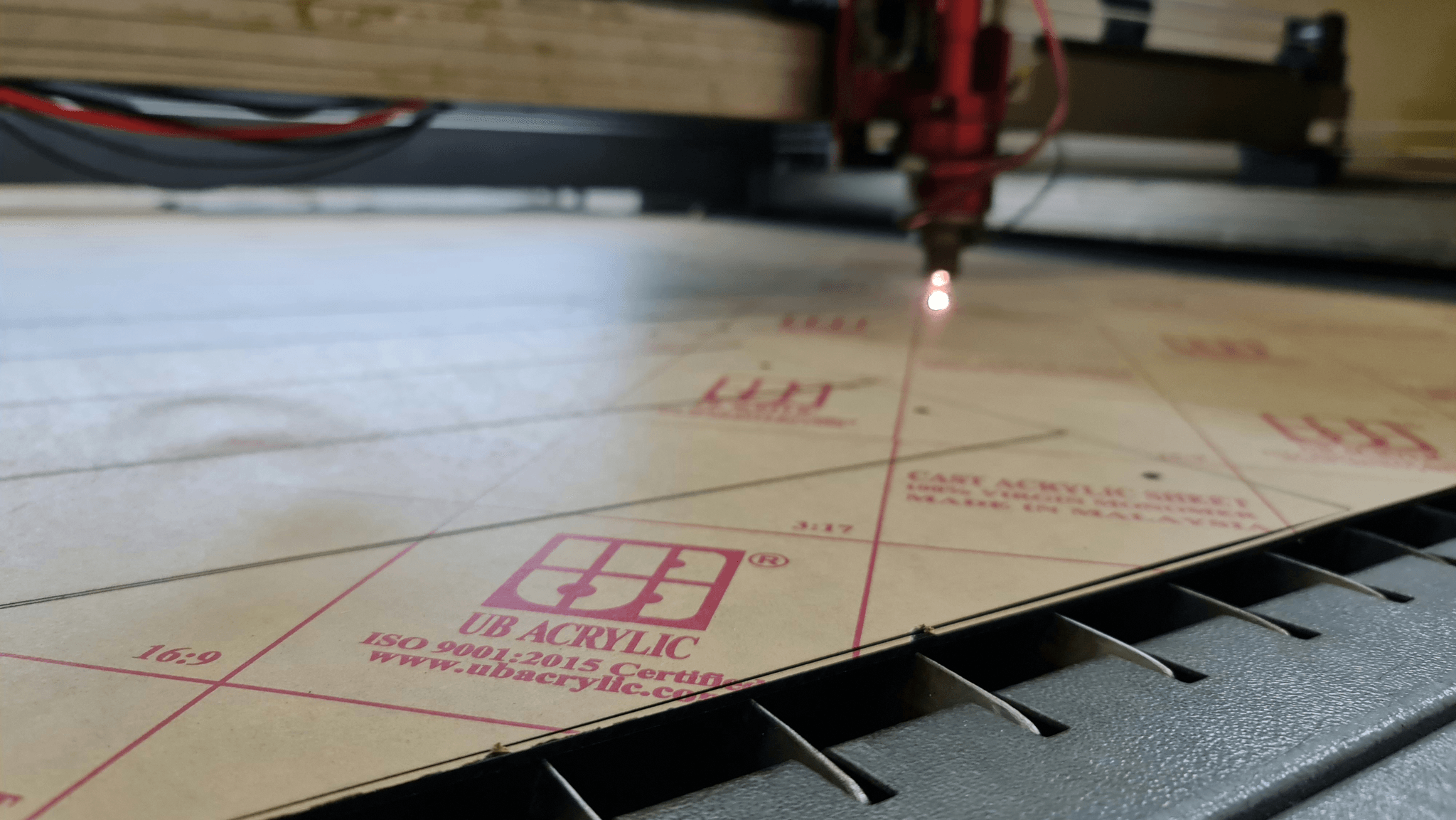

Non-metal materials such as wood, acrylic, and fabric are gaining traction in industries that utilize flatbed lasers for creative applications like signage or custom furniture design. Wood is especially popular due to its natural aesthetic appeal; however, it is vital to consider factors such as grain direction when setting up your large laser cutter for optimal results. Acrylic also offers vibrant color options but requires precise temperature control during cutting to prevent melting or charring at the edges.

Fabric presents unique challenges as well; while it’s easy enough for an industrial laser cutter to slice through layers quickly, fraying can occur if not handled correctly. To mitigate this issue with fabric or any other non-metal material using a cutting machine laser effectively requires familiarity with each material's properties—this ensures smooth operation without compromising quality or design integrity. As these materials continue gaining popularity across various sectors—from fashion design to interior decor—the importance of mastering their compatibility with laser machinery cannot be overstated.

Composite Materials and Their Challenges

Composite materials combine elements from both metal and non-metal categories but come with their own distinct set of challenges when operating an industrial laser cutter or flatbed laser system. These intricate structures often consist of layers that include plastics reinforced with fibers or metals blended together for enhanced strength—making them trickier than single-material counterparts during processing operations like cutting or engraving via a cutting machine laser.

The primary challenge lies in managing heat distribution effectively; composites may warp if subjected to excessive temperatures during cutting processes conducted by large laser cutters designed primarily for uniform materials like steel or wood alone. Additionally, operators must account for varying densities within composite layers which could lead to uneven cuts if not calibrated correctly on an industrial scale. Therefore investing time in research about specific composite types before attempting any projects involving these materials will pay off significantly in terms of quality outcomes.

Investing in Industrial Laser Cutting Machines

Investing in an industrial laser cutting machine is no small feat; it requires careful consideration and strategic planning. Flatbed laser technology offers various options tailored to different industries, but not all machines are created equal. Understanding what to prioritize when purchasing a cutting machine laser can make a world of difference in efficiency and output quality.

Factors to Consider in Your Purchase

When selecting a large laser cutter, several factors come into play, starting with the type of materials you'll be working with. Different industrial laser cutters have varying capabilities for metals, non-metals, and composites, so it's essential to ensure compatibility with your specific needs. Additionally, consider the power requirements and operational costs associated with running the flatbed laser; these can significantly impact your overall investment.

Another crucial element is the machine's precision and speed. A high-precision cutting machine can save time and reduce material waste, translating into cost savings over time. Finally, evaluate the manufacturer's reputation for customer support and maintenance services; investing in reliable service can extend the lifespan of your laser machinery.

The Cost-Benefit Analysis

A thorough cost-benefit analysis is vital before committing to an industrial laser cutter purchase. While upfront costs may seem steep for advanced flatbed lasers, consider long-term savings generated from increased productivity and reduced material waste. A well-chosen cutting machine can pay for itself through improved efficiency and quality over time.

Moreover, factor in potential revenue increases from offering new services or products made possible by enhanced capabilities of modern cutting machines. The versatility of a large laser cutter allows businesses to expand their offerings without significant additional investment in new equipment or processes. Ultimately, understanding how an industrial laser cutting machine fits into your business model will help justify its cost.

How Kiant Machinery Stands Out

Kiant Machinery sets itself apart by providing top-notch flatbed lasers that combine innovation with reliability at competitive prices. Their extensive range of industrial laser cutters caters to various industries while ensuring that each unit boasts advanced features designed for optimal performance. With a strong emphasis on customer service, Kiant Machinery supports clients throughout their purchasing journey and beyond.

Additionally, Kiant's commitment to sustainability ensures that their cutting machines not only perform well but also minimize environmental impact—a crucial factor for many modern businesses today. By investing in Kiant's cutting machine laser solutions, you're choosing both quality machinery and responsible practices that align with future trends in manufacturing technology.

Maintenance Tips for Laser Machinery

Maintaining your industrial laser cutting machine is crucial for ensuring optimal performance and longevity. Regular upkeep not only enhances the efficiency of your cutting machine but also minimizes downtime, which can be a costly affair in production environments. Here are some essential maintenance tips to keep your flatbed laser and other laser machinery running smoothly.

Routine Checks for Long-Lasting Performance

To ensure that your industrial laser cutter operates at peak performance, establish a routine maintenance schedule. Regularly inspect critical components such as lenses, mirrors, and the cooling system to prevent any build-up of dust or debris that could impair functionality. Additionally, checking the alignment of the cutting machine laser ensures precise cuts and extends the lifespan of your equipment.

Another important aspect is to monitor the power levels and settings on your large laser cutter; fluctuations can indicate underlying issues that may need addressing before they escalate into major problems. Keep an eye on wear-and-tear indicators on parts like belts and bearings—these are often early signs that replacements may be necessary soon. By staying proactive with these routine checks, you’ll save time and money in the long run while keeping your flatbed laser operating efficiently.

Troubleshooting Common Issues

Even with regular maintenance, issues can arise with any industrial laser cutting machine from time to time. One common problem is inconsistent cutting quality; if you notice uneven edges or excessive dross, it might be due to incorrect settings or worn-out components like nozzles or lenses. Start by recalibrating your cutting machine settings before diving deeper into hardware checks.

Another frequent issue involves focusing errors—if you find that cuts are not penetrating through materials as expected, check whether the focus lens is clean and correctly positioned. It’s also wise to consult operational logs to identify patterns in malfunctioning; this data can provide insights into recurring problems with specific materials or processes used by your cutting machine laser. By being diligent about troubleshooting these common issues early on, you can maintain a high level of productivity.

Upgrading Your Technology for Efficiency

As technology advances rapidly in the field of industrial laser cutters, staying updated with new features can significantly improve efficiency in operations. Consider investing in upgrades such as advanced software solutions for better design integration or enhanced automation capabilities that allow for quicker setup times on various jobs with your large laser cutter. These innovations not only streamline operations but also reduce manual errors during production runs.

Additionally, look into newer models of flatbed lasers that feature improved energy efficiency or faster processing speeds—these upgrades could yield substantial savings over time while boosting output capacity significantly compared to older models. Keeping abreast of technological advancements ensures that you're utilizing state-of-the-art capabilities within your existing framework while preparing for future demands in manufacturing processes involving cutting machines.

The Future of Laser Cutting Technology

The world of laser cutting technology is evolving at a breakneck pace, and the future looks brighter than ever for flatbed laser systems. As industries seek faster, more efficient solutions, innovations are paving the way for advanced capabilities in industrial laser cutting machines. From improved precision to enhanced automation, the next generation of cutting machine lasers promises to revolutionize manufacturing processes across various sectors.

Innovations on the Horizon

Emerging technologies are set to redefine what we can expect from industrial laser cutters. One exciting development is the integration of artificial intelligence (AI) into flatbed laser systems, enabling real-time adjustments during the cutting process for optimal results. Additionally, advancements in fiber laser technology are making large laser cutters more efficient and capable of handling thicker materials with ease, reducing operational costs while increasing productivity.

Another noteworthy innovation is the push towards hybrid systems that combine traditional cutting methods with advanced laser machinery. These versatile machines can switch between different techniques seamlessly, allowing manufacturers to tackle a wider range of projects without investing in multiple pieces of equipment. As these innovations continue to unfold, businesses will find themselves equipped with tools that not only enhance capabilities but also drive competitiveness in an ever-evolving marketplace.

Sustainability in Cutting Machine Practices

Sustainability is no longer just a buzzword; it's becoming a cornerstone of modern manufacturing practices, including those involving industrial laser cutting machines. With rising energy costs and environmental concerns at the forefront, manufacturers are increasingly looking for ways to minimize their ecological footprint through energy-efficient flatbed lasers and optimized operational processes. This shift not only benefits our planet but also leads to cost savings over time.

Moreover, advancements in recycling technology mean that waste generated by cutting machine lasers can be significantly reduced or repurposed. Many companies now focus on using sustainable materials and reducing scrap through precise cuts made possible by modern industrial laser cutters. By prioritizing sustainability alongside efficiency, businesses can contribute positively to environmental conservation while enjoying competitive advantages.

How Smart Technology is Changing the Game

The integration of smart technology into industrial laser machinery is transforming how manufacturers operate on multiple levels. From predictive maintenance that anticipates equipment failures before they occur to data analytics that help optimize production schedules, smart features enhance both reliability and performance in large laser cutters. This technological shift allows companies to maximize uptime while minimizing costly disruptions.

Additionally, cloud connectivity enables remote monitoring and control over cutting machine operations from anywhere in the world—a game-changer for businesses operating across multiple locations or those managing complex supply chains. By harnessing these smart technologies within their flatbed lasers and other equipment, manufacturers can streamline workflows and improve overall efficiency significantly.

As we look ahead at these exciting developments within industrial laser cutter technology—ranging from innovative designs to sustainable practices—it’s clear that this field will continue evolving rapidly as it embraces new possibilities.

Conclusion

In wrapping up our exploration of flatbed laser technology, it's clear that the advantages of this cutting-edge method are numerous. From high precision to versatility across various materials, industrial laser cutting machines have revolutionized how we approach manufacturing and design. With their ability to deliver clean cuts and intricate designs, these machines stand out as essential tools for modern industries.

Recap of Flatbed Laser Advantages

Flatbed laser cutters offer remarkable precision that is hard to match with traditional cutting methods. Their ability to handle a variety of materials—from metals like steel and aluminum to non-metals such as wood and acrylic—makes them incredibly versatile. Additionally, the efficiency of these industrial laser cutters not only speeds up production but also reduces waste, making them a smart choice for businesses looking to maximize productivity.

The Versatility of Industrial Laser Cutters

Industrial laser cutters are not just one-trick ponies; they can adapt to a plethora of applications across diverse sectors. Whether it's crafting intricate designs in signage or producing components for automotive manufacturing, the capabilities of a large laser cutter are virtually limitless. This versatility ensures that businesses can leverage cutting machine lasers for everything from prototyping to mass production without compromising on quality.

Choosing the Right Partner: Kiant Machinery

When it comes to investing in laser machinery, selecting the right partner is crucial for success—and that's where Kiant Machinery shines. With a robust lineup of cutting machine options tailored for various needs, they provide not only equipment but also expertise in maximizing your investment in an industrial laser cutting machine. By choosing Kiant Machinery, you ensure that your business benefits from top-notch support and innovative solutions designed to keep you ahead in this competitive landscape.