Introduction

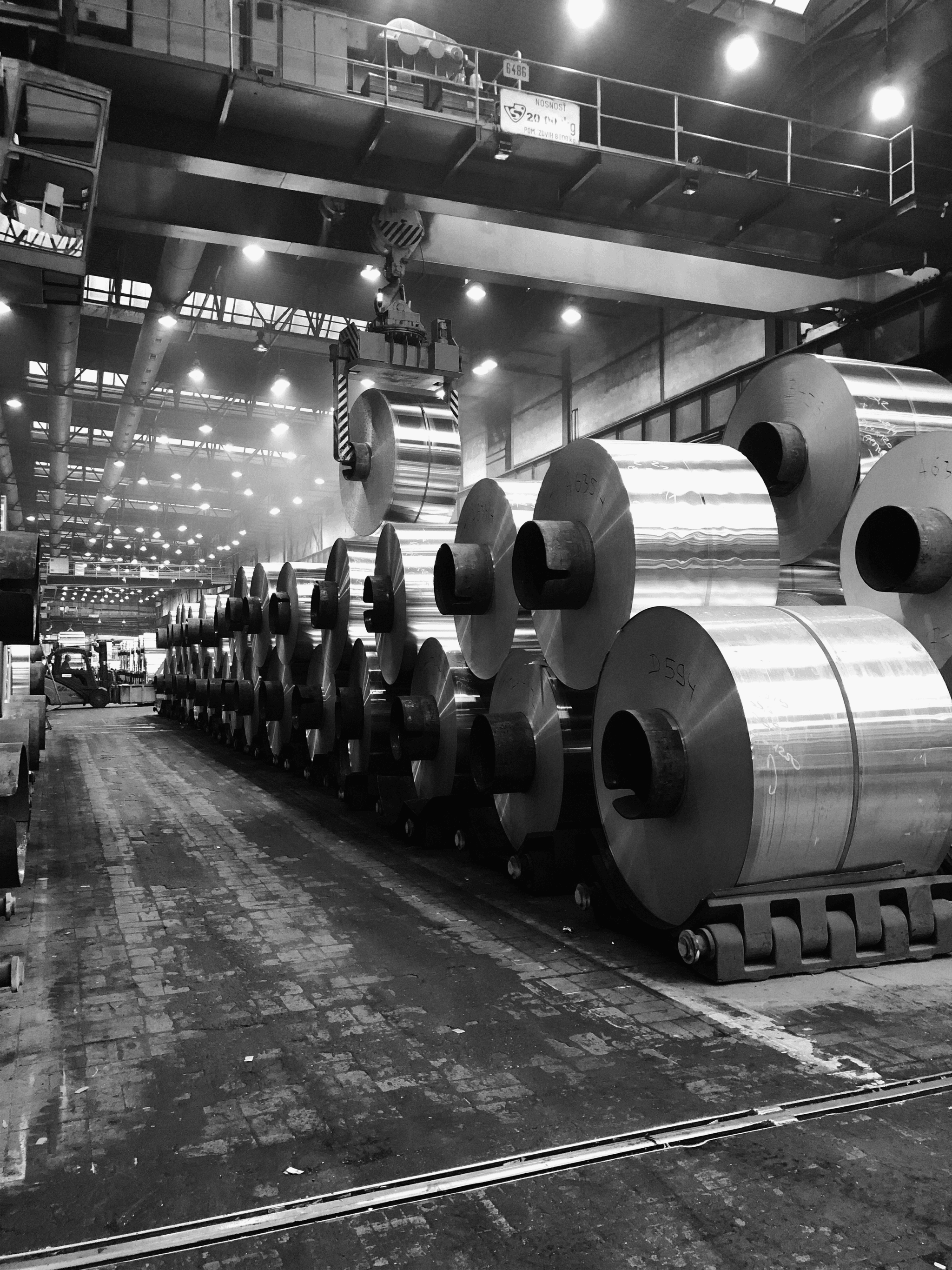

In the ever-evolving world of construction, roll forming steel framing has emerged as a game-changer, revolutionizing how we think about building materials. With the rise of light gauge steel, builders and architects are reaping the benefits of a material that is not only durable but also lightweight and versatile.

Understanding Roll Forming Steel Framing

Roll forming is a manufacturing process that shapes metal into desired profiles by passing it through a series of rollers. This technique is particularly effective for producing consistent and precise shapes ideal for steel framing applications. With roll forming machines for sale from reputable manufacturers like FrameMAC, businesses can streamline their production processes while ensuring high-quality output.

The Rise of Light Gauge Steel

Light gauge steel has surged in popularity due to its remarkable strength-to-weight ratio and flexibility in design applications. What is light gauge steel used for? From residential buildings to commercial structures, this material provides an excellent alternative to traditional framing options like wood. As builders increasingly ask themselves: Is light gauge steel cheaper than wood? they often find that while initial costs may vary, long-term savings on maintenance and durability make it a wise investment.

Why Choose FrameMAC for Your Needs

When considering roll forming machines for your projects, choosing FrameMAC means opting for quality and reliability in every aspect of your operation. Their advanced Roll Forming Steel Framing Machines are designed with user-friendly features that enhance productivity without sacrificing performance. Plus, with exceptional customer support and training programs available through Kiant Machinery's distribution network, you can feel confident in making informed decisions about your investments in steel framing technology.

The Basics of Roll Forming Steel

Roll forming is a highly efficient manufacturing process that shapes metal into desired profiles by passing it through a series of rollers. This technique is particularly popular for producing long lengths of consistent cross-sectional shapes, making it ideal for various applications in construction and manufacturing. When considering the investment in a roll forming machine for sale, understanding this process can significantly enhance your decision-making.

What is Roll Forming?

At its core, roll forming involves feeding flat metal sheets, typically steel, through a set of rollers that progressively shape the material into specific profiles. The process is continuous and can produce large volumes with minimal waste, which is essential for businesses looking to optimize costs. By using a roll forming machine for sale, manufacturers can achieve precision and speed in creating components such as frames and panels.

Applications of Roll Forming Steel Framing Machines

Roll Forming Steel Framing Machines are incredibly versatile and find applications across various industries including construction, automotive, and furniture design. They are commonly used to create structural components like studs and tracks in light gauge steel framing systems, which are increasingly popular due to their strength-to-weight ratio. Additionally, these machines are perfect for producing roofing panels and siding materials that require uniformity and durability.

Benefits of Using Roll Forming Steel

One significant benefit of using roll forming steel is its ability to create lightweight yet robust structures that outperform traditional materials like wood in many scenarios. Not only does this lead to reduced labor costs during installation, but it also offers long-term savings due to lower maintenance needs—so if you're asking yourself how much does light gauge steel framing cost?—the answer often reveals itself as more economical over time compared to wood alternatives. Furthermore, understanding what light gauge steel is used for helps clarify its advantages; it's not just about cost but also about performance in various applications.

Exploring Light Gauge Steel

Light gauge steel has become a go-to material in construction, especially for those looking for strength without the heft. This versatile material is used in a variety of applications, from residential buildings to commercial structures. With the increasing availability of roll forming machines for sale, light gauge steel framing is more accessible than ever.

What is Light Gauge Steel Used For?

What is light gauge steel used for? Well, it’s not just a fancy term thrown around at construction sites! Light gauge steel is primarily used in wall framing, roof trusses, and floor joists. Its lightweight nature makes it easier to handle and transport compared to traditional materials like wood. Additionally, it’s often favored for its durability and resistance to pests and fire—qualities that are essential in modern construction.

Is Light Gauge Steel Cheaper than Wood?

Is light gauge steel cheaper than wood? The answer isn't as straightforward as you might think! While the initial cost of light gauge steel framing can be higher than wood due to manufacturing processes and equipment like Roll Forming Steel Framing Machines, it often leads to long-term savings. When considering factors such as maintenance costs, longevity, and energy efficiency, many find that investing in light gauge steel pays off over time.

Key Advantages of Light Gauge Steel

The key advantages of light gauge steel are hard to overlook! First off, it's incredibly strong yet lightweight—making it an ideal choice for various construction needs without sacrificing structural integrity. Furthermore, unlike wood, light gauge steel won't warp or shrink over time; this means fewer headaches during your project timeline! Plus, with the growing number of roll forming machines for sale tailored specifically for this material type, getting started with your own framing projects has never been easier.

Costs Associated with Framing

When considering the costs associated with framing, it's essential to evaluate various materials and their long-term implications. Light gauge steel framing has gained traction in construction due to its durability and cost-effectiveness. As we dive into this section, we'll explore how much light gauge steel framing costs, compare it with traditional wood options, and highlight potential long-term savings.

How Much Does Light Gauge Steel Framing Cost?

How much does light gauge steel framing cost? The price can vary based on several factors including project size, design complexity, and local market conditions. On average, the material costs for light gauge steel are competitive with wood; however, when you factor in labor and installation efficiency provided by Roll Forming Steel Framing Machines, the overall expenses can be surprisingly favorable.

Investing in a roll forming machine for sale can further reduce your costs by streamlining production processes. These machines allow for precise cuts and shapes tailored to your project needs while minimizing waste. Thus, while initial expenses might seem daunting at first glance, they often pay off through reduced labor costs and material efficiency.

Comparing Costs: Steel vs. Wood

Is light gauge steel cheaper than wood? While the upfront cost of wood may appear lower at first glance, a deeper dive reveals that light gauge steel often provides better value over time. Not only does steel resist pests and rot better than wood, but it also requires less maintenance—saving you money on repairs down the line.

Additionally, when weighing the benefits of Roll Forming Steel Framing Machines against traditional woodworking tools, it's clear that automation leads to faster project completion times. This speed translates into lower labor costs as well since fewer hours are needed on-site for assembly and installation compared to wood framing methods. Ultimately, while both materials have their merits, light gauge steel frequently emerges as a more economical choice when considering total lifecycle costs.

Long-Term Savings with Steel Framing

Long-term savings with steel framing are significant when evaluating material lifespan and maintenance needs. Unlike wood that can warp or succumb to pests over time—incurring additional repair expenses—light gauge steel maintains its structural integrity for decades without major interventions required. This longevity is a crucial factor in making your investment worthwhile.

Moreover, using Roll Forming Steel Framing Machines not only enhances precision but also minimizes waste during production—a win-win scenario for both budget-conscious builders and environmentally aware projects alike! By choosing light gauge steel over traditional materials like wood or hot rolled steel in specific applications (like non-load-bearing walls), you’re setting yourself up for financial success down the road.

In summary, understanding how much light gauge steel framing costs compared to other options helps clarify its advantages in both short- and long-term scenarios—especially when backed by efficient machinery like roll forming machines available for sale today.

Comparing Steel Types

When it comes to steel framing, understanding the differences between hot rolled steel and light gauge steel is crucial. Each type of steel has its own unique characteristics and applications, making them suitable for different projects. In this section, we will delve into these differences, helping you decide which type fits your needs best.

What is the Difference Between Hot Rolled Steel and Light Gauge Steel?

Hot rolled steel is produced at high temperatures, allowing it to be shaped and formed easily before being cooled. This process results in a strong, durable material often used for structural applications where high strength is needed. On the other hand, light gauge steel is thinner and lighter, typically manufactured through roll forming machines that create precise shapes suited for framing applications like walls and roofs.

Light gauge steel offers flexibility in design while maintaining strength; it's commonly used in residential construction as well as commercial buildings. When asking yourself “What is light gauge steel used for?”, think about its versatility in crafting intricate designs without compromising structural integrity. In contrast, hot rolled steel's robustness makes it ideal for heavy-duty structures like bridges or industrial facilities.

Understanding these distinctions can help you determine which option aligns with your project's requirements. If you're considering a roll forming machine for sale to produce light gauge frames, knowing these differences will guide your investment decision effectively.

When to Choose Each Type of Steel

Choosing between hot rolled and light gauge steel depends largely on your project's specific needs. If you're working on a large-scale construction project that requires significant load-bearing capacity, hot rolled steel might be the better choice due to its superior strength properties. However, if your focus is on lightweight framing solutions that are cost-effective—like when evaluating How much does light gauge steel framing cost?—light gauge options are often more economical.

For residential projects or smaller commercial builds where flexibility and ease of installation are priorities, light gauge steel becomes an attractive alternative due to its lightweight nature and straightforward handling during construction. Conversely, if durability under extreme conditions or heavy loads is paramount—such as in industrial settings—hot rolled would be the go-to option.

Ultimately, assessing your project’s goals will clarify when to choose each type of steel effectively while ensuring optimal performance throughout the building's lifespan.

Performance Considerations

Performance varies significantly between hot rolled and light gauge steels based on their intended use cases. Hot rolled steel excels in scenarios requiring high tensile strength and resistance to deformation under heavy loads; hence it's favored in structural applications where safety cannot be compromised. On the flip side, when asking “Is light gauge steel cheaper than wood?” many find that while initial costs may vary slightly depending on market conditions, long-term performance often favors light gauge due to lower maintenance requirements over time.

Moreover, environmental factors play a role; both types of steels can withstand various climates but differ in how they respond over time under stress or exposure to elements like moisture or temperature changes. Understanding these performance considerations allows builders to make informed choices about materials based not just on cost but also on longevity and reliability.

In conclusion, whether you're looking at roll forming machines for sale or debating between different types of framing materials for your next project—the choice should always align with both immediate needs and future expectations regarding performance standards.

FrameMAC’s Unique Offerings

When it comes to roll forming machines, FrameMAC stands out in the industry with a variety of unique offerings tailored to meet the needs of modern construction. Their Roll Forming Steel Framing Machines are designed for efficiency and precision, making them an ideal choice for projects that require high-quality output. With a focus on innovation, FrameMAC not only delivers machines but also solutions that enhance productivity and reduce costs.

Advantages of FrameMAC Machines

FrameMAC machines are engineered to provide unparalleled performance in roll forming applications. They offer versatility in producing various profiles, which is essential for understanding what light gauge steel is used for across different construction projects. Moreover, the durability and reliability of these machines ensure that you won’t be asking yourself how much does light gauge steel framing cost in terms of maintenance and repairs—saving you money in the long run.

One major advantage is their user-friendly interface, allowing operators to easily adjust settings without extensive training. This feature is particularly beneficial when considering whether light gauge steel is cheaper than wood; streamlined operations can significantly lower overall project costs. Additionally, FrameMAC’s commitment to quality means their machines consistently outperform competitors when comparing features like speed and energy efficiency.

Kiant Machinery's Role in Distribution

Kiant Machinery plays a pivotal role as a distributor for FrameMAC's advanced roll forming machine for sale options. Their extensive network ensures that customers have access to top-tier Roll Forming Steel Framing Machines wherever they are located. With Kiant's expertise in machinery distribution, clients can trust they’re investing in reliable equipment backed by solid support.

Kiant Machinery also provides valuable insights into which machines best suit specific needs, helping businesses understand what is the difference between hot rolled steel and light gauge steel when choosing materials for their projects. By facilitating access to cutting-edge technology from FrameMAC, Kiant helps streamline the purchasing process while ensuring competitive pricing on all equipment sold.

Furthermore, their commitment doesn’t stop at sales; Kiant Machinery offers comprehensive training programs designed to get your team up and running with your new machinery quickly and efficiently.

Customer Support and Training Programs

FrameMAC places a strong emphasis on customer support and ongoing training programs that help clients maximize the use of their roll forming machine for sale investments. Understanding how much does light gauge steel framing cost includes recognizing the value added through effective training—ensuring your team knows how to operate machinery safely and efficiently can prevent costly mistakes down the line.

Their dedicated support staff is always ready to assist with any technical questions or issues that may arise during operation, ensuring minimal downtime for your projects. Plus, ongoing training opportunities keep your staff updated on best practices related to using Roll Forming Steel Framing Machines effectively—an essential aspect when considering both performance metrics and safety standards.

In an ever-evolving industry landscape where understanding what light gauge steel is used for becomes crucial as new applications emerge, having access to expert guidance from FrameMAC makes all the difference in maintaining competitive edge.

Conclusion

In wrapping up our exploration of roll forming steel framing, it's clear that this method is not just a trend but a forward-thinking solution for modern construction needs. As the demand for efficient, durable, and cost-effective building materials continues to rise, the future of steel framing looks bright. With innovations in technology and manufacturing processes, including advancements in roll forming machines for sale, we can expect even more streamlined operations and enhanced performance in projects across the board.

The Future of Steel Framing

The future of steel framing is poised for significant growth as builders increasingly recognize the benefits that light gauge steel brings to the table. With applications ranging from residential homes to commercial structures, understanding what light gauge steel is used for will be crucial as we move forward. Additionally, as more companies invest in roll forming steel framing machines, we can anticipate a shift towards more sustainable practices that prioritize efficiency without compromising quality.

Maximizing Efficiency with FrameMAC

To truly maximize efficiency in your projects, investing in FrameMAC's offerings can make all the difference. Their advanced roll forming machines are designed to optimize production while ensuring high-quality outputs that meet industry standards. With FrameMAC's commitment to innovation and customer support, users can rest assured they are equipped with tools that enhance productivity and reduce waste—key factors when considering how much does light gauge steel framing cost compared to traditional materials.

Choosing the Right Roll Forming Machine for Sale

When it comes time to choose a roll forming machine for sale, understanding your specific needs is paramount. Considerations such as project scale and material type will guide you toward the best option available on the market today. Moreover, knowing what is the difference between hot rolled steel and light gauge steel will help you make an informed decision that aligns with your project requirements while also keeping costs manageable.