Introduction

In the realm of modern manufacturing, laser cutting technology has emerged as a game-changer. This innovative process not only enhances precision but also streamlines production, making it an invaluable asset for industries ranging from automotive to aerospace. As we delve into the world of laser cutting machines, understanding how do lasers cut materials will illuminate their significance in today’s industrial landscape.

Understanding Laser Cutting Technology

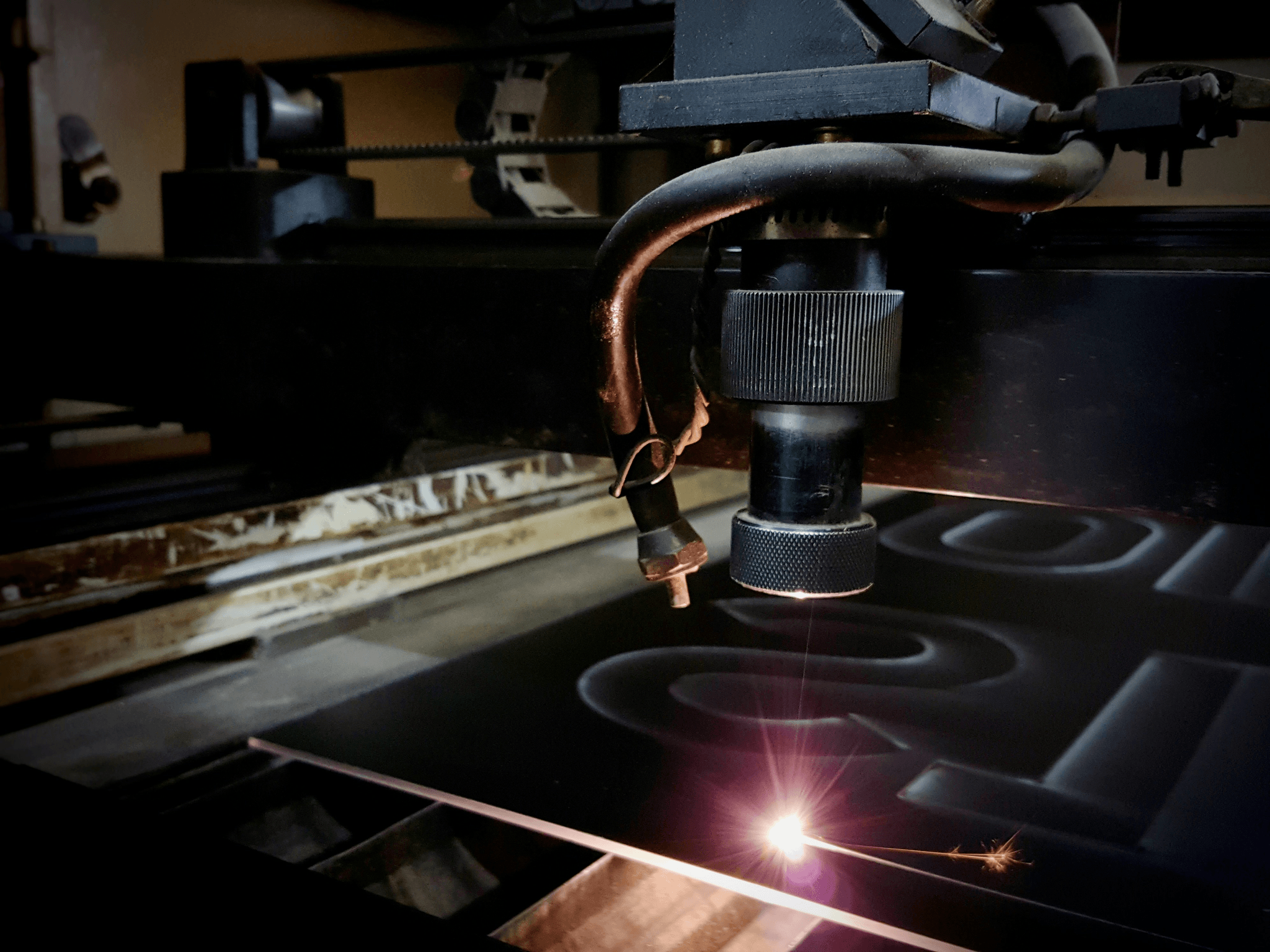

Laser cutting technology utilizes focused beams of light to slice through various materials with remarkable accuracy and speed. The principle is rooted in the ability of lasers to generate intense heat that melts or vaporizes material at a precise point, creating clean cuts without the mechanical force often associated with traditional methods. This technique has revolutionized how manufacturers approach tasks such as metal fabrication and intricate design work, offering a level of detail that was previously unattainable.

The Basics of Laser Cutting Machines

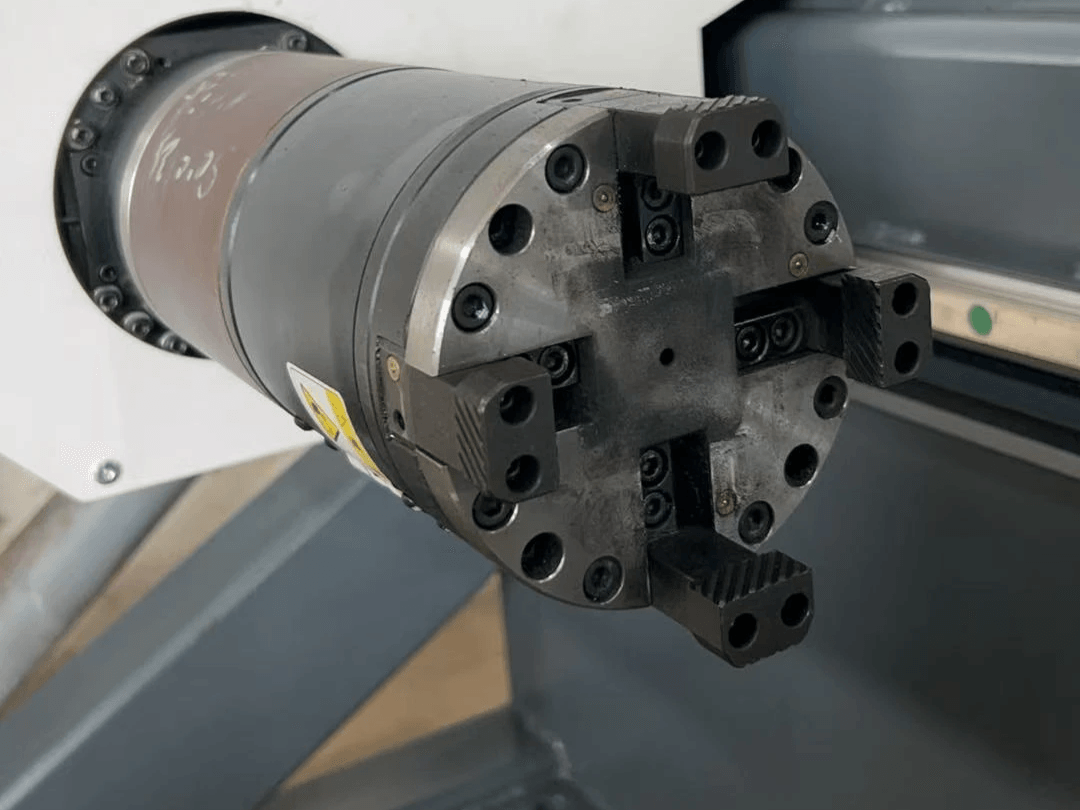

At the heart of this technology lies the industrial laser cutter—a sophisticated machine that combines optics and mechanics to achieve exceptional results. These machines come in various types, each designed for specific applications, such as CO2 and fiber laser cutters, catering to different materials and thicknesses. Understanding these basics is essential for anyone looking to invest in an industrial laser cutting machine or simply wanting to grasp how this technology works.

Key Applications of Laser Cutting

The versatility of laser cutting machines makes them suitable for a wide array of applications across multiple industries. From creating intricate designs in textiles to precise metal components in machinery, these machines have proven their worth time and again. As we explore further into this topic, it becomes clear that the capabilities of a cutting machine laser extend far beyond simple tasks; they are integral to innovation and efficiency in modern manufacturing processes.

What is Laser Cutting?

Laser cutting is a modern manufacturing process that utilizes focused laser beams to slice through materials with precision and speed. This technology has revolutionized the way industries approach metal fabrication, allowing for intricate designs and high-quality finishes that were once difficult to achieve. By understanding how do lasers cut, we can appreciate the efficiency and versatility of industrial laser cutters in various applications.

Definition and Principle of Operation

At its core, laser cutting involves directing a high-powered laser beam onto a material's surface, which melts or vaporizes it to create a clean edge. The principle behind this method relies on the conversion of electrical energy into light energy, producing an intense beam that can be finely focused for accuracy. This innovative process enables operators to achieve precise cuts without the need for physical contact between the cutting machine laser and the material.

Types of Laser Cutting Machines

There are several types of industrial laser cutting machines available on the market today, each designed for specific applications and materials. The most common types include CO2 lasers, which excel in cutting non-metal materials like wood, plastics, and textiles, and fiber lasers, known for their effectiveness in processing metals such as steel or aluminum. Understanding these different machines helps businesses choose the right one based on their unique requirements.

Comparison with Traditional Cutting Methods

When comparing laser cutting with traditional methods like plasma or mechanical cutting, it's clear that each has its strengths; however, lasers often come out on top regarding precision and versatility. Traditional methods can be limited by tool wear or require more extensive setup times, while an industrial laser cutter can operate continuously without sacrificing quality over time. Moreover, since laser cutting machines produce minimal waste and require less post-processing work than conventional techniques, they offer significant cost savings in the long run.

How Do Lasers Cut Materials?

The process of laser cutting is both fascinating and complex, combining advanced technology with fundamental physics. At its core, the question how do lasers cut? can be answered by understanding how high-intensity light beams interact with different materials. This section delves into the science behind laser cutting, factors that influence its efficiency, and the types of materials commonly processed by industrial laser cutting machines.

The Science Behind Laser Cutting

Laser cutting operates on a simple yet powerful principle: concentrated light energy creates heat that melts or vaporizes material. When using a cutting machine laser, a focused beam of light is directed onto the material's surface, generating temperatures high enough to cause it to either melt away or turn into gas. This method allows for incredibly precise cuts and intricate designs that are often unattainable with traditional metal cutting machines.

The wavelength of the laser also plays a significant role in how effectively it can cut through various materials. Different types of lasers—like CO2 and fiber lasers—emit light at distinct wavelengths, making them suitable for specific applications. Understanding these principles helps operators optimize their industrial laser cutter settings for maximum efficiency and accuracy.

Factors Influencing Cutting Efficiency

While the science behind laser cutting is straightforward, several factors influence how effectively an industrial laser cutting machine performs its task. The thickness and type of material being cut are crucial; thicker materials require more power and slower speeds to achieve clean cuts while thinner ones can be processed quickly with less energy. Additionally, the quality of the laser beam itself affects performance; higher-quality beams result in cleaner edges and reduced post-processing time.

Another vital factor is the assist gas used during the process—typically oxygen or nitrogen—which helps improve cut quality while reducing oxidation on metal surfaces during operation. The speed at which the cutting machine laser moves across the material also impacts efficiency; too fast may lead to incomplete cuts while too slow can result in excessive heat buildup and warping of sensitive materials. Balancing these elements ensures optimal performance from your industrial laser cutter.

Common Materials for Laser Cutting

Industrial laser cutters are versatile tools capable of processing a wide array of materials, making them indispensable across various industries. Metals like steel, aluminum, brass, and copper are commonly cut using metal cutting machines due to their strength and durability requirements in manufacturing applications. Additionally, non-metals such as wood, acrylics, leather, and textiles benefit from precise cuts offered by a high-quality laser cutting machine.

Each material presents unique challenges; for instance, reflective metals require specialized settings on your industrial laser cutting machine to prevent damage or inefficiency during operation. Conversely, softer materials like wood may burn if not properly managed with appropriate speed settings or assist gases during processing. Understanding these nuances allows operators to make informed decisions about which materials best suit their specific projects while maximizing productivity through effective use of their equipment.

Different Types of Industrial Laser Cutters

When it comes to industrial laser cutters, the choice can be overwhelming. Two of the most popular types are CO2 and fiber laser cutters, each boasting unique features suited for different applications. Understanding how these machines operate and what they can do is essential for making an informed decision.

CO2 vs. Fiber Laser Cutters

CO2 laser cutters utilize a gas mixture that generates a high-powered beam, ideal for cutting non-metal materials like wood, acrylic, and textiles. They excel in creating intricate designs with precision, making them a favorite in industries requiring detailed engraving. On the other hand, fiber laser cutters use solid-state technology to produce a beam that is particularly effective for metal cutting applications; they deliver faster speeds and greater efficiency than their CO2 counterparts.

In terms of maintenance and operational costs, fiber lasers often take the lead due to their lower energy consumption and longer lifespan. However, if you’re primarily working with softer materials or need high-quality engravings on non-metals, a CO2 industrial laser cutting machine might be your best bet. Ultimately, the choice between these two types of cutting machine lasers hinges on your specific needs—whether speed or versatility takes precedence.

Choosing the Right Industrial Laser Cutting Machine

Selecting the right industrial laser cutting machine requires careful consideration of several factors including material type, thickness, and desired cut quality. Start by evaluating what materials you’ll be working with; if metals dominate your projects, then investing in a fiber laser cutter could pay off handsomely in terms of efficiency and precision. Conversely, if your focus leans more towards plastics or wood products, a CO2 cutter may provide better results.

Another critical aspect is understanding how do lasers cut through different materials; this knowledge will guide you toward the appropriate power levels and settings needed for optimal performance. Additionally, consider future growth—will your operations expand into new material types? If so, versatility should weigh heavily in your decision-making process when choosing an industrial laser cutter.

Applications of Each Type of Laser Cutter

The applications for both CO2 and fiber laser cutters are vast and varied across multiple industries. For instance, CO2 lasers shine in sectors such as signage production where intricate designs are paramount; they also perform exceptionally well in crafting decorative items from wood or acrylics due to their fine detail capabilities. In contrast, metal fabrication shops often favor fiber lasers because they can slice through thick steel plates with remarkable speed while maintaining excellent edge quality.

Moreover, both types find their place in automotive manufacturing—CO2 lasers handle interior components while fiber lasers tackle structural parts efficiently. Whether you're looking at creating prototypes or mass production runs across different sectors like aerospace or fashion design using a metal cutting machine laser or another type altogether—the right choice will enhance productivity while ensuring top-notch results every time.

Advantages of Using a Laser Cutting Machine

When it comes to cutting materials, laser cutting machines have revolutionized the industry with their superior capabilities. The advantages they offer are not just a matter of convenience; they fundamentally change how businesses approach manufacturing and production. From precision to cost-effectiveness, let’s explore why industrial laser cutters are becoming the go-to choice in various sectors.

Precision and Accuracy in Cutting

One of the standout features of a laser cutting machine is its incredible precision. When you ask, how do lasers cut? the answer lies in their ability to focus intense energy on a very small area, allowing for intricate designs and tight tolerances that traditional methods simply can't achieve. This level of accuracy is especially crucial in industries like aerospace and automotive manufacturing, where even the slightest deviation can lead to significant issues.

Moreover, the precision offered by an industrial laser cutter minimizes waste material during production. With cleaner cuts and less need for post-processing, businesses can save both time and resources—an essential factor when working with expensive materials like metals or plastics. This sharp accuracy not only enhances product quality but also boosts customer satisfaction as products meet exact specifications every time.

Cost-Effectiveness and Efficiency

Cost-effectiveness is another compelling advantage of using an industrial laser cutting machine. While the initial investment may seem steep, the long-term savings from reduced labor costs and material waste quickly make up for it. In addition, these machines operate at high speeds without sacrificing quality, allowing businesses to increase their output significantly.

Efficiency doesn't end with speed; it also extends to energy consumption. Modern metal cutting machines using lasers are designed to be more energy-efficient than traditional cutting methods, further reducing operational costs over time. As companies strive for sustainability alongside profitability, choosing a laser cutting machine aligns perfectly with both goals.

Versatility Across Various Industries

The versatility of a laser cutting machine is nothing short of remarkable—it can handle a wide range of materials including metals, plastics, wood, and even textiles! Whether you're in automotive manufacturing or fashion design, there's an industrial laser cutter suited for your needs that can adapt to different applications seamlessly. This adaptability makes them indispensable tools across various sectors.

Furthermore, advancements in technology have led to specialized machines capable of executing complex tasks beyond simple cuts—like engraving or marking—making them multi-functional assets within any workshop or factory setting. As industries evolve and demand more customization options from suppliers, having access to such versatile equipment becomes increasingly valuable.

Maintenance and Safety Tips for Laser Cutting Machines

When it comes to operating an industrial laser cutting machine, maintenance and safety are paramount. Regular upkeep not only prolongs the life of your cutting machine laser but also enhances its performance, ensuring that you achieve the precision and efficiency that laser technology promises. Here are some essential tips to keep your equipment running smoothly while prioritizing safety in your workspace.

Routine Maintenance Practices

To ensure optimal performance of your metal cutting machine laser, establishing a routine maintenance schedule is crucial. This includes regular cleaning of lenses and mirrors, checking for any alignment issues, and replacing worn-out parts promptly to avoid costly downtime. Additionally, keeping the workspace tidy can help prevent accidents and ensure that the industrial laser cutter operates without unnecessary interruptions.

Another key aspect of routine maintenance is monitoring the cooling system of your laser cutting machine. Overheating can lead to diminished performance or even catastrophic failure if not addressed promptly. Regularly inspect coolant levels and replace any filters as needed to maintain a stable operational temperature.

Lastly, don’t forget about software updates! Many modern industrial laser cutting machines rely on sophisticated software for optimal operation. Keeping this software up-to-date ensures you benefit from the latest features and improvements that enhance both functionality and safety.

Safety Precautions When Using a Cutting Machine Laser

Safety should always be at the forefront when using a cutting machine laser, especially given their powerful capabilities. First and foremost, operators must wear appropriate personal protective equipment (PPE), including goggles designed specifically for laser use to protect against harmful light exposure. Additionally, flame-resistant clothing can help mitigate risks associated with sparks generated during metal cutting processes.

Creating a safe work environment also involves ensuring proper ventilation in areas where an industrial laser cutter is used. Fumes produced during cutting operations can be hazardous; hence investing in effective extraction systems is vital for maintaining air quality. Always familiarize yourself with emergency procedures specific to your facility as well—knowing how to react quickly in case of an incident can make all the difference.

Finally, training is essential! Ensure that everyone operating or working near a metal cutting machine laser has undergone comprehensive training on both operation techniques and safety protocols specific to lasers. Knowledgeable staff are far less likely to engage in unsafe practices or overlook critical safety measures.

Troubleshooting Common Issues

Even with proper maintenance practices in place, issues may arise with your industrial laser cutting machine from time to time—don’t panic! Familiarizing yourself with common problems can save valuable time when troubleshooting effectively. For instance, if you notice inconsistent cut quality or excessive dross on cut edges, it could indicate issues related to lens cleanliness or focus alignment; addressing these concerns promptly often resolves such problems quickly.

Another common issue might be unexpected shutdowns during operation—this could stem from overheating due to coolant failure or improper settings within the software controlling the metal cutting machine laser. Regular checks on system temperatures combined with understanding how do lasers cut will equip operators with insights into potential causes behind sudden interruptions.

Lastly, if you encounter error messages from your industrial laser cutter's software interface, consult the user manual first! Most manuals include troubleshooting sections tailored specifically for common errors encountered by users which can guide you toward quick resolutions without needing professional assistance every time something goes awry.

Conclusion

In wrapping up our exploration of laser cutting technology, it's clear that this innovative method offers a plethora of benefits for various industries. From precision and accuracy to cost-effectiveness and versatility, the advantages of using a laser cutting machine are undeniable. Whether you're working with metals or more delicate materials, understanding how do lasers cut can transform your production processes.

Recap of Laser Cutting Benefits

Laser cutting machines provide unparalleled precision, making them ideal for intricate designs that traditional methods struggle to achieve. The efficiency of an industrial laser cutter means faster production times and reduced waste, ultimately saving costs in the long run. Additionally, these machines can handle a wide range of materials—from metals to plastics—showcasing their versatility across different applications.

Choosing Kiant Machinery for Laser Solutions

Their range includes advanced metal cutting machine lasers designed for high performance and reliability in various settings. With expert guidance on selecting the right equipment tailored to your needs, Kiant ensures you have the best tools at your disposal for optimal results.

The Future of Laser Cutting Technology

Looking ahead, the future of laser cutting technology promises even greater advancements with automation and artificial intelligence integration. As industries continue to evolve, so will the capabilities of industrial laser cutters, making them more efficient and user-friendly than ever before. By keeping an eye on these trends and understanding how do lasers cut in new ways, businesses can stay ahead in this competitive landscape.