Introduction

In the world of manufacturing and fabrication, the debate between CNC routers and laser cutters is as heated as a metal shop on a busy day. Both technologies offer unique advantages and capabilities, making them popular choices across various industries. Understanding the nuances of these two cutting-edge tools can help you make an informed decision about which one best suits your needs.

Understanding CNC Routers and Laser Cutters

CNC routers utilize rotating bits to carve out shapes from materials, while laser cutters employ high-powered lasers to slice through surfaces with precision. The fundamental operation of a CNC router revolves around mechanical movement, making it ideal for larger pieces or thicker materials. On the other hand, the CNC fiber laser cutter excels in delivering intricate designs with minimal material waste, particularly in thin sheets of metal.

Key Differences in Technology

When comparing CNC router vs laser cutter technology, one must consider factors like speed, precision, and material compatibility. CNC routers are generally better suited for softer materials like wood or plastics due to their cutting mechanics. In contrast, when evaluating CNC vs laser cutter for metal applications, the laser cutter shines with its ability to achieve clean edges and fine details that are often unattainable with traditional routing methods.

Applications for Different Industries

Both machines find their place in various sectors such as woodworking, metal fabrication, signage production, and even jewelry design. A Desktop CNC Laser Cutter is perfect for small-scale projects requiring detailed work without occupying much space—ideal for hobbyists or small businesses alike. Meanwhile, industries that focus on heavy-duty operations often turn to a robust CNC router for larger panels or components that demand strength alongside precision.

The Basics of CNC Routers

CNC routers are a staple in the world of precision cutting and shaping. They operate using computer numerical control (CNC) technology, allowing for automated and highly accurate machining processes. Whether you’re crafting intricate designs or mass-producing components, understanding how CNC routers work is essential for effective use.

How CNC Routers Work

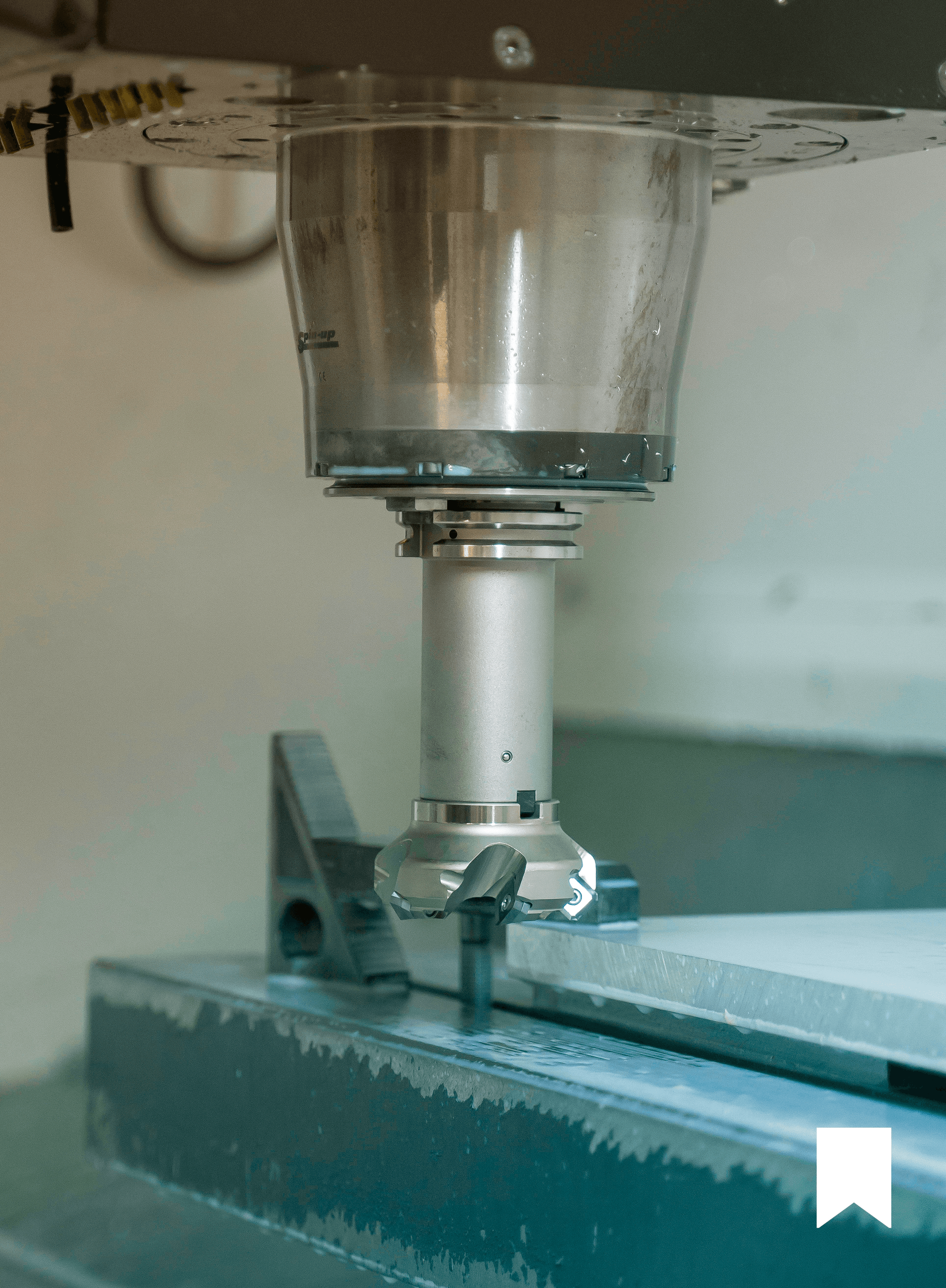

At their core, CNC routers function by translating digital designs into physical cuts through a series of controlled movements. The machine utilizes a rotating spindle that holds various cutting tools, which move along multiple axes to carve out shapes from materials like wood, plastic, or composites. Unlike a CNC fiber laser cutter that uses focused light beams to cut materials, the router physically removes material with its bits, making it ideal for creating three-dimensional objects.

The process begins with design software where users create their models before sending them to the router’s computer system. This system interprets the design data and directs the router's movements with pinpoint accuracy. When comparing CNC router vs laser cutter technologies, it’s crucial to remember that while both offer precision, they employ different methods—one through mechanical cutting and the other through thermal energy.

Advantages of CNC Routers

One of the standout benefits of using CNC routers is their versatility across various materials; they can handle everything from softwoods to hard plastics and even some metals when equipped properly. Additionally, they provide exceptional repeatability—meaning once you set up your design correctly, you can produce identical pieces time after time without deviation in quality or detail. This reliability makes them an excellent choice for industries needing consistent output.

Another advantage lies in cost-effectiveness; while initial investments may vary based on size and capabilities (think Desktop CNC Laser Cutter versus larger industrial models), operating costs tend to be lower compared to laser systems when considering maintenance and consumables like lenses or gases used in lasers. Furthermore, many users appreciate how user-friendly modern CNC systems have become—with intuitive interfaces that make programming accessible even for beginners.

Ideal Materials for CNC Routing

When discussing ideal materials for CNC routing versus laser cutting applications, it's clear that each has its strengths depending on what you're working with. Wood is undoubtedly one of the most popular choices; it allows for intricate designs while being easy on tools due to its softer nature compared to metals or plastics. However, advanced routers can also handle aluminum and certain alloys effectively if fitted with appropriate tooling.

Plastics like acrylic are another favorite among hobbyists and professionals alike because they can be cut cleanly without melting—a common issue faced when using lasers on thicker sheets due to heat buildup (a notable point in discussions around CNC vs laser cutter for metal). Additionally, composite materials often yield excellent results under routing conditions as well—making them suitable for everything from furniture making to signage manufacturing.

In conclusion, understanding these basics lays a solid foundation when deciding between options like a CNC laser cutter for metal or traditional routing machines based on your specific needs and projects ahead.

Diving into Laser Cutters

Laser cutters have revolutionized the way materials are processed, offering precision and versatility that is hard to match. Understanding how these machines operate can help you make informed choices when considering CNC router vs laser cutter options for your projects. With their unique capabilities, laser cutters are becoming increasingly popular across various industries.

Working Principles of Laser Cutters

At the heart of a laser cutter's functionality is a focused beam of light that is generated by a high-powered laser source, such as a CO2 or fiber laser. This beam is directed through optics and mirrors to concentrate its energy on a specific point, allowing it to cut through materials with incredible accuracy. The process involves moving the material or the laser head along predefined paths using computer numerical control (CNC), making it highly efficient for intricate designs.

Unlike traditional cutting methods, which may involve physical blades or tools that wear down over time, a CNC fiber laser cutter maintains its cutting edge indefinitely since it relies on light rather than mechanical contact. This not only improves precision but also reduces wear and tear on equipment, resulting in lower maintenance costs over time. The ability to adjust the power and speed settings allows for customization based on material thickness and type, providing flexibility in production.

Benefits of Using Laser Cutters

One of the standout advantages of using a CNC laser cutter for metal is its ability to produce clean edges without requiring secondary finishing processes. The heat-affected zone is minimal compared to other cutting methods, which means that there’s less distortion in the material being cut—an essential factor when working with metals that need precise tolerances. Additionally, laser cutting can handle complex geometries effortlessly; intricate designs can be achieved quickly without sacrificing quality.

Another significant benefit lies in the speed at which laser cutters operate. For businesses looking to maximize productivity while minimizing downtime, these machines offer rapid processing times that can significantly enhance workflow efficiency. Moreover, advancements in technology have led to more compact options like desktop CNC laser cutters that allow small-scale operations or hobbyists access to high-quality cutting capabilities without needing large industrial setups.

Lastly, versatility is another feather in the cap of laser cutters; they can work with various materials beyond just metal—wood, acrylics, textiles—you name it! This adaptability makes them an excellent investment for businesses looking to diversify their product offerings while maintaining high standards of quality across different applications.

Perfect Materials for Laser Cutting

When discussing ideal materials for laser cutting versus CNC routing techniques like those employed by CNC routers or even comparing CNC vs laser cutter for metal applications specifically, it's crucial to understand what works best with each technology's strengths and weaknesses. Laser cutters excel at processing thin sheets of metals such as stainless steel and aluminum due to their precision and speed; they can achieve fine details without compromising structural integrity.

In addition to metals, non-metal materials such as wood are also prime candidates for this type of machining process—allowing artisans and manufacturers alike creative freedom when designing products ranging from furniture pieces to decorative items. Plastics like acrylics are another favorite among users since they yield smooth cuts while providing vibrant colors and textures ideal for signage or display purposes.

However, certain materials do pose challenges; reflective metals may require specialized settings or additional considerations when using a CNC fiber laser cutter due to potential reflections affecting performance quality during operation. Understanding these nuances will help ensure optimal results regardless of whether you’re working with complex projects involving diverse substrates or focusing solely on metal fabrication tasks.

CNC Router vs Laser Cutter for Metal

Comparing Performance on Metal

CNC routers are designed primarily for milling and shaping materials like wood, plastics, and softer metals such as aluminum. However, when it comes to cutting thicker or harder metals, CNC fiber laser cutters take the lead due to their ability to produce high-powered beams that can slice through materials with ease. The choice between CNC vs laser cutter for metal ultimately hinges on the specific application—if you need intricate designs in thinner sheets, a desktop CNC laser cutter might be your best bet, while heavier-duty projects may require a robust CNC router.

Precision and Detail Differences

Precision is where the CNC laser cutter truly shines compared to traditional methods like a CNC router. Laser cutters can achieve finer details with cleaner edges due to their focused beam of light that minimizes heat-affected zones—essentially reducing warping or distortion during the cutting process. For those looking at a CNC vs laser cutter for metal projects requiring intricate designs or detailed engravings, opting for a CNC laser cutter for metal applications will yield superior results.

Industry Applications for Metal Cutting

The industries that benefit from these technologies vary widely; automotive manufacturing often employs CNC routers for shaping parts while using laser cutters for precise cuts in components like brackets or frames. In aerospace engineering, where precision is non-negotiable, the choice leans heavily towards advanced lasers capable of handling complex geometries with minimal waste. Whether you’re crafting custom signage or producing parts at scale, understanding when to use each method can enhance production efficiency and product quality in your business.

Choosing the Right Equipment for Your Needs

Factors to Consider in Decision Making

First off, consider the materials you'll be working with; this is perhaps the most significant factor in the CNC router vs laser cutter debate. If you're primarily cutting wood or soft plastics, a CNC router might be your best bet due to its efficiency with these materials. However, if you’re tackling metal projects—especially intricate designs—then diving into the realm of CNC fiber laser cutters could be worth your while.

Next up is precision and detail; here’s where things get interesting!If you're looking for that perfect finish on small components or intricate patterns, a desktop CNC laser cutter could provide the edge you need.

Lastly, consider ease of use and maintenance requirements. Some machines may require extensive setup or have steep learning curves that could hinder productivity initially. For beginners exploring options like a CNC laser cutter for metal or wood projects, user-friendly models with robust support systems are invaluable.

Cost Analysis: CNC vs Laser Cutter

When it comes to cost analysis between CNC routers and laser cutters, it's essential to evaluate both initial investment and long-term operational costs. Generally speaking, entry-level CNC routers tend to have lower upfront costs compared to high-end laser cutters; however, this can vary significantly based on features and capabilities like those found in a high-quality CNC fiber laser cutter.

Operational costs also differ considerably; while lasers may consume more energy during operation due to their intensity levels needed for metal cutting tasks, they often require less maintenance than traditional routers over time. Additionally, consider factors such as material waste—laser cutting typically produces cleaner cuts with less scrap than routing processes.

In summary, while initial purchase prices are crucial in deciding between a desktop CNC laser cutter versus other equipment types like routers or fiber lasers for metal work; ongoing operating expenses should not be overlooked either! A thorough cost-benefit analysis will help you make an informed decision that aligns with both your budgetary constraints and operational needs.

Recommendations for Beginners

For beginners venturing into this exciting world of machining technology—start simple! If you're primarily interested in woodworking or crafting basic designs without breaking the bank initially, then investing in an affordable yet reliable desktop CNC router makes sense. As you grow more comfortable with routing techniques over time—and if your projects evolve—you can always upgrade later!

On the flip side of things—if you foresee yourself needing precision cuts on various materials including metals right from day one—a beginner-friendly CNC laser cutter for metal might be your best option! Look for models that offer intuitive controls along with excellent customer support resources so you won't feel lost navigating through new software interfaces or machine operations.

Ultimately though—it’s all about finding what fits best within both your creative aspirations AND practical limitations as well! Take some time exploring different options before making any final decisions; after all—your journey into crafting awaits!

Kiant Machinery: A Leader in Cutting Solutions

Their commitment to quality and performance makes them a trusted name in the competitive landscape of CNC routers and laser cutters. Whether you're looking for a CNC Fiber laser cutter or a Desktop CNC Laser Cutter, Kiant has you covered with equipment that meets the highest standards.

Equipment Tailored for Laser Cutting

Kiant Machinery offers an impressive range of equipment specifically designed for laser cutting applications. From powerful CNC Fiber laser cutters that can handle thick materials with ease to compact Desktop CNC Laser Cutters ideal for smaller projects, they provide options for every need. The versatility of their machines allows users to efficiently tackle various tasks, bridging the gap between hobbyists and industrial professionals.

The precision and speed of Kiant's laser cutting technology ensure that projects are completed with exceptional accuracy. This is especially important when comparing CNC routers vs laser cutters, as the latter excels in intricate designs and fine details. With Kiant's advanced systems, you can achieve clean cuts on materials ranging from plastics to metals, making them suitable for diverse applications.

Support and Training for Users

Kiant Machinery understands that investing in cutting technology is just the first step; proper training is crucial for maximizing your equipment's potential. They offer comprehensive support programs designed to help users get acquainted with their machines quickly and effectively. Whether you're new to using a CNC laser cutter for metal or transitioning from traditional methods, their training sessions equip you with essential skills.

Their dedicated support team is always ready to assist customers with troubleshooting or operational questions, ensuring smooth sailing throughout your projects. This commitment not only enhances user experience but also fosters confidence in utilizing both CNC routers and laser cutters effectively. After all, knowing how to operate your machinery properly can make all the difference when it comes time to produce high-quality results.

Advantages of Choosing Kiant Machinery

Choosing Kiant Machinery means opting for reliability and innovation in cutting solutions tailored specifically to your needs. Their extensive product line includes not just high-performance machines but also accessories that enhance functionality across various projects—be it metal fabrication or artistic endeavors using a Desktop CNC Laser Cutter.

Moreover, by selecting Kiant's equipment, users gain access to ongoing support which ensures they remain informed about updates or advancements in technology relevant to both CNC vs laser cutter scenarios. Ultimately, investing in Kiant Machinery means investing in quality craftsmanship backed by expert guidance—an unbeatable combination whether you're tackling complex designs or straightforward cuts.

Conclusion

In the ongoing debate of CNC router vs laser cutter, understanding the nuances between these two technologies is essential for making an informed decision. Each method has its unique strengths and weaknesses, which can significantly impact your projects' outcomes. By summarizing the key differences, we can clarify which tool might be best suited for your specific needs.

Summarizing Key Differences

When comparing CNC routers and laser cutters, one must consider their operational principles and material compatibility. CNC routers excel in handling a variety of materials such as wood, plastics, and soft metals while offering robust cutting capabilities. On the other hand, laser cutters shine when it comes to precision and detail, particularly with thin materials like acrylics or intricate designs—especially relevant in the discussion of CNC vs laser cutter for metal applications.

The technology behind each machine also plays a crucial role in their performance. CNC routers utilize rotating bits to carve out shapes, making them ideal for three-dimensional work and larger pieces. In contrast, laser cutters employ focused beams of light to slice through materials with remarkable accuracy but may struggle with thicker metals compared to a CNC Fiber laser cutter.

Best Use Cases for Each Technology

For woodworking shops or industries focusing on large-scale production of furniture or cabinetry, a Desktop CNC Laser Cutter is often the go-to choice due to its versatility with various substrates. Meanwhile, businesses that require precise cuts on intricate designs will benefit from using a CNC laser cutter for metal applications where detail is paramount.

Final Thoughts on Your Cutting Solution Choices

Ultimately, selecting between a CNC router and a laser cutter boils down to your specific project requirements and budget considerations. If you often work with diverse materials and need flexibility in design options, investing in both technologies could be worthwhile over time. However, if precision cutting of thin materials is your primary goal—especially when considering applications like jewelry making or detailed signage—the advantages offered by a dedicated CNC laser cutter are hard to ignore.